·4 ·

I. SAFETY PRECAUTIONS

Indicate a possibility of invalid warranty and personal

or equipment damage if instructions are not followed.

Please pay special attention to the followings:

1. Strictly set the engine according to the regulated power on the owner's

manual. Do not overload, overspeed the engine or run it with low load

and at low speed in a long time.

2. Use specified grade of gasoline. The fuel should be fully deposited

and filtrated before use. Keep clean the fuel filler, change the oil

periodically.

3. Periodically check the installation, connection and the degree of

tightness of the xed bolt. Tighten it if necessary.

4. Periodically clean the element of the air cleaner, change it when

necessary.

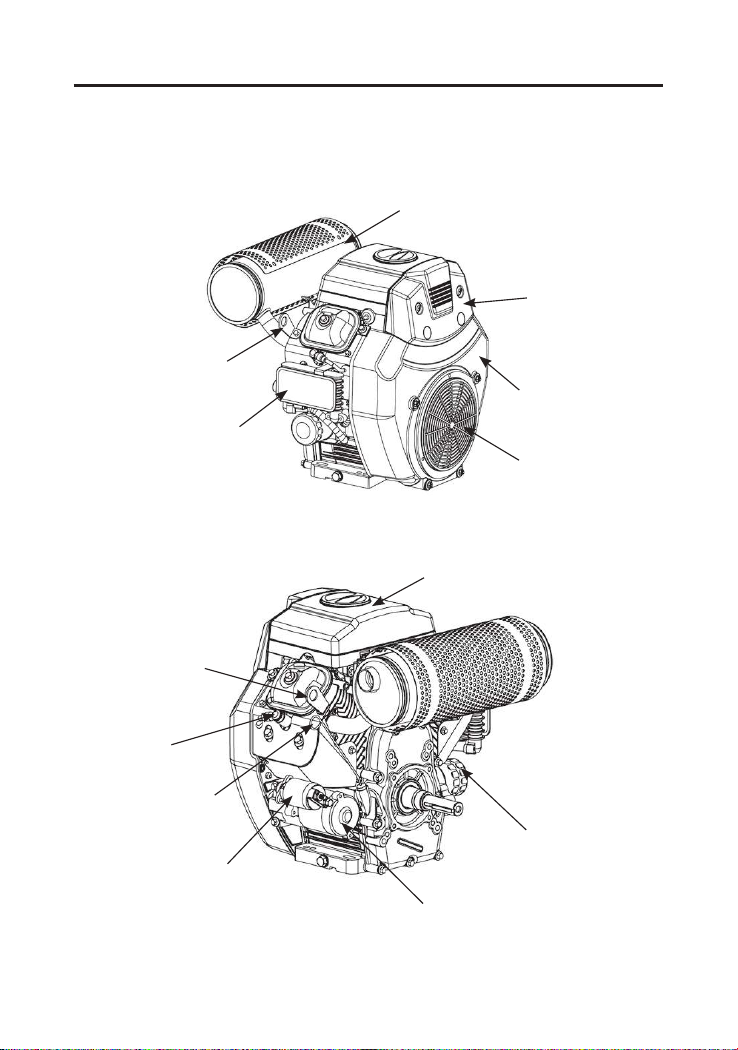

5. The engine is air-cooled, so clean the radiator, fan cover and fan in

time in order to make the engine cool normally.

6. The operator should be familiar with the working principle and

structure of the gasoline engine, knowing how to make an emergent

stop and the operation of all controlling parts. Any one without

training is forbidden to operate the engine. Keep periodical

maintenance. Solve problems in time. Do not run the engine in spite

of malfunction.

7. Running the engine in a well -ventilated place, keep it at least one

meter away from building walls or other equipments, keep away from

SAFETY PRECAUTIONS