TRIBUTARY Sawtooth II User manual

AIRE, P.O. Box 186, Meridian, ID 83680

Ph: 208-888-1772 or 800-247-3432 | Fax: 208-884-2089 or 800-701-2473

Sawtooth II

!CAUTION

ALWAYS WEAR A GOVERNMENT APPROVED FLOATATION DEVICE.

KNOW THE LIMITS OF YOUR ABILITY AND THE LIMITS OF YOUR EQUIPMENT!

The Sawtooth II Contains:

1 - Sawtooth II

2 - Deluxe Cheetah Chairs 1 - Repair Kit

1 - Skeg

Repair Kit Includes:

2 - 6” x 6” PVC Material

2 - 6” x 6” Vinyl

1 - 6” x 6” Urethane Coated Nylon

1 - Summit 2 Valve Wrench

1 - Summit 2 Valve Adapter

1 - Vinyl Tubing Adapter

3 - Type B Adhesive Patches

2 - Alcohol Prep Pads

1 - Tear Aid Instruction Sheet

1 - Piece Sandpaper

**Glue Not Included**

Item Needed for Inflation: (not included)

1 - Pump

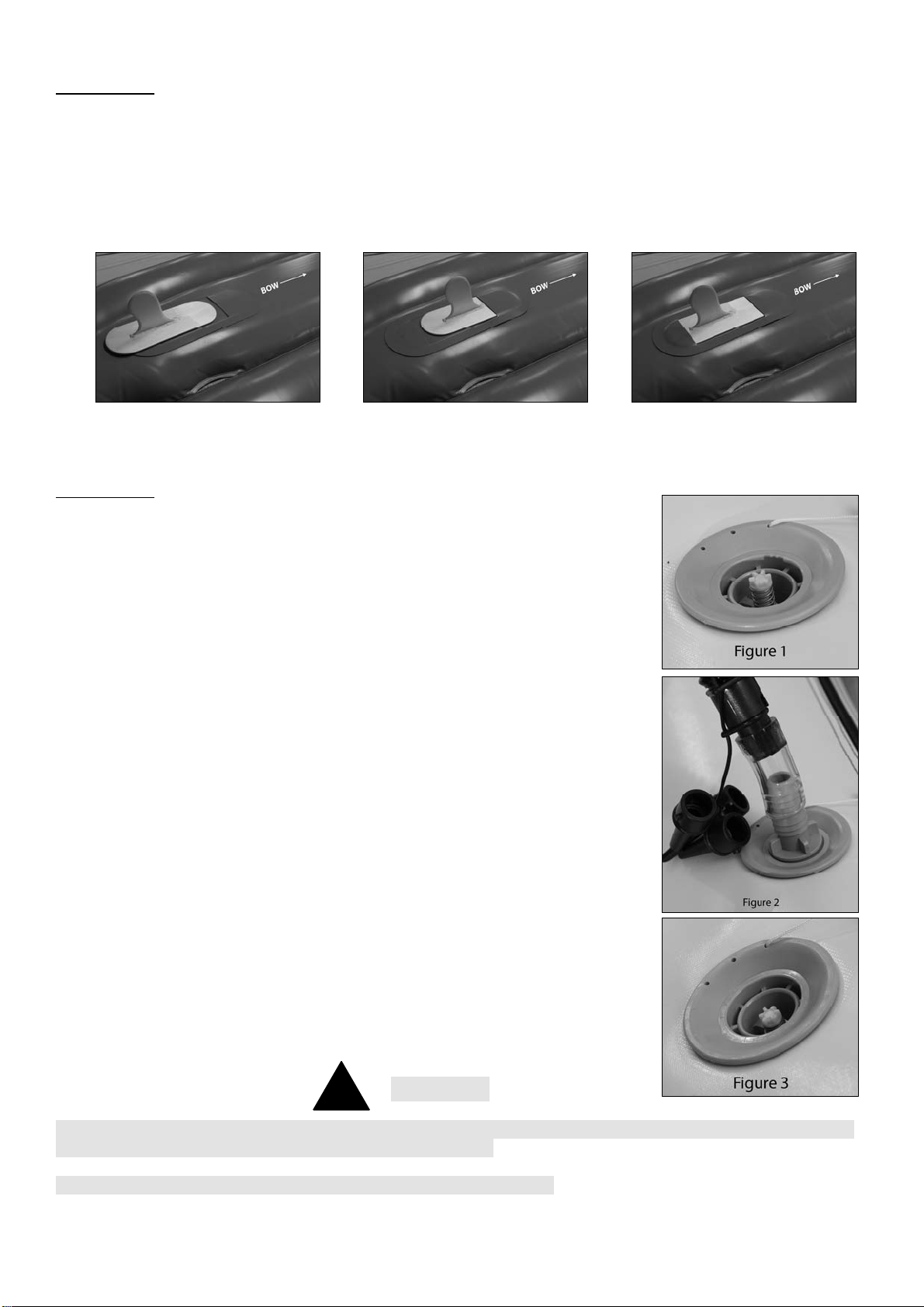

Skeg Installation

Items needed:

1 - Sawtooth II 1 - Skeg

1. With the boat deflated, align the skeg as shown in Figure 1.

2. Insert the long end of the skeg base into the pocket. Slide it all the way in toward the front of the kayak.

(Figure 2)

3. Next, insert the rear of the skeg base into the rear slot and slide it back until it stops. (Figure 3)

Inflating the boat to operating pressure will lock the skeg in place.

Figure 1 Figure 2 Figure 3

Inflation

Items needed:

1 - Sawtooth II

1 - Summit 2 Valve Adapter 1 - Vinyl Tubing Adapter

1 - Pump (not included)

Inflate the Sawtooth II using a hand, foot or an electric pump designed for inflatable

