B&C BC3500 User manual

1

BC3500

Trailer Winch

BC3500

Owners / Installation Guide

model

BC3500ATV

BC3500CP

BC3500CPR

Read and understand guide before

installation and use of BC3500

2

Introduction BC3500

Thank you for choosing a BC3500.

Please read this owner’s manual to fully understand the product and provide you with

safe and reliable performance.

The BC3500 is a compact, powerful, high performing and versatile winch.

It comprises of a 1.2kW DC permanent magnet motor,140:1 ratio 3 stage heavy duty

gearing, automatic load holding brake and stronger steel fabricated drum.

The stronger fabricated steel drum on all models provides the best & safest option to use

either steel or synthetic rope.

With sealed motor and gearbox the BC3500 has an IP68 rating to provide protection from

water, dirt and dust.

The BC3500 operation has ability to power forward and reverse and with freespool as

standard feature.

Winch control options consist of wired remote, wireless remote and permanent mounted

waterproof switch.

Specifications BC3500

Rated Line Pull 1590 kg (3500 lb) single line pull

Gear Box 3 Stage planetary

Gear Ratio 140 : 1

Motor 12v 1.2 kW 1.6 hp)

Motor 24v 1 kW (1.3hp)

Dimensions As per line drawings in this manual.

Weight Range unboxed 10.5 kg 12 kg 13.3 kg

Mounting 2, bolt, 3 bolt or 4 bolt

Rope maximum length 10M & 15M of 5mm steel or synthetic option

Performance As per performance chart in this manual

Current Draw Maximum 260 Amps

Freespool Rotate lock & unlock

3

Performance BC3500 recovery winch

Fist layer Performance

Line Pull in kg (lb’s) Line Speed M p/m (Ft p/m) Current Draw Amps 12V

O load 7.5 (24.6) 23 Amps

227 kg (500 lb) 5.9 (19.3) 45 Amps

454 kg (1000 lb) 5.3 (17.3) 67 Amps

680 kg (1500 lb) 4.6 (15.3) 90 Amps

907 kg (2000 lb) 4.12 (13.8) 114 Amps

1134 kg (2500 lb) 3.7 (12.3) 138 Amps

1361 kg (3000 lb) 3.3 (10.8) 164 Amps

1588 kg (3500 lb) 2.8 (9.3) 190 Amps

Important !!

It is the installers and operators responsibility that before use the BC3500 is

mounted to a suitable platform or structure.

It is to be correctly and adequately secured capable to stand all loads applied with

suitable margin of safety. Consult a structural engineer if uncertain.

Suitable ropes must be used with suitable minimum breaking strain.

A SK78 minimum 5 mm diameter Dyneema

If a high tensile steel rope is used a minimum diameter of 5 mm is required.

The BC3500 must not be used for lifting, supporting or transportation of people.

The BC3500 must not be used to support, move or hold loads above people.

The BC3500 must always be used in a safe manner, making sure hands, body

parts and all people are clear of the rope and objects being moved while the

BC3500 is in use.

Never use the BC3500 for securing loads while transporting.

Allow slack in the rope between the load an winch during transport.

Use suitable rated load restraints for load securing.

4

Safety and Precautions

It is important all precautions are take for the safe operation of the BC3500..

It is the owner’s and operator’s responsibility to understand the correct safe installation

and operation of the BC3500. This will help to avoid injury, death and or damage to prop-

erty.

This manual will assist the owner with product information and installation.

Additional information is provided for safety guidance, contrary use or installation can re-

sult in injury, death and damage to property.

Safe Operation

Be sure the BC3500 has been installed and wired correctly before use. Inspect mounting

hardware is secure.

Check rope is winding on correctly, incorrect wind on direction will have no brake load

holding. Rope must feed onto the bottom of the drum, looking at the winch from the rope,

motor is on the left.

Inspect rope is not damaged, damaged rope can fail resulting in rope breaking, causing

loss of load, death, injury or damaged property.

Be certain the winch rope is secured to the load at a suitable location with adequate

strength for load applied. Use safety sling if no suitable anchor point is available.

Always make sure winch rope is being applied onto the winch in a straight line horizontal

to the ground and at 90 degrees to the winch.

Use directional pulley if needed, ensure the rope is always at the correct height level and

direction. Wind rope evenly onto the drum.

Make sure all areas between the winch and the load are clear of obstruction and people,

stand clear of the rope when winching., keep hands clear from the winch.

Avoid stop start recovery, plan for one continuous single operation. Do not have repetitive

loads without allowing winch to cool. Do not use the winch at high load for extend period

of time.

