Avid Technology F Series Quick start guide

AVID Water Systems

12630 US Highway 33 N

Churubusco, IN 46723

Phone (260) 693-1972 Fax (260) 693-0602

F-FM-FE Series Instruction Manual 191205.docx

F, FM, & FE Series

Water Softening System

Installation Instructions and Owner’s Manual

MODEL NUMBERS:

Time Clock Mechanical Metered

FC Series FCM Series

F Series FM Series

High Efficiency High Efficiency

FC-HE Series FCM-HE Series

F-HE Series FM-HE Series

MODEL NUMBERS:

Electronic Metered

FCE Series FE Series

High Efficiency

FCE-HE Series FE-HE Series

1

Pre-installation Instructions

Page 2

Installation

Page 4

Brine Tank

Page 5

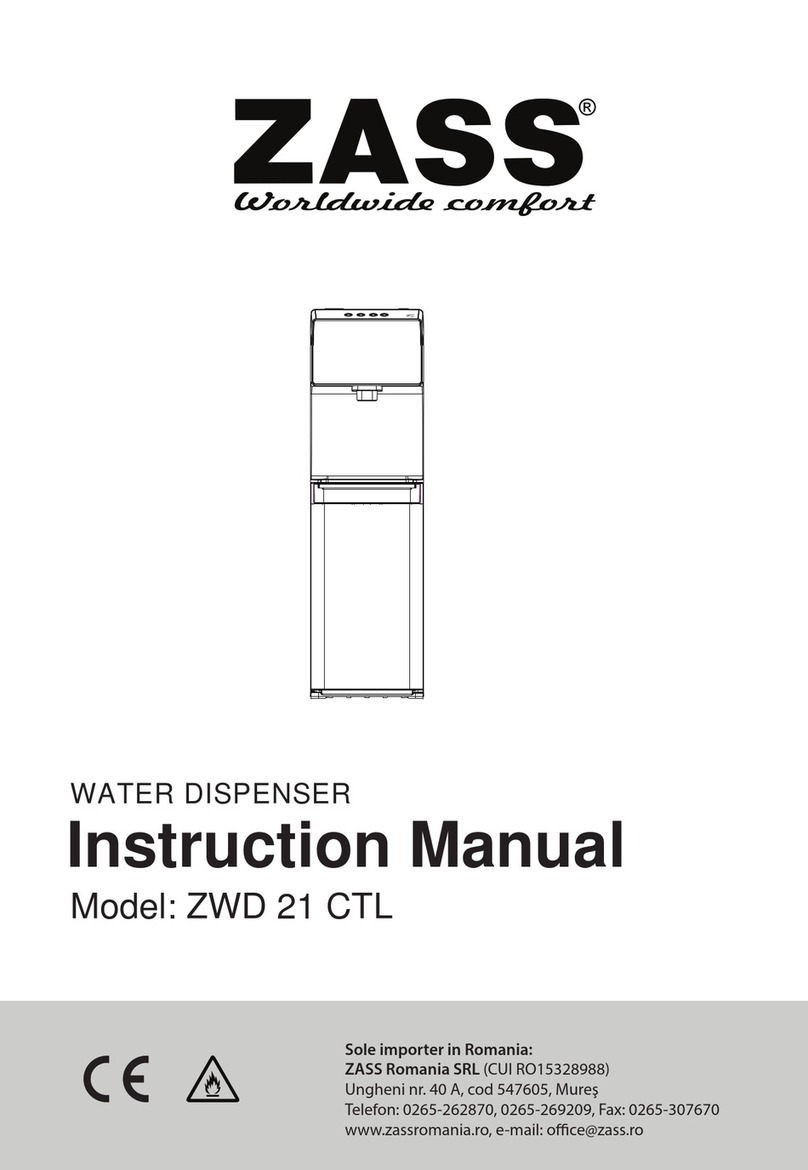

Bypass Valve

Page 5

F Time Clock Timer Setting

Page 7

FM Meter Setting

Page 10

F & FM Adjust Time of Regeneration

Page 11

FCE & FE Series Programming

Page 12

Unit Model Specifications

Page 15

Component Parts Breakdown & List

Page 17

F Control Valve Breakdown

Page 19

F Control Valve Parts List

Page 20

FM Control Valve Breakdown

Page 21

FM Control Valve Parts List

Page 22

FE Control Valve Breakdown

Page 23

FE Control Valve Parts List

Page 24

Troubleshooting

Page 25

Ten Year Limited Warranty

Page 27

Table of Contents

2

Description of the water softener system

This water softener system includes a brine (salt) tank and a resin (media) tank with a backwashing control

valve. Incoming water flows into the control valve and is directed down through the ion exchange softening

resin. This resin exchanges the hardness ions for softer ions. The softened water then returns to the control

valve where it is directed into the service lines.

Periodically the control valve will go through a regeneration cycle. The frequency of this regeneration process

will depend on the size of water softener, incoming water quality and amount of water used. This cycle is

factory preset to begin at 2:00 A.M. At this time the control valve will draw the brine solution out of the salt tank

and flush both the accumulated hardness and excess salt to the drain. The control valve will then put fresh

water back into the salt tank to make brine for the next regeneration cycle.

Water Quality

The water should be tested to determine the concentration, or levels of the items listed below:

Hardness - Hardness in drinking water is defined as those minerals that dissolve in water having a

positive electrical charge (cat ions). The primary components of hardness are calcium (Ca++) and

magnesium (Mg++) ions. But dissolved iron (Fe++) and manganese (Mn++) also contribute to total

“adjusted” hardness.Hardness produces scale, soap scum and white mineral deposits which shorten

the life of water using appliances, plumbing and fixtures. Water that has less than 1 grain of hardness is

considered to be “soft” water.

pH - A measurement of the acidity of the water. pH is reported on a scale from 0 to 14. Neutral water has a pH

of 7.0, lower values indicate acidic water. If your pH is below 6.8 you may consider installing an acid neutralizer

before the water softener to elevate the pH.

Iron - A naturally occurring metallic element. Iron levels in excess of 0.3 milligrams/liter (mg/l) combine with

oxygen causing orange or red (rust) stains on plumbing fixtures. Iron exists in some water sources in clear

water (ferrous) state, red water (ferric) state or bacterial form. Iron levels that exceed 2.0 mg/l require special

ion exchange resin for reduction, or if bacterial or ferric (red water) iron is present or iron level exceeds 4.0 mg/l,

an iron filter should be installed ahead of this water softener.

Manganese - A naturally occurring metallic element. Manganese levels as low as 0.05 milligrams/liter (mg/l)

can combine with oxygen to cause dark brown or black staining on fixtures. Additionally, manganese can cause

an odor in the water similar to a “rotten egg” smell. This water softener may reduce manganese as well as iron;

however, an iron filter may be required in some cases.

Tannin - A naturally occurring humic acid. Tannin is caused by water passing through decaying vegetation.

Coffee and Tea are prime examples of tannin in water. Tannin levels as low as 0.5 milligrams per liter can

cause a yellow discoloration in water. Consult your dealer for a system designed to remove both tannin and

hardness.

Hydrogen Sulfide - A naturally occurring gas. Hydrogen sulfide, more commonly referred to as sulfur gas,

causes a distinct odor similar to “rotten eggs.” Due to its gaseous nature, hydrogen sulfide must be tested at the

well site within 1 minute of drawing the sample. If sulfur is present additional equipment will be required. The

O3 iron filter can typically treat up to 2 milligrams per liter of sulfur gas.

