Example 2:

Set a 2-stage cooking programme in Memory space 2.

Stage 1: 5 minutes 30 seconds cooking time using 100%

Power.

Stage 2: 3 minutes 10 seconds cooking time using 10%

power.

Active theprogramming function.

Press the Programme pad (B), in the present instance:"2".

Stage 1

Press "Manual/Repeat" pad (C).

Press pads "5", "3","0".

Stage 2

Press "Manual/Repeat" pad (C).

Press pads "3", "1","0".

Press Power Selection pad (F).

Press pad "1" for 10% power.

Press Memory pad (G).

Cancel the programming function.

In order to use the remaining 8 programming spaces, you

repeat the process for the One-stage and Two-stage

programme as described under the above two examples.

Used programme pads can simply be overwritten if required.

5.4 To use the programme function once the microwave has been

programmed follow the instructions below.

Open the door.

Put the food which is to be cooked in the microwave oven

and close the door.

By pressing the desired Programme pad (B) the cooking

process will immediately start up.

An acoustic signal will be given at the end of the cooking

process. The signal continues until the door is opened.

Remove the food from the microwave oven.

In order to allow the oven to cool off, the fan will continue

running for another minute. Do not disconnect the

Microwave oven from the mains during this time.

Interrupting the cooking process

Pressing the Stop pad (D) will interrupt the cooking process.

The remaining cooking time will be shown on the digital

display.

Close the door and press the Start pad (E) to continue the

cooking process.

Cancelling the cooking process

The cooking process will be automatically cancelled by

opening the door. The remaining cooking time is not shown

on the digital display. If you wish to continue select a NEW

PROGRAMME.

9

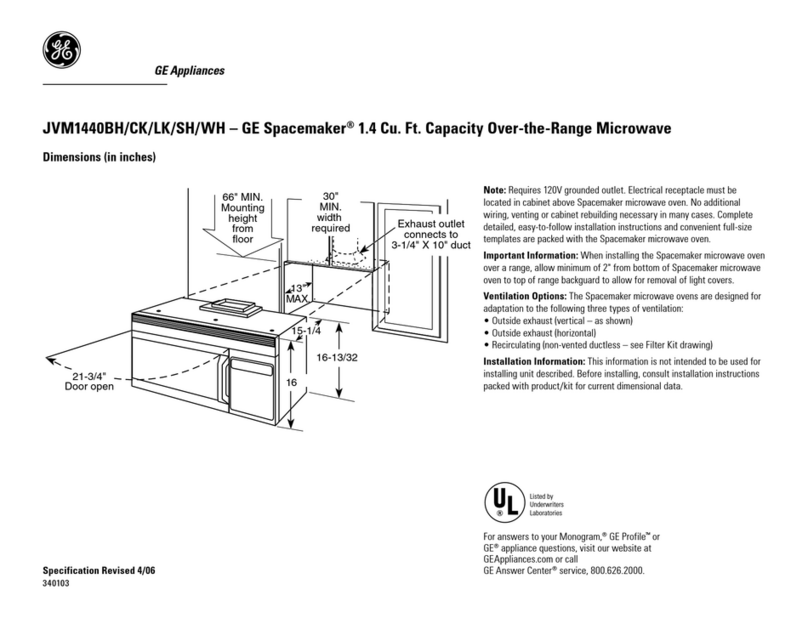

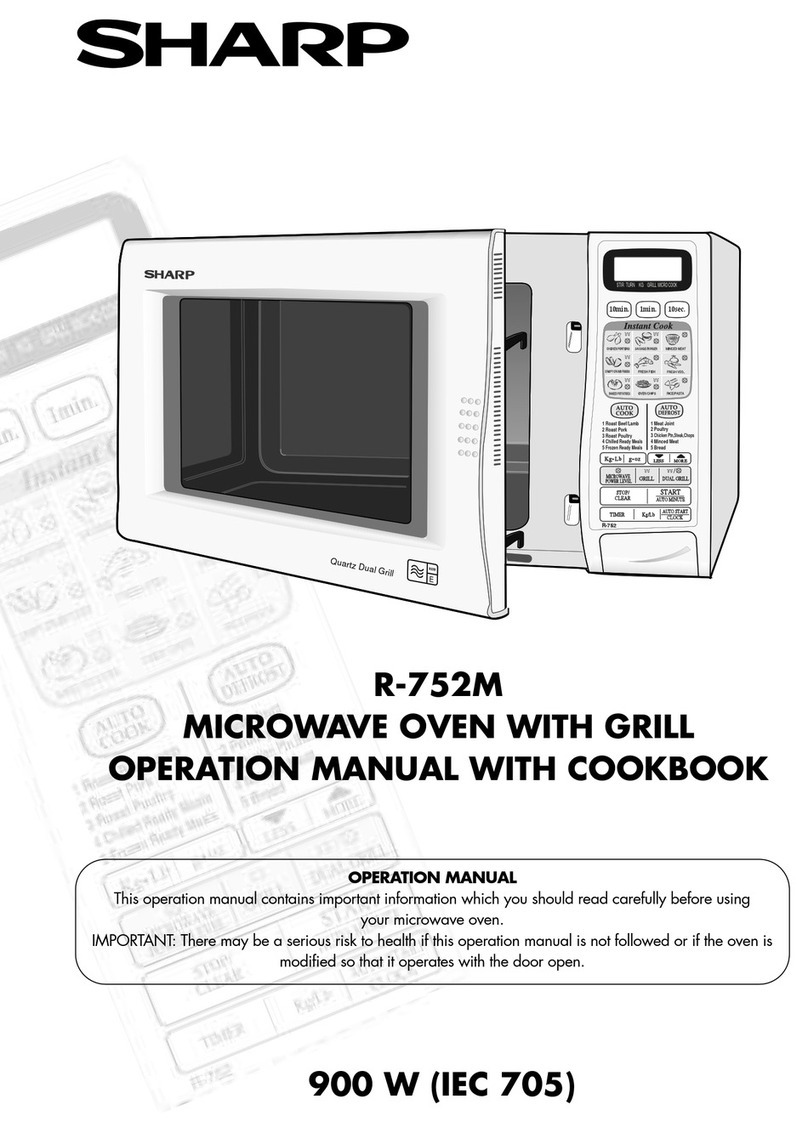

MEMORY CHECK AUTO MANUAL POWER

COOK X2 X32211

A

B

C

D

E

F

GHI