B-G Instruments DataPlot CB1224 User manual

Page 1of4

ONE CONTROL BOARD: MANY PRINTERS

This control board accepts input data from a data interface,

such as parallel, serial RS232, etc. and provides the logic and

drive functions needed to operate B-G Instruments' DataPlot

print mechanism model numbers PM1224, PM1320, or

PM1416.The corresponding control board part numbers are:

CB1224, CB1320, or CB1416. Although it is possible to

convert one model control board to another by replacing the

program chip, that procedure should only be performed

by B-G Instruments or under its

direction. This document pertains to

all 3 control board models.

CHARACTER FONTS.

DataPlot printer models 1224, 1320,

and 1416 are able to print either

across the width of the paper

(x-direction) or down its length

(y-direction) in 5 different fonts, 4

different sizes of each font and 2

degrees of boldness. Two of these

fonts include both-upper and lower

case, subscripts and superscripts.

Font selections can be made by

software command or through an

attached keypad. Refer to another

data sheet entitled "Standard

DataPlot Character Fonts" for

examples and a complete discussion.

PRINT/PLOT COMMANDS

Printing in the x-direction is done much as on most printers;

send the desired characters followed by a CR ($O D). DataPlot

printers are also able to print in the y-direction and plot high

resolution curves, bar charts, etc., addressing individual dots

and groups of dots as necessary. For a complete description of

these functions and the commands used to invoke them, refer to

anotherdata sheet entitled "Standard DataPlot Commands".

GENERAL DESCRIPTION

This control board is based on an 80C31 microprocessor with

a complement of other CMOS chips. It provides for both

parallel and serial digital input, a battery-backed

clock/calendar, and interfaces for a keypad and a paper

take-up reel. For analog inputs and other special applications,

a daughter board can be attached with full access to the

microprocessor data bus.

MATING CONNECTORS

The stepper motor (J1) and printhead (J3 or J4) mating

cables are supplied by B-G instruments. Other mating

connectors are:

For J7: T&B Ansley 609-2000M or equivalent.

For J8: T&B Ansley 609-1400M or equivalent

For J9: T&B Ansley 609-2000M or equivalent

For J10: Molex 22-01-3077 housing, 08-50-0114 terminals

For JP1 & JP4, Aries ML100S or equivalent

DataPlot Control Board

Models CB1224, CB1320 and CB1416

Technical Data and Instructions

Release B, March 15, 2000

Page 2of4

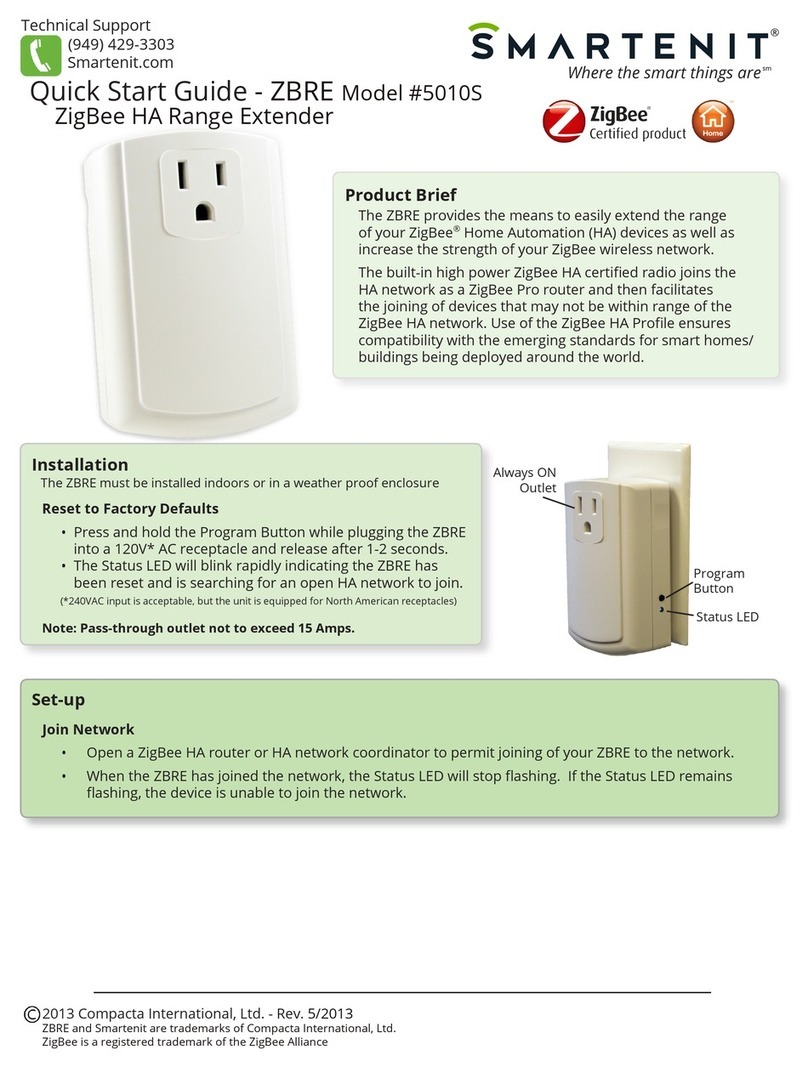

CONNECTING TO PRINT MECHANISM

As shown in the Interface diagram, this control board

connects to the print mechanism it drives through 2 cables.

