AVIAIR AVI35 User manual

Table of contents

Popular Heating System manuals by other brands

ITR

ITR POLAR HD Installation and operating manual

Froling

Froling Turbomat TM 400 installation instructions

STIEBEL ELTRON

STIEBEL ELTRON HSBC 300 cool Operation and installation

Amana

Amana APG14 M Series manual

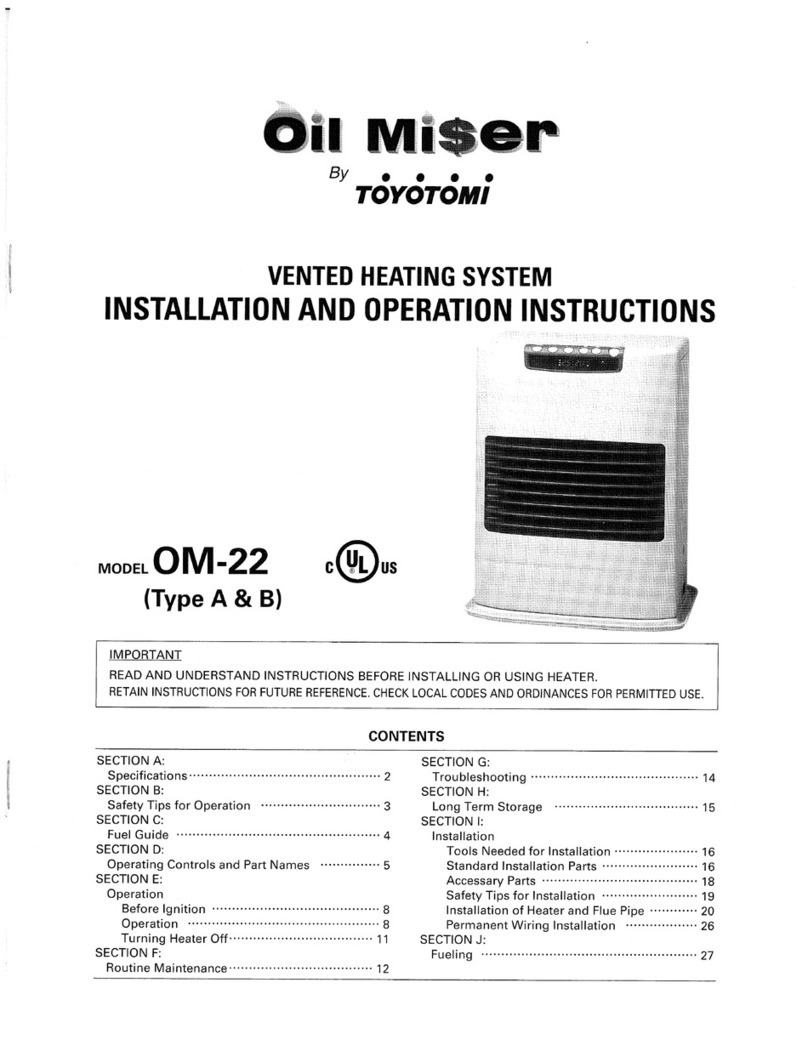

Toyotomi

Toyotomi OM-22 Type A Installation and operation instructions

Vectaire

