Autonetics RECOMP II User manual

RECOMP

•

COMPUTER

S·E RV

ICE

MANUAL

Autonetlce

~

Industrial

Products

A DIVISION

OF

NORTH

AMERICAN

AVIATION

.

INC

3584

WILSHIRE BOULEVARD.

LOS

ANGELES 5.

CALIFORNIA

RE

MPII

• • • • •

• • •

.

...........

......

...

..........

...

.....

• •

•••••

• •

••

•••

••

•

••

•

COMPUTER

SERVICE

MANUAL

20

August 1959

Autonetlcs

~

Industrial

Products

A

DIV'ISION

OF

NORTH

AMERICAN

AVIATION,

INC,

3584

WILSHIRE BOULEVARD,

LOS

ANGElES

5,

CAliFORNIA

188

11

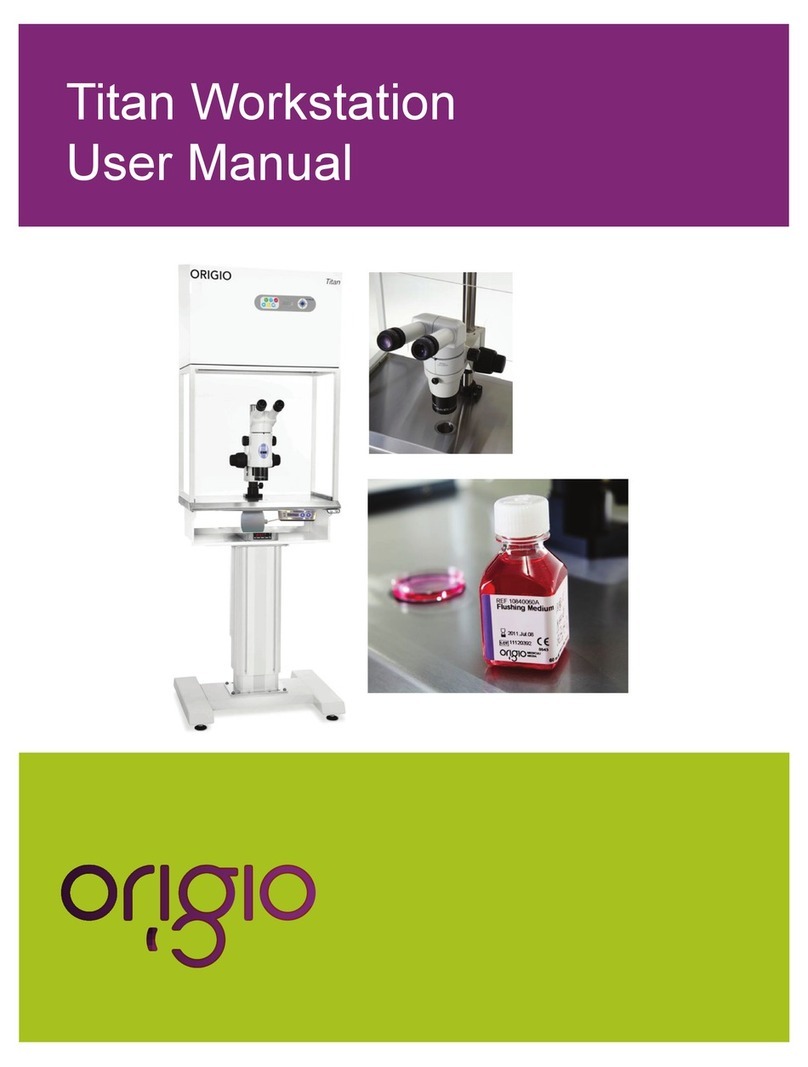

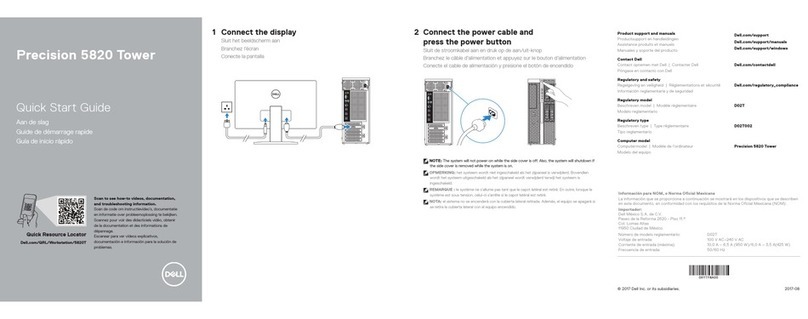

SYSTEM

TESTER

REFER

TO

TEST

EallPMENT

SERVICE

MANUAL

PUB

508-T-9

TYPEWRITER

REFER

TO

INPUT-

OUTPUT

SERVICE

MANUAL

PUB

508-T-8

TYPEWRITER

ASSEMBLY

PHOTOELECTRIC

TAPE

READER

ASSEMBLY

TAPE

READER

COMPUTER

REFER

TO

COMPUTER

SERVICE

MANUAL

PUB

508-T

-7

TYPEWRITER

POWER

SUPPLY

AND

CONTROL

DESK

CONSOLE

r-::I

L::J

REFER

·

TO

INPUT-OUTPUT

SERVICE

MANUAL

PUB

508-T-8

RECOMP

II

System

Block

Diagram

DESK

COMPUTER

•

CONTROL

CONSOLE

REFER

TO

INPUT-

OUTPUT

SERVICE

MANUAL

PUB

508-T-8

COMPONENT

TESTER

REFER

TO

TEST

EallPMENT

SERVICE

MANUAL

PUB

508-T-9

NOTE

:

SYSTEM

SERVICE

MANUAL

PUB

508-T-6

CONCERNS

COMPONENTS

ONLY

WHEN

CONNECTED

TOGETHER

AS

A

SYSTEM.

RC7-183

508-T-7

PREFACE

This

manual

is

1

of

a

set

of

5

published

by

Autonetics

to

provide

main-

tenance

information

on

the

RECOMP

II

computer

system.

System

Service

Manua~:

Publication

No.

508-T-6

Computer

Service

Manual:

Publication

No.

508-T-7

Input-Output

Service

Manual:

Publication

No.

508-T-B

Test

Equipment

Service

Manual:

Publication

No.

508-T-9

System

Refe

rence

Schematic

s:

Publication

No

..

508

- T - 11

The

block

diagram

