Barkell THERM-X HRFL II Instruction manual

THERM-X

HRFL II

Installation

Operation &

Maintenance

Manual

P02-0329-1117-UK

BARKELL

AIR HANDLING UNITS

2

1. BEFORE YOU BEGIN

Symbol Meaning

Before installation of the unit, properly read the manual Safe operation of the ventilation

unit. Here you can nd the whole manual on how to use this product safely and properly.

Warning or notice

Important instructions

Practical tips and information

More technical information

Link to another part of the manual

ATTENTION!

IMPORTANT NOTICE!

YOU WILL NEED

TECHNICAL INFORMATION

This manual contains important instructions for the safe installation of the ventilation unit. Before

installation of the ventilation unit, please properly read all the instructions below and follow them!

The manufacturer reserves the right to make changes, including to the technical documentation without

prior notice. Please store this manual for future use, the service manual is a part of the product.

EC CONFORMITY DECLARATION

The product has been designed, manufactured, placed on the market, complies with all applicable regula-

tions and is in compliance with the requirements of the directives of the European Parliament and the Coun-

cil, including amendments to the proposal, under which it was classified.

When handled/operated under normal conditions and in accordance with the instruction manual, the

installation and operation of this product is safe. The harmonized European standards referred to in the

relevant EC declaration of conformity have been applied in the assessment.

For the current and full version of the EC Declaration of Conformity, please refer to the document

package provided at the time of order confirmation.

3

2. UNPACKING

2.1 CHECK THE DELIVERED UNIT 2.2 UNPACK THE UNIT

IMPORTANT NOTICE!

IMPORTANT NOTICE!

● Immediatelyafterreceivingthedelivery,make

anvisualinspectionoftheproduct.Incaseof

visible packaging damage note the damage in

thedeliverynoteandinformthemanufacturer.

● Check whether the delivered type and quanti-

tyof theproducts matchesthe order.In case

of disagreement, do not unpack the unit and

report this to Barkell.

● Ensure that any ancillary items are included.

Thesewillnormallybepackedtogetherwiththe

unitsor inthecaseoflargeitems suchasat-

tenuatorsorducttransitionssuppliedonasep-

aratepallet.

● After unpacking, check whether the unit and

otherpartshavebeensuppliedin goodcondi-

tion.Ifindoubt,contactBarkellaftersalesde-

partmentimmediately.

● All claims for damage or missing goods must

beconrmedinwritingin2workingdaysupon

receiptoftheunitsotherwisetherighttoclaim

willbelost.

● Nevertrytoputadamagedventilationunitinto

operation.

● Ifthe unitis notunpacked immediatelyafter

delivery, it has to be stored in a dry interior

atanambienttemperaturebetween+5°Cand

+35°C.

● Themethodofpackingisforproductstobeloadedonto

pallets(max.2unitsinheight)andfastenedtothemby

means of bolts. A protective lm is added to minimize

wateranddustingress.

● Ensure the securing bolts are unfastened before at-

tempting to remove the unit from the pallet otherwise

permanentdamageofthesupportingbracketsmightoc-

cur.

● Ifthe ventilation unit was transportedattemperatures

below 0°C, it is necessary to leave it in the operating

environmentforatleast2hourswithoutturningonafter

unpacking,fortemperaturecompensationinsidetheunit

tooccur.

This product has to be properly disposed of in accordance with

local laws, regulations and directives.

The product contains batteries, therefore these have to be

recycled or disposed of separately from household waste.

When the battery or product reaches the end of its durability,

contact the distributor or local authorities for information about

recycling options. Separate collection and recycling of your

product and its battery will help to protect natural resources

and ensures that the product will be recycled in such a way that

protects human health and the environment.

3

2.1 CONTRÔLEZ LA LIVRAISON

2. DEBALLAGE

• Lors de la livraison, contrôlez directement si

l'emballage du produit est intact. En cas

d'endommagent de l'emballage, prévenez le

transporteur. Si la réclamation n'est pas déclarée

à temps, une demande ultérieure ne sera plus

acceptée.

• Contrôlez si le type de produit livré correspond à

votre commande. En cas de constatation d'une

différence, ne déballez pas le récupérateur et

prévenez immédiatement le fournisseur.

• Après le déballage, contrôlez l'état des unités et

de tous ses éléments. En cas de doute, adressez-

vous au fournisseur.

• N'utilisez jamais une unité endommagée.

• Si vous ne déballez pas directement le

récupérateur après réception, il devra être

entreposé dans un endroit intérieur sec ayant une

température ambiante de +5 °C à +35 °C.

A LIRE ATTENTIVEMENT!

Tous les matériaux

d'emballage utilisés sont

écologiques et peuvent être

réutilisés ou recyclés.

Participez activement à la

protection de

l'environnement et assurez-

vous que les matériaux

d'emballage sont

convenablement revalorisés.

2.2 DEBALLEZ L'UNITE

• Si l'unité de ventilation a été exposée à des

températures inférieures à 0°C durant le

transport, laissez l'unité déballée à la

température ambiante durant au moins 2 heures

avant de la brancher, pour permettre

l'égalisation de la température dans l'unité de

ventilation.

A LIRE ATTENTIVEMENT!

PLATE BOX

PLATE BOX

1x

8m PLATE BOX

Notice complète

INSTALLATION

PLATE BOX… et PLATE BOX ELEC….

PLATE BOX

Numéro de notice France air

NTE: 1260 A

FR

3

2.1 CONTRÔLEZ LA LIVRAISON

2. DEBALLAGE

• Lors de la livraison, contrôlez directement si

l'emballage du produit est intact. En cas

d'endommagent de l'emballage, prévenez le

transporteur. Si la réclamation n'est pas déclarée

à temps, une demande ultérieure ne sera plus

acceptée.

• Contrôlez si le type de produit livré correspond à

votre commande. En cas de constatation d'une

différence, ne déballez pas le récupérateur et

prévenez immédiatement le fournisseur.

• Après le déballage, contrôlez l'état des unités et

de tous ses éléments. En cas de doute, adressez-

vous au fournisseur.

• N'utilisez jamais une unité endommagée.

• Si vous ne déballez pas directement le

récupérateur après réception, il devra être

entreposé dans un endroit intérieur sec ayant une

température ambiante de +5 °C à +35 °C.

A LIRE ATTENTIVEMENT!

Tous les matériaux

d'emballage utilisés sont

écologiques et peuvent être

réutilisés ou recyclés.

Participez activement à la

protection de

l'environnement et assurez-

vous que les matériaux

d'emballage sont

convenablement revalorisés.

2.2 DEBALLEZ L'UNITE

• Si l'unité de ventilation a été exposée à des

températures inférieures à 0°C durant le

transport, laissez l'unité déballée à la

température ambiante durant au moins 2 heures

avant de la brancher, pour permettre

l'égalisation de la température dans l'unité de

ventilation.

A LIRE ATTENTIVEMENT!

PLATE BOX

PLATE BOX

1x

8m PLATE BOX

Notice complète

INSTALLATION

PLATE BOX… et PLATE BOX ELEC….

PLATE BOX

Numéro de notice France air

NTE: 1260 A

FR

THERM-X

THERM-X HRFL2

THERM-X HRFL2

3

2.1 CONTRÔLEZ LA LIVRAISON

2. DEBALLAGE

• Lors de la livraison, contrôlez directement si

l'emballage du produit est intact. En cas

d'endommagent de l'emballage, prévenez le

transporteur. Si la réclamation n'est pas déclarée

à temps, une demande ultérieure ne sera plus

acceptée.

• Contrôlez si le type de produit livré correspond à

votre commande. En cas de constatation d'une

différence, ne déballez pas le récupérateur et

prévenez immédiatement le fournisseur.

• Après le déballage, contrôlez l'état des unités et

de tous ses éléments. En cas de doute, adressez-

vous au fournisseur.

• N'utilisez jamais une unité endommagée.

• Si vous ne déballez pas directement le

récupérateur après réception, il devra être

entreposé dans un endroit intérieur sec ayant une

température ambiante de +5 °C à +35 °C.

A LIRE ATTENTIVEMENT!

Tous les matériaux

d'emballage utilisés sont

écologiques et peuvent être

réutilisés ou recyclés.

Participez activement à la

protection de

l'environnement et assurez-

vous que les matériaux

d'emballage sont

convenablement revalorisés.

2.2 DEBALLEZ L'UNITE

• Si l'unité de ventilation a été exposée à des

températures inférieures à 0°C durant le

transport, laissez l'unité déballée à la

température ambiante durant au moins 2 heures

avant de la brancher, pour permettre

l'égalisation de la température dans l'unité de

ventilation.