Pre-installation Instructions

3

Location Considerations

The proper location to install the water softener system will ensure optimum performance and satisfactory water

quality. The following factors should be considered in selecting the location of the equipment.

1. The water softener should be installed after the pressure tank on a private well system or after the

water meter on municipal water. Operating pressure of the softener must be limited to within 30 –

100 psi range.

2. The water softener should be installed as close as possible (preferably within 15’) to an adequate

floor or laundry drain capable of handling the backwash cycle volume and flow rate (refer to unit

specifications).

3. All water conditioning equipment should be installed prior to the water heater. Water temperatures

exceeding 100°F can damage the internal components of the control valve and filter tank. Install

with at least 10’ of pipe before the water heater to prevent thermal damage to the equipment. An

expansion tank may need to be installed in the line to the water heater in order to allow for thermal

expansion and comply with local plumbing codes.

4. The water softener should not be subject to freezing temperatures.

5. Ensure that any cartridge or in-line type filter installed prior to the water softener does not restrict

the water flow and pressure available for backwash and interfere with normal operation.

6. Appliances requiring extended periods of continuous or high flow water use (i.e. geothermal heat

pumps, swimming pools, lawn irrigation, outside hose bibs, etc.) should bypass the water softener.

(see installation diagram Fig. 1).

Water Heater

Inlet from

water

supply

Softened

Cold Water

Iron Free Water

Softened

Hot Water

Untreated Water

Water Softener

Iron Filter

w/ Coupling

Check

Valve

Installed

(if required)

Pressure Tank

(well system only)

10’ Minimum Distance

Grounding Straps

Pre-installation Instructions (cont.)

FIGURE 1: Typical Installation

Expansion Tank

4

STEP 1: Carefully remove all components from packaging. DO NOT DISCARD PACKAGING until all

water softener components and fittings have been located.

STEP 2: Use clips and screws provided and attach bypass valve to the inlet/outlet of the control valve.

See figure 2 below.

IMPORTANT: Mechanical metered (FM) units require the installer to insert the meter cable into the top

of the meter module.

STEP 3: Place unit at desired installation position. DO NOT plug into electrical outlet at this time

(see STEP 10 on page 6). DO NOT put salt into brine tank at this time (see STEP 16 on

page 6).

STEP 4: Shut off water at main supply. Relieve pressure by opening nearest faucet. On private well

systems, turn off power to pump and drain pressure tank. SHUT OFF POWER OR FUEL

SUPPLY TO WATER HEATER.

STEP 5: Cut main supply line as required to fit plumbing to inlet and outlet of bypass valve. DO NOT

PLUMB INLET AND OUTLET BACKWARDS. Piping should be supported. Do not apply

heat to any fitting attached to the bypass or control valve.

STEP 6: Use polyethylene drain line tubing provided (NO VINYL TUBING) to run drain line from control

valve discharge fitting to floor drain or sump pit capable of handling the backwash rate of the

softener (refer to specifications and flow rate on page 15). DISCHARGE END OF THE

DRAIN LINE MUST BE FIRMLY SECURED! There must be an air gap at the end of the

drain line to prevent siphoning of waste water and meet plumbing code. Total length of drain

line should be 15’ or less. AVOID OVERHEAD DRAINS.

Installation Instructions

OUTLET

SOFT WATER

INLET

HARD WATER

ADAPTER CLIPS

& SCREWS

ADAPTER CLIPS

& SCREWS

BYPASS

METER MODULE

METER CABLE

INJECTOR

ASSEMBLY

BRINE VALVE

DRAIN CONNECTOR

VALVE COVER

FIGURE 2: Top View of FM Series Mechanical

Metered Control Valve with Bypass

5

STEP 7: Connect one end of the provided 3/8” brine line to the control valve quick connect fitting. Insert

the other end of the brine line through the hole in the brine tank and into the quick connect

fitting on the safety brine valve. Remove the quick connect collet retainer clip (if included)

before inserting the brine line into each fitting, press the tube in very firmly and replace the

retainer clip behind the collet. NOTE: THE BRINE TUBING SHOULD BE INSERTED 5/8”

INTO THE FITTING. DO NOT PUT SALT INTO THE BRINE TANK AT THIS TIME.

STEP 8: Install overflow tubing from overflow elbow on brine tank to floor drain. Tubing must be lower

than overflow elbow at all times. DO NOT CONNECT DRAIN LINE FROM SOFTENER

CONTROL VALVE TO BRINE TANK OVERFLOW. DO NOT CONECT BRINE TANK

DRAIN LINE TO THE SOFTENER DRAIN LINE.

STEP 9: Place bypass valve in the “Bypass” position (refer to Figures 4 below). Open main supply

valve or turn on power to pump on private well systems.

Installation Instructions (cont.)

FIGURE 3: Brine Tank Components

FIGURE 4: Stainless Steel Bypass Valve Operation

6

STEP 10: For all models except FE Series, plug the softener into an unswitched electrical outlet and

slowly rotate the Manual Regeneration Knob (see Fig. 5, page 7 or Fig. 6, page 10) clockwise

until two clicks are heard. This is the “BACKWASH” position.

For the FE Series, plug the transformer into an un-switched electrical outlet and attach the

power cord into the control valve. Then press and hold down the center “ADVANCE” button

until “GO TO BW” appears on the screen (see Fig. 8, page 12). Wait until the valve reaches

the backwash position before going to STEP 11 (a countdown timer will appear on the

display).

STEP 11: Unplug the softener from the electrical outlet to keep it in the backwash position.

Refer to Figure 4 (page 5) for appropriate bypass valve operation. Rotate bypass lever of

stainless steel bypass ¼ of the way to “Service” allowing unit to fill slowly. You should hear

water trickling into the mineral tank. Filling the mineral tank in this position will force any

trapped air to the drain. When all air has been purged from the system and only water is

running to the drain, slowly open the bypass valve fully to the service position.

STEP 12: Add enough water to the brine tank to a level approximately 1” above the top level of the

salt grid.

STEP 13: Plug the softener back into the electrical outlet.

For all models except FE Series, slowly rotate the Manual Regeneration Knob

clockwise until two clicks are heard. This is the “BRINE DRAW” position. Verify that the

water level in the brine tank is dropping. Allow water level to drop below the top level of

the salt grid before continuing. If the water level does not drop, refer to page 25 for

Troubleshooting. Otherwise, advance the control valve to the “FAST RINSE” position by

continuing to rotate the knob clockwise until seven more clicks are heard. Allow the

softener to complete the remainder of the regeneration cycles automatically which

includes “BRINE REFILL” to put water into the brine tank.

For the FE Series, press the center “ADVANCE” button briefly and the control valve will go to

the “BRINE DRAW” position (“GO TO DR” will display). Once the cycle countdown begins,

verify that the water level in the brine tank is dropping. Allow water level to drop below the salt

grid before continuing. If the water level does not drop, refer to page 26 of Troubleshooting.

Otherwise, advance the control valve to the “BRINE REFILL” cycle by continuing to press the

“ADVANCE” button briefly each time a cycle countdown begins until the “GO TO BR” is

displayed. Allow the softener to complete the “BRINE REFILL” cycle automatically to put

water into the brine tank.

STEP 14: Check for leaks and correctas necessary.

STEP 15: Turn on power or fuel supply back on to water heater.

STEP 16: Set the current time of day on the timer (note AM and PM) (refer to Fig. 5, Fig. 6 or Fig. 8,

depending on the model number).

STEP 17: Set the regeneration frequency (refer to Fig. 5, Fig. 6, or Fig. 8 depending on the model

number).