Vectaire WHHR100/60DC Installation, operating and maintenance instructions

Hydro-Hot

Hydro-Hot HHE-200-09E owner's manual

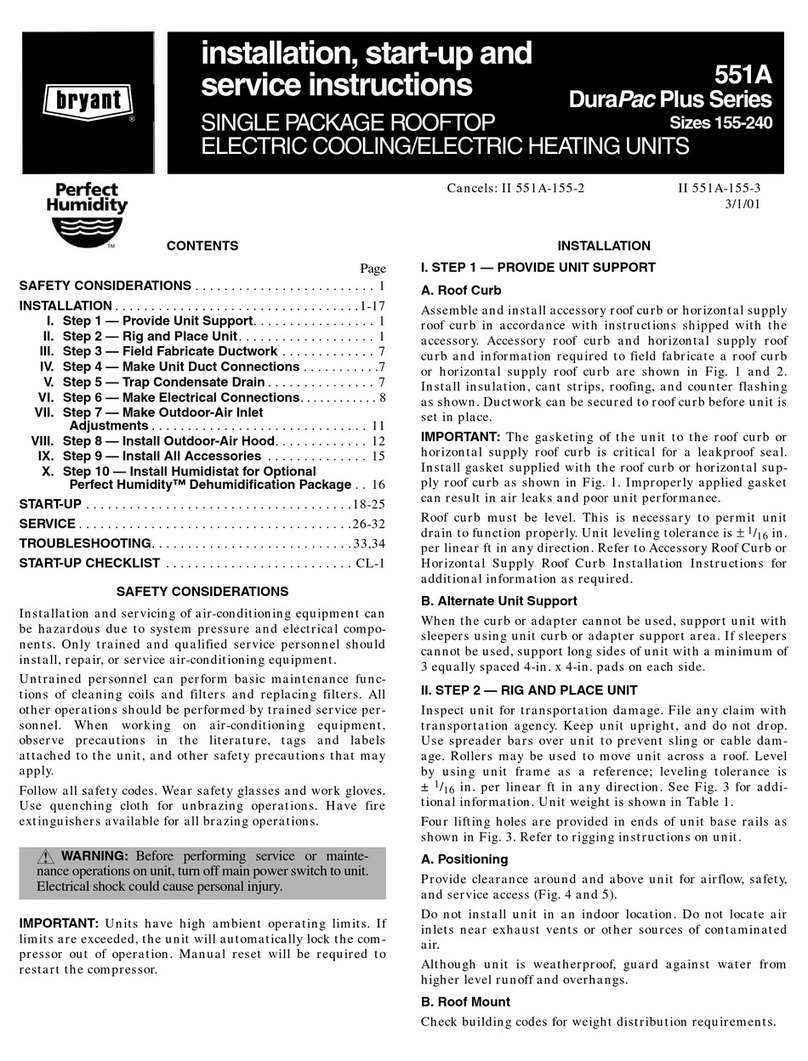

Bryant

Bryant 551A Installation, Start-Up and Service Instructions

Steffes

Steffes ThermElect Hydronic 9150 Owner's and installer's manual

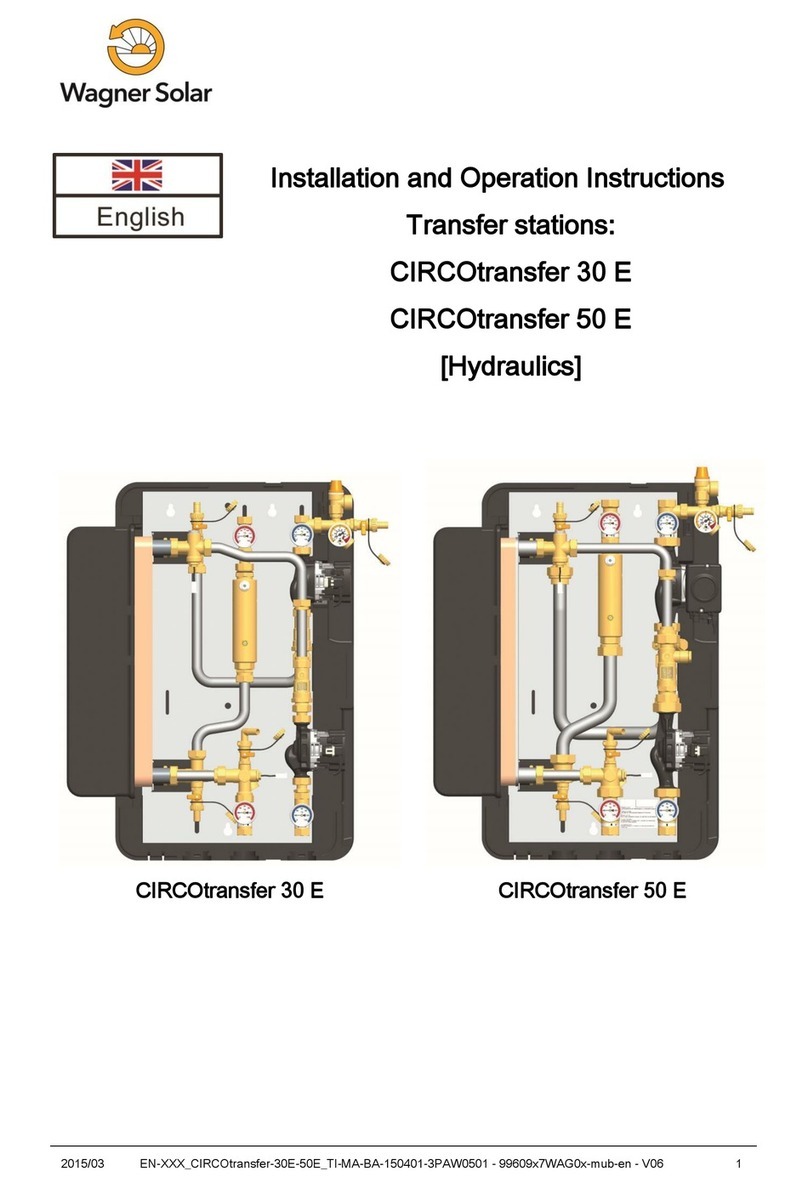

wagner solar

wagner solar CIRCOtransfer 30 E Installation and operation instructions

Airxcel

Airxcel Aqua-Hot 100 Series Use and care guide