A LIRE ATTENTIVEMENT!

PLATE BOX

PLATE BOX

1x

8m PLATE BOX

Notice complète

INSTALLATION

PLATE BOX… et PLATE BOX ELEC….

PLATE BOX

Numéro de notice France air

NTE: 1260 A

FR

3

2.1 CONTRÔLEZ LA LIVRAISON

2. DEBALLAGE

• Lors de la livraison, contrôlez directement si

l'emballage du produit est intact. En cas

d'endommagent de l'emballage, prévenez le

transporteur. Si la réclamation n'est pas déclarée

à temps, une demande ultérieure ne sera plus

acceptée.

• Contrôlez si le type de produit livré correspond à

votre commande. En cas de constatation d'une

différence, ne déballez pas le récupérateur et

prévenez immédiatement le fournisseur.

• Après le déballage, contrôlez l'état des unités et

de tous ses éléments. En cas de doute, adressez-

vous au fournisseur.

• N'utilisez jamais une unité endommagée.

• Si vous ne déballez pas directement le

récupérateur après réception, il devra être

entreposé dans un endroit intérieur sec ayant une

température ambiante de +5 °C à +35 °C.

A LIRE ATTENTIVEMENT!

Tous les matériaux

d'emballage utilisés sont

écologiques et peuvent être

réutilisés ou recyclés.

Participez activement à la

protection de

l'environnement et assurez-

vous que les matériaux

d'emballage sont

convenablement revalorisés.

2.2 DEBALLEZ L'UNITE

• Si l'unité de ventilation a été exposée à des

températures inférieures à 0°C durant le

transport, laissez l'unité déballée à la

température ambiante durant au moins 2 heures

avant de la brancher, pour permettre

l'égalisation de la température dans l'unité de

ventilation.

A LIRE ATTENTIVEMENT!

PLATE BOX

PLATE BOX

1x

8m PLATE BOX

Notice complète

INSTALLATION

PLATE BOX… et PLATE BOX ELEC….

PLATE BOX

Numéro de notice France air

NTE: 1260 A

FR

3

2.1 CONTRÔLEZ LA LIVRAISON

2. DEBALLAGE

• Lors de la livraison, contrôlez directement si

l'emballage du produit est intact. En cas

d'endommagent de l'emballage, prévenez le

transporteur. Si la réclamation n'est pas déclarée

à temps, une demande ultérieure ne sera plus

acceptée.

• Contrôlez si le type de produit livré correspond à

votre commande. En cas de constatation d'une

différence, ne déballez pas le récupérateur et

prévenez immédiatement le fournisseur.

• Après le déballage, contrôlez l'état des unités et

de tous ses éléments. En cas de doute, adressez-

vous au fournisseur.

• N'utilisez jamais une unité endommagée.

• Si vous ne déballez pas directement le

récupérateur après réception, il devra être

entreposé dans un endroit intérieur sec ayant une

température ambiante de +5 °C à +35 °C.

A LIRE ATTENTIVEMENT!

Tous les matériaux

d'emballage utilisés sont

écologiques et peuvent être

réutilisés ou recyclés.

Participez activement à la

protection de

l'environnement et assurez-

vous que les matériaux

d'emballage sont

convenablement revalorisés.

2.2 DEBALLEZ L'UNITE

• Si l'unité de ventilation a été exposée à des

températures inférieures à 0°C durant le

transport, laissez l'unité déballée à la

température ambiante durant au moins 2 heures

avant de la brancher, pour permettre

l'égalisation de la température dans l'unité de

ventilation.

A LIRE ATTENTIVEMENT!

PLATE BOX

PLATE BOX

1x

8m PLATE BOX

Notice complète

INSTALLATION

PLATE BOX… et PLATE BOX ELEC….

PLATE BOX

Numéro de notice France air

NTE: 1260 A

FR

4

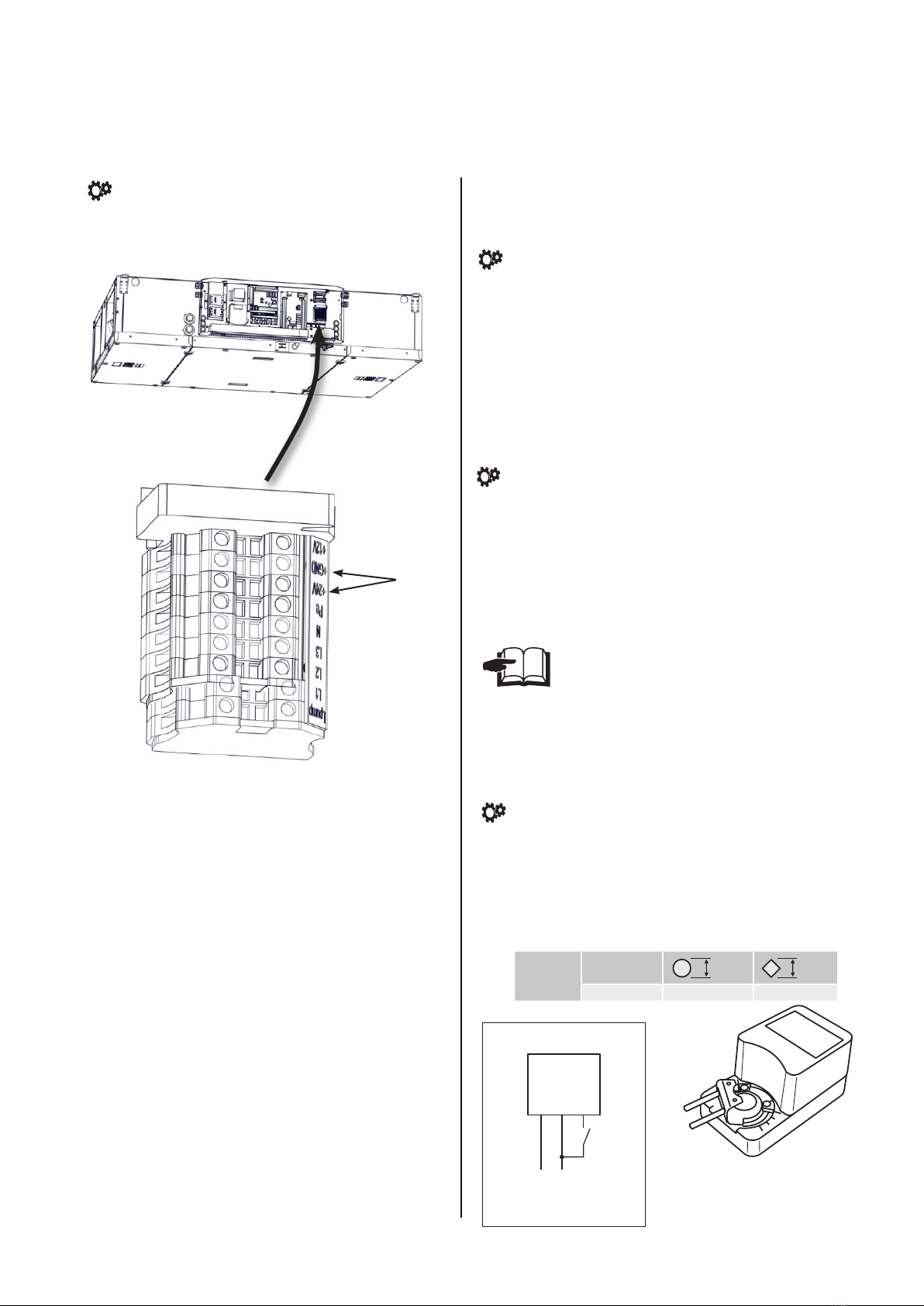

3. MAJOR PARTS

Fan

Mains isolator

Control panel

Service access to the unit

Central panel - Access to PHE

Side panels - Access to filters,

fans and coils

Filters

Supply: F7

Extract: G4

THERM-X

HRFL II 040/070/150/200

Delivered with the product:

1 x Touchscreen Controller

Note: Cabling not included, UTP cable

recommended

The cable length should not exceed 50 m (0.5

mm2)

1 x Room Temperature Sensor

Note:

Sensor supplied loose, cabling not included

Note:

All HRFL II ceiling mounted units are supplied with F7 and M5 filters as standard. If a different filter grade is

selected the filter is supplied loose for replacement on site by others.

