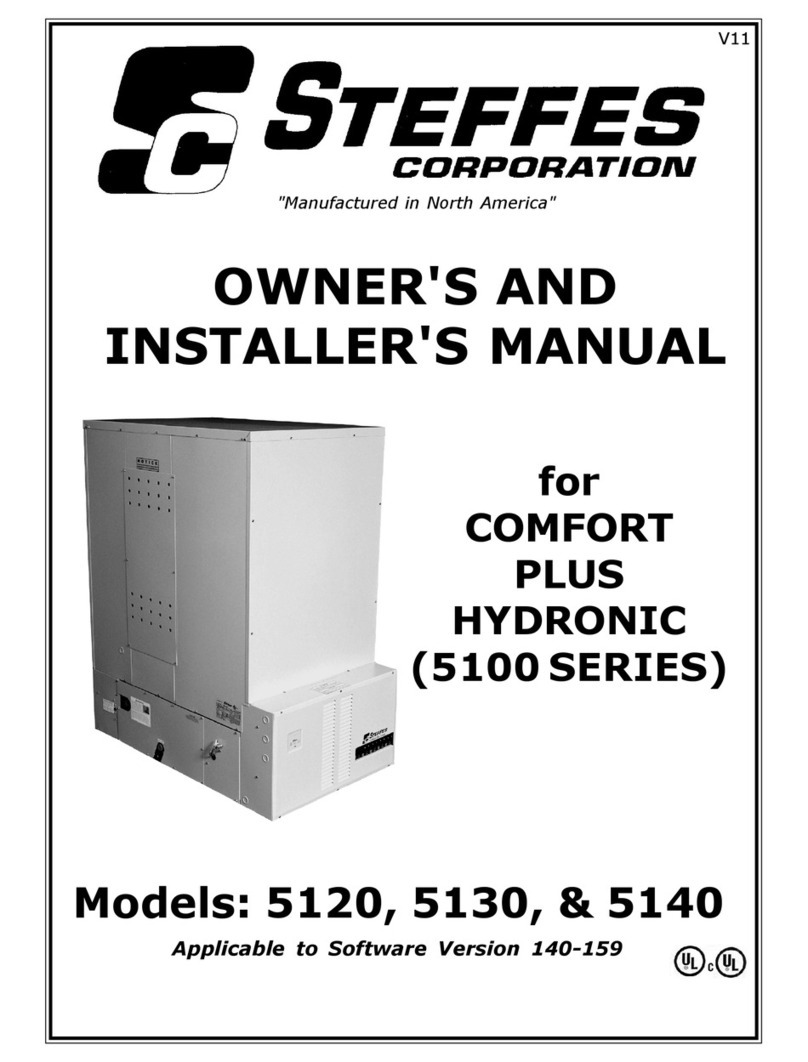

Steffes ThermElect Hydronic 9150 User manual

OWNER'S AND

INSTALLER'S MANUAL

Models: 9150, 9180

Applicable to Software Version 2.XX

Hydronic

LISTED

For Customer Use

Please record your model and serial number below. This number is found on the identification labels

located on the front of and inside the electrical panel. Retain this information for future reference.

Model No. ________________________________________________________________________

Serial No. ________________________________________________________________________

RECOGNIZE THESE SYMBOLS AS SAFETY PRECAUTIONS

It is important, both for your personal safety and to avoid possible damage to the

equipment and your property, that you observe the safety instructions given follow-

ing these symbols.

w The equipment described herein is intended for installation by a quali!ed

technician in accordance with applicable local, state, and national codes and

requirements.

w To insure proper installation and operation of this product, completely read

all instructions prior to attempting to assemble, install, operate, maintain or

repair this product. Upon unpacking of the system, inspect all parts for dam-

age prior to installation and start-up.

w This manual should be retained by the owner upon completion of the installa-

tion and made available to service personnel as required.

w Disclaimer: In compiling this manual, Steffes Corporation has used its best

judgement based upon information available, but disclaims any responsibility

or liability for any errors or miscalculations contained herein, or any revisions

hereof, or which result, in whole or in part, from the use of this manual or any

revisions hereof.

IMPORTANT

SAFETY PRECAUTIONS

Fully assemble the system and load ceramic heat storage1.

brick prior to energizing the system.

Pressure relief valve must be installed prior to operation of2.

the system.

Use or storage of explosive or •ammable gasses or liquids3.

within close proximity of the system presents a hazard.

Clearance requirements are critical to safe operation of the4.

system. Follow all requirements speci•ed in this manual

(Page 3.03).

Keep the top of system clear.5.

Use caution when working around the heating system as inlet6.

and outlet piping can be very hot.

De-energize all branch circuits before servicing. This heating7.

system may be connected to more than one branch circuit.

Installation of and/or service to this heating system should be8.

performed by a quali•ed technician in accordance with in-

formation contained herein and with national, state, and local

codes and requirements.

Repeated error codes on the system display (pages A.10 –9.

A.13) indicate a need for service by a quali•ed technician.

Special requirements must be considered if placing the sys-10.

tem in a garage or other area where combustible vapors may

be present. Consult local, state and national codes and regula-

tions to ensure proper installation.

BUILT-IN SAFETY DEVICES

The ThermElect Hydronic heating system incorporates safety devices to ensure normal operating temperatures are

maintained. The chart below describes these safety devices.

THERMELECT HYDRONIC SAFETY INFORMATION

DEVICE LOCATION

ON SYSTEM

Core Charging High

Limit Switches

(Auto Reset)

These limit switches monitor the core and top temperatures.

If normal operating temperatures are exceeded, the system

will display "CORE FAIL" and the elements will not be

allowed to operate.

Right side of system.

This linear limit switch monitors the temperature of the wa-

ter in the exchanger and interrupts power to the core blower

if a water temperature of 250oF/121oC is exceeded. If this

limit switch opens, contact a quali•ed service technician.

