6 (28)

2. Designed purpose of use

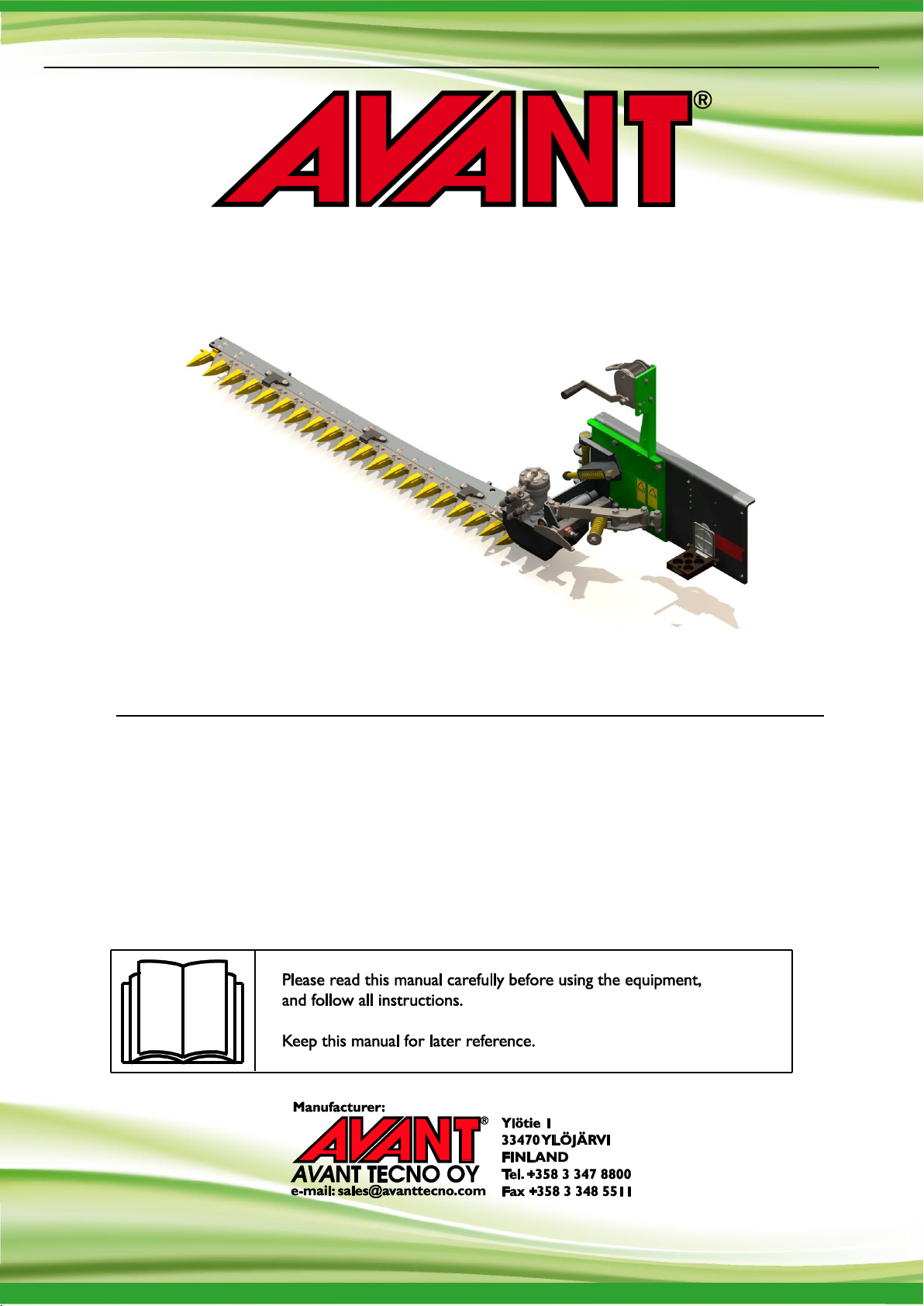

The AVANT Cutter bar mower is an attachment suitable for use with AVANT multi purpose loaders shown in

Table 1. The mower is a very effective attachment for cutting hay from fields, meadows and road shoulders. It

makes cutting and easy collecting of even long hay possible, while it allows to easily collect the cut hay. The

attachment can also be used vertically for hedge cutting. The mower is attached on the quick coupling plate of

the loader boom, giving excellent visibility to the blade bar that is on the right side of the attachment. The side

reach and blade tilting make it possible to mow also from slopes. The blade guides on the blade bar support

and protect the replaceable special steel blades.

Before each use the blade is adjusted to working position with a manual winch or with the optional electric

actuator system. When transporting the mower, the blade is set to its upper position. The attachment is

started and operated from the driver’s seat driving forward at calm speed that is adjusted according to

operating and terrain conditions. The electric actuator of blade position control can be controlled either with

the optional attachment control switch pack of the loader or with a separate cable kit that is supplied with the

attachment.

The spring release mechanism of the blade bar allows the blade bar to move back when hitting an obstacle.