boats. If using an electric pump for initial inflation, a hand pump must be used to top

off the kayak.

To inflate:

1. Remove the dust cap from the valve.

2. Push and turn the valve stem 1/4 turn to the left. This positions the valve

stem in the up or closed position. Having the valve stem in the closed position

allows air to be pumped into the chamber and will prevent the air from

escaping. See Figure 1

3. Connect the clear vinyl valve adapter to the pump hose and to the gray

Summit 2 valve adapter and insert it into the boat’s valve. A 1/4 turn to the

right will lock the adapter to the valve. See Figure 2

4. Inflate the chamber to a soft pressure.

5. Repeat procedure for all chambers.

6. Once all chambers are softly inflated, top off all chambers to 2.5 psi.

Do not over inflate the kayak.

Inflation Pressure: A good rule for gauging the proper pressure is to push down with

your thumb at the center of the tube. If you can deflect about a half an inch from the

top plane of the tube, it will be close to 2.5 psi.

To deflate:

Depress the valve stem and turn it 1/4 turn to the right (clockwise). This positions the

valve stem in the down or open position and will allow air to escape freely from the

chamber. See Figure 3

!CAUTION

Changes in air temperature and elevation could cause the air inside the boat to expand which could cause the kayak

to burst. Always release some air when these conditions occur.

Never leave your boat sitting in direct sunlight when it is out of the water.