STEP 18: Fill the brine tank with salt.

Installation Instructions (cont.)

7

How to set Time of Day:

1. Press and hold the red button to disengage the 24 hour gear.

2. Turn the large 24 hour gear until the actual time of day is at the time of day arrow.

3. Release the red button to again engage the 24 hour gear.

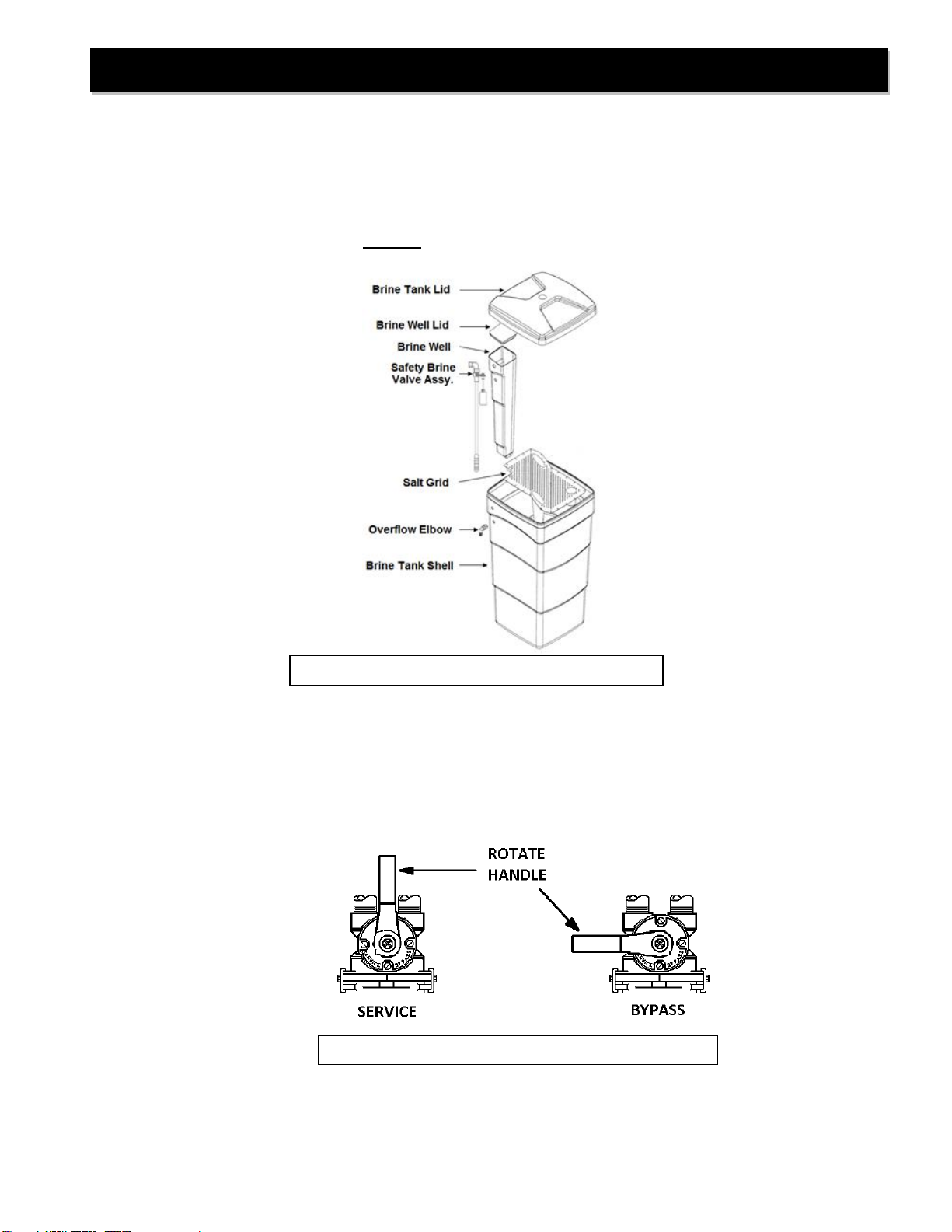

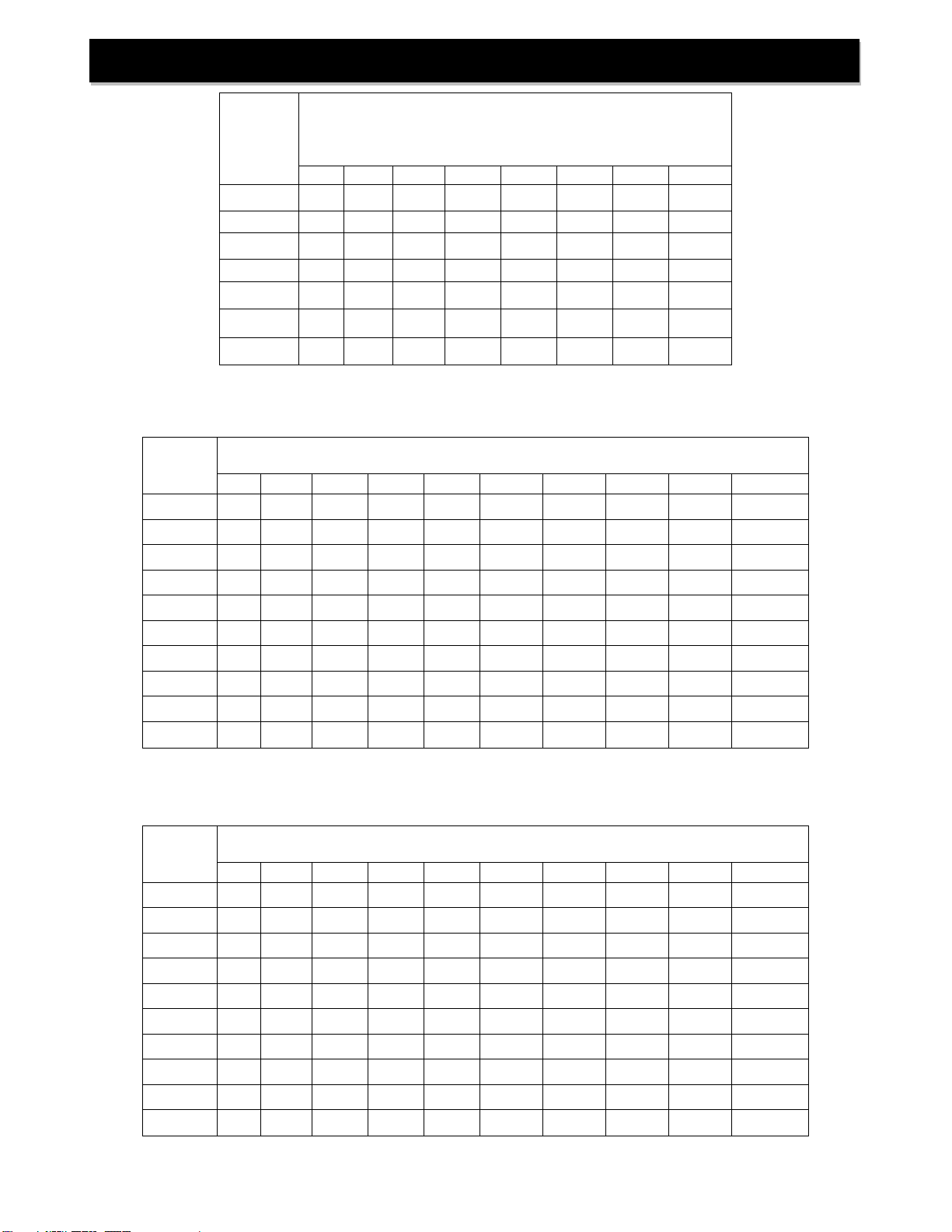

How to set the Days of Regeneration:

Calculate the Adjusted Hardness by multiplying the iron concentration (ppm) by 3, the manganese

concentration (ppm) by 5 and adding to the water hardness test results (grains).

