4 Configuration Instructions

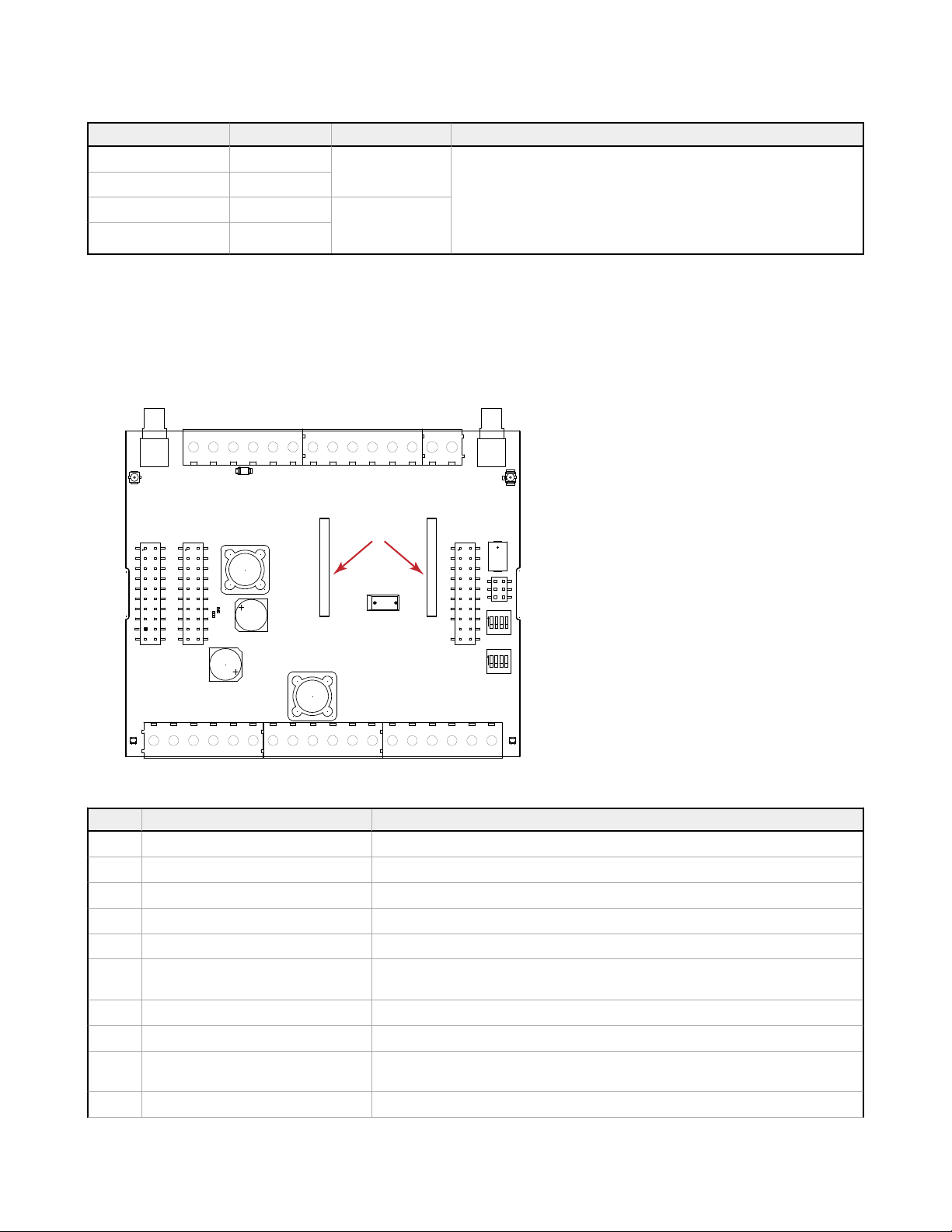

4.1 DXM100-A Configuration

Use the DXM Configuration Software to customize the configuration of the controller. Select the DXM100-A model when

using the configuration software.

To configure the DXM-100Ax, connect the DXM's USB to a computer. When the USB cable is plugged into the DXM

Controller, the device is powered by the USB power. When the USB cable is unplugged, the device resets itself and is

powered by the connected battery.

The software allows the user to define parameters for the DXM, then saves the configuration in an XML file on the PC. After

the configuration file is saved, upload the XML configuration file to the DXM for operation. There are several example

configuration files available in our Configuration Library at http://bannerengineering.com/dekconfig. This quick start guide

outlines the basic operations to set up a DXM using the configuration software. For a more comprehensive explanation of

features, refer to the software Instruction Manual (p/n 209933).

For a complete list of all associated product documentation, refer to your model's instruction manual.

The DXM100-A kit has operating limitations based on the storage capacity of the 12 V lithium iron phosphate battery (5.5

Ah), the 5 W solar panel (0.29 A maximum) and the days of autonomy desired. The main power consumption contributors

are:

• Cellular push interval, which should be set to 15 minutes or longer (use the Sample Count parameter for greater

granularity)

• RS485 communications of external Modbus devices using switched power

• Poor cellular signal strength and/or radio signal strength, creating multiple retry attempts.

Efficient operations include:

• DC Latch operations

• SDI-12 operations

• I/O operations

• ISM radio network operations

Some example configuration that operate on less than 5 mA (on average), and operate using the 12 V battery (5.5 Ah)

without sun for over 20 days include:

• SDI-12 reading in 15-minute intervals

• Two DC latching outputs toggling every 5 minutes

• One temperature/humidity probe powered from 16 V switched power reading every 5 minutes

• ScriptBasic program controlling temperature/humidity power and reading, DC latching control

• Read rules operating every 5 to 15 minutes for solar charging parameters and SDI-12 data

• Cellular push every 15 minutes, sampling every 5 minutes, for 16 Local Registers

• ISM radio devices operating at 0.25 W transmit power mode (default radio transmit power is 1 W)

Verify the battery consumption. When creating custom configurations, measure the current draw on the battery. Load the

DXM100-A device configuration and measure the average current draw over two or three cellular pushes. A meter in series

with the battery may cause the device to brown out if the battery is not fully charged.

4.2 Introduction to Traditional Setup Mode

This section will walk you through the traditional method of setting up the DXM Configuration Software and communicating

with a connected DXM device. Version 4 of the configuration software supports multiple DXM device models, each of which

incorporates different features.

As of DXM Configuration Software v4.10.28, the Simple Setup procedure is only available with the DXM100, DXM700,

DXM1000, DXM1200, and DXM1500 models.

As soon as a DXM model is connected to your computer, the software automatically detects the correct model and loads the

appropriate screens. You may also manually select which model of DXM you are configuring if you intend to create a

configuration file without connecting a device. This ensures that the interface and the configuration file use the correct

features.

Not all screens are available for all models. To change to another model of DXM, go to the Connect to DXM screen and use

the drop-down list to select another model. If the active configuration is incompatible with the selected model, you will be

prompted to either proceed and wipe out the active configuration or cancel the model change and preserve the configuration.

DXM Enclosure Kit (DEK) Series

10 www.bannerengineering.com - Tel: + 1 888 373 6767