AV & Hanging Brackets

PHE

Condensate drain

MUST BE TRAPPED

5

4. DIMENSIONS

OTA

EHA

SUP

ETA

OTA - Outside air

SUP - Supply air

ETA - Extract air

EHA - Exhaust air

THERM-X

HRFL II 040/070/150/200

Type H h a B b i j K k c d C D X x Y y Zz condensate ø

HRFL2-040 780 670 1190 310 300 1120 700 485 21 250 150 274 174 166 166 332 332 166 166 18

HRFL2-070 1080 970 1400 310 300 1330 1000 590 21 300 200 324 224 242 242 517 517 242 242 18

HRFL2-150 1385 1270 1700 390 380 1630 1305 720 21 500 250 524 274 323 323 625 625 323 323 18

HRFL2-200 1710 1600 2000 470 460 1430 1630 902 21 600 300 624 324 433 433 735 735 433 433 18

a

b

B

K

k

18

2x1/2"

C

D

c

d

h

i

j

H

x z

X

Z

Y

y

INDOOR ENVIROMENT

OUTDOOR ENVIROMENT

a

b

B

K

k

18

2x1/2"

C

D

c

d

h

i

j

H

x z

X

Z

Y

y

INDOOR ENVIROMENT

OUTDOOR ENVIROMENT

All sizes in mm

C

22

AB

B

A

AA

D

E

EE

DD

A B

C D

E

DD

EE AB AA

MODUL-400

334 470 295 250 150 274 174 366 397

MODUL-800

484 470 300 300 200 324 224 516 547

MODUL-1600

636 470 380 500 250 524 274 668 699

MODUL-2500

800 470 460 600 300 624 324 832 863

THERM-X

HRFL II 040/070/150/200

WCO (Changeover)/DX (Direct Expansion) external module

Type A B C D E DD EE AB AA condensate ø WCO connection

HRFL2-400 334 470 295 250 150 274 174 366 397 22 3/4“

HRFL2-700 484 470 300 300 300 324 224 516 547 22 3/4“

HRFL2-1500 636 470 380 500 500 524 274 668 699 22 3/4“

HRFL2-2000 800 470 460 600 600 624 324 832 863 22 3/4“

6

5. TECHNICAL SPECIFICATIONS

Model without electric pre-heating coil and...

...without coil / with water heating coil / with WCO coil / with DX coil

Model with electric pre-heating coil and...

...without coil / with water heating coil / with WCO coil / with DX coil

Characteristics of the fan electric motor (per fan)

Characteristics of LPHW coil

* For water temperature gradient 60/40 and inlet air temperature 15°C

...electric post heating coil

...electric post heating coil

Characteristics of electric preheater coil

Type Voltage [V] Frequency [Hz] Rated power [kW] Rated current [A]

HRFL2-040 230 50 0.34 2.7

HRFL2-070 230 50 0.33 2.5

HRFL2-150 230 50 1 5.6

HRFL2-200 230 50 1 6.3

Type Voltage [V] Frequency [Hz] Rated power [kW] Rated current [A]

HRFL2-040 230 50 0.9 4.1

HRFL2-070 230 50 1.8 8.8

HRFL2-150 400 50 3.7 18

HRFL2-200 400 50 5.8 13.5

Type Voltage [V] Frequency [Hz] Rated power [kW] Rated current [A]

HRFL2-040 230 50 1.7 7.4

HRFL2-070 230 50 3.1 13.5

HRFL2-150 400 50 6.3 14.7

HRFL2-200 400 50 9.4 19.8

Type Voltage [V] Frequency [Hz] Rated power [kW] Rated current [A]

HRFL2-040 230 50 2.7 11.8

HRFL2-070 400 50 4.5 11.7

HRFL2-150 400 50 9 18

HRFL2-200 400 50 14.2 24.8

Type Phase [pcs] Voltage [V] Frequency [Hz] Rated power [W] Rated current [A] Speed [r/min] Protection IP Insulation class

HRFL2-040 1 230 50 169 1.35 4120 54 B

HRFL2-070 1 230 50 175 1.3 2800 44 B

HRFL2-150 1 230 50 455 3.1 2600 54 B

HRFL2-200 1 230 50 500 3.15 1970 54 B

Type Phase [pcs] Voltage [V] Frequency [Hz] Rated power [kW] ∆ T [°C]

HRFL2-040 1 230 50 1.1 6.3

HRFL2-070 1 230 50 1.6 6.3

HRFL2-150 1 230 50 2.7 5.3

HRFL2-200 3 400 50 4.8 6.3

Type Phase [pcs] Voltage [V] Frequency [Hz] Rated power [kW] ∆ T [°C]

HRFL2-040 1 230 50 1.35 10

HRFL2-070 1 230 50 2.7 10

HRFL2-150 3 400 50 5.3 10

HRFL2-200 3 400 50 8.4 10

Type Rated capacity *[kW] Water pressure loss [kPa] Air pressure loss [Pa] Connections diameter Air fl w [m³/h]

HRFL2-040 1.75 1 10 1/2“ 400

HRFL2-070 2.71 3 15 1/2“ 700

HRFL2-150 5.92 17 27 1/2“ 1500

HRFL2-200 9.22 9 21 1/2“ 2000

Characteristics of electric post heating coil

NOTE: Please note all performance data is displayed for reference only. Coil performance is based on the nominal conditions stated and should be

checked for the actual operational conditions of the equipment at the time of selection.

7

* For water temperature gradient 7/12 and inlet air temperature 25°C with 70% of relative humidity.

Characteristics of water changeover cooling / heating coil (WCO) - Heating

* For water temperature gradient 60/40 and inlet air temperature 15°C.

Characteristics of water changeover cooling / heating coil (WCO) - Cooling

Characteristics of direct expansion coil (DX)

Type Rated capacity [kW]* Water pressure loss [kPa] Air pressure loss [Pa] Connection diameter Air fl w [m³/h]

HRFL2-040 2.51 0.29 80 3/4“ 400

HRFL2-070 4.6 0.59 71 3/4“ 700

HRFL2-150 9.41 0.69 99 3/4“ 1500

HRFL2-200 15.7 1.67 83 3/4“ 2000

Type Rated capacity

[kW]*

Water pressure loss

[kPa]

Air pressure loss

[Pa] Connection diameter Air fl w [m³/h]

HRFL2-040 1.94 2.65 91 3/4“ 400

HRFL2-070 3.68 5.4 80 3/4“ 700

HRFL2-150 7.34 6.57 112 3/4“ 1500

HRFL2-200 12.62 15.79 94 3/4“ 2000

Type Airfl w

[m³/h]

Power*

[kW]

Temperature behind the direct

evaporator [°C]RH [%] Fluid pressure loss

[kPa]

Air pressure loss

[Pa]

Connection

[gas]

Connection

[fluid

HRFL2-040 400 2.54 10 92 11 79 1/2“ 1/2“

HRFL2-070 700 4.65 10 92 41 69 1/2“ 5/8“

HRFL2-150 1500 9.94 10 92 12 97 1/2“ 7/8“

HRFL2-200 2000 16.15 10 92 28 91 3/4“ 7/8“

* For inlet air temperature 27°C with 70% of relative humidity and evaporation temperature 5°C, refrigerant R410A.

NOTE: Please note all performance data is displayed for reference only. Coil performance is based on the nominal conditions stated and should be

checked for the actual operational conditions of the equipment at the time of selection.

8

• The unit is not designed for air containing am mable

or explosive mixtures, chemical vapours, heavy

dust, soot, grease, toxins, pathogenic or ganism, etc.

• The degree of IP protection of the product is IP 20

when ducted (protection against objects bigger than

12.5 mm, does not protect against water!).

6.1-1 Access distances required for

unit service

6. INSTALLATION

6.1 CHOOSE THE PLACE OF

INSTALLATION

• Theunithastobeoperatedonlyinadry

environmentandprotectedagainstexternal

atmosphericconditionswithanambient

temperaturefrom+5°Cto+35°C.

The temperature of the inlet air should be in the

range from -20 °C to +60 °C and humidity up to

90%.

TECHNICAL INFORMATION

All the dimensions listed in the table are in mm

Type A

HRFL2-040

310

HRFL2-070

360

HRFL2-150

460

HRFL2-200

560

•Before installing the units in position ensure that

there is suitable access for connecting all services.

•The design of the ceiling must provide for access to

the unit units for commissioning and maintenance.

•The minimum distances for servicing the unit are

portrayed below.

60

750 mm

100 mm

0 mm

A

9

● AlltheHRFL IIunitsmustbeplacedinthehori-

zontalposition.Anyotherpositionisprohibited.

