User Manual

Operating Instructions

WWW.AvantcoEquipment.com 6

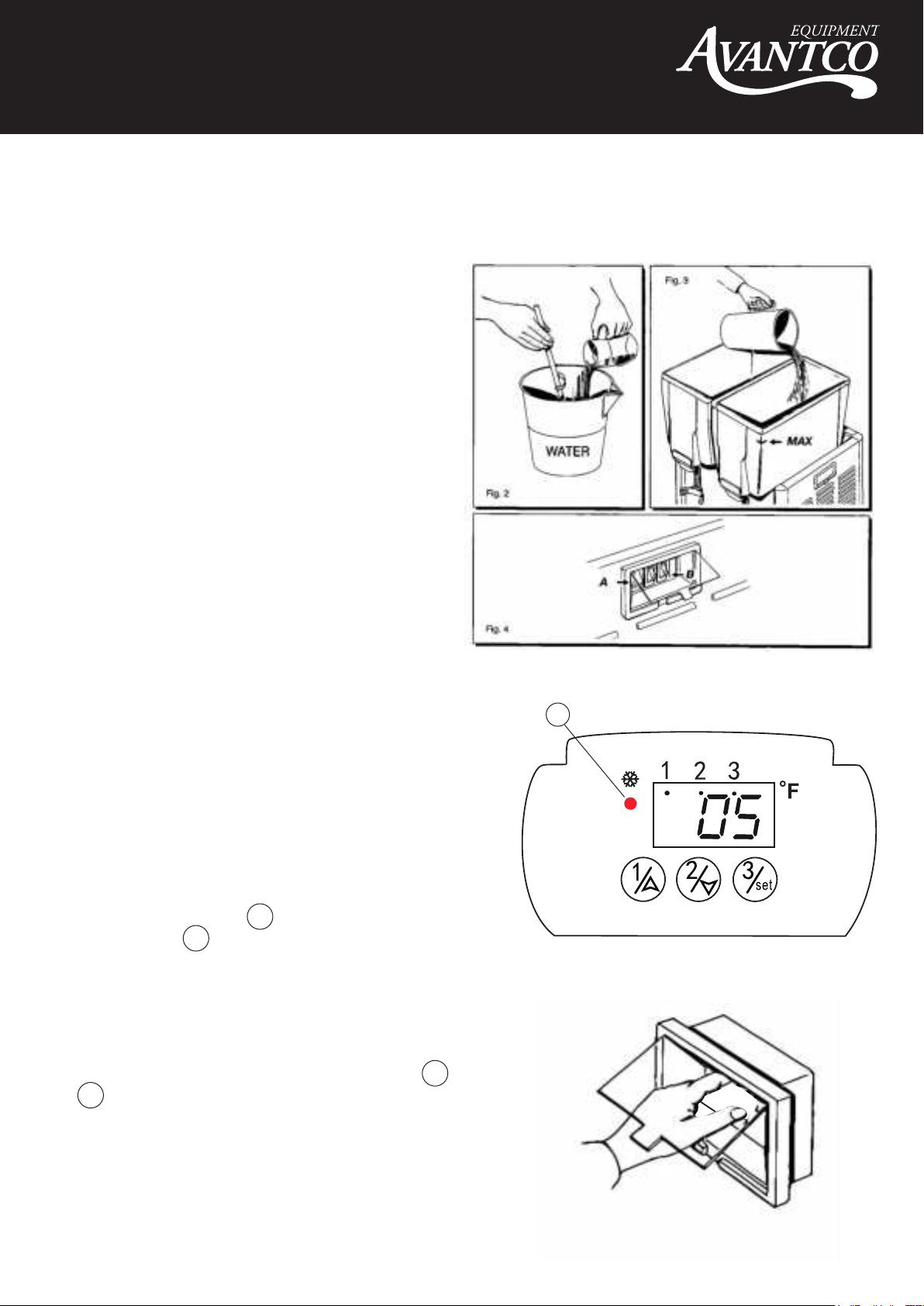

How To Use:

Before using, the tanks and taps of the

appliance should be cleaned carefully

Filling

To ensure correct usage of the machine ensure

that the liquid level of the tank does not go

below 3-4 Qt (please use the level lines on the

tank for reference).

1. Mix product in a separate container (FIG. 2).

2. Make sure to unplug the appliance before

¿OOLQJXSWKHFRQWDLQHU

'RQRW¿OOWKHFRQWDLQHUZLWKKRWSURGXFW

4. Do not let liquid level exceed the “MAX” level

line (FIG. 3).

Beverage Temperature Adjustment (FIG.5)

To adjust the temperature of each individual bowl,

lift up the plastic cover on left side of

the unit. Bowl 1 is on the left hand side of the unit

when looking from the front.

1. Turn on the main switch on the right hand of the

unit. The main power light (A) will now

indicate on the digital control.

2. To set the temperature of bowl no.1

press the button marked 1 twice. The indicator

lamp under bowl 1 at the top of the display will now

LOOXPLQDWHDQGWKHFXUUHQWVHWWHPSHUDWXUHZLOOÀDVK

Adjust the arrow keys to set the desired temperature

and then press “set”. The temperature range may

be set between 32°F and 50°F.

The control temperature for bowl 1 is now set.

Repeat the process using the buttons marked 2

and 3 to set the temperature of the remaining

bowls.

3. When in operation the unit will automatically

display the actual temperature of each bowl for 2

seconds as indicated by the lamp beneath the bowl

symbols.

Fig. 5

A