If the motor gets to hot allow adequate time for cooling. Do not put your hands on a hot

motor. Allow motor to cool until a comfortable to touch temperature.

Overheating will result in winch failure.

When winch is not in use remove control switch or remote were fitted.

Shut off power supply to the winch where possible.

Never leave the winch unattended while under load. Visual contact must be maintained of

the winch and load during operations.

Important !!

5

Options & operation BC3500

The BC3500 is supplied with many options and accessories.

This makes it versatile to suit your installation and application.

The BC3500 supplied as an ATV version is supplied with a mount

plate suitable for hawse or roller fairlead mounting.

A standard base plate can be requested if no hawse or roller is

not required.

The aluminium hawse is not to be used with steel rope and the

roller fairlead may be required.

If a hawse or roller is used the winch rope can only be in the un-

derwound direction. Rope winding is explained in under rope in-

stallation.in this manual.

The BC3500 supplied with control box mounted and used with

rope in overwound direction can not be used with mounted

hawse or roller fairlead.

This installation may be used on boat & car trailers to maintain

the most direct line for boat retrieval.

Over wound rope will have the winch motor to the right and gear-

box to the left when viewing the winch mount with the rope com-

ing towards you..

The BC3500 supplied with control box mounted and used with

rope in underwound direction .

This installation may also used on boat & car trailers to maintain

the most direct line for boat retrieval.

Under wound rope will have the winch motor to the left and gear-

box to the right when viewing the winch mount with the rope

coming towards you.

In most trailer applications the rope is always feeding onto the

winch in direct line 90 degrees to the drum. In this situation a

guide hawse or roller fairlead offers minimal benefit.

The BC3500 supplied with control box mounted and used with

rope in underwound direction .

This installation may also used on boat & car trailers to maintain

the most direct line for boat retrieval.

Under wound rope will have the winch motor to the left and gear-

box to the right when viewing the winch mount with the rope

coming towards you.

This option is also available with mounted hawse or roller fair-

lead for use with steel rope.

BC3500 accessories. Include wireless controls & roller fairlead.

6

Dimensions BC3500ATV

7

Dimensions BC3500 control box

8

Mounting BC3500

Correct mounting of the BC3500 is the customers responsibility.

Before mounting your BC3500 inspect for and signs of possible damage and all assembly

bolts and screws are secure.

Mounting hardware must be of a minimum M8 high tensile grade 8 bolts.

M10 bolts may be used with non hawse mount plate.

Dimensional diagram shows cut outs in mounting plate for suitable securing positions.

A minimum of two mounting bolts must be used being centre holes front hole and rear.

The bolts must be secured with spring washer behind the nut or lock nut should be used.

Two flat washers should be used on the bolts on both sides of the mounting plate one un-

der the bolt head and one under the lock washer or lock nut. Ensure all nuts are firmly

secured at 30 Nm of torque for M8.

The use of undersized or under strength bolts can result in the mounting failing under

load. This can result in injury, death or damage.

The mounting platform or structure must be of adequate strength to support the full line

pull capability of the winch. Plus incorporate a safety factor which will eliminate possible

distortion of the mounting platform. A steel mounting platform of 6mm thickness may be

required. Seek qualified engineering support if uncertain.

The BC3500 must be located in a position it will not be submerged in water.

The BC3500 can be mounted horizontally or inverted but must be mounted so the rope

feeds on in a direct straight line either from the load or via a pulley block.

When mounted the rope must feed onto the winch drum from the underside of the drum

when looking at the winch with the motor to the left and gearbox on the right.

Incorrect installation of the rope will eliminate the load holding mechanical brake.

9

Incorrect wiring can result in short circuit, fire and damage.

Double check all wiring.

Once inspected connect power cables to the battery

Test winch both forward and reverse directions

A circuit breaker will prevent over loading, overheating or damaging the

BC3500.

Fitting instructions of a circuit breaker are included in the manual and is

connected to the main positive cable from the battery.

Follow wiring instructions provided in the manual to suit your winch model.

Always provide power to the winch direct from + & - battery.

DO NOT use vehicle chassis or body for negative supply.