of

figure

1

illustrate

s

each

system

component

and

shows

its

applicable

service

manual.

In

brief,

the

scope

of

each

RECOMP

II

service

manual

is

as

follows:

System

Service

Manual:

This

manual

describes

the

general

concept

of

RECOMP

II

maintenance

and

provides

operating

instructions

for

checkout

of

the

computer

system

using

the

system

tester

and

both

manual

and

automatic

test

routines.

The

goal

of

these

system

test

procedures

is

to

isolate

mal-

functions

to

a

specific

operational

area

or

system

component.

Computer

Service

Manual:

This

manual

describes

the

operational

com-

ponents

located.in

the

computer

assembly,

including

memory

unit,

power

circuits,

and

signal

circuits.

It

also

provide

s

maintenance

instructions

and

adjustments

for

computer

components,

and

gives

a

detailed

set

,Of

test

pro-

cedures

for

computer

circuit

boards

using

the

component

tester.

Input-Output

Service

Manual:

This

manual

describes

the

operational

characteristics

·of

RECOMP

II

input-output

equipment

(control

console,

type-

writer,

tape

reader,

and

tape

punch).

It

also

provides

maintenance

and

test

instructions

for

these

input-output

devices

and

the

associated

desk

assembly.

Test

Equipment

Service

Manual:

This

manual

describes

the

functional

characteristics

of

the

system

tester

and

component

tester.

It

also

provides

maintenance

and

test

instructions

for

these

two

RECOMP

II

test

equipments.

System

Reference

Schematics:

This

publication

provides

a

set

of

schernatics,

assembly

drawings,

wiring

charts,

and

signal

charts

for

each

system

component;

i.

e.,

computer,

desk,

control

console,

tape

reader,

typewriter,

and

tape

punch.