● Theunitmustbeinstalledinsuchawaysothat

the direction of the air inlet and outlets corre-

spondswiththeaircirculationinthedistribution

ductwork.

● Theremustalsobeadequateaccesstotheunits

oncetheyareinstalledforroutinemaintenance

and the removal of access panels and internal

componentssuchasfans,filters,plateheatex-

changer,coilsanddraintrays.

● Accessspacemustbeprovidedprimarilytoal-

lowremovalofthebottom panels,controlpanel

lidandallowelectricaland pipingconnectionsto

theservicesideofthe units.

TECHNICAL INFORMATION

● Allmaterialsusedatadistancelessthan100mm

from the ventilation unit have to be non-am-

mable (do not burn, ame up, burn down) or

onlyslightly ammable (donotburn,fallapart

– e.g. plasterboard). However, these materials

mustnotcovertheinletandoutletopeningsof

theunit.

● The safe distance of ammable materials from

theunitopeningsis500mm.

● Thesafedistance of ammable materialsin all

otherdirectionsis100mm.

6.1-2 Safe installation distance

ATTENTION!

6. INSTALLATION

10

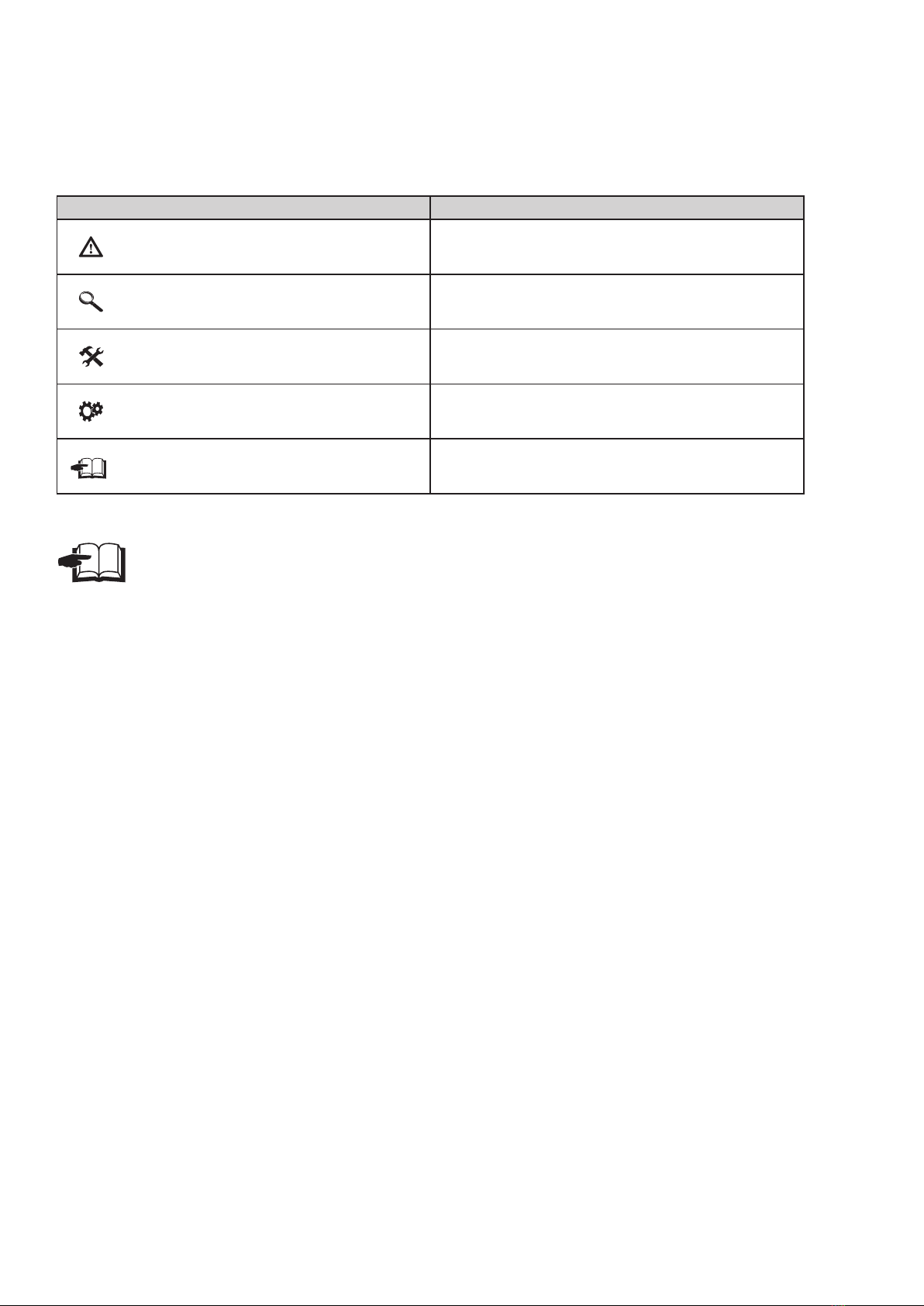

6.1-3 Hanging the unit

For location of the anchorage points, use the drill-

ing template listed below.

The units are equipped with mounting brackets

which should be used in conjunction with threaded

drop rods ZTZ-M8/1.0 or equivalent to facilitate

levering and leveling.

• Duetotheweightoftheunit,itisnecessaryto

useanappropriateliftingdevicewhenassem-

bling(e.g.aforklift,scissorlift,etc...)

• It’srecommendedthattheunitisinstalledinto

position before making connections to duct

andpipeworkorelectricalconnections.

• Depending on the type of building structure

there can be a number of ways of attaching

thesuspensionsystem,suchasdrilled-inx-

ings,clampsandclips,wedgenuts,etc..En-

sure whatever system is utilized it has su-

cientstrengthtosupporttheunit.

• 4-6M8checknuts(accordingtotheunittype)

• 4-6studbolts

• 4-6 dowels of a suitable type and dimension

(accordingtotheceilingmaterialandtheunit

weight)

• Drillerwithdrillsofasuitabletypeanddimen-

sion

• Tongsandnutwrenches

Place the unit horizontally and then incline it by 3°

by adjusting the nuts on the drop rods so that the

condensate drains into the outlet connection on

the access side of the unit.

ATTENTION!

YOU WILL NEED

6. INSTALLATION

Establish the weight of each unit and make sure

that ceiling will be adequate to support up to four

times the weight of the unit.

Drill the holes in the ceiling, try the strength of its

material and attach the unit by the side brackets

using the hanging rods ZTZ-M8/1.0 or equivalent.

A

B

Type A B

HRFL2-040 700 1120

HRFL2-070 1000 1330

HRFL2-150 1300 1630

HRFL2-200 1630 1930

Type

Weight of unit (kg) Weight of accesso-

ries (kg)