The 8-pin plug attached to the stepper motor connects to J1.

The supplied 26-pin printhead cable connects to J3 or J4.

Use J3 to connect to PM1224 or PM1416 printhead.

Use J4 to connect to PM1320 printhead.

PAPER ADVANCE

The PAPER ADVANCE signal is a line available at pin 20 of

J7 and pin 1 of J9. It is pulled-up onthe logic board. To

advance paper, ground this line or drive it low through a TTL

driver. Paper can also be advanced or reversed a specified

number of steps by software command. See the "Standard

DataPlot Commands" data sheet for a full description.

PARALLEL INTERFACE-J7

The parallel data input is on connector J7 and includes 8 data

lines (bits 0 through 7), a STROBE* line to the printer and a

BUSY output line from the printer. The data lines are positive

true TTL logic. The STROBE* line is normally high. When a

STROBE* pulse is put on this line, its trailing (rising) edge

causes the data to be read and BUSY to be set high. (See the

timing diagram.) After BUSY returns low, the print can

accept more data. The polarity of the

BUSY signal can be inverted to

BUSY* by changing a jumper on JP4,

as shown at the left. Pin assignments

are:

Pin

Signal

1BUSY

3STROBE*

5bit 0

7bit 1

9bit 2

11 bit 3

13 bit 4

15 bit 5

17 bit 6

19 bit 7

PAPER

-

OUT SIGNALS

If the connected print mechanism is equipped with a paperout

sensor, the TTL signal out appears on pin 6 of J7. A high level

indicates paper-out; a low level indicates paper OK. In

addition, when the paper state changes from OK to out, the

printer sends a DC4 character ($14) via the serial interface.

When the paper state changes from out to OK, the printer

sends a DC2 character ($12).

In the standard DataPlot program, the paper state condition

is also used to inhibit attempts to print when paper is out and

to facilitate an autoload function when paperis inserted into

a powered-up empty printer.

INPUT DATA BUFFER

All characters received by the printer are placed in a FIFO

buffer which can hold 5120 characters. The BUSY condition is

signaled when the FIFO reaches 5088 characters. The READY

condition is again signaled when the F'IF'O drops to 5056 or

fewer characters. Additional buffers in the DataPlot program

are used to store characters for x printing, for y-printing and

for graphic grid storage. These are discussed fully in the data

sheets entitled "Standard DataPlot Commands".

HEX DUMP DIAGNOSTIC MODE

The HEX dump mode is established by holding down the "9"

key on the keypad ( or otherwise connecting pins 9 and 10 of

J9 together) while turning on the printer power. This mode will

remain selected Until power is turned off. While in HEX dump

mode, the printer will not respond normally to the data sent to

it, but will instead print

all received characters, in

hexadecimal, 16 bytes

per line. This feature is

often valuable for

troubleshooting an

instrumentsystem by

verifying the characters

actually received by the

printer.

POWER

-

ON DIAGNOSTICS

The printer automatically runs self-diagnostic tests when

power is turned on. If any errors are detected, the processor

will not complete its power-on initialization. In this condition,

the printer will not function, not even the paper advance

function. If, therefore, the paper advance function works, you

can assume that the power-on tests were completed normally,

without error.

Pin

Signal

2Ground

4Ground

6Paper Out

8Ground

10 Ground

12 Ground

14 Ground

16 Notused

18 Notused

20 Paper Advance

Page 3of 4

SERIAL INTERFACE

-

J8

J8 is a 14-pin connector that provides full duplex serial data I/O

to and from the printer. The format is RS232C with 1 start bit,

8 data bits, no parity and 1 stop bit. The baud rate as normally

shipped by B-G Instruments is set to 1200. This may be

changed to 2400, 4800 or

9600 by removing one or

both of 2 jumpers

installed on JP1, as shown

in the diagram at the right.

These jumpers aresensed

and the respective-baud

rate is established at

power-on, so that

changing jumper positions

after power on will not

change the baud rate.

