PREFACE

o ln rrrrlor lrrIrrvrrlc ()rrr customerswith quality, reliability and vcr:iirlrlrly.llrl'. Iro(ltt(;t has

l,r,r'rr nr,rrlo ll',lttr lptorlttt;tron standards.This manual includes all llrr:trlr l',',,ttV

l[1,,|il,rll,'r,rlrilrrl lrr,,l,rll;rliorr,debugging, disCharging andmainteni]rrr:r: l'lr,r:;c rcildthis

Ir,il[r,rl , ,rrr:lrrlly lrillorilyorr r)l)cn ormAintain the unit.The manUfaCturcol llrir; protlttctwill

lll l,r, lrr,l,lrl,,l,r.r',llrll ll ,,orrrrnrr:i inirlred orthe unit isdamaged, as aresttlt oI

Iilrl.r,,l,"r lh,,l,rll,rll,,rr ,l',1'il1ltllil(l,or ilnnilcossilrymaintenance.ltisVitalthatthe

lil,lrr, ll,,I,, *,tllrlrr llrl,: rririlrtrl ,rtil,rrllrrrtilrllo;rl ;rlllimeS. TheUnit mUSt beinStalled by

rlrr,rltltr',1 lrrt r,'rrrtll

rr I lrr rilrll , iilr,,Il! I'il rrr1,,rl[,rll,y ,l[,rllllr,,l l[',l,rllIr r ilttltr, ;tttr;tttltttllrlT:ln aUthoriSed

(l Nrrlrrlr,rrrrli 1, 1111r1 rrl,rrr,rllrrllll,,l lrrr r,rtrllrlrrrtl 'r, rltrlltrl; l,,llrl rrrr ltltrrtt(llrlllttttr:ttttl

lrlrllril, y,r,,,l,rllrl lttlltl,, trt,tltt,tl

rr 11,,,, 11r'tiltltr', t,l,ilrlrrl,l,i|l.rlt, Irlrl,, rrrly

I ,rtlrrrri lrr r rrlrlrlywlllr llrr",,' t,', lttrrtr,ltrl,tllott'.wlll lttv,tllrl,llu lltrr w,ttt,ttlly

{) ',wlllilil][1] I'onl llrrrrll'ilrrrI lltrll ltrr,rl:.llril,,wlnIilin(l lo0lw,tlilr ailr(l l(!r:p:;lll(! ltttttlltlt;tltlttl

r rrrr',l,rrrl I or :,plillylro lnrl, llru rrrrloor lrral(:inr lrc I)i:;r;rr:tclylrl<ltlctt ttr s(]trti-lti(ldellto

r,urI ir luxurylrousc.

