1 General information

2015/03 EN-XXX_CIRCOtransfer-30E-50E_TI-MA-BA-150401-3PAW0501 - 99609x7WAG0x-mub-en - V06 3

Contents

1General information ...........................................................................................................4

1.1 About these instructions ............................................................................................... 4

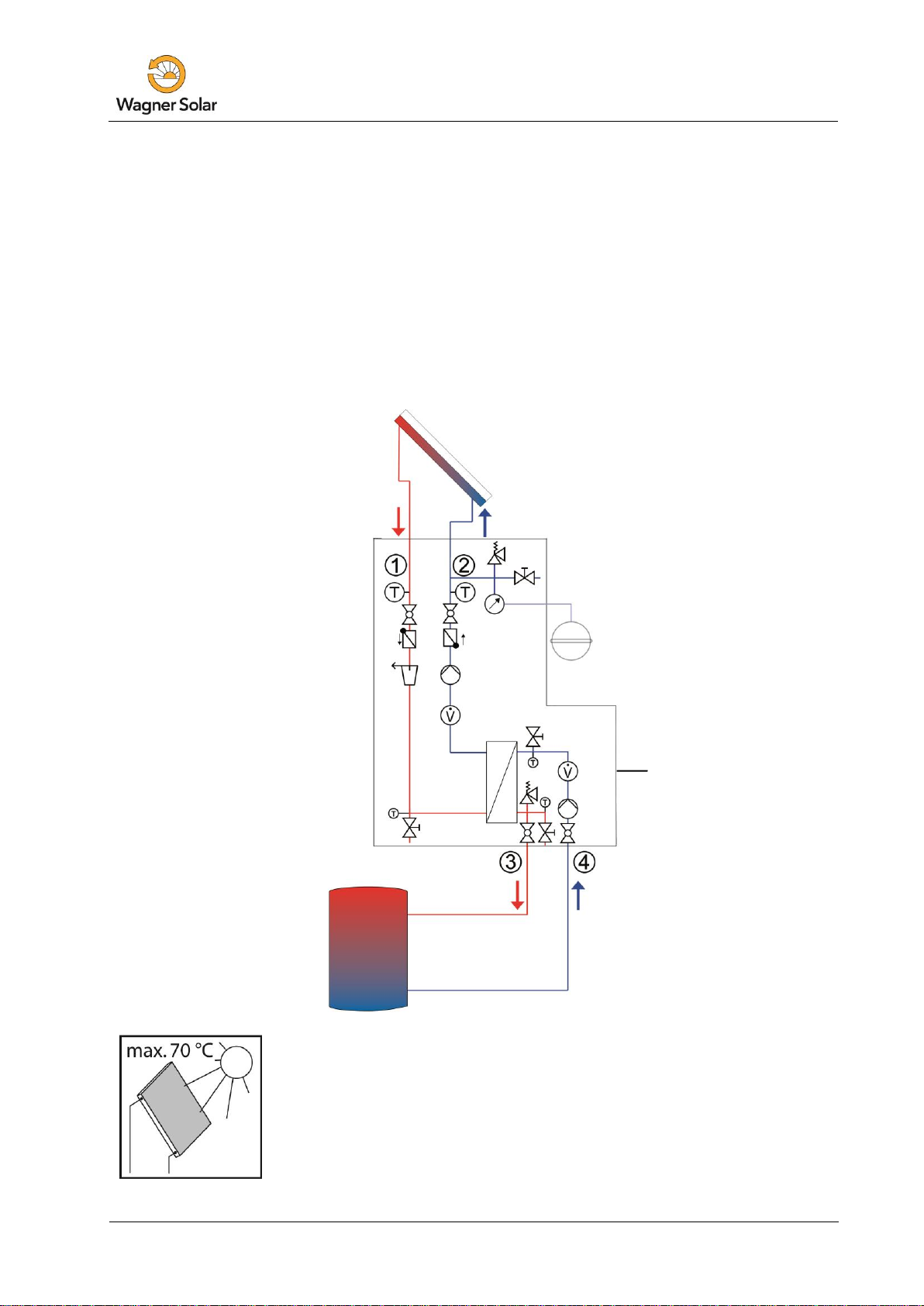

1.2 About this product ........................................................................................................ 5

1.3 Designated use ............................................................................................................ 6

2Safety instructions .............................................................................................................7