Two serial protocols are available for sending data to the

printer; DATA BUSY and XON/XOFF. If the DATA BUSY

protocol is used, the host computer should monitor the state of

the RTS line before sending each byte. A high condition at the

connector indicates READY, while a low condition indicates

BUSY. When the printer changes from the READY state to

the BUSY state, it transmits the XOFF character ($13) via the

serial output. When it changes from BUSY to READY, it

transmits the XON character ($11). This enables the host to

implement the XON/XOFF protocol, eliminating the need to

monitor the RTS line. At power-on, the printer sends an XON

character to the host. After that, XOFF and XON characters

will be sent alternately, as required by the BUSY/READY

condition of the printer.

The standard printer program does not implement any

protocol for use of the XON, XOFF, DC2 andDC4 characters

in transmission from printer to host, ie., the printer assumes

the host is always ready to receive the characters. In custom

applications, the printer can be programmed to use this

protocol or to monitor the DSR line to determine the

readiness of the host to receive data.

The following lists the serial interface pin assignments on J8.

This pin out is such as to match the standard 25-pin RS232C

"D" connector when connected via ribbon cable:

J8

“D”

Signal

Pin

Pin Name Meaning & Direction

32TDX transmitted data from printer

5

3RXD received data to printer

7

4RTS ready to send from printer

14

20 RTS “ “

11

6DSR data set ready to printer

13 7Signal gnd common return

KEYPAD

INTERFACE

-

J9

Connector J9 includes 8 sense lines and 8 drive lines which

may be used for various switching, sensing and output

functions in a custom application program. In the standard

DataPlot program, 4 of the sense lines and 3 of the drive lines

are used to interface a 3x4 matrix keypad, which may be used

to set and read an optional clock/calendar in "application”

mode and for various test and font selection purposes in "test"

mode. These functions are described further under

"CLOCK/CALENDAR" and "SELF TEST PRINTOUTS" in

this data sheet and in the "Standard DataPlot Character Fonts"

data sheet, respectively.

The diagram at the left shows the jumper positions on JP1

that establish "TEST" and "APPLICATION" modes for the

keypad.

The diagram below and to the left shows the portion of the J9

interface that is used for a keypad and paper advance switch in

the standard DataPlot program. J9 also has 4 additional sense

lines and 5 additional drive

lines that are not used by

the standard program but

are available for use by a

special application program

that may need the additional

input and/or output lines. If

your printer has such a

custom application, refer to

its special documentation

for assignment of any

additional interface pins.

CLOCK/CALENDAR

If your printer is equipped with the clock/calendar option, there

may also be a custom application program installed in the

printer. If so, refer to the documentation that describes that

program to determine the clock function and the manner of

setting the time and date.

The standard DataPlot program also provides for setting and

reading the time and date by using a keypad that is

connected to J9 as described under "KEYPAD

INTERFACE" elsewhere in this data sheet. For such use,

the keypad must be in "APPLICATION" mode.

To set the clock, key in the date and time in the format:

MMDDYYhhmm, then press the E key. If the time and date are

valid, the clock will be set and started and the date and time

will be printed for verification. The date and time will then be

printed whenever the keypad is in "APPLICATION" mode and

the E key is pressed with no preceding numerical entry.

Page 4of 4

SELF TEST PRINTOUTS

With the keypad connected and the keypad mode jumper

removed, pressing key "1" or key "2" will cause test patterns to

be printed in the x and y-directions respectively, using the

currently selected font, size and boldness. See the "Standard

DataPlot Character Fonts" data sheet for how to select other

fonts, sizes, boldness and print orientation using the keypad.

Refer to the "KEYPADINTERFACE" section of this data

sheet for keypad pin out information on connector J9.

PTU INTERFACE-J6

The 4-pin connector J6 is used for driving a Paper Take Up

assembly to automatically re-roll the printed paper. If your

system includes a PTU, connect its cable connector to J6 with

the red dot at the pin 1 end (marked on the board).

WARRANTY

B-G Instruments will repair or replace, at its option, any

DataPlot CB1224, 1320 or 1416 control board that

malfunctions within one year after the original date of sale,

provided that it is used only for control of the correct type of

DataPlot print mechanism and:

1. neither the control board nor the attached print

mechanism have been modified in any way not specifically

authorized in writing by B-GInstruments, Inc., and

2. electrical power supplied to the control board has always

been within the specifications given in this document, and

3. the control board shows no evidence of electrical,

thermal or mechanical damage.

B-G Instruments, Inc.