508-T-7

-

iii

-

Preface

Introduction

General

Operational

Characteristics

Power

Requirements

.

Physical

Characteristics

Functional

Description

General

Memory

Power

Circuits

Signal

Circuits

"

Trouble

Analysis

and

Adjustments

, , '

General

Memory

Power

Circuits

Signal

Circuits

General

Maintenance

Information

CONTENTS

,Removal

and

Replacement

of

Components

•

Computer

Connector

Signal

Chart

Circuit

Board

Connector

Signal

Charts

.

-

iv

-

Page

iii

I

I

I

2

2

4

4

4

12

22

42

42

45

53

63

96

96

100

100

50B-T-7

Figure

1.

2.

3.

4.

·5.

6.

7.

B.

9.

10.

lL

12.

13.

14.

15.

16.

17.

lB.

19.

20.

21.

22.

23.

24.

25.

26.

27.

2B~

29.

30.

31.

32.

33.

34.

35.

36.

37.

3B.

ILLUSTRATIONS

RECOMP

II

System

Block

Diagram.

Computer

As

sembly.

Exterior

Views

Computer

Assembly.

Interior

Views

Cross-Sectional

Diagram

of

Magnetic

Memory

Air

Thrust

Bearing

Diagram.

Write

Head

Construction

.

Flux

Diagram

of

Perpendicular

Recording.

Read

Head

Construction

Diagram

Reading

of

Perpendicularly

Recorded

Digits

Waveforms

in

Writing

and

Reading

.

Permanently

Recorded

Clock

Track

Waveform

..

Head

Positions

on

Magnet

Disk

(Systems

501

through

520)

..

'.

Head

Positions

on

Magnet

Disk

(Systems

521

and

Subsequent)

.

Simplified

Power

Control

Schematic.

Power

Control

Circuits

Block

Diagram

-100-

Volt

Power

Supply

B'lock

Diagram

-lB-

Volt

Power

Supply

Block

Diagram.

-12-Volt

Power

Supply

Block

Diagram

-6-

Volt

Power

Supply

Block

Diagram

75-

Volt

Power

Supply

Block

Diagram

6-Volt

Power

Supply

Block

Diagram

O.

75-Volt

Power

Supply

Block

Diagram

..

Location

and

Color

Coding

of

Computer

Etched

Boards,

Panel

Assembly

No.

1.

Location

and

Color

Coding

of

Etched

Boards

Panel

Assembly

No.2.

Clock

Circuit

Waveforms

and

Approximate

Voltages.

Clock

Boards

No.

1

and

No.

2

Block

Diagram.

Typical

Diode"

And"

Gate

Schematic

Typical

Diode

II

And-And"

Gate

Schematic

.

Use

of

IIAnd-Or"

Gates

in

a .1-

Word

Arithmetic

Register

Typical"

And-Or

ll

Gate

Schematic

Flip-Flop

Block

Diagram.

Read

Switching

Network

Block

Diagram

.•

Read

Amplifier

Block

Diagram

.

Write

Circuit

Block

Diagram.

Write

Head

Selection

Matrix

.

..

Loop

and

Register

Write

Amplifier

Block

Diagram

Information

Channel

Write

Amplifier

·Block

Diagram

Etched

Circuit

Board

Extractor

.

50B-T-7

Page

ii

. 2

3

5

6

6

7

8

9

9

10

11

12

13

16

17

18

19

20

21

21

22

23

24

26

27

2B

29

30

31

32

34

35

36

37

:39

40

45

-·v -

ILLUSTRATIONS

(Cont)

Figure

39.

Clock

Wave

Shape

40.

Origin

Wave

Shapes

41.

Strobe

for

Normal

Pulse

42.

Strobe

Setting

for

Wide

Pulse

with

Some

Jitter

43.

Read

Switching

Network

Adjustment

Points

44.

Oscilloscope

Template

for

Write

Switch

Checkout

45.