Carrier

Carrier 40VMZ Installation and maintenance instructions

DEVI

DEVI Devifoil Mirror installation instructions

Aereco

Aereco DXA 230 PREMIUM Installation and maintenance instruction

Sentinel

Sentinel SOLARFLUSH operating instructions

Oxygen

Oxygen X-Air V600 Installation and operation manual

Viessmann

Viessmann VITODENS operating instructions

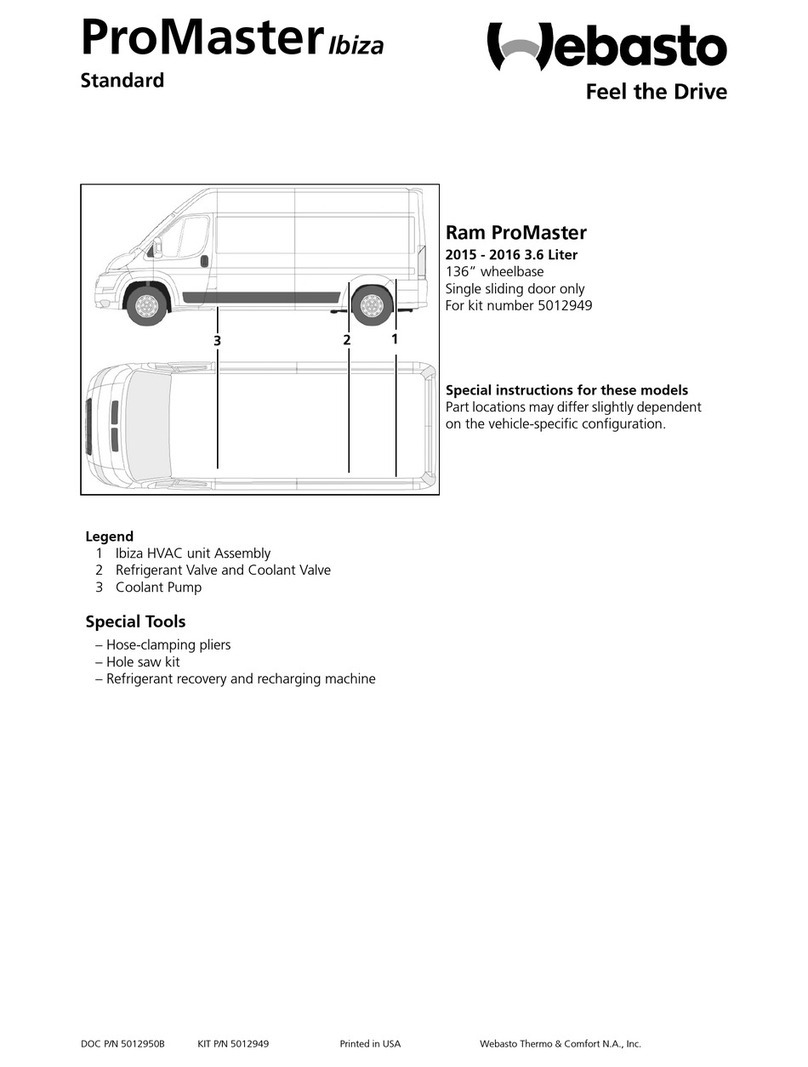

Webasto

Webasto ProMaster Ibiza manual