Example: Hardness = 25gpg (grains per gallon)

Iron = 1.0 ppm (parts per million)

Manganese = 0.2 ppm (parts per million)

Adjusted Hardness = 29 gpg [25 + (3 x 1.0) + (5 x 0.2)]

25 + 3 + 1 = 29

1. Refer tothe appropriate table for your water softener model number (pages 8and 9) to determine

how many TIMES in a 12 day cycle the softener should regenerate. If the adjusted hardness falls

between two numbers on the chart always use the higher number (never round down).

Example: Water Softener Model FS30

3 people in family

Adjusted hardness 29 gpg

Result: Set softener to regenerate 4 TIMES in 12-day cycle (once every 3 days)

2. Rotate the skipper wheel until the number 1 is at the red pointer. Each number represents a day.

The number by the red pointer is tonight.

3. Slide the metal tabs outward on the desired days of regeneration.

How to Manually Initiate a Regeneration Cycle:

1. Grab the manual regeneration knob and turn clockwise SLIGHTLY. The drive gear will engage the

backwash knob which will make a complete revolution and return to the “Service” position after the

regeneration cycle.

Timer Operation

FS Series Time Clock Setting Instructions

FIGURE 5: Front of Time Clock Timer Assembly

8

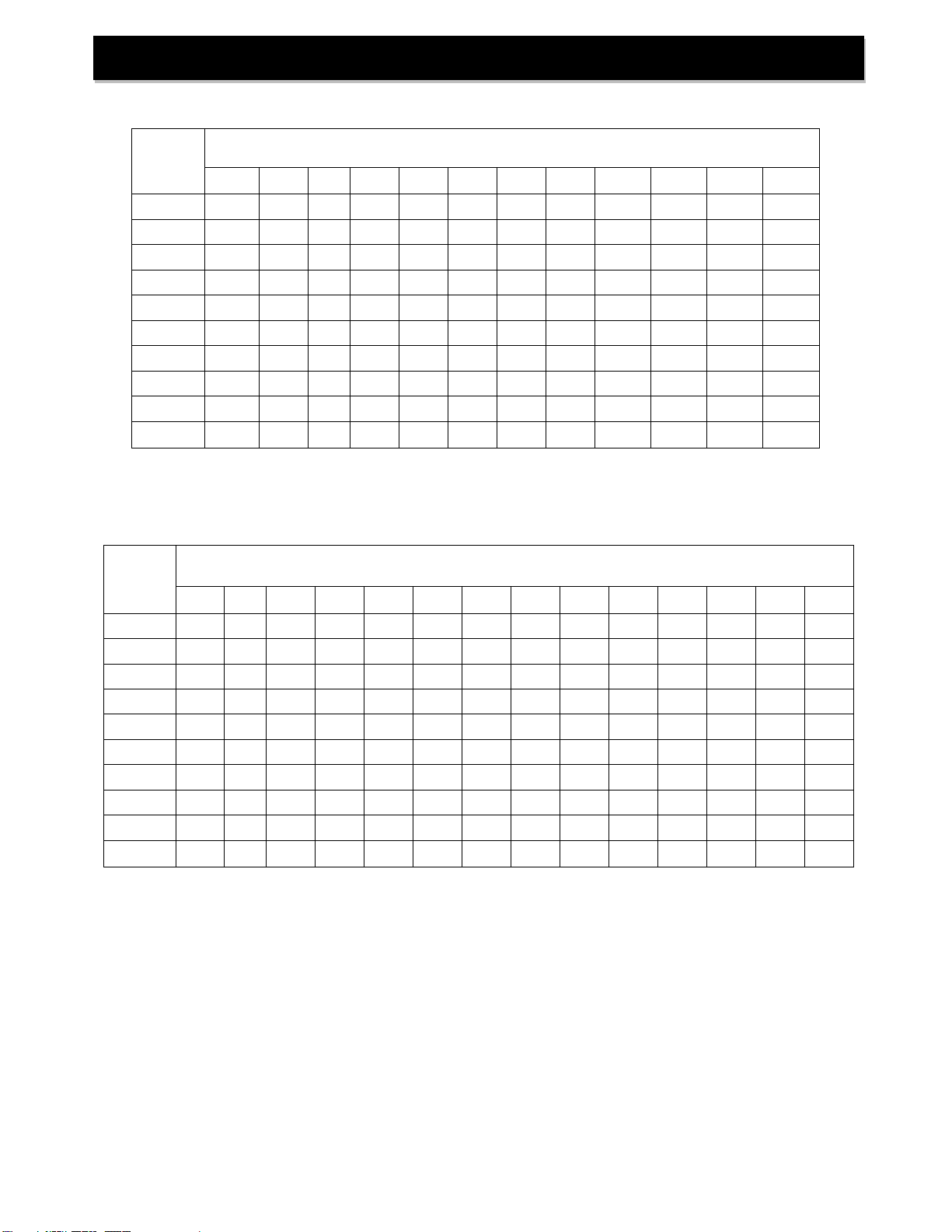

People

Adjusted Hardness -- Grains per Gallon

5

10

15

20

25

30

35

40

1

1

1

1

1

2

2

2

2

2

1

1

2

2

3

3

4

4

3

1

2

3

3

4

6

6

6

4

1

2

3

4

6

6

5

2

3

4

6

6

2

3

6

6

7

2

4

6

People

Adjusted Hardness -- Grains per Gallon

5

10

15

20

25

30

35

40

45

50

1

1

1

1

1

1

2

2

2

2

2

2

1

1

2

2

2

3

3

3

4

4

3

1

2

2

3

3

4

4

6

6

6

4

1

2

3

3

4

6

6

6

5

1

2

3

4

6

6

6

2

3

4

6

6

7

2

3

4

6

8

2

3

6

6

9

2

4

6

10

2

4

6

People

Adjusted Hardness -- Grains per Gallon

5

10

15

20

25

30

35

40

45

50

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

2

2

2

2

3

3

3

1

1

2

2

2

3

3

3

4

4

4

1

1

2

2

3

3

4

4

6

6

5

1

2

2

3

4

4

6

6

6

6

1

2

3

3

4

6

6

6

7

1

2

3

4

6

6

8

1

2

3

4

6

6

9

2

3

4

6

6

10

2

3

4

6

TABLE 1: Model Number F0844, FC0835

TABLE 2: Model Number F0948, FC1035, FI0948

TABLE 3: Model Number F1054, FI1054

F Series Time Clock Setting Instructions (cont.)