13607 E. Trent,

Spokane Valley, WA 99216, U.S.A

www.bginstruments.com

POWER REQUIREMENTS

-

J10

This control board requires + 5V + /-5% logic power at 300

mA and one additional higher voltage to drive the printhead

andstepper motor. This drive voltage depends on the model:

CB1224 +20V @ 3.0 amperes peak*

CB1320 +18V @ 3.4 amperes peak*

CB1416 +16V @ 4.5 amperes peak

* May be ordered for + 12V operation with some sacrifice in

maximum print speed. The drive voltage should be adjustable

over a + /-10% range about its nominal value to compensate

for normal differences in printhead resistance and for use as a

contrast control. The drive voltage must never be applied

before applying the + 5V logic power or when the + 5V is

outside its tolerance limits. Internal logic reset circuitry is

provided to prevent damage when the 2 supplies are energized

simultaneously. The + 5V supply must be free of spikes that

might cause the microprocessor to partially reset and

thereafter run improperly. The J10 pin assignments:

Pin 1

+5 volts

Pin 2 5 volt return

Pin 3 +drive voltage

Pin 4 drive voltage return

Pins 5 through 7 are not used.

Toll Free: (888) 244-4004

Phone: (509) 893-9881

Fax: (509) 893-9803

This manual suits for next models

2

Popular Network Hardware manuals by other brands

DivioTec

DivioTec SRA312-032 Series user manual

Compatible Systems

Compatible Systems DS3- Quad 10/100 RIOP installation guide

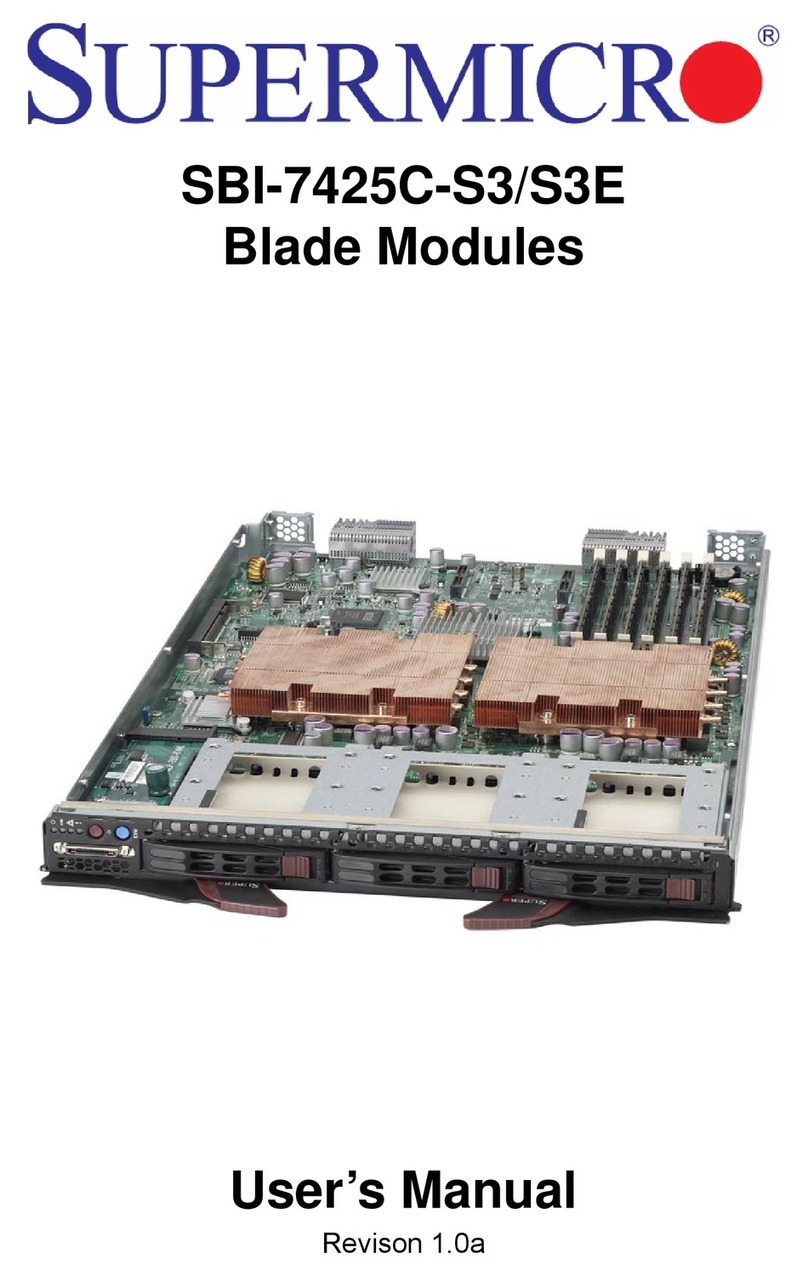

Supermicro

Supermicro SuperBlade SBI-7425C-S3 user manual

Avanu

Avanu WebMux A400X user manual

MikroTik

MikroTik ATL LTE18 kit user manual

Cisco

Cisco Network Storage System NSS3000 Series Getting started guide