Heat Exchanger

Limit Switch

(Manual Reset)

Behind front lower

painted panel. Reset

button visible in lower

right front corner.

This linear limit switch monitors the temperature of the

water in the exchanger and interrupts power to the core

blower if a water temperature of 225oF/107oC is exceeded.

Outlet Water

Temperature Limit

Switch (Auto Reset)

Behind front lower

painted panel.

Pressure Relief Valve Factory provided,

•eld installed to outlet

of heat exchanger.

If the water pressure exceeds maximum psig, the pressure

relief valve opens. Once water pressure of less than maxi-

mum psig is achieved, the valve closes.

FUNCTION

WARNING

Hazardous Voltage: Risk of electric

shock, injury, or death. This system

may be connected to more than one

branch circuit. Disconnect power

to all circuits before installing or

servicing. Installation of and/or

service to this equipment MUST be

performed by a quali!ed technician.

Risk of explosion. Operating the

system without the pressure relief

valve properly installed can cause

an explosion. Connect the pressure

relief valve in a vertical, upright po-

sition with the supplied !ttings. DO

NOT modify this assembly. DO NOT

cap, plug, or otherwise obstruct the

outlet of the pressure relief valve.

Risk of !re. Violation of the clear-

ance requirements can cause im-

proper operation of the equipment.

Maintain the placement and clear-

ance requirements speci!ed.

Hot Surface. Plumbing and other

surfaces can be hot. Use caution

when working near the system.

Table of Contents

TC

TABLE OF CONTENTS THERMELECT HYDRONIC

Operation

General Operation........................................................................................................................................................................1.01

System Use During Construction Phase ......................................................................................................................................1.01

System Start-Up...........................................................................................................................................................................1.01

Turning System "OFF" and "ON"................................................................................................................................................1.01

Control Panel ...............................................................................................................................................................................1.02

Operating Status...........................................................................................................................................................................1.02

Discharge Air/Water System........................................................................................................................................................1.03

Brick Core Charge Control .........................................................................................................................................................1.03

Charge Control Override..............................................................................................................................................................1.03

Maintenance and Cleaning...........................................................................................................................................................1.03

Optional Accessories

Load Management Control .........................................................................................................................................................2.01

Lifting Handles ............................................................................................................................................................................2.01

External Duct Sensor ...................................................................................................................................................................2.02

Static Heat Recovery Unit ...........................................................................................................................................................2.02

SCR Controller.............................................................................................................................................................................2.02

Control Circuit Step Down Transformer......................................................................................................................................2.03

Installation

Shipping and Packaging...................................................................................................................................................... 3.01-3.02

Placement and Clearance Requirements......................................................................................................................................3.03

Initial Set-up.................................................................................................................................................................................3.04

Electrical Panel Installation .........................................................................................................................................................3.04

Brick Loading ..................................................................................................................................................................... 3.04-3.05

Heating Element Installation............................................................................................................................................... 3.05-3.06

Brick Core Temperature Sensor Installation ..............................................................................................................................3.06

Line Voltage Electrical Connections............................................................................................................................................3.07

Low Voltage Electrical Connections

Outdoor Temperature Sensor Installation...............................................................................................................................3.08

Room Thermostat ...................................................................................................................................................................3.08

Air Conditioner/Heat Pump Interface ....................................................................................................................................3.09

Pressure Relief Valve Installation ................................................................................................................................................3.09

Plumbing..............................................................................................................................................................................3.10-3.11

Appendix

Speci!cations .....................................................................................................................................................................A.01-A.02

Exploded View Diagram - 50kW Storage Module .....................................................................................................................A.03

Exploded View Diagram - 80kW Storage Module .....................................................................................................................A.04

Parts List - Storage Module ........................................................................................................................................................A.05

Exploded View Diagram / List - Base .......................................................................................................................................A. 06

Typical System Line Voltage Wiring Diagrams ................................................................................................................A.07-A.08

Internal System Wiring Diagram - Low Voltage ........................................................................................................................A.09

Help Menu ..................................................................................................................................................................................A.10

Error Codes ........................................................................................................................................................................A.10-A.13

Warranty

GENERAL OPERATION

The ThermElect Hydronic heating system stores de-

mand off-peak electricity in the form of heat.

Operation of the heating system is automatic. During

hours when energy costs are lower the system converts

electricity to heat which is then stored in its ceramic

brick core. The amount of heat stored in the brick core

of the system varies in relation to outdoor temperature,

utility peak conditions, and/or the heating require-

ments.

A heat call from the thermostat or main system control

energizes the primary water loop pump. The vari-

able speed core blower automatically adjusts its speed

to achieve the desired outlet water temperature. The

heated water is then pumped to the area (zone) from

which the heat call originated.

The versatility of this system allows it to •t many ap-

plications. The system is designed for use as either a

sole heating source (“stand alone” furnace) for make

up air heating or as a supplement to another ducted

heating system such as a heat pump.

SYSTEM USE DURING

CONSTRUCTION PHASE

Like most heating equipment manufacturers, Stef-

fes strongly recommends that “Construction Heating

Units” be used instead of the permanent heating system

during the construction phase. Use of the permanent heating system during this phase may contaminate the duct

system and/or internal areas of the heating system. This may cause poor indoor air quality issues and/or improper

system operation or equipment damage.

SYSTEM START-UP

On start-up of the ThermElect Hydronic system, odors relating to •rst time operation of the heating components

may be experienced. Allow the system to charge to its maximum brick core charge level, on start-up, to expel

these odors. If the system has not been used for an extended period of time, dust may accumulate in the system.

Upon restart, there may also be an odor as these dust particles are expelled.

During operation, the system may produce minor expansion noises. These noises are the result of the internal com-

ponents reacting to the temperature changes.

TURNING SYSTEM "OFF" AND "ON"

The system is fully automatic and does not need to be manually disabled. Talk to your installer or energy manage-

ment person for additional information.