9

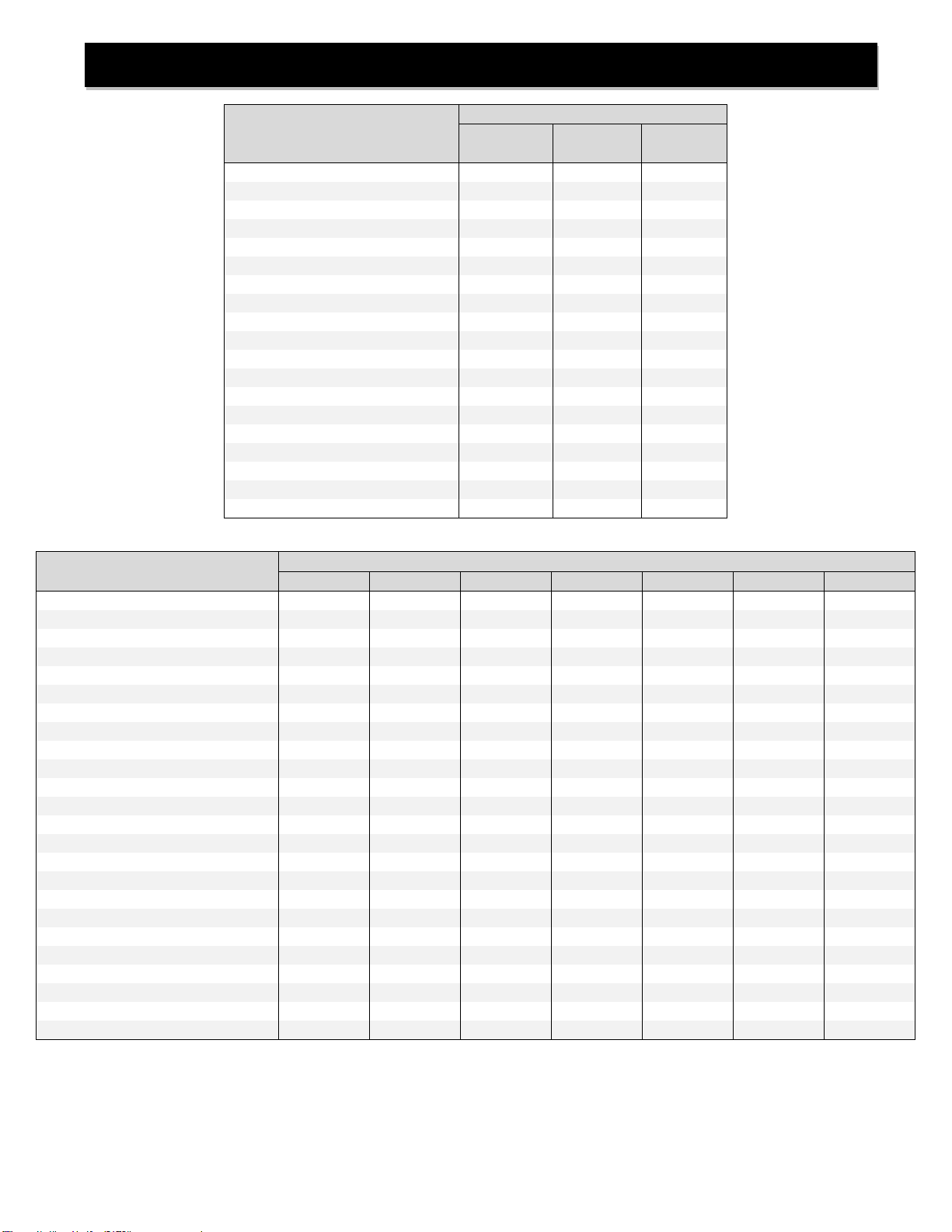

People

Adjusted Hardness -- Grains per Gallon

5

10

15

20

25

30

35

40

45

50

55

60

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

1

2

2

2

2

2

3

3

3

1

1

1

2

2

2

2

3

3

3

4

4

4

1

1

2

2

2

3

3

3

4

4

6

6

5

1

1

2

2

3

3

4

4

6

6

6

6

6

1

2

2

3

3

4

4

6

6

6

7

1

2

2

3

4

4

6

6

6

8

1

2

3

3

4

6

6

6

9

1

2

3

4

6

6

6

10

1

2

3

4

6

6

People

Adjusted Hardness -- Grains per Gallon

5

10

15

20

25

30

35

40

45

50

55

60

65

70

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

2

2

2

2

2

2

2

3

3

1

1

1

1

2

2

2

2

3

3

3

3

3

4

4

1

1

1

2

2

2

3

3

3

3

4

4

4

6

5

1

1

2

2

2

3

3

3

4

4

6

6

6

6

6

1

1

2

2

3

3

4

4

6

6

6

6

6

7

1

2

2

3

3

4

4

6

6

6

6

8

1

2

2

3

3

4

6

6

6

6

9

1

2

3

3

4

6

6

6

10

1

2

3

3

4

6

6

6

TABLE 4: Model Number F1248, FI1248

TABLE 5: Model Number F1354

F Series Time Clock Setting Instructions (cont.)

10

How to set Time of Day:

1. Press and hold the red button to disengage the 24 hour gear.

2. Turn the large 24 hour gear until the actual time of day is at the time of day arrow.

3. Release the red button to again engage the 24 hour gear.

How to set the Frequency of Regeneration:

1. Calculate the Adjusted Hardness by multiplying the iron concentration (ppm) by 3 and adding to

the water hardness test results.

Example: Hardness = 25gpg (grains per gallon)

Iron = 1.0 ppm (part per million)

Manganese = 0.2 ppm (parts per million)

Adjusted Hardness = 29 gpg [25 + (3 x 1.0) + (5 X 0.2)]

25 + 3 +1 = 29

2. Lift the “People Dial” on the gallon setting wheel.

3. Rotate the “People Dial” until the number of people in the household is aligned with the adjusted

water hardness.

4. Release the “People Dial” and ensure that it reengages the gallon wheel.

How to Manually Initiate a Regeneration Cycle:

1. Grab the manual regeneration knob and turn clockwise SLIGHTLY.

The drive gear will engage the backwash knob which will make a complete revolution and return to

the “Service” position after the regeneration cycle.

FM Series Meter Setting Instructions

FIGURE 6: Front of Meter Timer Assembly

11

How to Adjust Regeneration Time:

1. Disconnect the power source.

2. Locate the three screws behind the manual regeneration knob by pushing the red button in and

rotating the 24 hour dial until each screw appears in the cut out portion of the manual regeneration

knob.

3. Loosen each screw slightly to release the pressure on the time plate from the 24 hour gear.

4. Locate the regeneration time pointer on the inside of the 24 hour dial in the cut out.

5. Turn the time plate so the desired regeneration time aligns next to the raised arrow.

6. Push the red button in and rotate the 24 hour dial. Tighten each of the three screws.

7. Push the red button and locate the pointer one more time to ensure the desired regeneration time

is correct.

8. Reset the time of day and restore power to the unit.

F & FM Series Adjustable Regeneration Time Instructions

FIGURE 7: Front of Timer Assembly (Time Clock Assembly Shown)

