WWW.BALTIMOREAIRCOIL.COM

3

1. Coils: TrilliumSeries™ Adiabatic Producs have either microchannel, or tube/fin coils. The coils are

designed to be corrosion resistant, minimize refrigerant or fluid charge, allow for thermal expansion,

and be easy to inspect and clean.

2. Whisper Quiet Fan(s): The fans have integrated electronically commutated motors (ECMs).

These motors have embedded speed control and are highly efficient. They communicate with the

EcoFlex™ Controls via Modbus.

3. Pre-Cooler Pads: when saturated with water, the pads precool the air to 1-3°F above the wet

bulb temperature, thus improving the ability of the unit to reject heat on hot summer days. In

conjunction with the distribution system they are designed to keep the water off the coils. When

dry, the pads are removable for coil inspection or for cleaning.

4. Refrigerant/Fluid Connections: This is where customers connect to their piping systems. Some units

have these connections on the opposite end from the controls.

5. Discrete Spray Connection (Not Shown): Since uptime is critical, this backup connection is

available for water supply to the spray system. Should the pump or valve get damaged, or main

water supply be interrupted on a hot day, a garden hose can be connected to this connection for a

backup. See page 31 for more details.

6. Auto-Discrete Valve (Optional): This normally closed (NC) valve is located at the discrete spray

connection location. Should the pump, make-up valve, or float switch get damaged, the valve will

automatically open to supply water to the spray system.

7. Access Hatch: This door allows access to the sump, pump(s), float switch, strainer, and for general

inspection. There is no general need to climb inside the unit; reaching into the sump is all that

would be necessary during inspection and maintenance.

8. Pump(s): The industrial grade stainless steel pump(s) are controlled by the EcoFlex™ Controls to

deliver water to the distribution system when the unit is in the Pre-Cooler Mode. The pump(s) are

rated for continuous duty and can run dry for short periods without harm.

9. Pump Valve (Optional, Not Shown): This valve is a slow acting, normally open (NO) ball valve that

prevents water from discharging through the pump when the Discrete Spray Connection is used. When

the optional Auto-Discrete Backup Spray System mode is activated, the valve automatically closes.

10. Sump: This stainless steel basin collects the water from the gutters and the spray system, and

houses the pump(s). It can be accessed through the access hatch(es).

11. Strainer(s): The strainer(s) surrounds the pump(s). It protects the spray system from collecting

debris that is larger than the holes in the distribution system.

12. Float Switch (Not Shown for TSDC): The industrial grade stainless steel float switch detects the

water level in the sump, ensures that water doesn’t overflow, and, in concert with the EcoFlex™

Controls, protects the pump(s) from operating dry.

13. Make-up Valve: This normally closed (NC) valve provides fresh water to the unit to replenish the water

that evaporates into the entering air stream, and the water that is drained to keep the unit clean.

14. Make-up Pressure Balancing Valve (TSDC2 Only): This valve is adjusted to set the correct water

flow to the pre-cooler pads. This valve is preset a the factory. See page 24 for more information.

15. Water Distribution System: Water is evenly dispersed over the full length of the pad using a PVC

pipe system (TSDC) or a stainless steel gutter system (TSDC2 and TSDF2).

16. Water Collection Gutter: The unused water from the pre-cooling pads is collected in this gutter and

returned to the sump to be recycled instead of dumping the water to a drain.

17. Drain Valve: This valve is a slow opening, normally open (NO) ball valve that drains water from the

unit when the unit cycles into Dry Mode or during periodic cleaning cycles.

18. Outdoor Air Sensor (Not Shown): This sensor determines the outside temperature, and when

comparing it to the precool set temperature helps the controller determine whether the unit should

be in Dry Mode or Pre-Cooler Mode.

19. EcoFlex™ Controls: Each unit is shipped with custom controls logic that reduces energy

consumption and optimizes water usage. With preset controls, the system is programmed and ready

to operate upon arrival from the factory. For more information, see pages 28, 33 and 40.

20. Flow Meter(s) with Valve (TSDC2 and TSDF2 Only): This is set from the factory to control the flow

of water over the Pre-Cooler Pads. See page 24 for adjustment.

