3.0 Delivery

3.1 Owner’s Responsibilities

The following is a partial list of the owner’s

responsibility as the primary operator.

•Complete the Warranty Registration and assure

that it, along with the Dealer Commissioning

Checklist, are sent to Back Cove Yachts within

15 days of commissioning.

•Advise Back Cove Yachts of any change of

address, or change in ownership to allow the

maintenance of an accurate list of owners.

•Confirm that the dealer completes all items that

are the responsibility of the dealer. If the boat is

delivered to a location other than to the dealer it

may be, subject to purchase agreement, the

owner’s responsibility to perform all

commissioning.

•Operate the boat in accordance with the

instructions provided in this Owner’s Manual and

any literature provided by component suppliers

as well as all applicable Coast Guard regulations

and good sense.

•Supervise the maintenance of the boat by

competent marine service personnel.

•Supply and maintain all additional safety

equipment on board as required or

recommended by the Coast Guard and

appropriate to the nature of the boats usage.

•For your safety, the safety of your passengers,

other boaters and people in the water, you must:

oTake a boating safety course;

oGet instruction in the safe and proper

handling of your boat;

oUnderstand and follow the “rules of the road”;

oLearn how to navigate.

•Registration: In addition to the registration

requirements for your Back Cove 30 in the state

where it is used most frequently, many states

require additional registration when an out-of-

state boat is used within their boundaries.

Contact state boating authorities or any marine

dealer for registration requirements.

3.2 Information Sources

In North America, contact one of the following for

boating courses:

•U.S. Coast Guard Auxiliary

•U.S. Power Squadron

•Canadian Power and Sail Squadrons

•Red Cross

•State Boating Offices

•Yacht Club

Outside of North America, contact your boat dealer

and/or your governmental boating agency for

assistance.

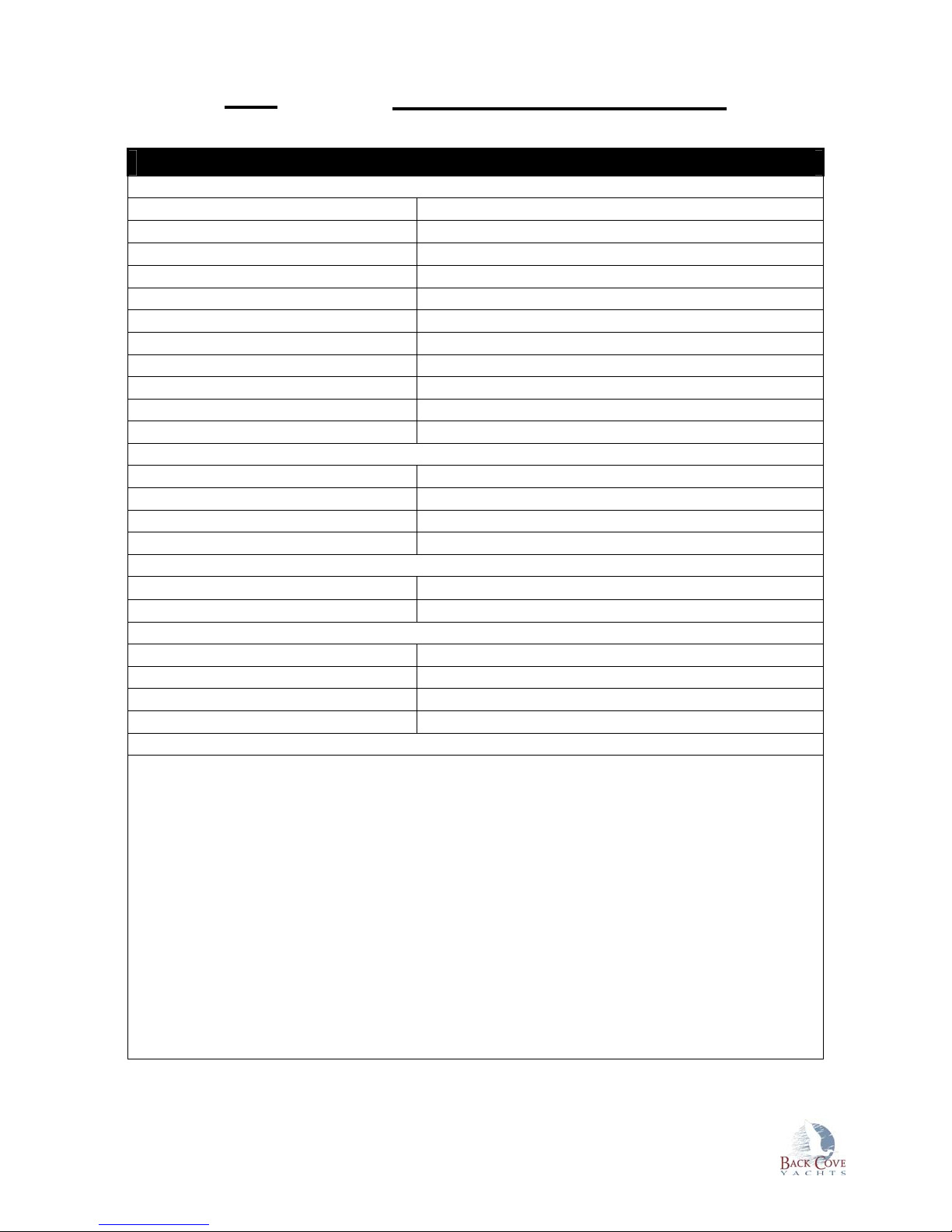

3.3 Dealer’s Responsibilities

All Back Cove Yachts are sold through dealers who

have been selected to represent Back Cove on the

basis of the dealer’s knowledge and ability to provide

appropriate service to the boat owner. Your Back

Cove dealer is responsible for the following

procedures during the purchasing and commissioning

of the boat:

•Preparing and communicating to Back Cove

Yachts a detailed specification for the boat

including any shop installed options.

•Inspecting the Back Cove upon delivery for

damage that occurred in transit and processing

any claims with the transport company. Shipping

damage needs to be noted promptly upon arrival

of the boat.

•Inspecting the packing boxes that come with the

boat to ensure that all items are received.

•Commissioning the boat following the Back

Cove Commissioning Checklist. The dealer must

check and initial each item on the list, review it

with the owner, and send a copy to Back Cove

Yachts.

•Sea trialing the Back Cove with the owner to

assure operation and understanding of all

onboard systems.

•Providing all necessary assistance and service

to assure the owner’s satisfaction upon

completion of commissioning.