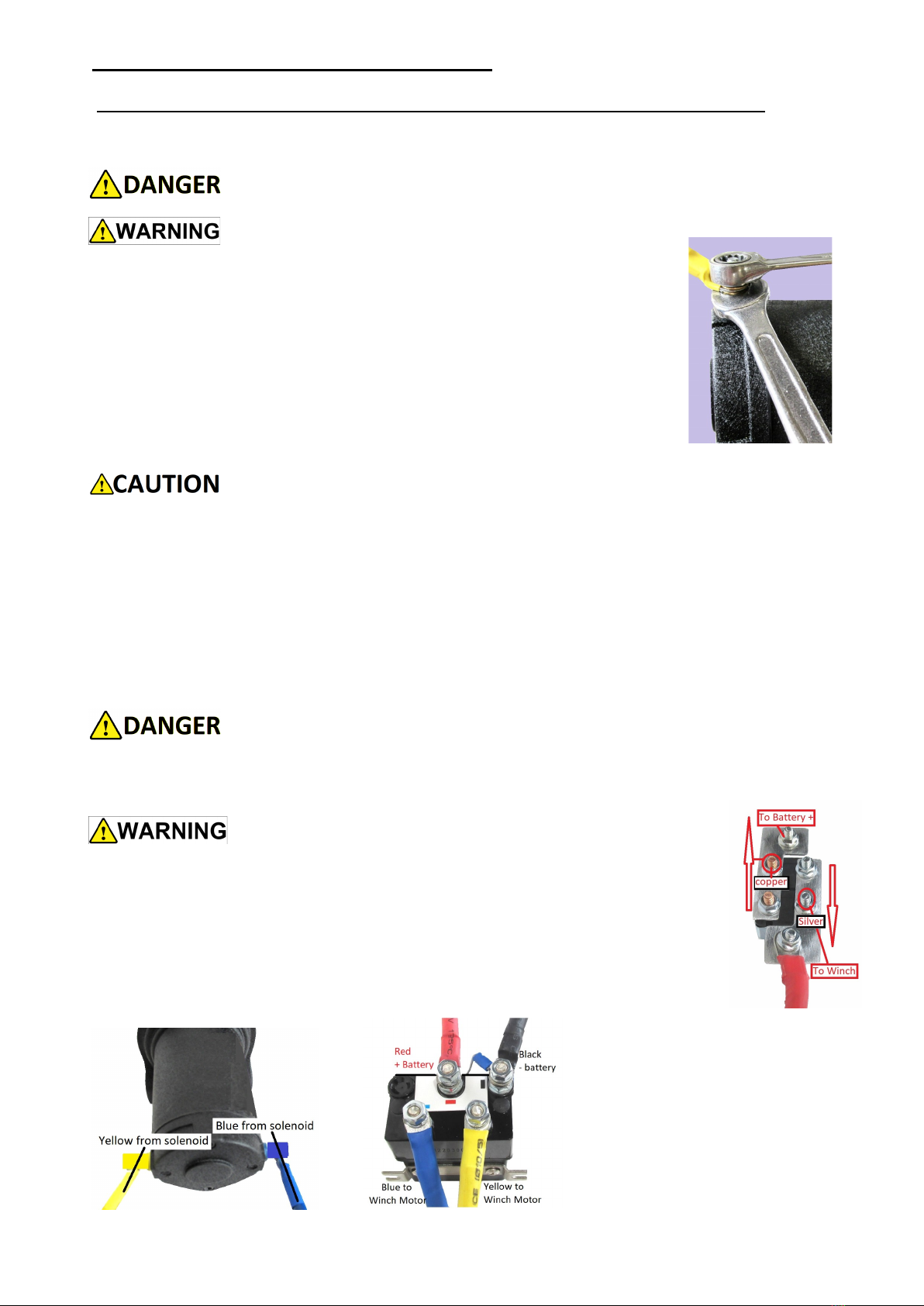

Electrical Installation BC3500 ATV

The motor and solenoid terminal have lower and upper securing nut.

Remove the upper nut and washer. It is important to inspect the lower

nut is firm but do not overtighten.

Apply the power cable lug eye over the bottom nut. Use flat washer on

either side were provided or spring washer below the upper nut.

Use a spanner to support the lower nut when tightening and securing

the upper nut. Tighten nuts to maximum torque 5Nm.

This will help prevent over tightening and turning of motor or solenoid

terminal, rotation of the terminal will result with internal damage to the

motor or solenoid.

When routing the power cables select a suitable path which will not interfere with

the operation of the winch or be in the path of the winch rope.

Use additional protection on the wiring conduit which comes into contact with sharp

objects or any surface which can rub and wear the electrical conduit.

Power cables should be at shortest required length where possible.

A qualified electrician may shorted cable length if required.

Make sure the wiring is clear of any surfaces which have the potential to get hot.

Any additional length or loose and hanging wiring must be secured with cable ties

to strong support out of harms way.

