Harmonic Drive MMA Series User manual

Flat Hollow Shaft AC Servo Motors

compatible with Mitsubishi Electric

MELSERVO-J4 series

MMA s eries manual

ISO14001

ISO9001

Introduction

Introduction

Thank you for purchasing our MMA series AC servo motor.

Incorrect handling or improper use of this product may result in unexpected accidents or a shorter

product life. Read this manual carefully and use the product correctly so that the product can be used

safely for many years.

The information contained in this manual is subject to change without notice.

Company names and product names in this document are generally registered trademarks or

trademarks of their respective companies.

Keep this manual in a convenient location and refer to it whenever necessary in operating or

maintaining the product.

The end user of the product should have a copy of this manual.

SAFETY GUIDE

1

SAFETY GUIDE

To use this product safely and correctly, be sure to read the SAFETY GUIDE and other parts of this

document carefully and fully understand the information provided herein before using the product.

NOTATION

Important safety information you must note is provided herein. Be sure to observe these instructions.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious personal injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate personal injury and/or damage to the equipment.

Indicates what should be performed or avoided to prevent non-operation or

malfunction of the product or negative effects on its performance or function.

LIMITATION OF APPLICATIONS

The equipment listed in this document may not be used for the applications listed below:

・Space equipment

・Aircraft, aeronautic equipment

・Nuclear equipment

・Household apparatus

・Vacuum equipment

・Automobile, automotive parts

・Amusement equipment, sport equipment, game machines

・Machines or devices acting directly on the human body

・Instruments or devices to transport or carry people

・Apparatus or devices used in special environments

If the above list includes your intended application for our products, please consult us.

If this product is utilized in any facility in which human life is

at stake or that may incur material losses, install safety

devices so that accidents do not occur even when the output

control is disabled due to damage.

WARNING

CAUTION

CAUTION

SAFETY GUIDE

2

SAFETY NOTE

ITEMS YOU SHOULD NOTE WHEN USING THE MOTOR

CAUTIONS RELATED TO THE DESIGN

Always use the motor under the specified conditions:

The motor is designed to be used indoors. Observe the following conditions:

・Ambient temperature: 0 to 40 ℃

・Ambient humidity: 20 to 80 % RH (no condensation)

・Vibration: Max. 25 m/s2

・No contamination by water or oil

・No corrosive or explosive gas

Always follow the instructions in the related manuals to

install the motor in the equipment.

・Follow the instructions in the manual to ensure that the center of the motor

is aligned with the center of the paired unit.

・Improper alignment may cause vibration or damage to the output shaft.

OPERATIONAL PRECAUTIONS

Do not exceed the allowable torque.

・Do not apply a torque exceeding the maximum torque.

・Be aware that, if arms directly attached to the output shaft are hit, the output

shaft may become uncontrollable.

Never connect cables directly to a power supply socket.

・Motors must be connected to the proper servo amplifier to operate.

・Do not connect a commercial power supply directly to the motor. Failure to

observe this caution may damage the motor, possibly resulting in a fire.

Do not apply impacts and shocks to the motor.

・Do not tap the motor with a hammer or other tool because an encoder is

connected directly to the motor.

・If the encoder is damaged, the motor may become uncontrollable.

Do not pull the cables.

・Pulling the cables can damage connectors, causing the motor to become

uncontrollable.

CAUTION

WARNING

SAFETY GUIDE

3

ITEMS YOU SHOULD NOTE WHEN USING THE SERVO AMPLIFIER

Read the related manuals to ensure safe operation. For details on the related

manuals, refer to the [Related manual] (P6).

Be sure to read the “MELSERVO-J4 SERIES AC SERVO SAFETY GUIDE”, which

comes together with the servo amplifier, before using this product.

OPERATIONAL PRECAUTIONS

Never change any wiring while the power is active.

Make sure that the power is not active before servicing the products. Failure to

observe this caution may result in an electric shock or uncontrollable operation.

Do not touch the terminals for at least 5 minutes after turning

OFF the power supply.

・Even after the power supply is turned OFF, electric charge remains in the

servo amplifier. In order to prevent electric shock, perform inspections 5

minutes or more after the power supply is turned OFF.