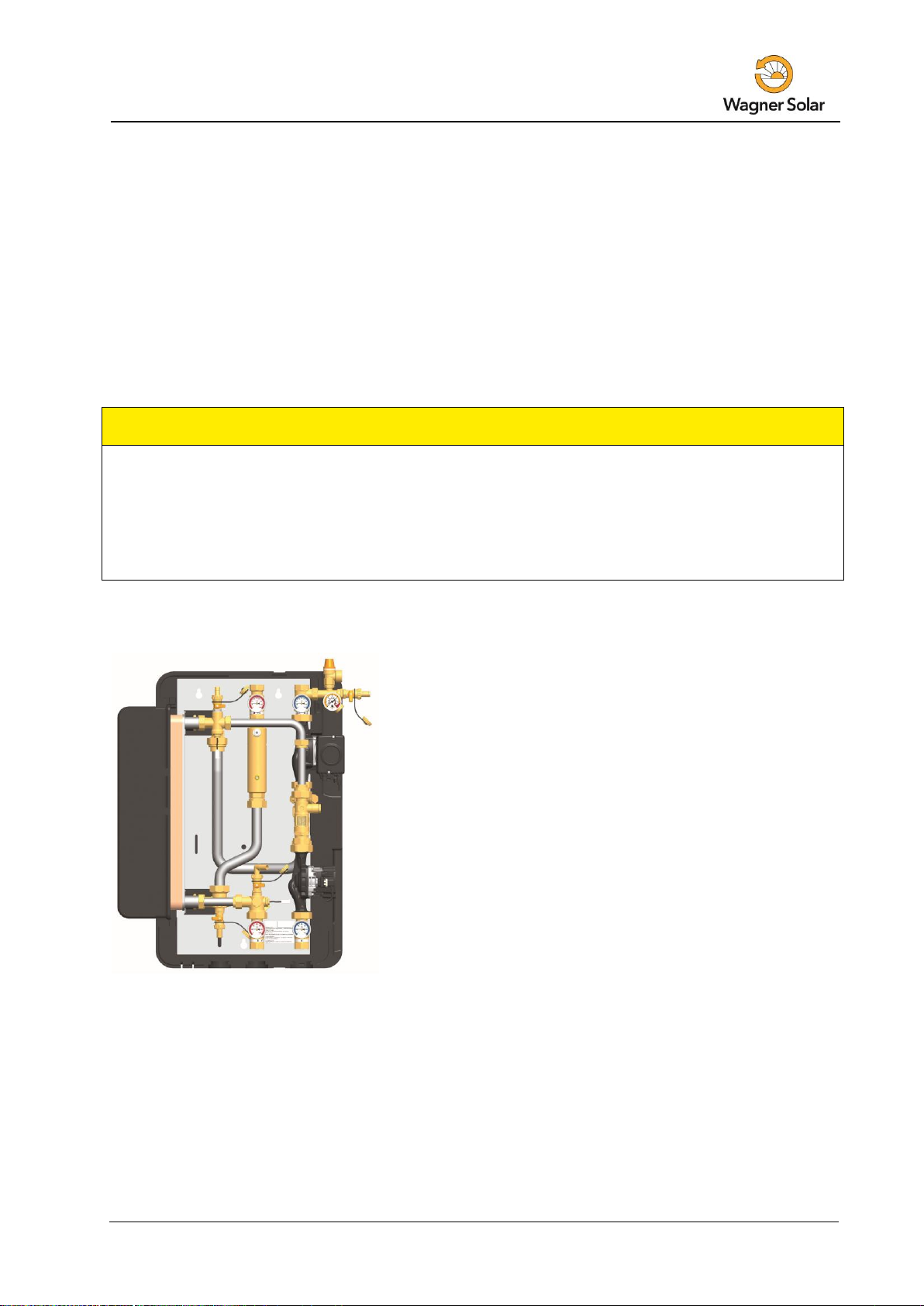

3Assembly and installation [specialist] ..................................................................................9

3.1 Controller connection ................................................................................................. 11

4Commissioning [specialist] ...............................................................................................12

4.1 Preparations before flushing and filling....................................................................... 13

4.2 Flushing and filling the storage tank circuit................................................................. 13

4.3 Flushing and filling the solar circuit............................................................................. 14

4.4 Maintenance [specialist] ............................................................................................. 19

4.5 Draining the solar installation ..................................................................................... 20

4.6 Deinstallation.............................................................................................................. 20

5Spare parts [specialist].....................................................................................................21

5.1Spare parts primary circuit CIRCOtransfer 30 E (15020220)...................................... 21

5.2 Spare parts secondary circuit CIRCOtransfer 30 E (15020220) ................................. 22

5.3 Spare parts primary circuit CIRCOtransfer 50 E (15020221)...................................... 23

5.4 Spare parts secondary circuit CIRCOtransfer 50 E (15020221) ................................. 24

6Technical data .................................................................................................................25

6.1 Dimensional drawing CIRCOtransfer 30 E ................................................................. 26

6.2 Dimensional drawing CIRCOtransfer 50 E ................................................................. 27

6.3 Pressure drop characteristics CIRCOtransfer 30 E .................................................... 28

6.4 Pressure drop characteristics CIRCOtransfer 50 E .................................................... 28

7Function of the check valves [specialist]............................................................................29

8Commissioning report ......................................................................................................31