Damaged wiring must not be used.

Damaged wiring can result in short circuit, fire and electric shock.

Avoid electric shock. Disconnect battery when installing

the winch

10

Electrical Installation BC3500 ATV

Battery Not included

Ignition Switch Not included

Handlebar

Switch

Only one switch required for

winch operation, both can be

installed

11

Electrical Installation BC3500 CP & CPR

The BC3500 CP & CPR is wired with an Anderson plug for easy installation..

An additional plug is provided to connect to a vehicle battery or independent battery.

The BC3500 solenoid control box has a 4 pin sock with

locating notch. This is used for all plug in control options..

The socket is suitable to accept the corded hand held

control or the wireless receiver.

Plug in corded remote forward and reverse control

Wireless receiver plugs into the control box

Wireless receiver can become corded remote to plug

into control box

12

The BC3500 is suited to both steel or synthetic rope.

In either installation the rope is fed under the drum from the front of

the winch and then into the drum from behind the winch. This is

correct with the motor on your left and gearbox on your right when

facing the winch. Incorrect rope attachment will not allow the brake

to function correctly and support loads..

Wear leather gloves when handling steel ropes

STEEL ROPE.:

For best performance determine the working length of rope required plus additional 5

wraps of first layer on the drum. The first 5 wraps are important to help secure the rope

on the drum. Do not exceed maximum rope length recommendation.!

When installing the steel rope pass under the drum and then into the hole in the drum

from behind the winch.

The grub screw used to retain the steel rope may need to be unwound to allow the rope

to pass. Push the rope through and loop it through the second hole, push until flush with

the drum hole on the outer side.

Tighten the grub screw until firm and slight crush on the steel rope, Apply the rope onto

the drum under tension of minimum 5kN. Guide the rope so it layers onto the drum even-

ly, overlapping the rope will damage the rope.

SYNTHETIC ROPE :

When selecting a synthetic rope for be certain to select a quality rope suitably rated for

such applications.

Do not use excessive rope, maintain a suitable working length plus first layer on the

drum.

Unused rope compresses and flattens onto the drum, this creates extreme pressure on

the barrel and against the cheek plates of the drum. This may damage the drum and the

rope.

If applying synthetic ropes to a winch once having steel rope carefully inspect the drum

surface for any abrasive surface.

The first layer of rope applied to the drum secures the rope

onto the drum.

The first layer should be applied under load of minimum 5kN

and must always remain on the drum when BC3500 is used.

The remaining rope is to be layered onto the drum evenly.

Synthetic ropes should only be used where abrasion or

sharp edges can be avoided.

Get information regarding any replacement rope you use for

strength and longevity and consideration of being used in an

environments with high ultraviolet exposure.

All rope should be inspected before use for wear and damage.

The BC3500 is powerful enough to sever fingers. Keep fingers clear of the rope at the

drum or where it may be in contact with any surface. Avoid handling the rope.

Rope Installation BC3500

13

BC3500 parts exploded view.

14

Maintenance BC3500

The BC3500 gearbox is lubricated with an extreme pressure lithium grease. No additional

lubrication is expected for the life of the winch. If re-lubrication is performed use only

compatible grease.

1/ Regular inspection for tightness of all bolts should be performed to maintain safe se-

cure mounting. All assembly bolts should also be inspected for tightness.

2/ Electrical connections must be regularly inspected to ensure they are tight and secure.

4/ Servicing or repairs must only be undertaken by approved service centre.

5/ Remove any dirt or moisture from ropes and winch

Any worn or damaged components must be replaced.

Do not use the BC3500 if any parts are damaged. Use only genuine replacement parts.

Inspection of ropes to be performed before each operation if any damaged to the rope it

must be replaced before use.

Replace rope if damaged or worn, kinked or frayed..

Trouble Shooting BC3500

Symptom Possible cause Remedy

Winch will not operate Flat Battery

Brocken connection

Damaged switch

Damaged solenoid

Damaged motor

Circuit breaker tripped

Replace battery

Check all connections

Replace switch

Check / Replace solenoid

Replace motor

Reset circuit breaker

Winch Operates slow

Or low line pull

Low battery supply

Poor earth

Low gauge power cables

Worn or damaged motor

Charge or replace battery

Connect earth direct to battery

Power cable undersize

Replace motor

Winch will not shut off Damaged solenoid

Damaged control switch

Replace solenoid

Replace switch

Winch operates in only

one direction

Solenoid energising wire

Faulty solenoid

Faulty control switch

Check solenoid connections

Replace solenoid

Replace switch

Motor extremely hot Excessive on time

Excessive load

Poor power supply

Allow to cool

Check load weight

Refer slow line pull symptom

Winch will not hold load Load too heavy

Brake is worn or damaged

Cable wound on incorrectly

Check weight of load

Replace brake

Check rope installation guide

15

Wireless Control Duo

Owner’s operating manual

Read and understand the owners manual before use.