THERMELECT HYDRONIC OPERATION n1.01

Operation

1

Operation

SUPPLY

WATER

WATER

RETURN

VARIABLE SPEED

CORE BLOWER

MOTOR ASSEMBLY

225° AUTO

RESET LIMIT

250° MANUAL

RESET LIMIT

AIR TO WATER

HEAT EXCHANGER

HEAT

STORAGE

BRICK

HEATING

ELEMENT

CONTROL PANEL

Operation of the ThermElect Hydronic system is automatic. All operational func-

tions are stored in its microprocessor in function locations and are factory preset. If

necessary, the installer can adjust them through the control panel. (See Figure 1.)

Four-Digit LED Display

The four digit LED displays speci!c operating information. During the con!gura-

tion process, the con!guration number and the values set in these con!gurations are

displayed for viewing and adjusting purposes.

AM and PM Indicator Lights

The AM and PM indicator lights are only utilized if the Steffes Time Clock Module

is being installed and using 12 hour time display. With this module installed,

the system displays time on AM/PM intervals. The light "ashes next to the ac-

tive designator/symbol. The system can be con!gured to display military time,

in which case both the AM and PM lights illuminate.

Mode (Edit) Button

Used to access menus on the system (i.e. Help Menu or Con!guration Menu)

and to allow modifying of con!guration settings.

Up and Down Arrow Buttons

Used to scroll up or down when viewing or modifying operating functions.

Interface Port

Allows technician external access for advanced operating modes, updating software, and troubleshooting.

OPERATING STATUS

The four digit LED will display various operating information as described below. Press and release the up arrow

to view this data.

Operating Mode - Indicates the current operating mode of the system followed by the outlet

water temperature.

C = Off-Peak (Charge) Time

P = On-Peak (Control) Time

A = Anticipated Peak Time

Outdoor Temperature -“O” followed by a number indicates current outdoor temperature.

Heat Call Status - indicates the current heat call status as determined by the room thermostat(s).

The faceplate displays the highest heat call value present. If receiving a Stage 1 Forced Air Heat

Call and a Hydronic Heat Call, the display will read “HC_3”.

A bar illuminates on the lower portion of the display's third digit whenever one or

more heating elements are energized.

Brick Core Charge Level - “CL” (charge level) followed by a number indicates the current per-

centage of heat stored in the brick core. “CL:_” indicates the core is below minimum charge level

and “CL: F” represents a full core charge level.

Targeted Brick Core Charge Level - “tL” (target level) followed by a number indicates the cur-

rent percentage of brick core charge being targeted by the system. A display of “tL:_” indicates

charging is not allowed and “tL: F” indicates a full core charge target level.

Load Control - Current demand (kW) divided by 10. A value of “d 75” is equal to a demand of

750kW.

OPERATION n1.02 THERMELECT HYDRONIC

CAUTION

Editing configuration

information may alter

the performance and

operation of the system.

Operation

ñò

M

CONTROL PANEL

FIGURE 1

MM

PP

M

MM

AA

THERMELECT HYDRONIC OPERATION n1.03

DISCHARGE AIR/WATER SYSTEM

The 9100 Series heating systems can be used as straight hydronic heating appliances or as a combination hydronic

and forced air system with the addition of a •eld supplied air handler, water coil, and duct sensor. In all systems, to

deliver stored heat, the 9100 Series needs to receive a signal from a thermostat, BACNet system, energy manage-

ment system, or serial communication input. This signal will initiate one of several levels of heat call.

When a heat call is initiated, the system displays the type of heat call on the status screen of the control panel, the

primary loop pump is energized, and the outlet water temperature is monitored. The desired discharge water tem-

perature is regulated based off of the target temperature (L127) established.

BRICK CORE CHARGE CONTROL

Steffes heating systems are capable of providing a wide variety of heating options for various applications. The

heating system's primary function is to store energy in the form of heat. Because the system is operated with mi-

croprocessor based control, it is very flexible in meeting the demands of the application. The rate at which energy

is stored can be controlled with BACNET, 4-20, or pulse inputs.

The amount of energy stored is based on the target level which is determined by outdoor temperature, utility peak

conditions, building automation system, and/or the heating requirements. Sensors monitor the brick core tempera-

ture and communicate this information to the processor control board. If the current charge level is lower than the

target level of any core, elements will be energized as allowed by the load management system.

CHARGE CONTROL OVERRIDE

If desired, the ThermElect Hydronic system can be programmed to allow a charge control override. This override

allows the user to force the system to target a full core charge level and can be initiated or cancelled at any time. If

an override is initiated, the system targets a full core charge level during the next off-peak period. It continues to

charge during off-peak hours until it achieves full (maximum) core charge or until the override is cancelled. Once

full charge is achieved or the override is cancelled, the system charges according to the standard configuration.

MAINTENANCE AND CLEANING

Any air filter(s) in the system should be replaced on a regular basis to ensure proper operation and to maintain

overall efficiencies. No additional routine maintenance is required.

If utilizing a heat pump or air conditioning system with the ThermElect Hydronic system, the indoor coil should

be cleaned periodically as dirt accumulation may reduce system efficiency. It is important to follow the manufac-

turer’s maintenance and cleaning recommendations for these devices.

Operation

LIFTING HANDLES

LOAD MANAGEMENT CONTROL

The system is designed to operate under one of many load management control strategies.

1. BACNet Control

Steffes commercial heating furnaces are available with a BACNet control option

(Order Item #1301013 or #1301015). This device is easily integrated into most

building automation systems to provide building managers full control and vis-

ibility of the heating system’s operation. BACNet allows the following functions

to be monitored with simple, twisted pair communication:

Real time system monitoring•

Full thermostat control•

Monitoring of heat storage levels in the brick and all system temperatures•

Remote con!guration, testing and adjustment•

Service requirement alerts•

2. 4-20 Milliamp Control (1-5 volt DC)

System receives a signal from an external load control device such as a building load management

system. This external signal dictates the maximum amount of energy which can be consumed dur-

ing a preset time interval.