Calibration

Template,

Clock

Board

No.1,

Outputs

1

and

2

46.

Calibration

Template,

Clock

Board

No.1,

Outputs

3

and

4

47.

Calibration

Template,

Clock

Board

No.1,

Output

5

48.

Calibration

Template,

Clock

Board

No.2,

Pulse

Output

.

49.

Use

of

Etched

Circuit

Board

Extractors

50.

Computer

Connector

Signal

Chart

.

51.

Circuit

Board

Connector

Signal

Chart

No.

1

52.

Circuit

Board

Connector

Signal

Chart

No.

2

53.

Circuit

Board

Connector

Signal

Chart

No.

3

54.

Circuit

Board

Connector

Signal

Chart

No.

4

55.

Circuit

Board

Connector

Signal

Chart

No.

5

56.

Circuit

Board

Connector

Signal

Chart

No.

6

-

vi

-

Page

47

47

52

52

73

79

88

91

92

95

99

103

104

105

106

107

108

109

508-T-7

TABLES

Page

1..

Internal

Test

Points

43

2.

Channel

Selector

Flip-Flop

Settings

for

Main

Memory

Gain

Adjustment

48

3.

Flip-Flop

TI

and

Preamplifier

Connections

50

4.

Channel

Length

Indications

51

5.

Pulse

Coincidence

51

6.

Power

Supply

Voltages

54

7.

Power

Transformer

Voltages

54

8.

Gate

Selector

Positions

64

9.

Clamp

Diodes

Test

68

10.

Individual

Diodes

Test

.

69

11.

Individual

Resistors

Test

70

508-T-7

-vii-

INTRODUCTION

GENERAL

This

manual

provide

s a

de

scription

of

the

operational

components

located

in

the

computer

assembly,

including

memory,

power

circuits,

and

signal

circuits.

It

also

provides

maintenance

and

repair

instructions

for

these

components,

including

detailed

test

procedures

for

the

etched

circuit

boards

using

the

component

tester.

In

most

cases,

the

functional

tests

described

in

the

RECOMP

II

System

Service

Manual

must

be

performed

before

the

instruc-

tions

contained

in

this

manual

are

used.

OPERATIONAL

CHARACTERISTICS

The

RECOMP

II

computer

(figures

2

and

3)

is

a

general

purpose

digital

.

computer

that

utilizes

the

binary

number

system

for

all

internal

operations.

The

input

equipment

used

to

address

the

computer

consists

of:

photoelectric

paper-tape

reader,

electric

typewriter,

and

control

panel

keyboard.

Output

equipment

include

s

visual

readout

via

the

control

panel,

typewriter,

and

teletype

-coded

paper

-tape

punch.

The

computer

memory

is

a

rotating

magnetic

disk.

It

has

a

capacity

of

4080

nonvolatile

words

plus

two

8-word,

rapid

access

loops.

Nonvolatile

refers

to

the

fact

that

even

during

power

interruptions

the

disk

retains

the

recorded

information.

Also

on

the

disk

memory

unit

are

the

permanently

recorded

timing

tracks

(clock

and

origin),

and

five

I-word

arithmetic

registers.

A

RECOMP

word

consists

of

41

binary

digits.

One

digit

is

used

for

a

synchronizing

bit

and

is

not

available

for

programming.

A

word

can

either

be

a

number

(sign

plus

39

significant

digits)

or

a

command.

(In

actual

operation,

there

will

be

2

commands

to

1

word.)

There

are

five

basic

types

of

commands

in

RECOMP

II:

arithmetic,

transfer

(conditional

or

unconditional),

store,

interchange,

and

input

or

output.

ACCESS

TIME

Access

time

for

main

information

channels

is

0.52

millisecond

minimum.

and

16.9

milliseconds

maximum.

Access

time

for

the

high-speed

loops

is

0.95

millisecond

maximum

for

reading

and

2.34

milliseconds

maximum.

for

writing.

OPERATION

TIME

Operation

time

(excluding

access

time)

for

addition

or

subtraction

is

O.

:52

millisecond.