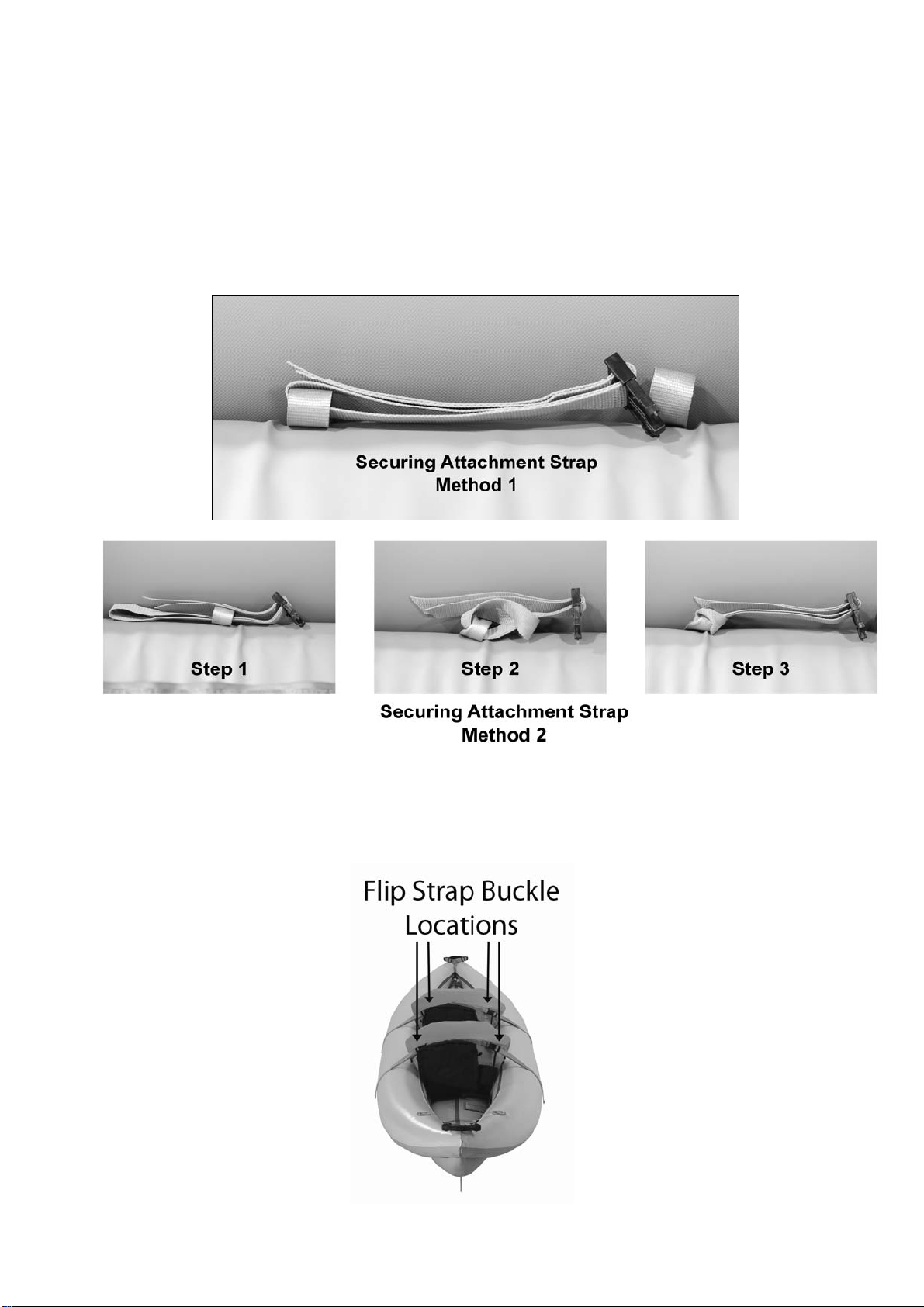

Seat Installation

Items needed:

1 - Sawtooth II 2 - Deluxe Cheetah Chairs

1. Find the seat locations that best suit you with the boat inflated. Position the chairs between the drain holes,

spacing so that each paddler is seated comfortably and weight is evenly balanced to slightly forward heavy.

(See photo on page 1 for approximate locations.) Installing the seats is easiest when the boat is deflated.

2. Connect the webbing located at the four corners of the Deluxe Cheetah Chair to the cargo loops along the

sides of the floor.

3. Connect the flip strap buckle to the top right side of the seat, loop it under the boat and finally secure the

buckle to the top left side of the seat. This strap can be used to right the kayak if the kayak capsizes as well

as providing additional support for the seat back.