Without

reheating

With electric

reheating

With water

reheating

WCO mod-

ule DX module

HRFL2-040 70 75 75 25.5 24

HRFL2-070 90 95 95 32 30

HRFL2-150 165 170 170 37 35

HRFL2-200 240 245 245 43 40

11

X

6. INSTALLATION

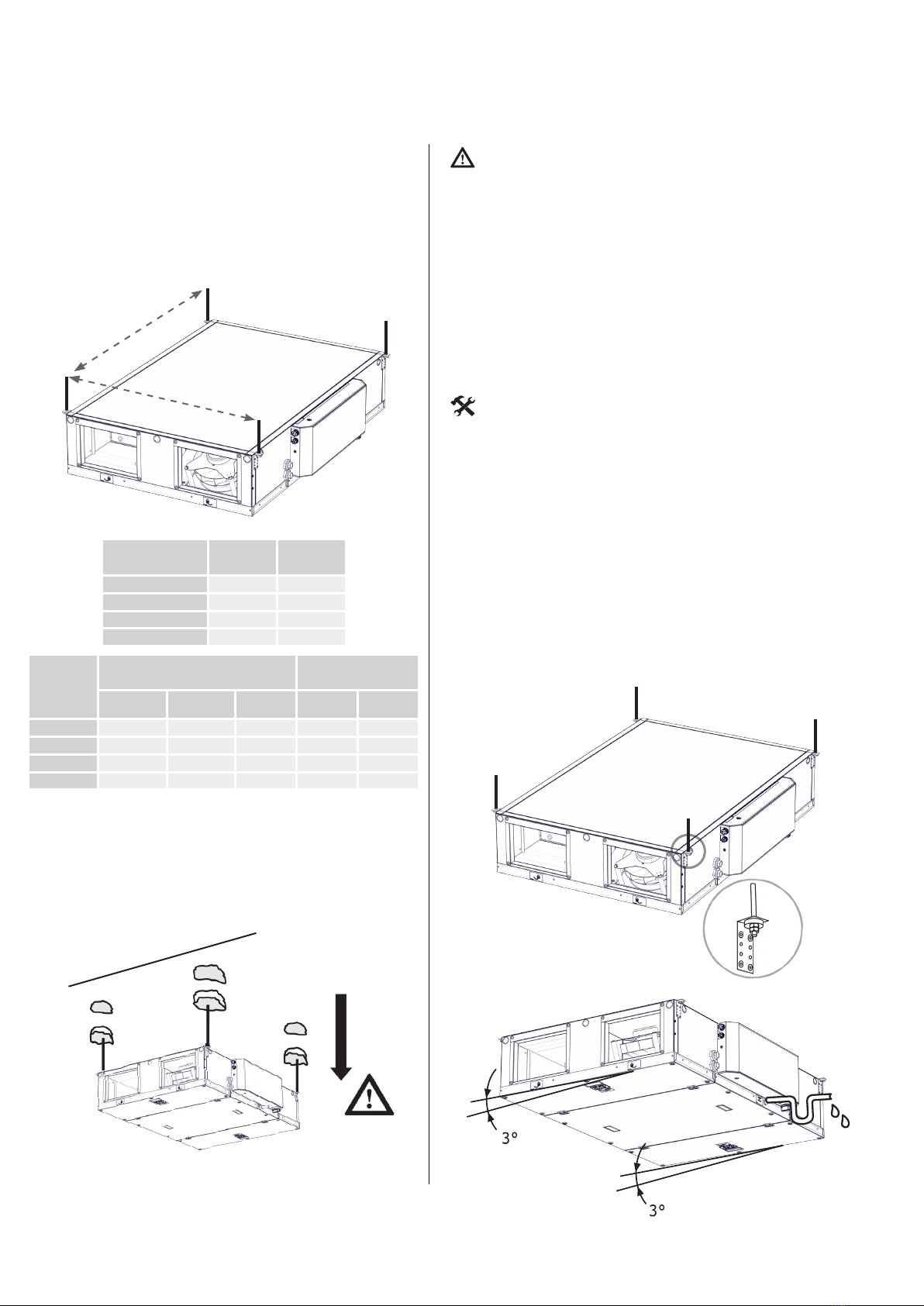

6.2-1 Rectangular to circular

transition

6.2 CONNECTING THE DUCTING

NOTE: This is an accessory and must be ordered

separately

Example of possible connection with flexible connectors.

NOTE: Barkell does not supply the accessories portrayed

above as standard

YOU WILL NEED

• Theconnectedductworkmusthavethesamedi-

mensionsastheinletandoutletopeningsofthe

ventilationunits.Inthecaseofasmallerdiame-

terofductwork,turbulencemightoccurresulting

onareductionoftheuniteciencyandlifetime.

• Connecttheinletandoutletopenings(rectangu-

lartocircular transition) using exiblejoints to

avoidvibrationsandensurethattheseareprop-

erlyalignedwiththeductwork.

• All ductwork must be supported independently

fromtheunit.

• Flexiblecorrugatedductingcanimposehighre-

sistances if formed into tight bends and should

thereforebeavoided.

All the dimensions are in mm

IMPORTANT NOTICE!

• 16M8screws

• 4pcsofrectangulartocirculartransitions( accessory

can be acquired from Barkell)

• appropriatenutwrenches

• sealingtape/sealant

Type X Y D L M F

HRB-PR-01 250 150 200 150 50 20

HRB-PR-02 300 200 250 200 50 20

HRB-PR-03 500 250 315 250 70 20

HRB-PR-04 600 300 400 300 70 20

Ductwork should be connected to the inlets and outlets

of the unit by means of a transition piece.

NOTE: Barkell does not supply the accessories portrayed

above as standard

Connections to the distribution ductwork should be

made using suitable clamps or clips ensuring that an

airtight joint is made and the ductwork then

insulated and taped down. The minimum distance

between any ductwork bends or the adapters and

the unit outlets is 500 mm.

SUP

EHA

ETA

OTA

OTA - Outside air

SUP - Supply air

ETA - Extract air

EHA - Exhaust air

12

6. INSTALLATION

NOTE: Barkell does not supply the accessories

portrayed above as standard

NOTE: Barkell does not supply the accessories

portrayed above as standard. These accessories

must be ordered and are supplied loose for

installation and wiring by others.

6.2-2 Protection of the unit

openings

(Not a part of the delivery)

6.3 CONNECTION OF THE

If an opening of the unit is not connected to the

ductwork, an metallic mesh in accordance with the

Machinery Directive Requirements or similar pro-

tection must be used to avoid the contact of water

and moving solid particles with the fan, heating

coils etc.

MECHANICAL ACCESSORIES

6.3-1 Shut-off dampers

These rectangular shut-off dampers are used for

shutting off the ductwork connected to the ven-

tilation unit.

●

2rectangularshutodampers(accordingtotheunit

model)

● 2actuators(withoneortwowires230V)

● 8M8screwsandnuts

● 16washers

● correspondingnutwrench

● aatheadandcross-pointscrewdriver,sealingtape

andsealant

YOU WILL NEED

Attach the damper to the ductwork at a distance of

around 2 m ahead of the fresh air inlet opening and to

the outlet ductwork at a distance of around 2 m from

the outlet opening. Install the actuators on the damper

shafts and to the corresponding connectors in the con-

trol housing. See chapter Connection of the electri-

cal wiring and the electrical equipment.

Adjust the damper in such a way that it is fully closed

when the unit is turned o and fully opened when the

unit is in operation. Other arrangements may damage

the unit.

Technical details of the MLKR Shut-Off damper

ATTENTION!

If the unit openings are un-ducted during op-

eration there is a potential risk of injury due

to rotating parts and heat surfaces inside the

unit.

•The anged damper frame is manufactured ofgal-

vanized steel.

•The blades are made of aluminum.

Unit type Rectangular damper A B

HRFL2-040 MLKR/S-250150 250 150

HRFL2-070 MLKR/S-300200 300 205

HRFL2-150 MLKR/S-500250 500 255

HRFL2-200 MLKR/S-600300 600 305

10mm

13

6. INSTALLATION

Technical details of the KRTK-A Shut-Off damper

Produced in EU

COMPONENTS КОМПОНЕНТЫ

The company reserves the right of change without previous announcement. ©2VV, spol. s r.o.

451

Your partner in ventilation...

- Diameters: 100, 125, 150, 160, 200, 250, 315, 355 mm

- Manual or servo drive control

The KRTK-A shutting flap is designed for tight closing of

individual branches in HVAC systems. The flap is designed

for operation in the basic environment for conveying air

free of rough dust, grease, chemical fumes, and other

contaminants. The flap housing is made of galvanized

plate. The flap may be fitted with a servo drive after

removing the manual control lever.

BASIC FEATURES

- диаметры: 100, 125, 150, 160, 200, 250, 315, 355 мм

- управление ручное или посредством сервопривода

Запорный клапан KRTK-A предназначен для

герметичного закрытия отдельных воздуховодов

вентиляционных систем. Клапан предназначен для

эксплуатации в основной среде и устанавливается

в системах, в которых движется воздух без грубой пыли,

жиров, химических испарений и других загрязнений.

Корпус клапана изготовлен из оцинкованного листа.

После демонтажа рычага ручного управления можно

оборудовать клапан сервоприводом.

КРАТКАЯ ХАРАКТЕРИСТИКА

PRIMARY PARAMETERS ГЛАВНЫЕ ПАРАМЕТРЫ

KRTK-A

Type

Тип

KRTK-A-100

KRTK-A-125

KRTK-A-150

KRTK-A-160

KRTK-A-200

KRTK-A-250

KRTK-A-315

KRTK-A-355

Weight [kg]

Bес [кг]

0,4

0,6

0,7

1,0

1,4

2,1

3,6

5,1

D L L1L2

40

40

40

40

40

60

60

60

200

200

200

200

200

200

200

300

280

280

280

280

280

320

320

420

100

125

150

160

200

250

315

355

Dimensions [mm]

Размеры [мм]

L

h

L1

L2L2

iD

Sheet thickness [mm]

Толщиналиста

[мм]

0,55

0,55

0,55

0,55

0,55

0,80

0,80

0,80

h

76

73

71

70

67

65

64

63

•The damper housing is manufactured of galvanized

steel.

•

The damper may be tted with a actuator after

removing the manual control lever.

