Manual 2100-516H

Page 3 of 19

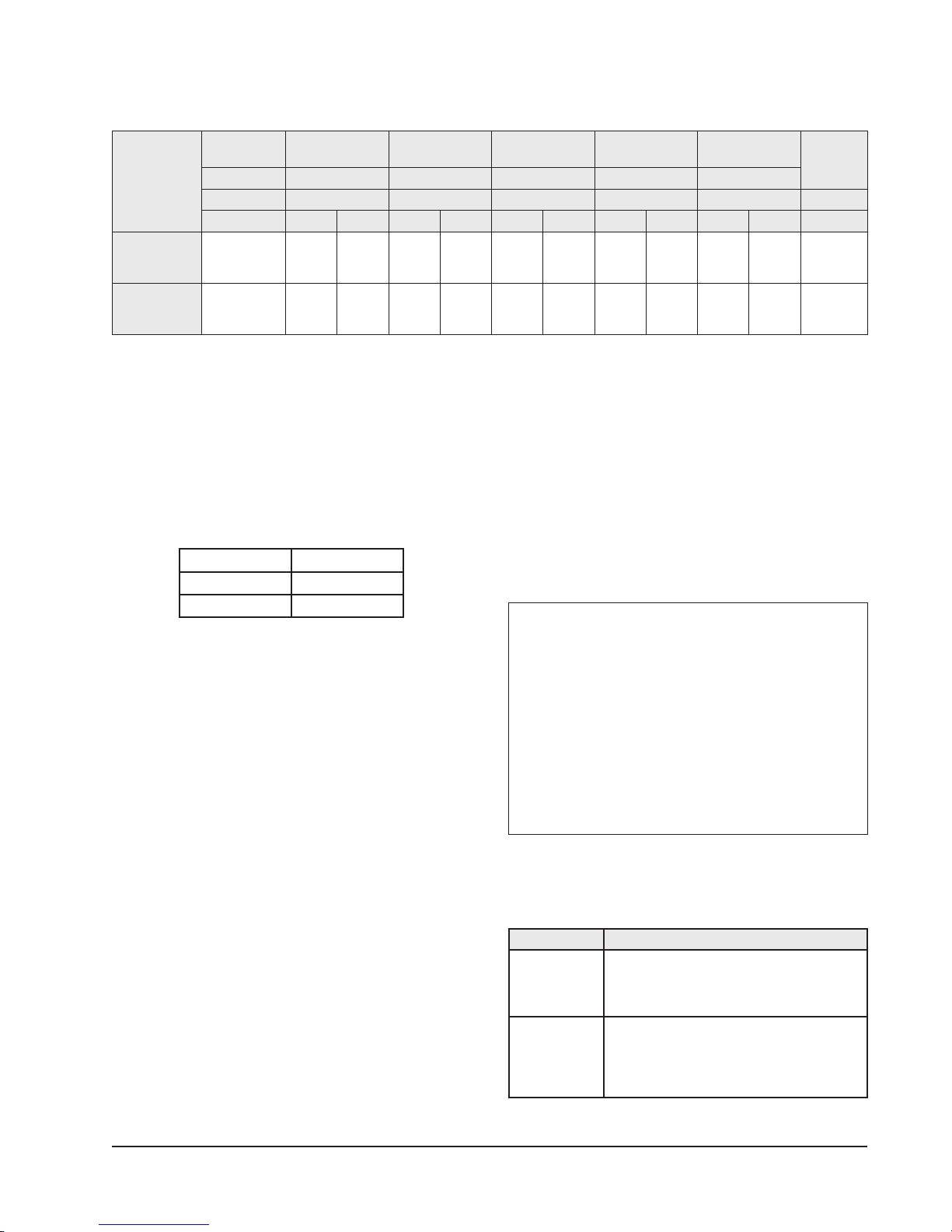

TABLE 1

DIAGRAM TO USE WITH UNIT AND VENTS

System

Vent None CRV, ERV, MFAD CRVMWH-3

CHCRV-5 EIFM

Economizer ECONWM* CS2000A*

Vent Code X R, M, V, P C E T, W, S

Thermostat Programmable Programmable Programmable Programmable Programmable All

Model Series No Yes No Yes No Yes No Yes No Yes

Heat Pump S**H

T**H

W**H 1 1 3 & 4 2 15 14 N/A 5 N/A 13 11

Heat Pump with

Dehumidication

S**H*D

T**H*D

W**H*D 7 6 9 & 10 8 N/A 14 N/A 12 N/A 13 N/A

NOTE: Thevoltageshouldbemeasuredattheeldpower

connectionpointintheunitandwhiletheunit

isoperatingatfullload(maximumamperage

operatingcondition).

WIRING – LOW VOLTAGE WIRING

230/208V, 1 phase and 3 phase equipment dual primary

voltage transformers. All equipment leaves the factory

wired on 240V tap. For 208V operation, reconnect

from 240V to 208V tap. The acceptable operating

voltage range for the 240V and 208V taps are:

TABLE 3

WALL THERMOSTAT

TABLE 2

OPERATING VOLTAGE RANGE

An 18 gauge copper, color-coded thermostat cable is

recommended. The connection points are shown in this

Manual. See Table above.

Low Voltage Connection

These units use a grounded 24-volt AC low voltage

circuit.

The “R” terminal is the hot terminal and the “C”

terminal is grounded.

“G” terminal is the faninput.

“Y” terminal is the compressorinput.

“B” terminal is the reversingvalveinput. The reversing

valve must be energized for heating mode.

“R” terminal is the 24 VAC hot.

“C” terminal is the 24 VAC grounded.

LOW VOLTAGE CONNECTIONS

FOR DDC CONTROL

Fan Only Energize G

Cooling Mode Energize Y, G

Heat Pump Heating Energize Y, G, B

2nd Stage Heating

Energize G, W2, Y, B

w/Heat Pump (if employed)

Ventilation Energize G, O1

Emergency Heat

Energize B, W2, E, G

Dehumidication EnergizeW3

“L” terminal is compressorlockoutoutput. This

terminal is activated on a high or low pressure trip by the

electronic heat pump control. This is a 24 VAC output.

“W2” terminal is second stage heat (if equipped).

“O1” terminal is the ventilationinput. This terminal

energizes any factory installed ventilation option.

“E” terminal is the emergencyheatinput. This terminal

energizes the emergency heat relay.

“W3” terminal is the dehumidicationinput. This

terminal energizes compressor, blower and three-way

valve.

TAP RANGE

240V 253 – 216

208V 220 – 187

Part Number Predominate Features

8403-058

(TH5220D1151)

2 stage Cool, 2 stage Heat - Conventional

1 stage Cool, 2 stage Heat - Heat Pump

Electronic Non-Programmable

Auto or Manual changeover

8403-060

(1120-445)

3 stage Cool; 3 stage Heat

Programmable/Non-Programmable Electronic

HP or Conventional

Auto or Manual changeover

Dehumidication Output