12

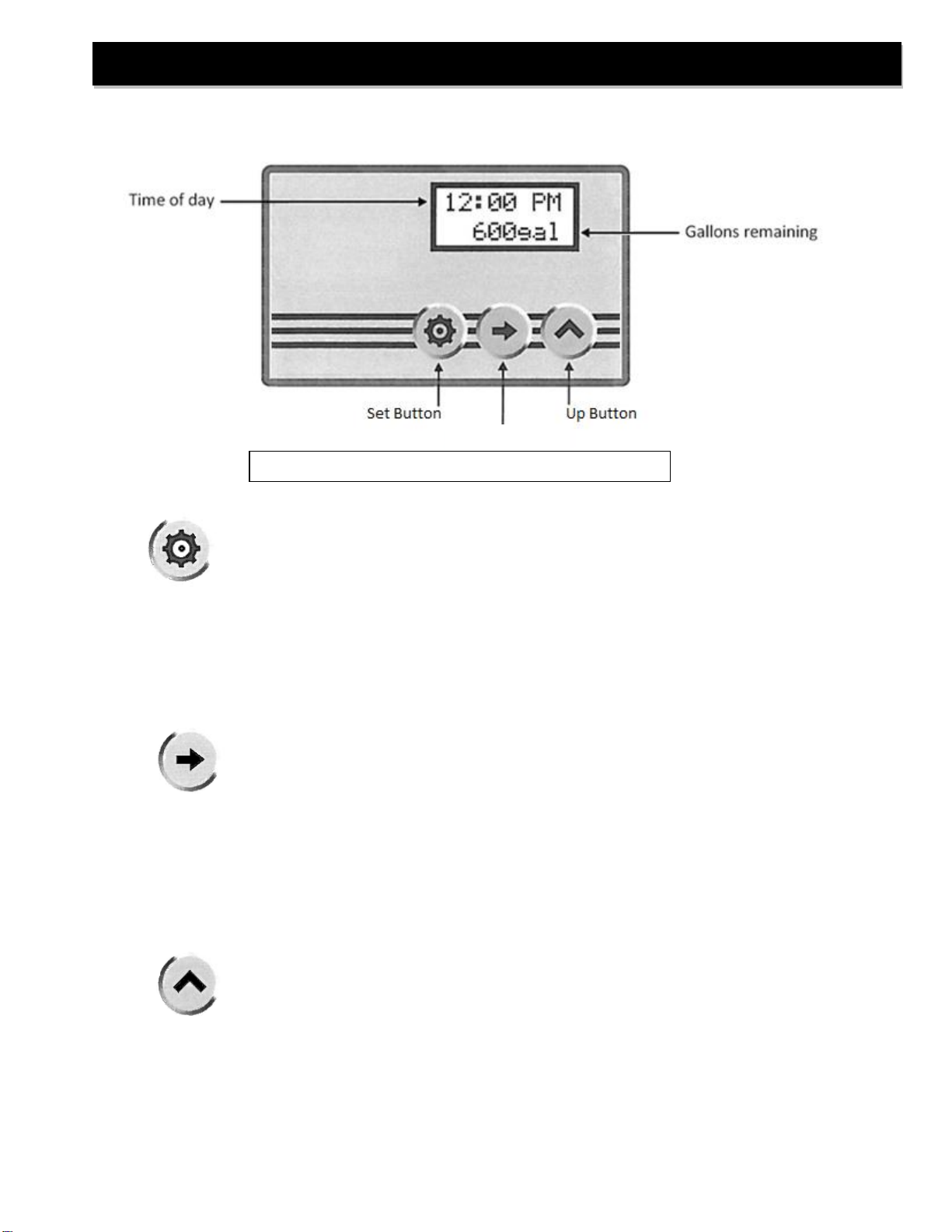

SET BUTTON

1. Press and hold “Set Button”for 5 seconds to enter Programming Mode.

2. When valve is in Programming Mode, press “Set Button”to confirm setting and advance to next

menu option.

ADVANCE BUTTON

1. Press and hold “Advance Button”for 5 seconds to initiate an immediate regeneration cycle.

2. Press and release “Advance Button”during a regeneration cycle to immediately advance the valve

to the next step in the regeneration process.

3. When the valve is in ProgrammingMode, press the“Advance Button”to move the cursor.

UP BUTTON

1. When the valve is in the Programming Mode, press “Up Button”to adjust setting.

FCE & FE Series Programming

Advance Button

FIGURE 8: Front of Electronic Meter Timer Assembly

13

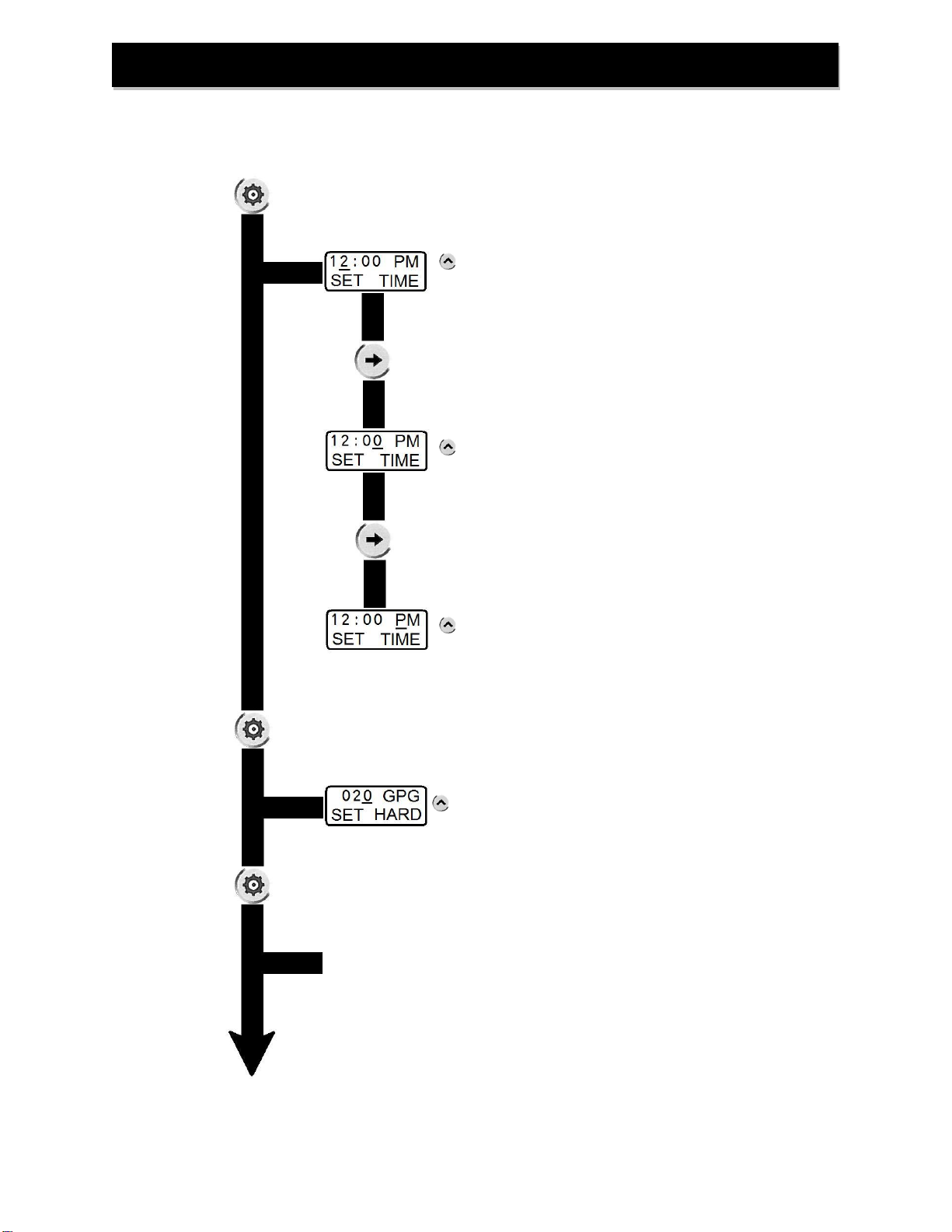

Enter Programming Mode:

Press and Hold the SET Button for 5 seconds.

FEC & FE Series Programming

Use Up Button to set current hour

Use Up Button to set current minute

Use Up Button to set AM/PM

Use Up Button to set ADJUSTED Hardness

Exit Programming Mode

14

This page intentionally left blank.