21. Easy Pad Removal (Not Shown) (TSDC2 and TSDF2 Only): Steel partitions facilitate pad removal

without damage while minimizing downtime. See page 36 for more information.

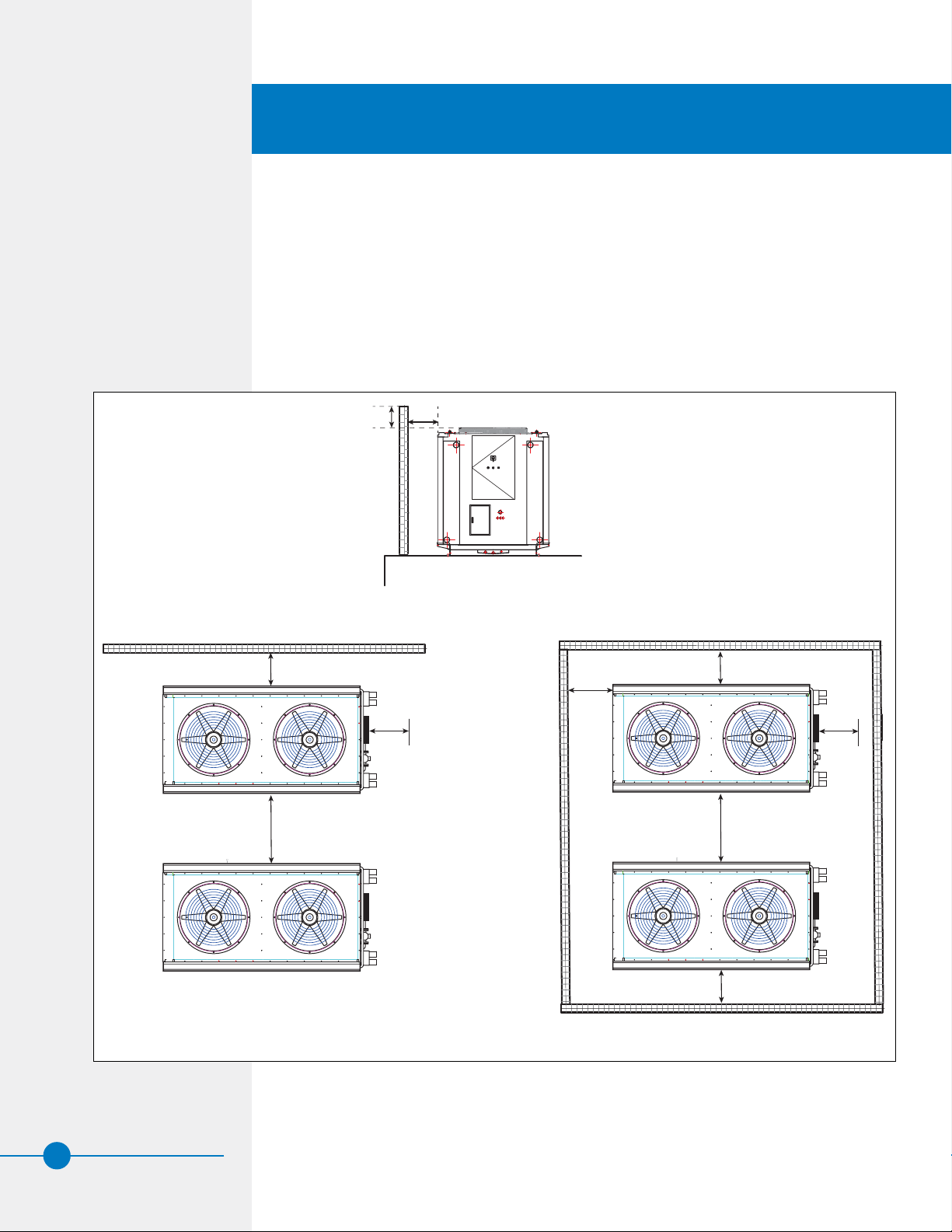

Unit Description

Unit Overview

Detail A, TSDC Shown

Detail B. TSDC2 Shown

NOTE: For transcritical CO2

operation, the coil operates

with vapor in and vapor out. For

subcritical CO2operation, the coil

operates with subcritical vapor in

and liquid out.