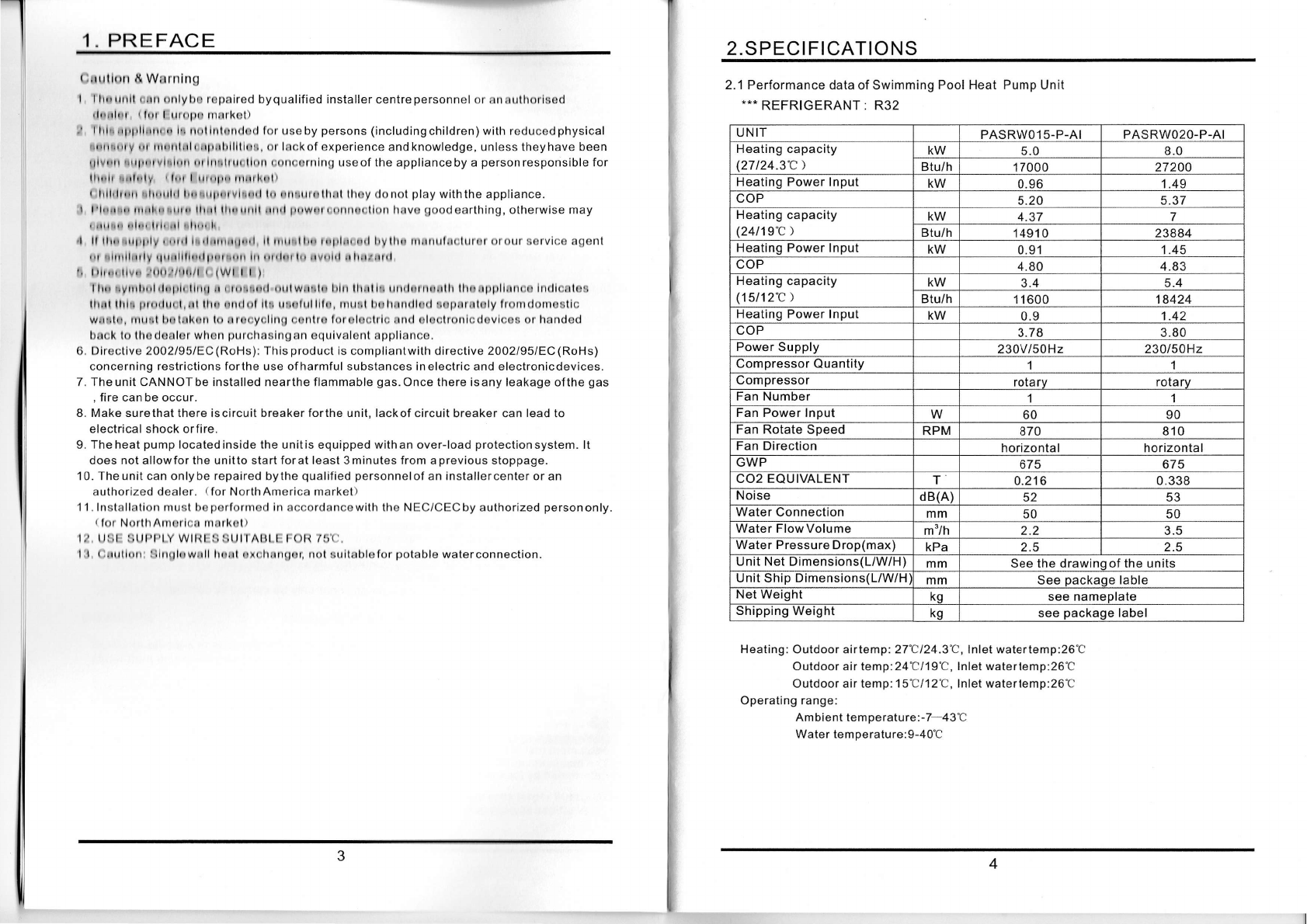

Our heat pumphas following characteristics:

1 Durable

The heatexchanger is madeof PVC &Titanium tubewhich can withstandprolonged

exposure to swimming pool water.

2 lnstallation flexibility

The unit can be inslalled outdoors.

3 Qttiet o[)cr;rlion

l lro rrrril r;orrrpr ir;c:; i ttr cllir:tcrrl rol:rr y/ :;r;r ollr:r)nrl)t ossor and a low-noise fan motor,

wlrtr lr r;rt.rt,rtlrrrr:, rl',rlrlrl olrot;tlton

,l /\r lv,rt rr lr I r r rr rl t llltr rr I

Ilril rilrll1il, 1ilr1,,.. [ilr ril ( rrrrl,illIr r.orrlrolltnrl,irllowirrg all operationparameterS tO be

.r',1 tll',,r,rll',r ,,l,rlr',r ,rrlrl rll:,II.rycrlotr lltr: I (llJwire controller.Remote controller canbe

r ltrr',rrtt .r,, ltlltltoolrll(llt

(J wAl{r'{lNr ;

l,o nol u:;orno;rr:; lo arcceleratethe defrosting processor to clean,

( )llr(!r llriur llloserecimmended by themanufacturer.

T'lrc irg>pliance shallbe stored ina room withoutcontinuously

operating ignition sources (for example:open flames, an

Operating gas applianceor an operatingelectric heater.)

Do not pierceor burn.

Be aware thatrefrigerants may notcontain an odour,

Appliance shall beinstalled,operated and storedin a ro()nrwrllr.r ll,,r .rto.r l.rtr;ct llt;ttt30m'.

NOTE Themanufacturer may provideothersuitable r-.x;rrngrlr",,,r rrr,ry lrrrrvrlo;rrltlitional

information about the refrigerant odour.

1. PREFACE

This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instructionconcerning use ofthe

appliance in a safe way and understand the hazards involved. Children shall not play with

the appliance. Cleaning and user maintenance shall not be made by children without

s u pe rvi si on.

lf the supplycord is damaged,it must bereplaced by themanufacturer, itsservice agent or

simi larly qualified persons in order to avoid a hazat d.

The appliance shallbe installed inaccordance with nationalwiring regulations.

Do not operateyour air conditionerin a wetroom such asa bathroom orlaundry room.

Before obtaining accessto terminals, allsupply circuits mustbe disconnected.

An all-pole disconnection device which has at least 3mm clearances in all poles , and

have a leakagecurrent that mayexceed 10mA, the residual current device(RCD) having

a rated residual operating current not exceeding 30mA, and disconnection must be

incorporated in thefixed wiring inaccordance with thewiring rules.

Do not use means to accelerate the defrosting process or to clean, other than those

recommended by the manufacturer

The appliance shallbe stored ina room withoutcontinuously operating ignitionsources (for

example: open flames, an operating gas appliance or an operating electric heater.)

Do not pierceor burn

Appliance shall beinstalled, operated andstored in aroom with afloor area largerthan 30

m2

Be aware thatrefrigerants may notcontain an odour.

The installation of pipe-work shall be kept to a minimum 30 m2

Spaces where refrigerantpipes shall becompliance with nationalgas regulations.

Servicing shall be performed only as recommended by the manufacturer.

The appliance shallbe stored ina well-ventilated areawhere the roomsize corresponds to

the room areaas specified foroperation.

All working procedure that affets safety means shall only be carried by competent persons.

Transport of equipment containing flammable refrigerants

Compliance with thetransport regulations

Marking of equipmentusing signs

Compliance with local regulations

Disposal of equipment using flammable refrigerants

Compliance with national regulations

Storage of equipment/appliances

The storage of equipment should bein accordance withthe manufacturer's instructions.

Storage of packed (unsold) equipment

Storage package protection should be constructed such that mechanical damage to the

equipment inside thepackage will notcause a leakofthe refrigerantcharge.

The maximum numberof pieces of equipment permitted to be stored togetherwill be

determined by local regulations.

e3

(,,

*

&

s

€,

2