3. Pulse Monitoring

System monitors pulse outputs from the power company's electric meter. Program parameters such

as desired maximum building kW and pulse ratios for the metering system being used are pro-

grammed into the ThermElect system. The system then charges proportionally when demand free

power is available. This keeps the total building kW usage at or below the desired level.

4. Conventional Peak Control

The ThermElect Hydronic system responds to heat calls during the on-peak and off-peak periods;

however, only consumes energy (energize heating elements) during the off-peak periods. The

ThermElect Hydronic system is controlled by an external control device such as a meter, time clock

module, or BACNet control.

LIFTING HANDLES

Optional lifting handles (Order Item #1302120) are available to aid in moving the

ThermElect Hydronic system into its !nal location.

Optional Accessories

2

Accessories

OPTIONAL ACCESSORIES n2.01 THERMELECT HYDRONIC

BACNET

Accessories

THERMELECT HYDRONIC OPTIONAL ACCESSORIES n2.02

EXTERNAL DUCT SENSOR

The optional external duct sensor (Order Item #1041536)

provides the ability to monitor the duct temperature at an area

beyond fresh air makeup and/or beyond other devices and

regulate the discharge air temperature accordingly.

The duct sensor feature is enabled if the 4 bit is set in Location

53 (L053). Once enabled, the ThermElect Hydronic system

monitors temperature at both the duct sensor and the output

sensor during Y, W, or E calls from the thermostat.

STATIC HEAT RECOVERY UNIT

During operation of the ThermElect Hydronic, there is some static dissipation that

comes off of the warm outer panels. The Static Heat Recovery unit (Order Item

#1302110) moves this heat from the ThermElect Hydronic system to an area requiring

heat. Utilizing this option can maximize ef!ciency when the system is installed in an

unheated area.

With the Static Heat Recovery unit installed, the ThermElect Hydronic system can be

set up to monitor temperature at the control board and/or in the brick core. If either of

these temperatures reach a point greater than the preset point, the blower is the Static

Heat Recovery unit is energized and draws heat from inside the painted outer panels of

the ThermElect Hydronic system and delivers it to the desired area of the structure.

SSR CONTROLLER

The Steffes SSR (Solid State Relay Panel) is an optional control device used with the

Steffes ThermElect 9100 Series and Comfort Plus Commercial (6100 and 7100 Series)

Heating Systems (Order Item #1301016). Refer to the Owner's and Installer's Manual to

verify compatibility for the application.

It utilizes SSR technology to enable more precise balancing of a building’s overall elec-

tric load by varying the amount of total element input that can be energized in a Steffes

furnace at any given time in relation to the maximum allowable building load. The Stef-

fes SSR optimizes a building’s power quality and control.

The SSR Controller can only accept input signals from the Steffes furnace; but, it can

respond to all types of control inputs to include 4 – 20 Milliamp, 1 – 5 Volt DC, electric

meter pulsing, BACNnet or other building energy management system. With the 4 –

20mA or 1 – 5 volt DC signals, the SSR will provide an output directly proportional to

the input signal. 4mA signal produces 0% output while a 20mA signal produces 100%

output. With the utility pulse meter input, the SSR output percentage will automatically

adjust to maintain a total maximum system load as dictated by the furnace’s set-up.

SENSOR

AIR HANDLER

9100 SERIES

THERMELECT

WATER

COIL

SSR CONTROLLER

CONTROL CIRCUIT STEP-DOWN TRANSFORMER

The internal controls and motors of all ThermElect systems operate at 240 volts (two wire). In systems with

277/480 or 347/600 volt element circuits, a transformer must be installed per the installation instructions to sup-

ply this voltage to the system’s controls. This transformer can be purchased as an optional device from Steffes

Corporation or sourced from your local electrical supply outlet. See the matrix below for proper sizing. load as

dictated by the furnace’s set-up. With a Bacnet, the furnace can be commanded to varying input levels remotely.

Accessories

OPTIONAL ACCESSORIES n2.03 THERMELECT HYDRONIC

Model

Primary

Voltage

Secondary

Voltage

KVA

Hevi Duty Item #

Steffes

Item #

277/480V

480

240

2

HS1F1BS or equal

1017082

347/600V

600

240

2

HS10F2AS or equal

1017080

Installation

3

SHIPPING AND PACKAGING

The ThermElect Hydronic system should always be transported in an upright position to avoid damage to internal

components and insulation materials. The left and right side panels and the top panel should not be removed from

the Storage Module. The information below describes the items shipped with each system.

1STORAGE MODULE

MODEL INPUT

9150 53kW

9180 80kW

INSTALLATION HARDWARE KIT

(shipped

inside the

electrical

panel)

7

HEATING ELEMENTS

WITH CERAMIC INSULATORS

6

INFORMATION PACKAGE

(includes Owner's Manual and Warranty Registration Card)

(included on pallet with the electrical panel )

5

ELECTRICAL PANEL

3

MODEL ELEMENTS

9150 12 (2 boxes of 6)

9180 18 (3 boxes of 6)

(shipped separately)

(includes electrical

panel mounting

screws, romex con-

nectors, and wiring

schematic)

4

PRESSURE RELIEF VALVE

(shipped behind the

exchanger access

panel)

Refer to Page 3.09

208/240V shown

SEAM TRIM

(shipped inside brick

storage module)

8

2BASE

Installation

THERMELECT HYDRONIC INSTALLATION n3.01

SHIPPING AND PACKAGING CONTINUED...