Multiplication

and

division

require

10.4

milliseconds

(exclt:j.ding

access

time.)

Transfer

control

requires

0.78

millisecond.

508-T-7

- 1 -

POWER

REQUIREMENTS

The

power

requirements

for

the

computer

are

115

volts,

60

cps,

single-

phase

at

400

watts

(excluding

input/output

equipment.)

PHYSICAL

CHARACTERISTICS

Size:

23

inches

wide,

21

inches

long,

and

16.5

inches

high

(excludes

input/output

equipment)

Weight:

196

pounds

(excludes

input/

output

equipment)

Structure:

Welded

aluminum

(steel

in

later

models)

Finish:

White.

cocoa

brown.

madrone.

and

pale

straw

gold

enamel

(or

anodize)

.

~~=;-

_

+-

___

1

--TYPEWRITER

AND

TAPE

PUNCH

CONNECTOR

(J23)

COMPUTER

REAR

VIEW

CONSOLE

C

ONNECTORS

(J24

,

J25, J26,

J27

)

,

-;;;-

_oCOMPUTER

MAIN

POWER

CONNECTOR

(J28)

Figure

2.

Computer

Assembly

-

Exterior

Views

RCI-I79

- 2 -

508-T-7

POWER

SUPP

L Y

AND

CONT

R

OL

r.

IRCUI

T

l>U'

AR~S

--,

SYS

TE

M

T

EST

ER

JAC

KS

508-T-7

POWER

}

Kl

K2

CONTROL

KS'

K6'

RELAYS

.

INTERLOCK

SWITCH

S2

POWER

TRA

NSF

ORM

ER

K3.

K4

POWER

CON

TROL

RELAYS

Fig

u

re

3.

Computer

Assembly

-

In

t e r

ior

View

s

J6

17

J8

SYSTEM

J9

no

TESTER

JAC

KS

(CHOKES)

MEMORY

CONNECTORS

RC

I-177

- 3 -

FUNCTIONAL DESCRIPTION

GENERAL

This

section

describes

mechanical

and

electrical

functional

characteristics

of

operational

components

located

in

the

computer

assembly.

The

computer

central

framework

houses

a

magnetic

disk

memory,

second-

ary

power

supplies,

and

two

blowers.

Hinged

to

both

sides

of

the

central

frame-

work

are

castings

that

form

the

sides

of

the

computer,

and

mounted

on

the

outside

of

these

castings

are

all

etched

circuit

boards

except

power

supply

circuit

boards.

The

inside

of

each

casting

supports

the

interconnecting

wiring

for

the

circuit

boards.

Receptacles

for

the

system

tester

connectors

mounted

on

the

unhinged

ends

of

each

casting.

MEMORY

The

RECOMP

II

memory

consists

basically

of

a

magnetic

disk

rotating

past

fixed

read

and

write

heads.

Information

is

stored

on

the

disk

in

the

form

of

flux

patterns

representing

binary

digits.

When

the

disk

is

rotating,

an

air

bearing

provides

an

air

gap

of

approximately

50

microinches

between

the

record-

ing

surface

of

the

disk

and

the

read

and

write

heads.

MECHANiCAL

OPERATION

Principal

parts

of

the

memory

assembly

are

illustrated

in

figure

4.

A

flexible

diaphragm

attaches

the

disk

to

the

rotor.

The

rotor

is

mounted

to

a

nonrotating

shaft

with

ball

bearings

held

in

place

by

snap

rings.

The

shaft

is

supported

by

2

parallel

diaphragms,

I

located

in

the

inner

edge

of

the

'head-

plate

and

I

in

the

lower

part

of

the

frame.

The

solenoid

coil

is

contained

in

a

housing

fixed

to

the

frame.

The

solenoid

plate

(armature)

is

m.ounted

to

the

lower

end

of

the

shaft.

The

shaft

is

spring

-loaded

between

the

solenoid

plate

and

solenoid

housing

collar.

Untill

power

is

applied

to

the

solenoid,

the

shaft

is

held

at

its

lowest

extremity

by"the

spring.