4. Repeat Step 2 and 3 for remaining seat.

Transporting

To avoid excessive wear and extend the life of this craft we recommend transporting this craft in an AIRE Small Kayak

Bag or cover with clean, dry tarp. Do not load other equipment, particularly heavy or sharp objects, on top of the craft.

If you transport your boat in an open truck bed please make sure all sharp objects are removed because more boats

are damaged in transport than on the water.

**VALVE CAPS SHOULD ALWAYS BE IN PLACE WHENEVER TRANSPORTING YOUR BOAT.**

Cleaning and Maintenance

Your inflatable boat is constructed with high quality materials and superior workmanship however, as with all outdoor

equipment, proper cleaning and maintenance will extend the use of the product and allow it to perform better. Most

damaging to your inflatable boat are extended UV exposure, insect repellents, plus mold and mildew. To keep your

boat performing its best please following these simple instructions.

•Do not set your boat on sharp objects. •Do not over inflate your boat.

•Keep the zippers clean. •Clean the boat with soap and water.

•Allow the boat to drain properly so it can be stored dry.

Storage

Short Term Storage - Allow to air dry, deflate and roll loosely

Long Term Storage - Store your boat dry and clean. After use, rinse off all debris and allow the boat to air dry on soft

pressure and out of direct sunlight. Residual water inside the bladders/airecells will not damage the boat. Store the

boat in a cool, dry place out of sunlight and away from exhaust fumes. If you store your boat inflated you should be

able to pinch an inch of material.

Basic Trouble Shooting

1. Valve does not retain air when pump is removed.

•Make sure that the valve stem is in the up and closed position.

•Clear any debris that might be preventing the valve from sealing. This can be accomplished by either

pumping quick bursts of air into the valve or removing the core valve assembly and cleaning the edge of

the rubber diaphragm with a cotton swab and denatured alcohol.

•Make sure that the core valve assembly is tight. Tighten valve if necessary.

2. Tube becomes soft after inflation process.

•Determine which air chamber is soft. Make sure the valve is functioning correctly, with no signs of

leaking. (See # 1 above.)

•Find the hole in the airecell and patch with the Tear Aid patch.

3. Tube is puckered or shows a void when inflated.

•The airecell might be misaligned. Deflate the tube(s) and as they are brought back up to pressure,

manipulate the tube(s) to free the airecell as it inflates. If this does not fix the problem, deflate the boat,

open the zipper and adjust the airecell.

4. Zipper is difficult to operate.

•Use a combination of soap, water and an old toothbrush to clean and clear the zipper of debris.

5. Tear Aid patch does not stick to airecell.

•Make sure the area to be patched is dry and clean. Use the alcohol pad to prep the area, if necessary.

This boat contains a starter repair kit that includes equipment for basic repairs.

The Repair Kit Includes:

2 - 6” x 6” PVC Material

2 - 6” x 6” Vinyl

1 - 6” x 6” Urethane Coated Nylon

1 - Summit 2 Valve Wrench

1 - Summit 2 Valve Adapter

1 - Vinyl Tubing Adapter

3 - Type A Adhesive Patches

2 - Alcohol Prep Pads

1 - Tear Aid Instruction Sheet

1 - Piece Sandpaper

**Glue Not Included**

Here is a list of items, not included, which you should strongly consider keeping with your repair kit at all times.

*1/4 Pint Stabond 2-Part Adhesive

Popsicle Stick or Tongue Depressor

Scissors or Knife

Small Paintbrush

Roller

MEK Solvent

Towel

Duct Tape

Old Toothbrush

Standard Screwdriver

*It is recommended that the glue be replaced every year or after use.

The Ultimate Extended Trip Repair Item

The ultimate repair part for any boat is an extra airecell.

Repair Tips

Prior to opening the boat’s zippers, make sure they are clean and clear of any debris so that they will operate freely,

by cleaning the zippers with soapy water and an old toothbrush.