CORE THERMOCOUPLES

9

9150 = Qty 2

9180 = Qty 3

CERAMIC BRICK

(shipped inside the

electrical panel)

OUTDOOR TEMPERATURE SENSOR

12

10

(shipped inside the electrical panel)

TOP AIR CHANNEL BLOCK

(shipped separately)

11

13 TRANSFORMER CONDUIT ASSEMBLY

(277V & 347V SYSTEMS ONLY)

Installation

INSTALLATION n3.02 THERMELECT HYDRONIC

MODEL BRICK LBS PALLETS

9150 192 3,360 2

9180 288 5,040 3

96 brick per pallet (shipped separately)

(shipped inside the electrical panel)

PLACEMENT AND CLEARANCE REQUIREMENTS

The system dimensions and required clearances MUST be taken into

consideration when choosing its location within a structure. (See

Figure 2 for dimensions and clearance requirements.)

The best installation location for the system is in a space requir-

ing heat so some amount of the heating requirements can be satis-

•ed through static dissipation from the warm outer panels of the

ThermElect Hydronic system. In situations where the system is not

installed in an area it is intended to heat (i.e. garage or storage area),

it is important to account for the heat lost through static dissipation

by making proper adjustments when sizing the system.

This area must remain free of debris and most importantly the

room air should be maintained at less than 85oFahrenheit. Area

may require ventilation. Refer to Speci•cations (Pages A.01-A.02).

It is the responsibility of the installer and system designer to provide

this ventilation.

In addition to the physical space requirements, the weight of the system must also be taken into consideration when

selecting the installation surface. A level concrete floor is the designed installation surface, but most well supported

surfaces are acceptable. If unsure of floor load capacity, consult a building contractor or architect.

Special requirements must be considered if placing the system in a garage or other area where com-

bustible vapors may be present. Consult electrical, building, and !re prevention codes.

SYSTEM REQUIREMENTS

FIGURE 2

DIMENSIONS

Some electrical codes may require a greater front and/or left side

clearances depending on operating voltages and other factors.

CLEARANCES

wBack = 8 inches

wBottom = 1 inch (from combustible material)

wRight Side = 12 inches

wTop = 8 inches (from combustible material)

wLeft Side & Front = 36 inches (for ease in servicing)

Adhere to clearances and provide appropriate ventilation to maintain

no greater than 85oF air temperature in area where system is installed.

Risk of •re. Can cause injury or death.

Violation of the clearance require-•

ments or failure to provide proper

ventilation can cause improper op-

eration of the system. Maintain the

placement and clearance require-

ments as speci•ed and provide

ventilation as necessary.

Moving the system after install•

may result in equipment damage.

Do NOT move system from original

installed location.

WARNING

34"

80KW

STORAGE

MODULE

40 1

16

9180 - 98"

9150 - 77"

51"

36" MINIMUM

CLEARANCE

36" MINIMUM

CLEARANCE

1" CLEARANCE

REQUIRED

8" MINIMUM CLEARANCE

12" MINIMUM

CLEARANCE

36" MINIMUM CLEARANCE

8" MINIMUM CLEARANCE

12" MINIMUM

CLEARANCE

Installation

THERMELECT HYDRONIC INSTALLATION n3.03

INITIAL SET-UP

Step 1 Remove the Information Package from the outside of the elec-

trical panel and unpackage the storage module and base.

Step 2 Move the base of the ThermElect system into location.

Step 3 Level the base ensuring the leveling legs are in full contact

with the floor so the base does not rock. The legs cannot

extend more than 1”.

Step 4 Remove the painted front and back panels of the storage mod-

ule. The right and left sides and the top panels should not be

removed from the storage module

Step 5 Position the brick storage module onto the base, making sure

the square holes (front) in the base line up with the square

holes of the storage module.

Optional lifting handles are available from Steffes

(Order Item #1302120).

Step 6 Reinstall painted back panel and attach right and back side seam trim using hardware provided.

Installation

ELECTRICAL PANEL INSTALLATION

Step 1 Remove the electrical panel front cover and locate the installation hardware package.

Step 2 Remove 1" trade size knockouts from the electrical panel and the ThermElect Hydronic's left side

panel to allow routing of element harnesses. DO NOT remove any unneeded knockouts.

Step 3 Remove 1/2" trade size knockout for routing of control wiring.

Step 4 Secure the electrical panel to the left side of the system with the 8 x 3/4" sheet metal screws supplied

in the electrical panel.

Knockouts must be effectively sealed by connectors.

BRICK LOADING

Step 1 Remove the seam trim from inside the storage module and

set aside.

Step 2 Remove the sheet metal screws around the outer edge of

the galvanized front panel. Remove the panel and set it

aside.

Step 3 Starting at the bottom, carefully lift the insulation blankets

and drape them over the top of the system.

Use and follow generally accepted safety practices

when handling insulation materials.

Step 4 Cut banding and remove the two packages of rigid insulation from inside the storage module. One of

the packages contains the back rigid insulation (no holes) and one package contains the front rigid

insulation (with holes).

CAUTION

Risk of improper operation or equipment damage. Read and follow installation instructions carefully.

• Remove system from shipping pallet prior to !nal placement.

• Ensure that leveling legs make solid contact with "ooring and do not extend more than 1 inch.

• Use and follow generally accepted safety practices when handling insulation materials.

• Equipment MUST be installed by a quali!ed technician in accordance with all applicable codes

and regulations.

WARNING

HEAVY OBJECT WARNING:

Risk of personal injury, or death.

ThermElect Hydronic systems

are heavy. Use lifting aids to

move system into place.

w Do not place object, hands,

and/or body parts under the

system when lifting.

w Do use care to keep objects,

hands, and/or body parts

clear of system when lifting.

Risk of equipment damage or

personal injury. Insulation boards

located behind the insulation blankets

may fall out when blankets are lifted.

Use caution when lifting insulation

blankets to avoid personal injury or

damage to the insulation boards.

CAUTION

INSTALLATION n3.04 THERMELECT HYDRONIC

Step 5 Locate and install the back rigid insulation inside the brick storage module. It will

be placed on top of the existing rigid insulation at the back of the module. The

angled edge will line up with the existing rigid insulation.