15

DESCRIPTION

UNIT MODEL NUMBER

FC0835

FC1035

F0844

F0948

F1054

F1248

F1354

FCM0835

FCM1035

FM0844

FM0948

FM1054

FM1248

FM1354

MEDIA VOLUME, ft3

0.75

1.0

0.75

1.0

1.5

2.0

2.5

CAPACITY, grains

@Factory Salt - 9lb/ft3

18,000

24,000

18,000

24,000

36,000

48,000

60,000

@Max. Salt - 15lb/ft3

22,500

30,000

22,500

30,000

45,000

60,000

75,000

SERVICE FLOW RATES, gpm

Continuous (3 gpm/ ft3)

2

3

2

3

5

6

8

Service (8 gpm/ ft3)

6

8

6

8

12

13

14

Peak*

16

16

13

14

14

16

16

BACKWASH & RAPID RINSE, gpm

2.4

3.0

1.5

2.4

3.0

4.0

4.0

INJECTOR

#1 - white

#1 - white

#1 - white

#1 - white

#1 - white

#2 - blue

#2 - blue

SERVICE PIPE LINES, inches

¾”

¾”

¾”

¾”

¾”

¾”

¾”

For 1” replace “-S” w/ “-1S” in model #

TOTAL WATER USED, gallons

43

48

36

43

56

93

95

DIMENSIONS in.

Mineral Tank (diameter x height)

10 x 35

10 x 35

8 x 44

9 x 48

10 x 54

12 x 48

13 x 54

Brine Tank (diameter x height)

12 x 34

12 x 34

14 x 34

14 x 34

14 x 34

18 x 33

18 x 33

Overall (depth x width x height)

12 x 23 x 44

12 x 23 x 44

14 x 23 x 53

14 x 24 x 57

14 x 25 x 63

18 x 27 x 57

18 x 32 x 63

APPROX. SHIP WEIGHT lbs.

86

104

86

107

140

165

216

DESCRIPTION

UNIT MODEL NUMBER

FC0835-HE

FC1035-HE

F0844-HE

F0948-HE

F1054-HE

F1248-HE

F1354-HE

FCM0835-HE

FCM1035-HE

FM0844-HE

FM0948-HE

FM1054-HE

FM1248-HE

FM1354-HE

MEDIA VOLUME, ft3

0.75

1.0

0.75

1.0

1.5

2.0

2.5

CAPACITY, grains

@Factory Salt - 6lb/ft3

20,250

27,000

20,250

27,000

40,500

54,000

67,500

@Max. Salt - 15lb/ft3

27,000

36,000

27,000

36,000

54,000

72,000

90,000

SERVICE FLOW RATES, gpm

Continuous (3 gpm/ ft3)

2

3

2

3

5

6

8

Service (8 gpm/ ft3)

6

8

6

8

12

15

15

Peak*

18

18

16

17

17

18

18

BACKWASH & RAPID RINSE, gpm

2.4

3

1.5

2.4

3.0

4.0

4.0

INJECTOR

#1 - white

#1 - white

#1 - white

#1 - white

#1 - white

#2 - blue

#2 - blue

SERVICE PIPE SIZE, inches

¾”

¾”

¾”

¾”

¾”

¾”

¾”

For 1” replace “-S” w/”-1S” in model #

TOTAL WATER USED, gallons

42

47

35

42

55

91

92

DIMENSIONS in.

Mineral Tank (diameter x height)

10 x 35

10 x 35

8 x 44

9 x 48

10 x 54

12 x 48

13 x 54

Brine Tank (diameter x height)

12 x 34

12 x 34

14 x 34

14 x 34

14 x 34

18 x 33

18 x 33

Overall (depth x width x height)

12 x 23 x 44

12 x 23 x 44

14 x 23 x 53

14 x 24 x 57

14 x 25 x 63

18 x 27 x 57

18 x 32 x 63

APPROX. SHIP WEIGHT lbs.

86

104

86

107

140

165

216

GENERAL REQUIREMENTS:

Water Temperature

33°F - 100°F

Water Pressure

30 - 100 psi

Electrical Requirements

110v/60hz

Electrical Current Draw

0.5 amps

NOTES:

*The control valve can handle flow rates greater than peak flow rates shown above.

Specifications

16

DESCRIPTION

UNIT MODEL NUMBER

FI0948

FI1054

FI1248

FIM0948

FIM1054

FIM1248

MEDIA VOLUME, ft3

1

1.5

2

CAPACITY, grains

@Factory Salt - 9lb/ft3

24,000

36,000

48,000

@Max. Salt - 15lb/ft3

30,000

45,000

60,000

SERVICE FLOW RATES, gpm

Continuous (2 gpm/ ft3)

2

3

4

Service (5 gpm/ ft3)

5

8

10

Peak*

14

14

16

BACKWASH & RAPID RINSE, gpm

1.5

2.4

3.5

INJECTOR

#1 - white

#1 - white

#2 - blue

SERVICE PIPE SIZE, inches

¾”

¾”

¾”

For 1” replace “-S” w/”-1S” in model #

TOTAL WATER USED, gallons

36

51

88

DIMENSIONS in.

Mineral Tank (diameter x height)

9 x 48

10 x 54

12 x 48

Brine Tank (diameter x height)

14 x 34

14 x 34

18 x 33

Overall (depth x width x height)

14 x 24 x 57

14 x 25 x 63

18 x 27 x 57

APPROX. SHIP WEIGHT lbs.

107

140

165

DESCRIPTION

UNIT MODEL NUMBER

FEC0835

FEC1035

FE0844

FE0948

FE1054

FE1248

FE1354

MEDIA VOLUME, ft3

0.75

1.0

0.75

1.0

1.5

2.0

2.5

CAPACITY, grains

@Factory Salt - 9lb/ft3

18,000

24,000

18,000

24,000

36,000

48,000

60,000

@Max. Salt - 15lb/ft3

22,500

30,000

22,500

30,000

45,000

60,000

75,000

SERVICE FLOW RATES, gpm

Continuous (3 gpm/ ft3)

2

3

2

3

5

6

8

Service (8 gpm/ ft3)

6

8

6

8

12

13

14

Peak*

16

16

13

14

14

16

16

BACKWASH & RAPID RINSE, gpm

2.4

3.0

1.5

2.4

3.0

4.0

4.0

INJECTOR

#1 - white

#1 - white

#1 - white

#1 - white

#1 - white

#2 - blue

#2 - blue

SERVICE PIPE LINES, inches (cm)

¾”

¾”

¾”

¾”

¾”

¾”

¾”

For 1” replace “-S” w/ “-1S” in model #

FACTORY REGENERATION SETTINGS

Default size setting

SMALL

SMALL

SMALL

SMALL

MEDIUM

LARGE

LARGE

Backwash (minutes)

6

6

6

6

6

8

8

Brine draw (minutes)

55

55

55

55

60

60

60

Fast Rinse (minutes)

4

4

4

4

6

6

6

Brine Refill (minutes)

3

3

3

3

4

6

6

TOTAL WATER USED, gallons

43

48

36

43

56

93

95

DIMENSIONS in.

Mineral Tank (diameter x height)

10 x 35

10 x 35

8 x 44

9 x 48

10 x 54

12 x 48

13 x 54

Brine Tank (diameter x height)

12 x 34

12 x 34

14 x 34

14 x 34

14 x 34

18 x 33

18 x 33

Overall (depth x width x height)

12 x 23 x 44

12 x 23 x 44

14 x 23 x 53

14 x 24 x 57

14 x 25 x 63

18 x 27 x 57

18 x 32 x 63

APPROX. SHIP WEIGHT lbs.