It is important to use the Duo safely and responsibly at all times.

Unsafe operation can cause property damage, injury or death.

16

Introduction Wireless Duo control

The Wireless Duo enables the operator to control a winch both the forward and reverse

direction from a distance of 20 metres wirelessly or 4 metres corded.

It is the operators responsibility to use the Duo safely and responsibly,

Read and understand safety precautions outlined in this manual.

1/ Never use the Duo if the winch or device being operated is not clearly visible.

2/ Never operate the winch or devise until all people and property are clear of the area.

3/ Do not use wireless controls in an area where radio interference may effect either the

intended or unintended operation of the Wireless Duo.

The Wireless Duo control includes.

- Plug in screw lock wireless receiver

- Forward and Reverse (In & Out) transmitter

- Adaptable cord to convert from wireless to wired plug in control

- Battery included and installed in transmitter.

17

Wireless Control Operation

The Wireless transmitter comes paired to the

The transmitter has an automatic

shut down to preserve battery life.

It will shut down after 2 minutes if

inactive.

Repeat startup to continue use.

The Wireless receiver comes paired to the transmitter ready for use.

Picture above shows installation of receiver.

The control box socket and receiver adaptor have corresponding location points and

must be paired when mounting the receiver to the socket.

Once inserted the rotating lock sleave can be used to secure the receiver in position.

The receiver is powered by the internal wiring of the control box.

There is no requirements for batteries in the receiver and the unit is sealed.

The Wireless transmitter comes paired to the

receiver ready for use.

Picture shows functions

To Start the transmitter press the On Off

Mode button and hold for 3 seconds.

The indicator light will flash when on and the

transmitter is now ready for use.

The operate buttons when pressed will signal

the receiver with your selected function.

Release pressure from the button and the

function will cease.

To switch off again press the On Off Mode

button and hold for 3 seconds.

18

Wireless Control Corded Opera-

The Wireless transmitter can become a 4 me-

tre corded control when required or if preferred.

There is a Wired Lead In adaptor at the top of

the transmitter. Remove the cap to expose a

locating point which matches that of the cord.

Once connected it has a threaded locking

sleave for retention. The opposite end will plug

into the control box socket, also use the locking

sleave to secured into position .

Once connected the Indicator Light Wired will

confirm the wired control is now in use.

The Operate Out In buttons can now be used.

Pairing receiver to transmitter

If The transmitter is replaced or requires re pairing to the receiver follow these step.

1/ Remove receiver from control box socket but leave power on at the control box.

2/ Hold down On Off Mode Button on transmitter until turned on.

3/ Press In & Out button simultaneously and hold until both Indicator lights remain on.

4/ When lights begin to slowly flash keep your buttons pressed while reconnecting the

receiver to control socket.

5/ Continue holding In Out button down until the indicator light turn off. Release the but-

tons and the receiver and transmitter are now paired.

19

Duo Wireless Control Maintenance

Battery Replacement

The Duo Wireless transmitter is powered by an A23 battery.

Replacing or accessing the battery by removing the rear cover.

Five (5) Philips head screws are located and accessible on the back of

the transmitter.

Remove the screws and cover to gain access to the A23 battery.

Refit the rear cover ensuring the seal is correctly in place.

Trouble shoot Problem

The Duo will not function wirelessly but will corded.?

1/ Check the receiver is correctly mounted into the socket.

2/ Check signal light is activating. Check Battery Power.

3/ Re pair receiver to transmitter.

The duo will not function both wireless and corded.?

1/ Check power supply to the winch.

2/ Make sure control box switch or isolator switch for the winch is on.

This manual suits for next models

3

Table of contents

Popular Winch manuals by other brands

Champion Power Equipment

Champion Power Equipment C20049F Owner's Manual and Operating Instructions

Ingersoll-Rand

Ingersoll-Rand BU7A Product Maintenance Information

1st-Relief

1st-Relief VERSACHOCK manual

Ingersoll-Rand

Ingersoll-Rand Force 5i Series Product Maintenance Information

Dover

Dover TWG Tulsa RUFNEK 80 DESIGN 001 Series Service manual

Huchez

Huchez SVERO MOTORBOX 300 CD 5 instruction manual