Step 6 Load the brick, one row at a time, starting at the back of the brick core and work-

ing forward. Load bricks as shown in Figure 3. Make certain brick debris does

not interfere with brick alignment front to back.

Step 7 Install top air channel block by sliding it up and

back into place on top of the bricks. (See Figure 4.)

For ease of installation, install top block

while loading bricks.

Step 8 Install the front rigid insulation (with holes) in front

of the bricks. Again, the existing angled rigid insula-

tion will line up with the front angled rigid insula-

tion.

The holes in the rigid insulation board

MUST line up with the brick openings so

elements can be installed.

Installation

HEATING ELEMENT INSTALLATION

Proper heating element installation is important to operation

of the system. Reference the "Useful Tools" section of the

Heating Element Service and Repair Guide included with the

heating elements for more information.

Step 1 After all bricks are loaded and rigid insulation boards

are in place, insert the heating elements through the

insulation, sliding them in until the cement side rails

are flush with the front side of the ceramic brick.

Make sure the elements designated as

"outer" elements are installed on the

electrical panel side of the system with

the shortest lead in the left most brick

position.

Step 2 Route the element termination lead with ceramic

insulator to the appropriate side of the system.

Insert the lead into position as shown in Figure 5.

Element leads must never cross each

other.

Step 3 Install element lead insulators. These ceramic insulators MUST maintain lead wire spacings as shown in

Figure 6.

Risk of •re. Can cause personal

injury or death. DO NOT operate

the Comfort Plus Hydronic system

if damage to the insulation panels

on the inner sides of the brick core

occurs.

WARNING

FIGURE 4

HAZARDOUS VOLTAGE: Risk of electric

shock. Can cause injury or death.

w DO NOT remove the electrical panel

cover while system is energized.

w Elements MUST be positioned prop-

erly to avoid short circuiting against

any surfaces within the system.

WARNING

FIGURE 6

BRICK INSTALLATION TIPS:

•Install bricks carefully to avoid damage to the insulation panels.

•Remove loose brick debris to prevent uneven stacking of brick as

this can make installation of the elements and the brick core tem-

perature sensor(s) dif#cult.

•Brick rows MUST line up front to back and top to bottom.

FIGURE 5

BRICK LOADING

FIGURE 3

THERMELECT HYDRONIC INSTALLATION n3.05

Step 4 Lower insulation blankets back into position, one at a time. Carefully tuck the sides of the insulation into

the edges, corners, and around the exposed portions of the heating element to ensure maximum ef•ciency.

Use face mask, gloves, and long sleeved garments when handling insulation materials in ac-

cordance with generally accepted safety practices.

Step 5 Reinstall the galvanized front panel and secure it to the system using the screws originally removed.

Step 6 Route element harnesses through connectors, using one connector/harness until tape is centered.

Step 7 Attach element lead wires to element terminals. Start at the top using the appropriate color chart below.

Repeat pattern as necessary. The neutral white wires are jumpered together in sets of three.

277/347V = Black (Top) 208/240V = Black (Top) 240V = Black (Top)

Systems White 3phase Red 1phase Red

Red Systems Blue Systems Black

White Black Red

Blue Red

White Blue

Step 8 Route the orange wire to the electrical compartment. Cut the wire and crimp ends (found on orange/

black wires in electrical compartment). Connect the orange wires to the orange/black wires.

Step 9 Remove the blower access cover from the base left side. Locate the blue core blower wires and purple

(violet) water temperature sensor wires.

Step 10 Route the wires through the flanged hole at the front left corner of the base. Continue routing up to the

electrical compartment through 1/2" knockout. Connect the blue core blower wires to black and the blue

wires. Connect the two purple (violet) wires to the two purple wires..

Step 1 Remove the screw(s) by the brick core temperature sensor con-

nector holes in the galvanized front panel.

Step 2 Route the brick core sensors through the 1/2" knockout up to

the relay driver board. The yellow wire from each sensor must

be connected to the Y terminal of the proper sensor connection

terminal block, and red to R. Polarity of sensors is critical.

Sensor connections MUST be installed as follows:

• Single Module - 9150 or 9180 (Figure 7)

• Bottom sensor to core C

• Second sensor to core D

• Third (if equipped) to core E

Step 3 Insert the brick core temperature sensors through the holes in

the galvanized front panel. The sensors must pass through the

blanket and board insulation and into the brick core. Use the

sensors to aid in making a passageway by rotating the sensors

while gently pushing inward.

Step 4 Once brick core sensors are installed, re-install sensor mount-

ing screws to secure and ground the sensors.

Risk of improper operation. Proper installation of the brick core temperature sensor is critical to

the operation of the heating system. Read and follow installation instructions carefully.

CAUTION

CORE TEMPERATURE SENSOR

CONNECTIONS

FIGURE 7

Core

Temperature

Sensors

Connect To Core "E"

On 80kW Module Only

Relay

Driver

Board

Connect To

Core "D"

Connect To

Core "C"

Installation

INSTALLATION n3.06 THERMELECT HYDRONIC

BRICK CORE TEMPERATURE SENSOR INSTALLATION

Installation

LINE VOLTAGE ELECTRICAL CONNECTIONS

To determine the correct wire size required for the circuit feeding

the system, refer to the Speci•cations (Page A.01-A.02) and the

system's identi•cation label located on the cover of the electrical

panel (Figure 8).

Step 1 Remove the electrical panel cover if not already removed.

Step 2 277/347 only. Mount the dry type enclosed transformer

below the electrical panel on the system's painted left

side. Use a 1/2" knockout from the bottom left side of the

electrical panel.

Install only the proper size and type fuses in

the factory supplied fuse block.

Step 3 Route all supply circuit •eld installed conductors through

a knockout and into the electrical panel.

Use copper or aluminum conductors rated at

75oC or higher for line voltage !eld connection

of this device.