Information

can

neither

be

written

on

nor

read

from

the

disk

because

of

th,e

separation

between

disk

and

headplate

when

the

shaft

is

in

this

position.

The

shaft

is

held

at

its

lowest

extremity

while

the

disk

motor

is

run

up

to

speed.

The

motor

is

a

split-phase

induction.:.type

incorporating

a

capacitance

start

with

an

operating

speed

of

3450

revolutions

per

m.inute.

When

the

m.otor

and

disk

reach

operating

speed,

the

solenoid

is

energized

and

forces

the

shaft

toward

theheadplate

against

the

preloaded

spring.

- 4 -

508-T-7

Because

the

shaft,

rotor,

and

disk

move

as

a

single

body,

the

disk

is

forced

near

the

headplate

(approximately

50

microinches).

Information

can

now

be

stored

and

extracted.

In

operating

position,

an

air

thrust

bearing

maintains

the

spacing

between

the

rotating

diskCl-nd

the

headplate.

The

air

bearing

consists

of

eight

grooved

radial

sections,

the

configurations

of

which

are

45

degrees

each

(8

x

45

==

360

degrees)

in.

width

around

the

circular

surface

of

the

headplate

(figure

5).

As

the

disk

rotates,

air

moves

in

the

direction

from

A

to

E,

expanding

in

the

grooved

sections

and

compressing

in

the

flat

sections.

Any

tendency

of

the

disk

to

touch

the

headplate

is

offset

by

the

pressure

of

the

air

'at

compression

points

.

.

READ

AND

WRITE

HEADS

Magnetic

read

and

write

heads

are

used

for

recording

information

on

and

reproducing

information

from

the

magnetic

disk.

They

are

mounted

in

slots

in

SliAFT

..

DlAPHRAGM

SOLENOID

HOUSING

SOLENOID

COIL

--"~"';L'UA1}J:;1J

SPRING

NONROT."TING

SliAFT

Figure

4.

Cros

s-Sectional

Diagram

of

Magnetlc

Memory

HEADS

CONNECTOR

RCl-10l

508-T-7

-5 -

DISK

MOTION

HEADPLATE

;

RCl-olS3

Figure

5.

Air

Thrust

Bearing

Diagram

the

headplate.

The

write

head

(figure

6)

consists

of

(1)

a

centertapped

coil

of

copper

wire,

(2) a

metal

core

formed

of

thin,

high-permeability

T-laminations,

(3)

two

fairly

high

permeability,

low-loss

magnetic

blocks,

and

(4)

ceramic

inserts.

Th.e

pole

tip

which

consists

of

the

edges

of

the

laminations

provides

the

writing

area.

Information

is

written

on

the

disk

"perpendicularly,"

as

diag~ammed

in

figure

7

...

When

the

coil

is

energized,

flux

concentrates

at

the

end

of

the

pole

tip

and

enters

the

iron

oxide

recording

material.

Because

this

material

is

of

CERAMIC

·INSERT

Figure

6.

Write

Head

Construction

CERAMIC

INSERT

POLE

TIP

- 6 -

508-T-7

low

permeability

as

compared

to

that

of

the

backing

material,

the

flux

does

not

spread

out.

It

flows

downward,

setting

up

vertical

magnets

in

the

iron

oxide,

and

then

enters

the

high-permeability

backing

material.

Here

it

spreads

out,

then

reenters

the

recording

medium.

Completion

of

the

flux

path

takes

place

through

the

magnetic

blocks

and

back

to

the

center

leg

of

the

T-laminations.

The

demagnetizing

effect

of

the

return

nux

on

the

magnets

already

produced

is

very

slight

because

the

return

flux

is

highly

diffused.

Current

through

the

write

head

is

in

the

form.

of

square

wave

pulses

flowing

through

one-half

of

the

coil

toward

the

center

tap

for

a

binary-l

signal

and·

through

the

other

half

toward

the

center

tap

for

a

binary-O

signal.