10mm

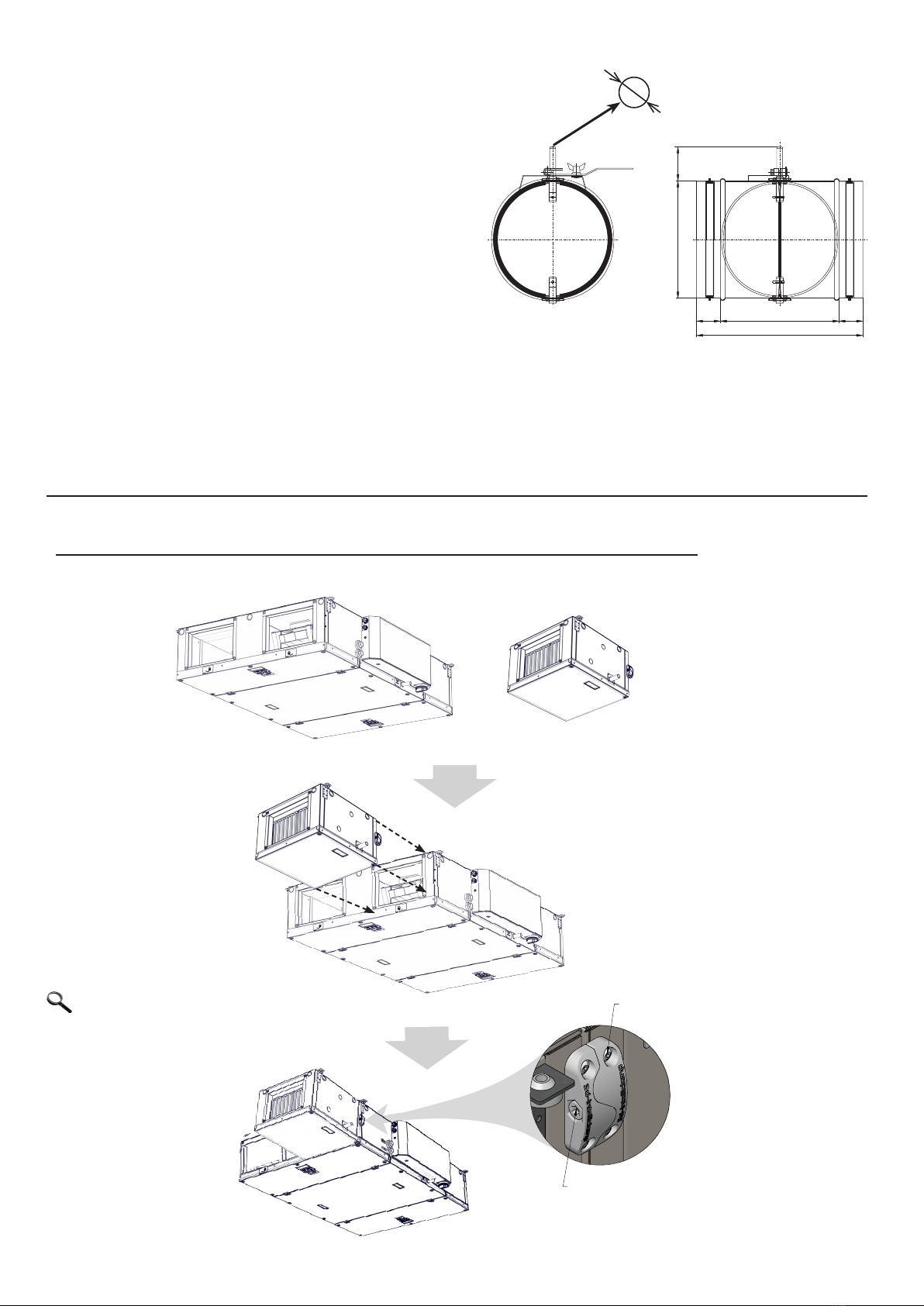

INSTALLATION OF EXTERNAL WCO, DX MODULE (accessories)

MODUL

JEDNOTKA

3D-Intelliclamp

4 x SR-ISO7380-5,0x25

(NA 1 UZAVER 3D-Intelliclamp)

A

DETAIL A

MĚŘÍTKO 1 : 1

SR-ISO7380-5,0x25

M8x35 DIN 912

e external

module includes

sensors(water and

air temperature),

PE ground-ing

conductor and

fasteners.

Unit type Circular damper Dimensions [mm]

D L L

1

L

2

h

HRFL2-040 KRTK-A-200 200 280 200 40 67

HRFL2-070 KRTK-A-250 250 320 200 60 65

HRFL2-150 KRTK-A-315 315 320 200 60 64

HRFL2-200 KRTK-A-400 400 520 300 60 65

NOTE: Damper actuators not

supplied with damper as standard.

These accessories must be

ordered and are supplied loose

for installation and wiring by others.

NOTE: External modules include a condensate

connection. This connection MUST BE

TRAPPED!

NOTE: Water coil valves/actuators are not

included as standard.

These accessories must be ordered and are

supplied loose for installation and wiring by

others.

NOTE: On units equipped with changeover

water heat exchangers it is recommended a 3

way diverting valve piping arrangement. If a 2

way valve must be used the length of the

pipework must be assessed in advance to avoid

issues with the method of control of the heat

exchanger.

OBSOLETE

14

6.4. CONNECTION OF THE

ELECTRICAL WIRING AND

THE ELECTRICAL

ACCESSORIES

ATTENTION!

●The main isolator switch of the electric

power supply must be turned off before

any intervention to the ventilation unit!

●Main supply voltages (220-240/400V)

present on this equipment might cause

death or serious injury by electric shock

● Theelectricalwiringoftheventilationunitmust

be executed according to the design by a

profes-sional electrician. The electrical wiring

mustbe realizedbyapersonauthorizedforthe

perform-ingofelectricalwirings.Itisnecessary

to follow all instructions of this manual as well

aslocal lawsandregulations.

● Thewiring diagrams listed on theproduct take

priorityoverdiagramslistedinthismanual!Be-

forewiringtheproduct,checkwhetherthecon-

nectormarkings corresponds tothe diagram. If

in doubt, contact the supplier and do not wire

theunitinanycase.

● Iftheproductisconnectedtoanothercontrol

systemthantheoriginalcontrolsystem,contact

thecompanythatsuppliedthissystemforin-

formationregardingtheelectricalwiringofthe

measuringsensorsandcontrols.

● Theunitmustbeconnectedtothepowersupply

lineusingarigidheatresistantisolatedcableof

adiameterthatcorrespondstothevalidlocal

regulations.

● Forpreservationoftheelectricalprotection,all

thecablesmustpassthroughthesideopenings

ofthecontrolhousing.

● Anyinterventionsormodificationsoftheinner

electricalwiringoftheunitareprohibitedand

leadtothelossofthewarranty!

● Theproperfunctionoftheunitcanbeguaran-

teedonlywhenusingtheoriginalaccessories.

● Ifitisnecessarytoplaceasensororaregulat-

ingcomponentinsidetheunitoronitscover,

consultitsplacementwiththeunitmanufacturer

(oritsrepresentative).

● Donotoverloadextensioncablingandwallout-

letsasthismightresultinariskoffireor electric

shock.

● Theunitmustbecorrectlyearthedtoavoidover

currentandearthfaultprotection.

15

All phases of the electric power supply must be

connected through a corresponding type of

circuit breaker. The distance between open

contacts must be greater than 3 mm.

The unit must be wired in such a way that it can

be disconnected from the electric power supply

using a single switch.

The unit must be connected to TN-S network, this

means that the neutral conductor must always be

connected.

I = current

P =

m = weight

IP =

ver = version

Product type data

U = voltage

F = frequency

n = fan speed

ph =

av = airow

Serial number

power/

absorber power

electrical

protection

number of

phases

6. INSTALLATION

Recommended cable and circuit breaker

sizes

Model with electric pre-heating coil

Model with electric post heating coil

Model with electric pre-heating and post heating coil

Recommended values. values must be specified by the person responsible

for the wiring in the building (e.g. designer) with regard to parameters of

the power line wiring and other parameters of the building

Recommended values. values must be specified by the person

responsible for the wiring in the building (e.g. designer) with regard to

parameters of the power line wiring and other parameters of the building

Recommended values. values must be specified by the person

responsible for the wiring in the building (e.g. designer) with regard to

parameters of the power line wiring and other parameters of the building

Number of

phases

Number of

phases

Number of

phases

Voltage (V)

Voltage (V)

Voltage (V)

Power (W)

Power (W)

Power (W)

Current (A)

Current (A)

Current (A)

Cable type*

Cable type*

Cable type*

Circuit breaker

type (A)*

Circuit breaker

type (A)*

Circuit breaker

type (A)*

HRFL2-040

HRFL2-070

HRFL1-150

HRFL1-200

HRFL2-040

HRFL2-070

HRFL1-150

HRFL1-200

HRFL2-040

HRFL2-070

HRFL1-150

HRFL1-200

1

1

3

3

1

1

1

3

1

3

3

3

230

230

400

400

230

230

230

400

230

400

400

400

1700

3100

6300

9400

900

1800

3700

5800

2700

4500

9000

14200

7,4

13,5

14,7

19,8

4,1

8,8

18

13,5

11,8

11,7

18

24,8

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

6.4-1 The power supply cable

The connecting terminal for the power supply ca-

ble is placed in the control device housing.