Step 4 Make line voltage connections to lugs of single feed bus and ground lug. Refer to the Line Voltage Wiring

Diagrams (Pages A.07 - A.08) for more information on these connections.

CONNECTION OF PRIMARY LOOP PUMP

In 277/347 volt installations, a 120 or 240V single phase pump can be used. Connect the pump only to terminals

inside the electrical panel marked for connection of the primary loop pump as shown in Figure 9B.

• A 240V pump is required for 208/240V applications

(Figure 9A) as no neutral terminal is provided.

• Do not use pumps with relay outputs or electronics

• Total rating of all connected pumps cannot exceed

1.2 amps on each pump output.

• Make wiring connections according to manufac-

turer's instructions and appropriate line voltage

wiring diagram.

SAMPLE SYSTEM IDENTIFICATION LABEL

FIGURE 8

w

HAZARDOUS VOLTAGE: Risk of elec-

tric shock, injury or death. Do not

energize the system until installation is

complete. Equipment MUST be installed

by a quali•ed technician in accordance

with all applicable local, state, national

codes and regulations.

w Risk of equipment damage, personal

injury or •re. Do NOT install any wir-

ing in line voltage compartment unless

rated for line voltage. To ensure proper

operation and safety, all wiring in the

line voltage compartment MUST be

rated for line voltage.

WARNING

THERMELECT HYDRONIC INSTALLATION n3.07

FIGURE 9

(277/347V Shown)

}

}

Neutral

Recovery Unit (240V)

Optional Static Heat

Secondary Pump Power

(Variable Speed)

Primary Pump

TRANSFORMERS

240v / 24v

COM

NO COM NO

NONO

1/4 Amp

COM COM

Transformer

120/240 VAC

BASE IO BOARD

EXCHANGER

LIMITS

N.C.

AUTO

DAMPER

RESET

225 °

MANUAL

COM.

WHITE

HIGH

RESET

250°

N.C.

L2 120

L1

L2 240

BLOWER

RESISTER

L1L2

Neutral

Power (240V)

}

Power (240V)

}

}

}

Recovery Unit (240V)

Optional Static Heat

Secondary Pump Power

(Variable Speed)

Primary Pump

Ground

4uf

Cap.

ORANGE

PRIMARY PUMP POWER

(VARIABLE SPEED)

SECONDARY PUMP POWER

OPTIONAL STATIC HEAT

RECOVERY UNIT (240V)

NEUTRAL

(240V)

}

}

}

RESISTER

RED

BLUE

BLACK

5 Amp

Secondary

CORE

BLOWER

Element Relay

Neutral

#11 Right

#11 Right

Element

Element Relay

#12 Left

Ground

Lug

#12 Left

Element

Element Relay

Element Relay

Element Relay

Element

#7 Right

Element

#9 Right

#7 Right

#9 Right

#5 Right

Element Relay

Element Relay

Element Relay

#10 Left

#8 Left

#6 Left

#3 Right

Element Relay

Element

#1 Right

Element

#3 Right

#1 Right

Element Relay

#5 Right

#4 Left

Element Relay

#2 Left

Element Relay

Element

Element

#2 Left

Element

#4 Left

Element

#8 Left

#10 Left

Element

#6 Left

Element

9A - 208/240V 9B - 277/347V

LOW VOLTAGE ELECTRICAL CONNECTIONS - OUTDOOR

TEMPERATURE SENSOR (OPTIONAL)

If using BACNet control, the outdoor temperature sensor may not be used. Follow the in-•

structions included with the BACNet Controller.

If connecting to the Steffes power line carrier (PLC) system, follow the installation instruc-•

tions in the PLC system's Owner's and Installer's Guide.

Outdoor sensor wire MUST NEVER be combined with other control wiring in a multi-con-•

ductor cable.

Theory of Operation: The outdoor sensor monitors outdoor temperature and provides this information to the

system. The system responds by automatically storing heat in its brick core according to

outdoor temperature and the heating requirements.

Location of: The outdoor sensor must be placed in a location where it can accurately sense outdoor temperature

and is not affected by direct sunlight or other abnormal temperature conditions.

Installation Methods: A) Hard wired to Steffes heating system "OS" and "SC" terminals (default)

OR

B) Connected to Power Line Carrier (PLC)

Wiring: • Route low voltage wire from the outdoor sensor to the electrical compartment through one of the

low voltage wire knockouts.

• Connect to "OS" and "SC" as shown in Figure 10.

• If the sensor wiring is routed through an external wall, the opening through which the wire is routed

MUST be sealed. Failure to do so may affect the accuracy of the outdoor temperature sensor.

• The outdoor sensor is supplied with a lead length of 40 ft. If a greater wire length is needed, it can

be extended to a total of 250 ft.

• No other loads can be controlled or supplied through this cable. It is for connection of the outdoor

sensor ONLY.

• This low voltage cable MUST not enter any line voltage enclosure.

• Unshielded Class II (thermostat) wire can be used as extension wire provided it is segregated from

any line voltage cabling.

LOW VOLTAGE ELECTRICAL CONNECTIONS - ROOM

THERMOSTAT (OPTIONAL)

A low voltage (24VAC) room thermostat can be used for room temperature control with the ThermElect Hydron-

ic system. If so, Steffes recommends using a digital thermostat. To iniate a heat call, the system needs a switch

closure from R to H. This energizes the primary loop pump outputs.