This

type

of

recording

is

termed

"nonreturn

to

zer::>"

because

the

recording

current

is

either

at

a

negative

or

positive

level

but

never

at

zero

level.

The

flux

pattern

induced

in

the

recording

medium

is

shown

in

figure

10.

Positive

square

wave

inducing

pulses

are

magnetized

as

square

waves

with

rounded

corners,

that

is,

lesser

intensity

at

the

leading'and

trailing

edges.

The

read

head

(figure

8) cO<1.sists

of

(1)

a

single-ended

coil,

(2)

a

metal

core

formed

of

T-laminations,

and

(3)

two

fairly

high-permeability,

low-loss

magnetic

blocks

shaped

to

form

a

shielding

extension

near

the

pole

tip.

In

reading,

the

read

head

senses

only

the

changes

in

the

magnetized

state

of

the

recording

material.

Essentially

triangular

voltage

pulses

result

POLE

LAMINA

TIONS

COIL

HIGH

PERMEABILITY

BACKING

MATERIAL

TO

WRITE

SIGNAL

POWER

AMPLIFIERS

MAGNETIC

BLOCK

LOW

PERMEABILITY

RECORDING

Figure

7.

Flux

DiagraITl

of

Perpendicular

Recording

RCl-l51

508-T-7

- 7 -

COIL

POLE

TIP

RCl-l~9

Figure

8.

Read

Head

Construction

Diagram

from

the

reading.

a

positive

pulse

representing

a

change

from

binary

0

to

binary

1

and

a

negative

pulse

representing

a

change

from

binary

1

to

binary

O.

For

a

succession

of

similar

binary

digits,

the

first

digit

is

reproduced

as

a

pulse

and

succeeding

digits

have

a 0

-volt

level.

The

magnetic

block

extensions

at

the

base

shield

the

coil

from

adjacent

recorded

digits,

thereby

permitting

only

one

digit

pattern

at

a

time

to

be

read.

(See

figures

9

and

10.

)

ERASE

HEADS

The

erase

heads

are

similar

to

the

read

and

write

heads

in

physical

dimen-

sions

and

appearance.

The

difference

is

that

the

erase

heads

have

a

permanent-

magnet

wire

along

the

center

instead

of

a T

-type

pole

piece

with

coil.

The

magnet

wire

is

now

the

central

pole

piece.

Magnetic

lines

issuing

from

this

pole

piece

return

through

the

magnetic

blocks,

as

for

the

read

and

write

heads.

The

strength

and

polarity

of

this

magnetic

field

is

such

that

all

changes

of

flux

are

removed

from

the

disk

as

it

passes

under

the

erase

heads.

CHANNELS

The

memory

disk

is

divided

into

channels

which

consist

of

concentric

tracks

0.025

inch

wide

and

separated

from

each

other

by

0.015

inch.

The

channels

are

utilized

as

follows:

- 8 -

508-T-7

HIGH

PERMEABILITY

BACKING

MATERIAL

TO

RE.,.D

SIGNAL

PREAMPLIFIER

MAGNETIC

BLOCK

(SECTIONAL

VIEW)

DIGIT

BEING

READ

Figure

9.

Reading

of

Perpendicularly

Recorded

Digits

1.

Sixty-four

permanent-

storage

information

channels,

which

store

64

words

per

channel.

(The

channels

are

identified

by

read

heads

numbered

octally

MO

through

M77

and

corresponding

write

heads

numbered

octally

W0

through

W77'

Channel

77

contains

only

48

addressable

word

spaces

because

the

last

16

addresses

are

assigned

to

the

rapid-access

loops

L

and

V,

loop

L

having

the

addresses

7760

to

7767,

and

loop

V

having

the

addresses

7770

to

7777.

2.

One

clock

channel

(C)

which

contains

permanently

recorded

sine

waves

(figure

11)

for

synchronization

of

computer

circuits.

508-T-7

BINARY

DIGIT

WRITE

CURRENT

FLUX

PATTERN

READ

HEAD

VOLTAGE

o

Figure

10.

o o o o o o o

Waveforms

in

Writing

and

Reading

- 9 -

3.