・When installing, make sure that the inner electronic components are hard to

reach.

DISPOSAL

The motor and servo amplifier must be disposed of as

industrial waste.

When disposing of the motor or servo amplifier, disassemble it as much as

possible, separate parts according to the material description (if indicated), and

dispose of them as industrial waste.

WARNING

CAUTION

4

Contents

SAFETY GUIDE .................................................................................................. 1

NOTATION .............................................................................................................1

LIMITATION OF APPLICATIONS............................................................................1

SAFETY NOTE ......................................................................................................2

Contents .............................................................................................................. 4

Related manual .................................................................................................... 6

Conformance to overseas standards..................................................................... 6

Chapter 1 Outlines

1-1 Outlines ....................................................................................................... 1-1

1-2 Combinations with servo amplifier and extension cables............................. 1-2

1-3 Model ......................................................................................................... 1-4

1-4 Specifications............................................................................................... 1-5

1-5 Holding brake............................................................................................... 1-7

1-6 External dimensions..................................................................................... 1-8

1-7 Mechanical accuracy.................................................................................. 1-12

1-8 Detector specifications (Absolute encoder)................................................ 1-13

1-9 Rotation direction ....................................................................................... 1-14

1-10 Shock resistance...................................................................................... 1-15

1-11 Resistance to vibration ............................................................................. 1-16

1-12 Operable range ........................................................................................ 1-17

1-13 Cable specifications ................................................................................. 1-19

Motor cable specifications .................................................................................1-19

Encoder cable specifications .............................................................................1-20

Chapter 2 Selection guidelines

2-1 MMA series selection ................................................................................... 2-1

Allowable load inertia moment.............................................................................2-1

2-2 Verifying and examining load weights .......................................................... 2-2

2-3 Examining the operating status.................................................................... 2-3

Examining motor rotational speed .......................................................................2-3

Calculating and examining load inertia moment...................................................2-3

Load torque calculation .......................................................................................2-4

Acceleration time and deceleration time ..............................................................2-5

Evaluating effective torque and average rotational speed....................................2-6

Contents

5

Chapter 3 Installing the motor

3-1 Receiving inspection .................................................................................... 3-1

Inspection procedure...........................................................................................3-1

3-2 Notices on handling...................................................................................... 3-2

Installation and transmission torque ....................................................................3-2

Precautions on installation...................................................................................3-3

Use of positioning pins ........................................................................................3-4

Motor material .....................................................................................................3-4

3-3 Location and installation............................................................................... 3-5

Environment of location.......................................................................................3-5

Installation ...........................................................................................................3-6

Chapter 4 Options

4-1 Options ....................................................................................................... 4-1

Cable taken out from side face (option code: Y) ..................................................4-1

Extension cables .................................................................................................4-2

Appendix

A-1 Unit conversion............................................................................................ 5-1

A-2 Calculating inertia moment .......................................................................... 5-3

Formulas of mass and inertia moment.................................................................5-3

Inertia moment of cylinder ...................................................................................5-5

Related manual

6

Related manual

The related manual is listed below. Use it as a reference as necessary.

Title

Document No.

Description

Obtaining method

MR-J4-_B_(-RJ)

SERVO AMPLIFIER

INSTRUCTION

MANUAL

SH-030098

The information on how to use the

"MR-J4-□B-S033" servo amplifier in

combination with the MMA series is

provided.

Can be downloaded from the

Mitsubishi Electric website.

MR-J4-□B-S033

PRODUCT

SPECIFICATIONS

BCN-B72000-090

The precautions for combining the

"MR-J4-□B-S033" servo amplifier

with the MMA series are provided.

Obtain by giving the manual

number to the supplier or

store where you purchased

your servo amplifier.

Conformance to overseas standards

The MMA series motors are compliant with the following overseas standards.

UL standards

UL1004-1, UL1004-6 (File No. E243316)

CSA standards

C22.2 No.100

European Low Voltage EC Directives

EN60034-1, EN60034-5

UL nameplate sticker

According to the UL1004-1, UL1004-6 (File No. E243316) standards, the following specifications are

indicated on the MMA series motors.