86

104

86

107

140

165

216

GENERAL REQUIREMENTS:

Water Temperature

33°F - 100°F

Water Pressure

30 - 100 psi

Electrical Requirements

110v/60hz

Electrical Current Draw

0.5 amps

NOTES:

*The control valve can handle flow rates greater than peak flow rates shown above.

Specifications (cont.)

17

Notes:

1.

Refer to pages 19 - 24 for complete control valve breakdown.

2.

-1S suffix for 1” FPT stainless steel bypass (60041SS)

Ref

Description

Model Number

FC08352

FCM08352

FEC08352

FC10352

FCM10352

FEC10352

F08442

FM08442

FE08442

F09482

FM09482

FE09482

F10542

FM10542

FE10542

F12482

FM12482

FE12482

F13542

FM13542

FE13542

A

Timeclock Valve

w/ 3/4”SS bypass

FC08352Vlv

Assy W/BP

FC10352Vlv

Assy W/BP

F08442Vlv

Assy W/BP

F09482Vlv

Assy W/BP

F10542Vlv

Assy W/BP

F12482VlvAssy

W/BP

F13542VlvAssy

W/BP

Metered Valve w/

3/4” SS bypass

FCM08352Vlv

Assy W/BP

FCM10352Vlv

Assy W/BP

FM08442Vlv

Assy W/BP

FM09482Vlv

Assy W/BP

FM10542Vlv

Assy W/BP

FM12482Vlv Assy

W/BP

FM13542Vlv

Assy W/BP

Elect. Meter Vlv

w/3/4” SS bypass

FCE08352Vlv

Assy W/BP

FCE10352Vlv

Assy W/BP

FE08442Vlv

Assy W/BP

FE09482Vlv

Assy W/BP

FE10542Vlv

Assy W/BP

FE12482Vlv Assy

W/BP

FE13542Vlv Assy

W/BP

B

Mineral Tank

MTP1035GR

MTP1035GR

MTP0844GR

MTP0948GR

MTP1054GR

MTP1248GR

MTP1354GR

C

Distributor

D100S-48

D100S-48

D100S-48

D100S-48

D100S-54

D100S-48

D100S-54

D

Resin

(1.5) H05P

(2) H05P

(1.5) H05P

(2) H05P

(3) H05P

(4) H05P

(5) H05P

E

1/4” X 1/8” Gravel

(1) QC20

(1) QC20

(1) QC20

(1) QC20

(1) QC20

(1) QC20

(1.5) QC20

F

Brine Tank Assy.

BT1234ASSY-FS

BT1234ASSY-FS

BT1434ASSY-FS

BT1434ASSY-FS

BT1434ASSY-FS

BTSQ1833ASSY-FS

BTSQ1833ASSY-FS

G

Overflow Fitting

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

H

Safety Brine

Valve

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

I

Salt Platform

BTSG12

BTSG12

BTSG14

BTSG14

BTSG14

BTSG18SQ

BTSG18SQ

J

Bypass2

Stainless Steel

60040SS2

60040SS2

60040SS2

60040SS2

60040SS2

60040SS2

60040SS2

Component Parts Breakdown

18

Ref

Description

Model Number

FC0835-HE2

FCM0835-HE2

FC1035-HE2

FCM1035-HE2

F0844-HE2

FM0844-HE2

F0948-HE2

FM0948-HE2

F1054-HE2

FM1054-HE2

F1248-HE2

FM1248-HE2

F1354-HE2

FM1354-HE2

A

Timeclock Valve

w/ 3/4” SS bypass

FC0835-HE2Vlv

Assy W/BP

FC1035-HE2

Vlv Assy W/BP

F0844-HE2Vlv

Assy W/BP

F0948-HE2Vlv

Assy W/BP

F1054-HE2Vlv

Assy W/BP

F1248-HE2Vlv

Assy W/BP

F1354-HE2Vlv

Assy W/BP

Metered Valve w/

3/4” SS bypass

FCM0835-HE2

Vlv Assy W/BP

FCM1035-HE2

Vlv Assy W/BP

FM0844-HE2

Vlv Assy W/BP

FM0948-HE2

Vlv Assy W/BP

FM1054-HE2

Vlv Assy W/BP

FM1248-HE2Vlv

Assy W/BP

FM1354-HE2Vlv

Assy W/BP

B

Mineral Tank

MTP1035GR

MTP1035GR

MTP0844GR

MTP0948GR

MTP1054GR

MTP1248GR

MTP1354GR

C

Distributor

D100S-48

D100S-48

D100S-48

D100S-48

D100S-54

D100S-48

D100S-54

D

Resin

(1.5) UHE05P

(2) UHE05P

(1.5) UHE05P

(2) UHE05P

(3) UHE05P

(4) UHE05P

(5) UHE05P

E

1/4” X 1/8” Gravel

(1) QC20

(1) QC20

(1) QC20

(1) QC20

(1) QC20

(1) QC20

(1.5) QC20

F

Brine Tank Assy.

BT1234ASSY-FS

BT1234ASSY-FS

BT1433ASSY-FS

BT1433ASSY-FS

BT1433ASSY-FS

BTSQ1833ASSY-FS

BTSQ1833ASSY-FS

G

Overflow Fitting

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

H

Safety Brine Valve

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

SBV33ASSY

I

Salt Platform

BTSG12

BTSG12

BTSG14

BTSG14

BTSG14

BTSG18SQ

BTSG18SQ

J

Bypass2

(stainless steel)

60040SS2

60040SS2

60040SS2

60040SS2

60040SS2

60040SS2

60040SS2

Ref

Description

Model Number

FI09482

FIM09482

FI10542

FIM10542

FI12482

FIM12482

A

Timeclock Valve

w/ 3/4” SS bypass

FI09482Vlv Assy

W/BP

FI1054Vlv

Assy W/BP

FI12482Vlv Assy

W/BP

Metered Valve w/

3/4” SS bypass

FIM09482Vlv

Assy W/BP

FIM10542Vlv

Assy W/BP

FIM12482Vlv Assy

W/BP

B

Mineral Tank

MTP0948GR

MTP1054GR

MTP1248GR

C

Distributor

D100S-48

D100S-54

D100S-48

D

Resin

(2) FH05P

(3) FH05P

(4) FH05P

E

1/4” X 1/8” Gravel

(1) QC20

(1) QC20

(1) QC20

F

Brine Tank Assy.

BT1434ASSY-FS

BT1434ASSY-FS

BTSQ1833ASSY-FS

G

Overflow Fitting

BT-OVERFLO

BT-OVERFLO

BT-OVERFLO

H

Safety Brine Valve

SBV33ASSY

SBV33ASSY

SBV33ASSY

I

Salt Platform

BTSG14

BTSG14

BTSG18SQ

J

Bypass2

(stainless steel)

60040SS2

60040SS2

60040SS2

Notes:

1.

Refer to pages 19 - 24 for complete control valve breakdown.

2.

-1s suffix for 1” FPT stainless steel bypass (60041SS)

Component Parts Breakdown (cont.)

19

F (Time Clock) Control Valve Breakdown

This manual suits for next models

43

Table of contents

Popular Water Dispenser manuals by other brands

Omnifilter

Omnifilter U25 Series E installation instructions

Elkay

Elkay ERPB8C 3C Series Installation, care & use manual

Culligan

Culligan Mark 100 Installation and operating instructions

Brita

Brita Platinum Performance Series installation manual

Halsey Taylor

Halsey Taylor WM8 Series owner's manual

Fountain Softeners

Fountain Softeners INO20 Service manual