One

origin

channel

Xor

which

contains

a

permanently

rec;:orded

pulse

for

initial

synchroni~ation

of

computer

circuits

and

for

resetting

the

digit

counter.

In

addition,

one

channel

provides

storage

space

for

the

following

loops

and

registers:

1.

Four

recirculating

I-word

·arithmetic

registers

(accumulator

A,

num-

ber

register

B,

r.emainder

register

R,

and

auxiliary

register

X).

2.

One

reCirculating

I-word

control

register

(command

register

Z).

3.

"

Two

high-speed

8-word

recirculating

loops

(L

and

V),

which

can

copy

and

store

any

8

consec\1tive

words

from

any

of

the

64

information

storage

channels,

An

additional

read

head

i.s

located

four

words

from

the

':IVrite

head

on

channelsL

and

V.

This

head

provides

acce,ss

to

information

stored

between

the

read

and

write

heads

on

the

8-word

loops,

thereby

reducing

the

access

time

for

re,adout.

Each

channel,

register,

and

loop

has

a

read

head

and

write

head.

(See

figure

12.)

The

read

heads

are

separated

from

the

write

heads

by

180

degrees

for

the

information

channels,

clock

channel,

and

origin

channel.

On

the

outer-

most

channel.

the

read

and

write

heads

are

spaced

approximately

I-word

length

for

the

I_word

A.

•.

B.

R.

X,

and

Z

registers.

The

read

and

write,

heads

are

spaced

at

8-word

lengths

for

the

L

and

V

loops

with

an

additional

read

head

spaced

at

4-word

lengths.

A

permanent

magnet

erase

head

on

the

outermost

channel.

which

contains

the

recirculating

registers

and

loops.

separates

the

end

of

each

register

or

loop

from

the

start

of

the

next.

By

this

location

of

the

erase

head.

information

read

from

one

register

is

erased

before

the

same

area

of

the

disk

passes

under

the

write

head

of

the

next

register.

DISK

MOTION"-..--_.._..,

-

..

Note:

Clock

channel

contains

26Z4

magnetized

sine

wave

cycles,

41

cycles

per

word

sector

Figure

11.

Permanently

Recorded

Clock

Track

Waveform

.;

10

-

508-T-7

LEGEND:

l-WORD

REGISTERS:

B,

X,

R,

A,

Z

a-WORD

REGISTERS:

L,

V

64-WORD

CHANNELS:

MAIN

MEMORY

CHANNELS

NUMBERED

OCTALLY

0

TO

77,

CLOCK

CHANNEL

(C),

ORIGIN

CHANNEL

(~OR)

M =

MAIN

MEMORY

READ

HEAD

W =

MAIN

MEMORY

WRITE

HEAD

SUBSCRIPT

R =

READ

HEAD

SUBSCRIPT

W =

WRITE

HEAD

ERASE

=

ERASE

HEAD

RCl-.lOO

Figure

12.

Head

Positions

on

Magnetit

Disk

(System

s

50l'through

520)

The

placement

of

the

heads

illustrated

in

figure

12

is

applicable

only

to

the

memories

originally

installed

in

systems

501

through

520.

Figure

13

shows

the

hea~plate

design

for

systems

subsequent

to

520,

wherein

the

channels

are

"pushed

out"

to

provide

for

a

greater

diameter,

and

thus

a

greater

circumfer-

ence,

for

the

inner

tracks.

This

greater

circumference

reduces

the

pos

sibility

of

the

origin

pulse

being

too

wide

in

terms

of

duration

and

also

reduces

the

possibility

of

amplitude

modulation

occuring

on

information

stored

in

the

inner

channels.

Principles

of

operation,

however,

are

the

same

as

previously

described

in

this

sectioh,

and

all

connection

details

and

logic

details

are

the

same

for

both

headplate

c

onfigu

ra

t

ion

s.

Memories

with

this

"push

out"

design

may

eventually

replace

those

now

installed

if

replacement

is

warranted

under

normal

operating

conditions.

508-T-7

-

11

-

Table of contents