Nameplate

field

Description

(1)

Output [W] at point A on the graph below

(2)

Voltage [V] between motor wires at point A on the

graph below

(3)

Allowable continuous current [A]

(4)

Rotational speed at point A on the graph below [r/min]

(5)

Current fundamental frequency [Hz] at point A on the

graph below

(6)

Allowable ambient temperature [

℃

]

(7)

Number of phases

(1)

(2)

(3)

(4)

(5)

(6)

(7)

UL nameplate sticker

Rated torque

A

Motion range during

acceleration and deceleration

Aluminum radiation plate: 320×320×16 [mm]

Continuous motion

range

Rotation speed [r/min]

Torque [N

・

m]

Conformance to overseas standards

7

The values displayed on the name plate for each model are shown below.

Model

Item

MMAB09

(1) Output at point A W 251

(2) Voltage at point A V 136

(3) Allowable continuous current

A

2.5

(4) Speed at point A

r/min

3000

(5) Frequency at point A

Hz

250

(6) Allowable ambient temperature

℃

40

(7) Number of phases

-

3

Model

Item

MMAB12

(1) Output at point A

W

406

(2) Voltage at point A

V

129

(3) Allowable continuous current A 4.2

(4) Speed at point A r/min

2500

(5) Frequency at point A

Hz

208

(6) Allowable ambient temperature ℃40

(7) Number of phases - 3

Model

Item

MMAB15

(1) Output at point A W 754

(2) Voltage at point A

V

125

(3) Allowable continuous current

A

7.8

(4) Speed at point A

r/min

2000

(5) Frequency at point A

Hz

167

(6) Allowable ambient temperature

℃

40

(7) Number of phases

-

3

Model

Item MMAA21A

(1) Output at point A

W

1320

(2) Voltage at point A

V

100

(3) Allowable continuous current A 20.0

(4) Speed at point A r/min

1000

(5) Frequency at point A

Hz

133

(6) Allowable ambient temperature ℃40

(7) Number of phases

-

3

Conformance to overseas standards

8

Chapter 1

Outlines

This chapter explains the features, functions and specifications of the motor.

1-1 Outlines ·············································································· 1-1

1-2 Combinations with servo amplifier and extension cables················ 1-2

1-3 Model················································································· 1-4

1-4 Specifications······································································· 1-5

1-5 Holding brake······································································· 1-7

1-6 External dimensions ······························································ 1-8

1-7 Mechanical accuracy ··························································· 1-12

1-8 Detector specifications (Absolute encoder) ······························· 1-13

1-9 Rotation direction································································ 1-14

1-10 Shock resistance······························································· 1-15

1-11 Resistance to vibration ······················································· 1-16

1-12 Operable range································································· 1-17

1-13 Cable specifications··························································· 1-19

1-1 Outlines

1-1

Outlines

1

Appe

1-1 Outlines

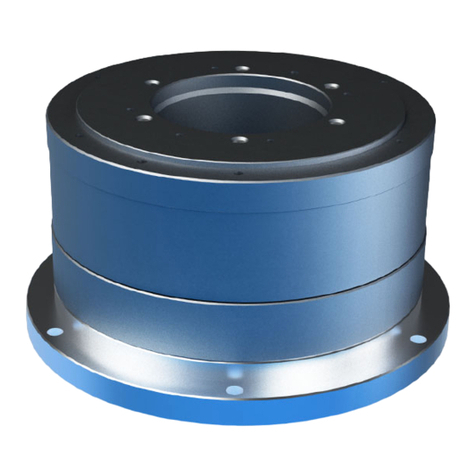

All MMA series AC servo motor models feature a hollow bore structure and compact design and they

can be controlled with the SSCNETIII/H when combined with the Mitsubishi Electric AC servo amplifier

MELSERVO-J4 series. Wires, pipes, ball screws, or laser beams go through the hollow bore depending

on the mechanism design required for your applications.

MMA series AC servo motors play an important role in driving various factory automation (FA)

equipment, such as robot joints, alignment mechanisms for semi-conductors and LCD devices, ATC of

metal-cutting machines, printing machine roller drives, etc.