Minimum size of the protective grounding lead

must be in compliance with local safety regula-

tions for heavy current through the lead of the

protective grounding of the device.

● Theparametersoftheelectricalwiringarelisted

onthecontroldevicehousinglabel.

TECHNICAL INFORMATION

Pe

L1 L2 L3 N

ATTENTION!

16

6. INSTALLATION

6.4-2 – Electrical accessories

Electrical accessories must be connected to the terminals located in the control panel according to the

wiring diagram and the markings on the terminals.

NOTE: The wiring diagrams present on the units control box take precedence over the provided wiring

diagrams.

Control panel

1

1. 1

5.

1

6.

1

2.

1

7.

1

8.

1

9. 1

10. 1

11. 1

12. 1

13. 1

14. 1

15. 1

16. 1

17.

1

3. 1

4.

1

20. 1

21. 1

22.

1

18. 1

19.

EN RU CZ

1. A (5-6) LF1 - FLAP INLET (output L-open), LF2 - FLAP OUTLET ( output L-open) LF1 ( L-), LF2 - ( L-) LF1 - KLAPKA PŘÍVOD (výstup L-open), LF2 - KLAPKA ODVOD ( výstup L-open)

2. A (7-8) RUN CONTACT (output -NO/NC settable) RUN ( - NO/NC ) RUN KONTACT (výstup -NO/NC nastavitelné)

3. A (9-10) ERROR CONTACT (output NO) ( NO) ERROR KONTACT (výstup NO)

4. A (11-12) PREHEATER WATER PUMP (11 - Lint, 12 - Lout) (11 - Lint,12 - Lout) VODNÍ ČERPADLO PŘEDEHŘEVU (11 - Lint, 12 - Lout)

5. A (13-14) BOOST (input NO) BOOST ( NO) BOOST (vstup NO)

6. A (15-16) FIRE (input NC) FIRE - ( NC) FIRE (vstup NC)

7. A (17-18) EXTERNAL CONTROL ON/OFF (input NC) ON/OFF ( NC) EXTERNÍ OVLÁDÁNÍ ON/OFF (vstup NC)

8. A (18-19) AQS SENSOR 0-10V (input) 0-10 () ČIDLO KVALITY VZDUCHU 0-10V (vstup)

9. B (1-2) WATER PUMP (1 - Lint, 2 - Lout) (1 - Lint, 2 - Lout) VODNÍ ČERPADLO (1 - Lint, 2 - Lout)

10. B (3-4) HEAT PUMP CONTROL settable (output - ON/OFF) ( - ON/OFF) ŘÍZENÍ TEPELNÉHO ČERPADLA nastavitelné (výstup - ON/OFF)

11. B (5-6) ADIABATIC MODULE output - ON/OFF ( - ON/OFF) ADIABATICKÝ MODUL výstup - ON/OFF

12. B (7-8) COOL / HEAT settable (CO = NC/NO - DX = output settable) / (CO = NC/NO - DX = ) CHLAZENÍ / TOPENÍ nastavitelné (CO = NC/NO - DX = výstup nastavitelné)

13. B (9-10) ADIABATIC MODULE ERROR input NO ERROR ( NO) ADIABATICKÝ MODUL ERROR vstup NO

14. B (11-12) HEAT PUMP DEFROST settable (input NC/NO) ( NC/NO) ODMRAŽOVÁNÍ TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

15. B (13-14) HEAT PUMP ERROR settable (input NC/NO) ( NC/NO) CHYBA TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

16. B (15-16) PIR (input NC) PIR ( NC) POHYBOVÉ ČIDLO PIR (vstup NC)

17. B (17-18) CONDENSATE OVERFLOW (input NC) ( NC) ČIDLO PŘETEČENÍ KONDENZÁTU (vstup NC)

18. B (46-47) EXTERNAL TEMPERATURE SENSOR (external postheater - input) ( - ) EXTERNÍ TEPLOTNÍ ČIDLO (externí dohřev - vstup)

19. B (44-45) EXTERNAL TEMPERATURE SENSOR (adiabatic module / recirc. chamber - input) ( / - ) EXTERNÍ TEPLOTNÍ ČIDLO (adiabatický modul / recirkulační komora - input)

20. B (38-39) EXTERNAL PREHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ PŘEDEHŘEV (výstup - vodní=0-10V, elektrický=PWM)

21 B (36-37) EXTERNAL POSTHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ DOHŘEV (výstup - vodní=0-10V, elektrický=PWM)

22 B (34-35) RECIRCULATION CHAMBER (output 0-10V) ( 0-10) RECIRKULAČNÍ KOMORA (výstup 0-10V)

A

B

Control panel

1

1. 1

5. 1

6.

1

2. 1

7.

1

8.

1

9. 1

10. 1

11. 1

12. 1

13. 1

14. 1

15. 1

16. 1

17.

1

3. 1

4.

1

20. 1

21. 1

22.

1

18. 1

19.

EN RU CZ

1. A (5-6) LF1 - FLAP INLET (output L-open), LF2 - FLAP OUTLET ( output L-open) LF1 ( L-), LF2 - ( L-) LF1 - KLAPKA PŘÍVOD (výstup L-open), LF2 - KLAPKA ODVOD ( výstup L-open)

2. A (7-8) RUN CONTACT (output -NO/NC settable) RUN ( - NO/NC ) RUN KONTACT (výstup -NO/NC nastavitelné)

3. A (9-10) ERROR CONTACT (output NO) ( NO) ERROR KONTACT (výstup NO)

4. A (11-12) PREHEATER WATER PUMP (11 - Lint, 12 - Lout) (11 - Lint,12 - Lout) VODNÍ ČERPADLO PŘEDEHŘEVU (11 - Lint, 12 - Lout)

5. A (13-14) BOOST (input NO) BOOST ( NO) BOOST (vstup NO)

6. A (15-16) FIRE (input NC) FIRE - ( NC) FIRE (vstup NC)

7. A (17-18) EXTERNAL CONTROL ON/OFF (input NC) ON/OFF ( NC) EXTERNÍ OVLÁDÁNÍ ON/OFF (vstup NC)

8. A (18-19) AQS SENSOR 0-10V (input) 0-10 () ČIDLO KVALITY VZDUCHU 0-10V (vstup)

9. B (1-2) WATER PUMP (1 - Lint, 2 - Lout) (1 - Lint, 2 - Lout) VODNÍ ČERPADLO (1 - Lint, 2 - Lout)

10. B (3-4) HEAT PUMP CONTROL settable (output - ON/OFF) ( - ON/OFF) ŘÍZENÍ TEPELNÉHO ČERPADLA nastavitelné (výstup - ON/OFF)

11. B (5-6) ADIABATIC MODULE output - ON/OFF ( - ON/OFF) ADIABATICKÝ MODUL výstup - ON/OFF

12. B (7-8) COOL / HEAT settable (CO = NC/NO - DX = output settable) / (CO = NC/NO - DX = ) CHLAZENÍ / TOPENÍ nastavitelné (CO = NC/NO - DX = výstup nastavitelné)

13. B (9-10) ADIABATIC MODULE ERROR input NO ERROR ( NO) ADIABATICKÝ MODUL ERROR vstup NO

14. B (11-12) HEAT PUMP DEFROST settable (input NC/NO) ( NC/NO) ODMRAŽOVÁNÍ TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

15. B (13-14) HEAT PUMP ERROR settable (input NC/NO) ( NC/NO) CHYBA TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

16. B (15-16) PIR (input NC) PIR ( NC) POHYBOVÉ ČIDLO PIR (vstup NC)

17. B (17-18) CONDENSATE OVERFLOW (input NC) ( NC) ČIDLO PŘETEČENÍ KONDENZÁTU (vstup NC)

18. B (46-47) EXTERNAL TEMPERATURE SENSOR (external postheater - input) ( - ) EXTERNÍ TEPLOTNÍ ČIDLO (externí dohřev - vstup)