12-Position Low Voltage Terminal Block Coding

R = Low Voltage Hot

C = Low Voltage Common

Y = Compressor/Stage 1 Heat Call

W = Stage 2 Heat Call

Y2 = Compressor Output

G = Fan Call

O = Reversing Valve Input

O2 = Reversing Valve Output

H = Hydronic Heat

OS = Outdoor Temperature Sensor

SC = Temperature Sensor Common

DS = Duct Temperature Sensor

Installation

INSTALLATION n3.08 THERMELECT HYDRONIC

LOW VOLTAGE CONNECTIONS

HYDRONIC HEATING SINGLE ZONE SYSTEM

FIGURE 10

Outdoor Sensor

Hydronic Heat Thermostat, Zone

Valve, End Switch, or Pump Control

SC

HOS

W

O2

O

G

Y Y2

C

R

12 Position Terminal Block

DS

Installation

THERMELECT HYDRONIC INSTALLATION n3.09

Step 1 Remove the exchanger access

panel and locate the pressure

relief valve assembly.

Step 2 Connect the pressure relief valve

to the outlet water port on the

left side of the ThermElect Hy-

dronic. It is extremely important

that the following conditions for installation of this part are met:

• Insure all connections, including the valve inlet are clean and free from any foreign material.

• Use pipe compound sparingly, or tape on external threads only.

• Mount the pressure relief valve in a vertical, upright, position directly to the outlet water port of

the system. Under no circumstances should there be a flow restriction or valve of any type be-

tween the safety relief valve and the pressure vessel.

Step 3 Use schedule 40 pipe to install a discharge line for the pressure relief valve.

This discharge line MUST:

• be connected from the valve outlet with no intervening valve and directed downward to a safe

point of discharge.

• allow complete drainage of both the valve and the discharge line.

• be independently supported and

securely anchored to avoid applied

stress on the valve.

• be as short and straight as possible.

• terminate freely to atmosphere

where any discharge is clearly vis-

ible and is at no risk of freezing.

• terminate with a plain end that is

not threaded.

• be constructed of a material suit-

able for exposure to temperatures

of 375oF or greater.

• be, over its entire length, of a pipe

size equal to or greater than that of

the valve outlet.

AIR CONDITIONER/HEAT PUMP INTERFACE

The ThermElect Hydronic system can be used in conjunction with an air conditioner or a heat pump. Contact

Steffes Corporation for more information.

PRESSURE RELIEF VALVE INSTALLATION

Available Pressure

Relief Valves

Minimum

BTU Rating

Maximum

Operating Pressure

Order

Item #

30 PSI

400,000

20 PSI

1100104

75 PSI

500,000

60 PSI

1100105

150 PSI

500,000

125 PSI

1100106

Note: 9100 Series Systems are shipped with 75 PSI pressure relief valves.

If a different valve is required order the item number listed above.

WARNING

Risk of explosion. Can cause injury or death. The factory supplied pressure relief valve MUST be

connected to the system with the supplied !ttings.

wDO NOT modify this assembly.

wDO NOT cap, plug, or otherwise obstruct the outlet of the pressure

relief valve.

wDO mount the pressure relief valve in a vertical, upright position.

wThis pressure relief valve is sized to service the needs of the

ThermElect Hydronic heating system. If multiple heating systems

are being used, pressure relief valving for the other system MUST be

provided separately.

Risk of injury or property damage. During opera-

tion, the pressure relief valve may discharge large

amounts of steam and/or hot water. To reduce the

potential for bodily injury or property damage, install

a discharge line.

wDO use schedule 40 pipe for the discharge line.

wDO NOT use schedule 80, extra strong pipe or

connections on the discharge line.

wDO NOT cap, plug, or otherwise obstruct the

discharge pipe outlet.

wDO follow all local, state, and national codes

and regulations.

CAUTION

Installation

PLUMBING

The ThermElect Hydronic system should be plumbed with a primary loop and secondary (zone) loops. The

primary loop needs to consist of a minimum of 12' of 1.25" pipe. The heat exchanger inlet and outlet are 1.5"

diameter, reducers will be required if 1.25" pipe is elected for the primary loop. The secondary (zone) loops re-

quire additional pump(s) to operate effectively. Refer to Typical Primary Loop and the Typical System Plumbing

Diagrams below for installation information.

The primary loop serves to regulate heat transfer from the system’s heat exchanger. The primary loop pump

should be powered by ThermElect Hydronic control system as shown in Figure 11. If using other control meth-

od, •ow MUST continue for at least 30 seconds at the end of a heat call.

TYPICAL PRIMARY LOOP

FIGURE 11

Air Vent

Air Separator

1

Expansion

Tank

Pressure

Relief Valve

(Factory Supplied)

Optional

Temperature and

Pressure Relief Valve

(Consult Local Code)

Inlet Outlet

*Primary

Loop

Pump

Piping MUST

Be Supported

Zone

Connection

Area

Primary Loop Pump

Control Wiring

INSTALLATION n3.10 THERMELECT HYDRONIC

TYPICAL SYSTEM PLUMBING SINGLE TEMPERATURE ZONES

FIGURE 12

Single Temperature Zone

NOTE: There are many additional ways to connect plumbing and regulate temperature from the primary loop onward.

White

Red

Primary Loop Secondary Loop

Primary

Loop Pump

ThermElect

Hydronic

Exchanger

This Valve Must

Be Open During

Normal Operation

White

Red

Primary Loop Secondary Loop

Other manuals for ThermElect Hydronic 9150

2

This manual suits for next models

1

Table of contents

Other Steffes Heating System manuals

Steffes

Steffes Comfort Plus Commercial 6140 User manual

Steffes

Steffes ThermElect Hydronic 9150 User manual

Steffes

Steffes 212EXT User manual

Steffes

Steffes Comfort Plus Hydronic 5120 User manual

Steffes

Steffes ThermElect 8150 User manual

Steffes

Steffes 3100 Series User manual

Steffes

Steffes 5120 User manual

Popular Heating System manuals by other brands

Pfannenberg

Pfannenberg FLH-T Series operating instructions

Carrier

Carrier 48DT Series installation instructions

elec-trace

elec-trace Cable Heating Floor System installation manual

Tecnosystemi

Tecnosystemi COMPACT 30 user manual

Warmup

Warmup DWS300 installation manual

Viesta

Viesta H Series instruction manual