Comes standard with a 17-bit magnetic absolute encoder

The MMA series AC servo motors are equipped with a highly reliable 17-bit magnetic absolute

encoder* with safety function. The serial communication requires fewer cables and provides not only a

multi revolution counting function which is a must-have feature of motors, but it also has an internal

backup battery to retain absolute positions even when the encoder cable is disconnected briefly.

The encoder also constantly compares two sets of detected angles. If any abnormality is found, the

encoder's built-in failsafe function outputs a signal to the host system. This helps you build a safe

system.

◆Supporting a combination with MELSERVO-J4 amplifiers

Combination with Mitsubishi Electric MELSERVO-J4 amplifiers is now available. It can be controlled

using the SSCNETIII/H high-speed motion network.

1-2 Combinations with servo amplifier and extension cables

1-2

Outlines

1

Appe

1-2

Combinations with servo amplifier and extension cables

The combinations of MMA motors, MR-J4-_B-S033 servo amplifiers, and extension cables are as

follows:

MMAB09 MMAB12 MMAB15 MMAA21A

SSCNETIII/H type

MR-J4-

60B-S033

MR-J4-

100B-S033

MR-J4-

200B-S033

MR-J4-

500B-S033

Extension

cables

(option)

Motor wire EWD-MB**-A06-TMC-M EWD-MB**-D09-

TMC-M2

Encoder wire

Note 1

MR-EKCBL□M-H (Long flex life product)

or

MR-EKCBL□M-L (Standard product)

** and □in the extension cable model indicates the cable length. See below for details.

Motor wire : 02 = 2 m, 05 = 5 m, 10 = 10 m

Encoder wire : 2 = 2 m, 5 = 5 m, 10 = 10 m

For details on encoder wires, contact Mitsubishi Electric customer support.

Note 1: When connecting the encoder wires MR-EKCBL□M-* and MMAA21A, please use the encoder

connector converter cable that comes with the motor.

The MR-J4-_B-S033 servo amplifier parameters (PA17: Motor series, PA18: Motor type) are set for the

above combination. For parameters not covered in this section, refer to [Related manual] (P6).

1-2 Combinations with servo amplifier and extension cables

1-3

Outlines

1

Appe

No.

Abbreviation

(Note) Name and function

Default

value

(units)

Setting

range

PA17

*MSR

Servo motor series setting

When driving MMA motor, select the motor type with [Pr.PA17] and

[Pr.PA18].

Set at the same time as [Pr.PA18].

For the setting values, refer to the following table.

0000h

0000h

to

FFFFh

PA18

*MTY

Motor type setting

When driving MMA motor, select the motor type with [Pr.PA17] and

[Pr.PA18].

Set at the same time as [Pr.PA17].

For the setting values, refer to the following table.

Motor series Combined servo

amplifier

Parameters

[Pr.PA18]

set value

MMAB09 MR-J4-60B-S033 09C9

MMAB12 MR-J4-100B-S033 0CC9

MMAB15 MR-J4-200B-S033 0FC9

MMAA21A MR-J4-500B-S033 15C9

0000h 0000h

to

FFFFh

Note: * The set values become effective when the servo amplifier power supply is connected.

Motor series

Parameters

[Pr.PA17]

set value

MMAB09

00E1

MMAB12

MMAB15

MMAA21A

1-3 Model

1-4

Outlines

1

Appe

1-3 Model

The model names for the MMA series motors and how to read the symbols are explained below.

Model example:

MMA B 09 A 200 - 16 S17b A - C Y - SP

(1) (2) (3) (4) (5) - (6) (7) (8) - (9) (10) - (11)

(1) Model: MMA series AC servo motor

(2) Motor version symbol

A Model No. 21A

B Model Nos. 09, 12, 15

(3) Model Nos.: 09, 12, 15, 21A

(4) Brake

A Without brake

B With brake

(5) Applicable servo amplifier input voltage

200 200 V

(6) Encoder format

16 Conforming to Mitsubishi format, transmission rate: 2.5 Mbps, 1-on-1 connection

(7) Encoder type, resolution

S17b 17-bit multi-turn absolute encoder, 131072 pulses/revolution

(8) Encoder phase angle: Phase difference between the voltage induced in motor phase U and

absolute origin

A 0 degree

(9) Connector specification

C With standard connector

N Without connector

(10) Option symbol

Y Cable taken out from the side

(It is not available for model No. 21A.)