When patching the airecell, apply the patch to the outside of the airecell. When patching the PVC shell, apply the

patch on the inside of the PVC. The airecell patch is for air retention. The PVC shell patch protects the airecell patch

as well as prevents the hole from tearing further.

Adhesive Patch Repair

Items needed:

Towel

Alcohol Prep Pad Type B Adhesive Patch

Tear Aid Instruction Sheet

For most repairs, the airecell does not need to be removed completely.

1. Locate the hole in the boat and access that area of the airecell and outer skin by opening the zipper.

2. Using a towel, dry the area to be worked on.

3. Clean area to be worked on with alcohol prep pad and let the area air dry.

4. Peel backing paper off Type B Adhesive Patch and apply patch over punctured area.

(See Tear Aid instruction sheet for more details.)

5. Press and rub patch so that the patch seals completely and is without bubbles.

6. Carefully close the zipper and replace the split ring. The boat can then be inflated for use.

Glue Repair

Items needed:

Scissors or knife

Standard Screwdriver

Roller

Stabond 2-part adhesive

Sandpaper

Popsicle stick

Small brush

PVC Material or Urethane Material

MEK or Alcohol Prep pads

For most repairs, the airecell does not need to be removed completely.

When patching the airecell, apply the patch to the outside of the airecell. When patching the PVC shell, apply the

patch on the inside of the PVC.

1. Locate the hole in the boat and access that area of the airecell and outer skin by opening the zipper.

2. Using a towel, dry the area to be worked on.

3. Cut a patch of fabric at least two inches large in length and width than the puncture, hole, or tear.

4. Clean the area to be patched (using MEK or alcohol prep pads).

5. Rough up both the patch and the area to be patched with the sand paper.

6. After opening the 2-part adhesive, prepare the Stabond glue by pouring the entire contents of the glass jar

into the metal can and stir using a popsicle stick or tongue depressor.

7. Apply an even coat of glue with a small brush to both the patch and the area to be repaired and let dry

completely, approximately 10-15 minutes.

8. Apply a second coat of glue, and let dry 5 minutes or until tacky. If the glue is too dry, reactivate it with a

small amount of MEK.

9. Place the patch over the hole or tear, and press together. Using a roller or another blunt object press from the

center of the patch to the edges to seal the patch to the airecell or outer skin. Make sure that the patch seals

completely and is without bubbles.

10. Let the glue cure at least one hour before inflating (overnight if possible is best). Do not inflate to full pressure

on the same day of the repair.

Extensive Repairs

If you have a major rip or tear in your boat that is beyond your abilities to repair, please contact AIRE at 800-247-3432

for a Return Authorization number. Please put a brief note with your contact information and a detailed description of

the repairs necessary inside the box and ship the package to the address below with the RA number clearly written on

the outside of the box. For your protection, please ship the boat with a service that provides a tracking number.

Warranty

This warranty covers defects in materials and workmanship only for a period of 1 year from the date of purchase for

the original owner for non-commercial use.

AIRE reserves the right to determine whether to repair or replace any product covered by this warranty and the right to

replace any discontinued models with current models when necessary. Colors may vary between original and

replacement parts.

If you have any questions, please contact us at

AIRE, 2021 E. Wilson Lane, Meridian, ID 83642

Ph: 208-888-1772 or 800-247-3432

www.aire.com

Thank you for choosing Tributary products.

Table of contents

Other TRIBUTARY Boat manuals

Popular Boat manuals by other brands

Jeanneau

Jeanneau MERRY FISHER 655 MARLIN owner's manual

Hermes Yachting

Hermes Yachting Alice Bavaria Cruiser 51 2016 Operation manual

Minicat

Minicat 420 Emotion user guide

Skeeter

Skeeter ZX24V Owner's/operator's manual

Sea Eagle Boats

Sea Eagle Boats Explorer 300x Instruction & owner's manual

Bayliner

Bayliner 1995 3587 owner's manual