However, you must stay alert and observe the terrain conditions and the operation of the machine in order to

avoid hitting obstacles. The dangers related to the strong and powerful cutting must always be kept in mind

when operating or otherwise handling the attachment. The attachment is intended for operators who have

learned the safe operation of the loader and the attachment, and are able to notice the risks arising from using

the equipment and terrain conditions. The attachment is not intended to be used by children. The mower can

cut small trees of about maximum around 20 mm in diameter, but the mower is not intended for clearing areas

from growing trees. After the spring release mechanism has freed the blade bar, the loader and attachment

must be stopped safely, and the blade must be turned back to its operating position. Using the attachment in

other ways than cutting hay or mild shrub while controlling the equipment from the driver’s seat of the loader is

prohibited.

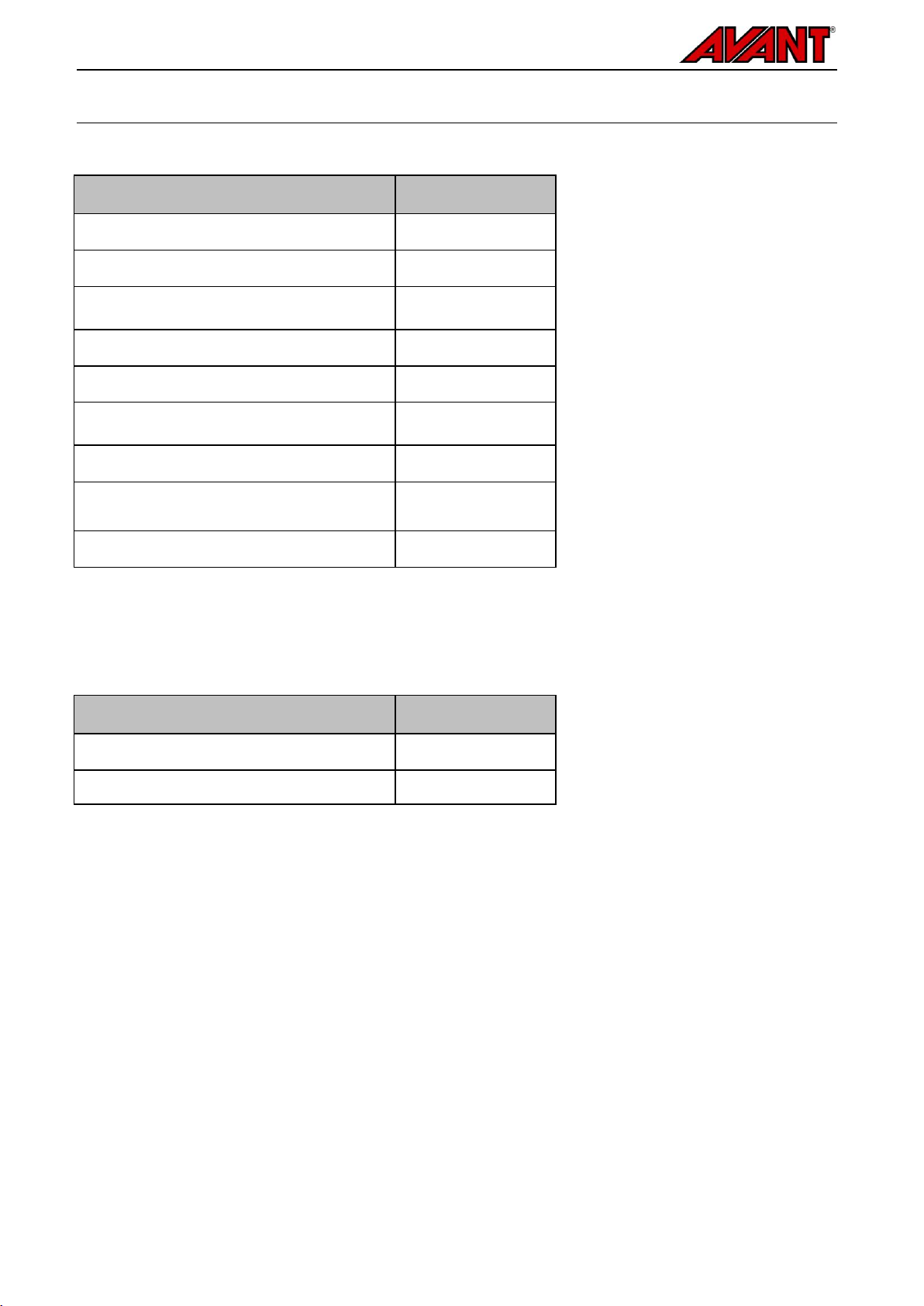

Table 1 - Cutter bar mower - Compatibility with Avant loaders

520

R20

525LPG

R28

528

e5

When using with models marked with (), full performance may not be achieved. Additional counterweights

may also be required. For compatibility with a model not shown in table, contact your Avant dealer.

To use with Avant 218 or 220 series 1 loaders, a separate coupling adapter and additional hydraulic

connectors are required. They are available from your Avant dealer.

Maintenance and service operations

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. All repair work can’t be performed by the operator, and demanding repair and

maintenance operations are to be left for professional maintenance. All maintenance work must be done using

proper safety equipment. Spare parts must be identical with original specifications, which can be ensured by

using only original spare parts. A separate spare parts catalogue may be available, consult your Avant dealer.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT retailer if you have additional questions about the operation or maintenance of the equipment, or if

you require spare parts or maintenance services.