(11) Special specification

No description Standard product

SP Special specification product

1-4 Specifications

1-5

Outlines

1

Appe

1-4 Specifications

The specifications of the MMA series motors are shown below.

Model

Item MMAB09 MMAB12 MMAB15 MMAA21A

Compatible servo amplifier MR-J4-60B-

S033

MR-J4-100B-

S033

MR-J4-200B-

S033

MR-J4-500B-

S033

Input power supply V 200 200 200 200

Rated output W 251 406 754 1320

Maximum momentary

torque*1

N

・

m 3.0 6.6 13 45

kgf

・

m 0.31 0.67 1.33 4.59

Rated torque*1*2 N

・

m 0.80 1.55 3.60 12.6

kgf

・

m 0.082 0.158 0.367 1.29

Max. rotational speed*1 r/min 5600 4800 4000 3000

Rated rotational speed r/min 3000 2500 2000 1000

Instantaneous max. current*1 A 8.9 18 29 75

Rated current*1*2 A 2.5 4.2 7.8 20.0

Torque constant*1 N

・

m/A 0.41 0.44 0.54 0.72

kgf

・

m/A 0.042 0.045 0.055 0.073

EMF constant*3 V/(r/min) 0.043 0.046 0.057 0.075

Phase resistance (20

℃

) Ω1.2 0.33 0.19 0.028

Phase inductance mH 3.0 1.4 1.2 0.29

Inertia moment

Values in

parentheses are for

models with a

brake.

GD2/4 ×10-4 kg

・

m21.78 6.45 15.8 125

(2.16) (6.83) (19.8) (141)

J ×10-4kgf

・

cm

・

s218.2 65.8 161 1280

(22.1) (69.7) (202) (1444)

Allowable radial load

(when stationary)

N 800 1200 2400 4500

kgf 81.6 122 245 459

Allowable axial load

(when stationary)

N 2400 3600 5000 14000

kgf 245 367 510 1429

Rated radial load

(at rated rotational speed)

N 185 233 530 1040

kgf 18.9 23.8 54.1 106.1

Rated axial load

(at rated rotational speed)

N 105 130 180 880

kgf 10.7 13.3 18.4 89.8

Encoder type Absolute encoder

Encoder resolution

Single-turn

detector

217 (131072)

Multi-turn

detector

*4

216 (65536)

Mass

Values in parentheses are for

models with a brake.

kg 2.0 3.4 5.5 17.5

(2.1) (3.8) (6.2) (19.7)

1-4 Specifications

1-6

Outlines

1

Appe

Environmental conditions*6

Operating temperature: 0 to 40 ℃/Storage temperature: -20 to 60 ℃

Service/storage humidity: 20 to 80 % RH (no condensation)

Resistance to vibration: 25 m/s2 (frequency: 10 to 400 Hz)

Resistance to impact: 300 m/s2 *5

No dust, metal powder, corrosive gas, inflammable gas, or oil mist.

To be used indoors, no direct sunlight.

Altitude: less than 1000 m above sea level

Motor insulation

Insulation resistance: 100 MΩ or more (500 VDC insulation tester)

Dielectric strength: 1500 VAC/1 min

Insulation class: A

Mounting direction Can be installed in any direction.

Protection structure Totally enclosed self-cooled type (IP54)

The table above shows the typical values.

*1: This displays representative characteristics for when combined with a dedicated amplifier (driven using an ideal

sine wave).

*2: Values after the temperature has risen and saturated when installed on the following aluminum radiation plates.

MMAB09 : 350×350×18 [mm]

MMAB12 : 400×400×20 [mm]

MMAB15 : 500×500×25 [mm]

MMAA21A : 650×650×30 [mm]

*3: Value of the phase-induced voltage constant multiplied by 3.

*4: The multi-turn detector range is -32768 to 32767.

*5: For testing conditions, refer to [1-10 Shock resistance] (P1-15) and [1-11 Resistance to vibration] (P1-16).

Motor operation is not guaranteed in applications where vibrations and impacts are continuously applied for a

long period of time.

*6: For details, refer to [3-3 Location and installation] (P3-5).

1-5 Holding brake

1-7

Outlines

1

Appe

1-5 Holding brake

The brakes equipped on MMA series motors are used to hold the motor shaft in place when the power

is cut off. With some models (MMAB09, 12), the motor's built-in circuit controls the voltage supplied to

the brake in order to reduce the power consumption while the brake is actuated.

Always use a DC power supply that has a proper brake excitation voltage and is capable of outputting

enough current during suction.

Specifications

Model

Item

MMAB09 MMAB12 MMAB15 MMAA21A

Type Dry non-excitation actuation type

Power-saving control Yes No

Brake excitation voltage V 24 VDC ± 10 % (no polarity) *1

Current consumption

during suction

A 0.8*2 0.8*2 0.7 0.9

Current consumption

during holding

A 0.3 0.3 0.7 0.9

Holding torque N

・

m 1.0 2.0 4.0 15

kgf·m 0.102 0.204 0.408 1.53

Allowable number of

normal brakings

*3

100000 times

Allowable number of

emergency stops

*4

200 times

*1: The power supply for the brake is not included in the product. Use a power supply that is capable of outputting

enough current during brake suction.

*2: The duration the current is supplied during suction is 0.5 second or less for the power supply of 24 VDC ± 10 %.

*3: When the brake is activated at the rotational speed of 150 r/min or less.

*4: When the brake is activated at the rotational speed of 3000 r/min, provided that the inertia moment of load is 3

times or less than that of the motor.

The holding brake cannot be used for deceleration.

Do not use the holding brake more than the allowable number of normal

brakings (100000 times at the rotational speed of 150 r/min or less) or allowable

number of emergency stops (200 times at the rotational speed of 3000 r/min,

provided that the inertia moment of load is 3 times or less than that of the

motor).

Exceeding the allowable number of normal brakings and allowable number of

emergency stops may cause the holding torque to decrease and consequently

become unusable as a brake.

WARNING

1-6 External dimensions

1-8

Outlines

1

Appe

1-6 External dimensions

The external dimensions of the MMA series motors are shown below.

MMAB09 (with/without brake)

Unit [mm] (third angle projection)

Note: For details on external dimensions, see our illustrated specifications.

Tolerances may vary with the product manufacturing method (foundry piece, machine-finished good).

Contact us for the differential range of the size that is not described.

Encoder cable

Motor cable

(Cable outer diameter:

φ5.6)

(Cable outer diameter: φ7.7)

Motor connector

Encoder connector

Housing

Pin contact

Pin contact

Housing

Tab contact

Clamp

R0.4 or less

R0.4 or less

15 or less

1-6 External dimensions

1-9

Outlines

1

Appe

MMAB12 (with/without brake)

Unit [mm] (third angle projection)

Note: For details on external dimensions, see our illustrated specifications.

Tolerances may vary with the product manufacturing method (foundry piece, machine-finished good).

Contact us for the differential range of the size that is not described.

Encoder cable

Motor cable

Motor connector

Encoder connector

Housing

Tab contact

Clamp

Housing

Pin contact

Pin contact

R0.4 or less

R0.4 or less

15 or less

(Cable outer diameter: φ7.7)

(Cable outer diameter: φ7.7)

This manual suits for next models

4

Table of contents

Other Harmonic Drive Engine manuals

Popular Engine manuals by other brands

Harbor Freight Tools

Harbor Freight Tools Chicago Electric 40132 Assembly and operating instructions

Kohler

Kohler Courage SV470 owner's manual

Engine distributors

Engine distributors CSG 637 Operator's handbook

Volvo Penta

Volvo Penta KAD/KAMD44P Operator's manual

Kohler

Kohler KD83V16 Service and repair manual

INOXPAN

INOXPAN Pando V2350e installation manual