19. B (44-45) EXTERNAL TEMPERATURE SENSOR (adiabatic module / recirc. chamber - input) ( / - ) EXTERNÍ TEPLOTNÍ ČIDLO (adiabatický modul / recirkulační komora - input)

20. B (38-39) EXTERNAL PREHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ PŘEDEHŘEV (výstup - vodní=0-10V, elektrický=PWM)

21 B (36-37) EXTERNAL POSTHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ DOHŘEV (výstup - vodní=0-10V, elektrický=PWM)

22 B (34-35) RECIRCULATION CHAMBER (output 0-10V) ( 0-10) RECIRKULAČNÍ KOMORA (výstup 0-10V)

AB

F1 2A

1. A (5-6) LF1 - INTAKE DAMPER (output L-open), LF2 – EXHAUST DAMPER (output L-open)

2. A (7-8) RUN CONTACT (output NO/NC adjustable)

3. A (9-10) ERROR CONTACT (output NO)

4. A (11-12) PREHEATING WATER PUMP (11 - Lint, 12 - Lout)

5. A (13-14) BOOST (input NO)

6. A (15-16) FIRE (input NC)

7. A (17-18) EXTERNAL CONTROL ON/OFF (input NC)

8. A (18-19) Air quality sensor 0-10V (input)

17

6. INSTALLATION

READ CAREFULLY!

●The wiring diagrams present on the units control box take precedence over the provided wiring diagrams.

● Accessoriesmustbeconnectedwithacableweprovideorwithacableappropriatetothespecifications

of thecomponent.

Control panel

1

1. 1

5. 1

6.

1

2. 1

7.

1

8.

1

9. 1

10. 1

11. 1

12. 1

13. 1

14. 1

15. 1

16.

1

17.

1

3. 1

4.

1

20. 1

21. 1

22.

1

18. 1

19.

EN RU CZ

1. A (5-6) LF1 - FLAP INLET (output L-open), LF2 - FLAP OUTLET ( output L-open) LF1 ( L-), LF2 - ( L-) LF1 - KLAPKA PŘÍVOD (výstup L-open), LF2 - KLAPKA ODVOD ( výstup L-open)

2. A (7-8) RUN CONTACT (output -NO/NC settable) RUN ( - NO/NC ) RUN KONTACT (výstup -NO/NC nastavitelné)

3. A (9-10) ERROR CONTACT (output NO) ( NO) ERROR KONTACT (výstup NO)

4. A (11-12) PREHEATER WATER PUMP (11 - Lint, 12 - Lout) (11 - Lint,12 - Lout) VODNÍ ČERPADLO PŘEDEHŘEVU (11 - Lint, 12 - Lout)

5. A (13-14) BOOST (input NO) BOOST ( NO) BOOST (vstup NO)

6. A (15-16) FIRE (input NC) FIRE - ( NC) FIRE (vstup NC)

7. A (17-18) EXTERNAL CONTROL ON/OFF (input NC) ON/OFF ( NC) EXTERNÍ OVLÁDÁNÍ ON/OFF (vstup NC)

8. A (18-19) AQS SENSOR 0-10V (input) 0-10 () ČIDLO KVALITY VZDUCHU 0-10V (vstup)

9. B (1-2) WATER PUMP (1 - Lint, 2 - Lout) (1 - Lint, 2 - Lout) VODNÍ ČERPADLO (1 - Lint, 2 - Lout)

10. B (3-4) HEAT PUMP CONTROL settable (output - ON/OFF) ( - ON/OFF) ŘÍZENÍ TEPELNÉHO ČERPADLA nastavitelné (výstup - ON/OFF)

11. B (5-6) ADIABATIC MODULE output - ON/OFF ( - ON/OFF) ADIABATICKÝ MODUL výstup - ON/OFF

12. B (7-8) COOL / HEAT settable (CO = NC/NO - DX = output settable) / (CO = NC/NO - DX = ) CHLAZENÍ / TOPENÍ nastavitelné (CO = NC/NO - DX = výstup nastavitelné)

13. B (9-10) ADIABATIC MODULE ERROR input NO ERROR ( NO) ADIABATICKÝ MODUL ERROR vstup NO

14. B (11-12) HEAT PUMP DEFROST settable (input NC/NO) ( NC/NO) ODMRAŽOVÁNÍ TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

15. B (13-14) HEAT PUMP ERROR settable (input NC/NO) ( NC/NO) CHYBA TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

16. B (15-16) PIR (input NC) PIR ( NC) POHYBOVÉ ČIDLO PIR (vstup NC)

17. B (17-18) CONDENSATE OVERFLOW (input NC) ( NC) ČIDLO PŘETEČENÍ KONDENZÁTU (vstup NC)

18. B (46-47) EXTERNAL TEMPERATURE SENSOR (external postheater - input) ( - ) EXTERNÍ TEPLOTNÍ ČIDLO (externí dohřev - vstup)

19. B (44-45) EXTERNAL TEMPERATURE SENSOR (adiabatic module / recirc. chamber - input) ( / - ) EXTERNÍ TEPLOTNÍ ČIDLO (adiabatický modul / recirkulační komora - input)

20. B (38-39) EXTERNAL PREHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ PŘEDEHŘEV (výstup - vodní=0-10V, elektrický=PWM)

21 B (36-37) EXTERNAL POSTHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ DOHŘEV (výstup - vodní=0-10V, elektrický=PWM)

22 B (34-35) RECIRCULATION CHAMBER (output 0-10V) ( 0-10) RECIRKULAČNÍ KOMORA (výstup 0-10V)

A

B

9. B (1-2) WATER PUMP (1 - Lint, 2 - Lout)

10. B (3-4) HEAT PUMP CONTROL adjustable (output ON/OFF)

11. B (5-6) ADIABATIC MODULE output ON/OFF

12. B (7-8) COOLING/HEATING adjustable (CO = NC/NO - DX = output adjustable)

13. B (9-10) ADIABATIC MODULE ERROR input NO

14. B (11-12) Heat pump defrost adjustable (input NC/NO)

15. B (13-14) Heat pump error adjustable (input NC/NO)

16. B (15-16) PIR MOVEMENT SENSOR (input NC)

17. B (17-18) CONDENSATE OVERFLOW SENSOR (input NC)

18. B (46-47) EXTERNAL TEMPERATURE SENSOR (external reheating - input)

19. B (44-45) EXTERNAL TEMPERATURE SENSOR (adiabatic module/recirculation chamber –

input)

20. B (38-39) EXTERNAL PREHEATING (output – water = 0-10V)

21 B (36-37) EXTERNAL REHEATING (output – water = 0-10V)

22 B (34-35) RECIRCULATION CHAMBER (output 0-10V)

18

6. INSTALLATION

● Lowvoltageswitchingcontact-maximumpos-

siblecontactload12V,0.4A.

● Cable with two conductors of cross sec-tion

min.0.5mm2Maximumlength50m.

● Thecontactisnormallyclosed.Whenthecon-

tactdisconnects,theunitoperatesaccordingto

thesettings.

6.5-2.2 Fire interlock

TECHNICAL DATA

TECHNICAL DATA

● Lowvoltageswitchingcontact-maximum possible

load12V,0.4A.

● Cablewithtwoconductorsofcrosssec-tionmin. 0.5

mm2, maximumlength50m.

● Thecontactisnormallyclosed.Whenthecontact is

open,theunitturnsoff.Thissettingcan be changed

intheservicemenu1616 on the controller.

6.5-2.3 OBSOLETE

TECHNICAL DATA

Locationofthe24Voutlettosupplyaccesso-

ries

24V DC

+ GND

24V outlet for powering accessories

from control panel.

Themaximumloadofthe24Voutletis0.5A.

6.5-2.1 External Control

Contact for external ON/OFF control of the unit.

NOTE: Barkell does not supply the above accessory.

The required settings can be adjusted

in the service menu 1616.

6.5-2.4 Damper actuator (no spring)

TECHNICAL DATA

● Theactuatorisfedby230VAC–three-wire

controlcable

●CABLE:two-wirecableofacrosssectionofat

least0.5mm²maximumlength50m.

NOTE: Barkell does not supply

the above accessory as

standard, it must be ordered

separately.

12

Power

supply

3

BLK

BRN

RED

Flap shaft Length [mm] [mm] [mm]

min. 40 8 up to 16 5 up to 12

19

6. INSTALLATION

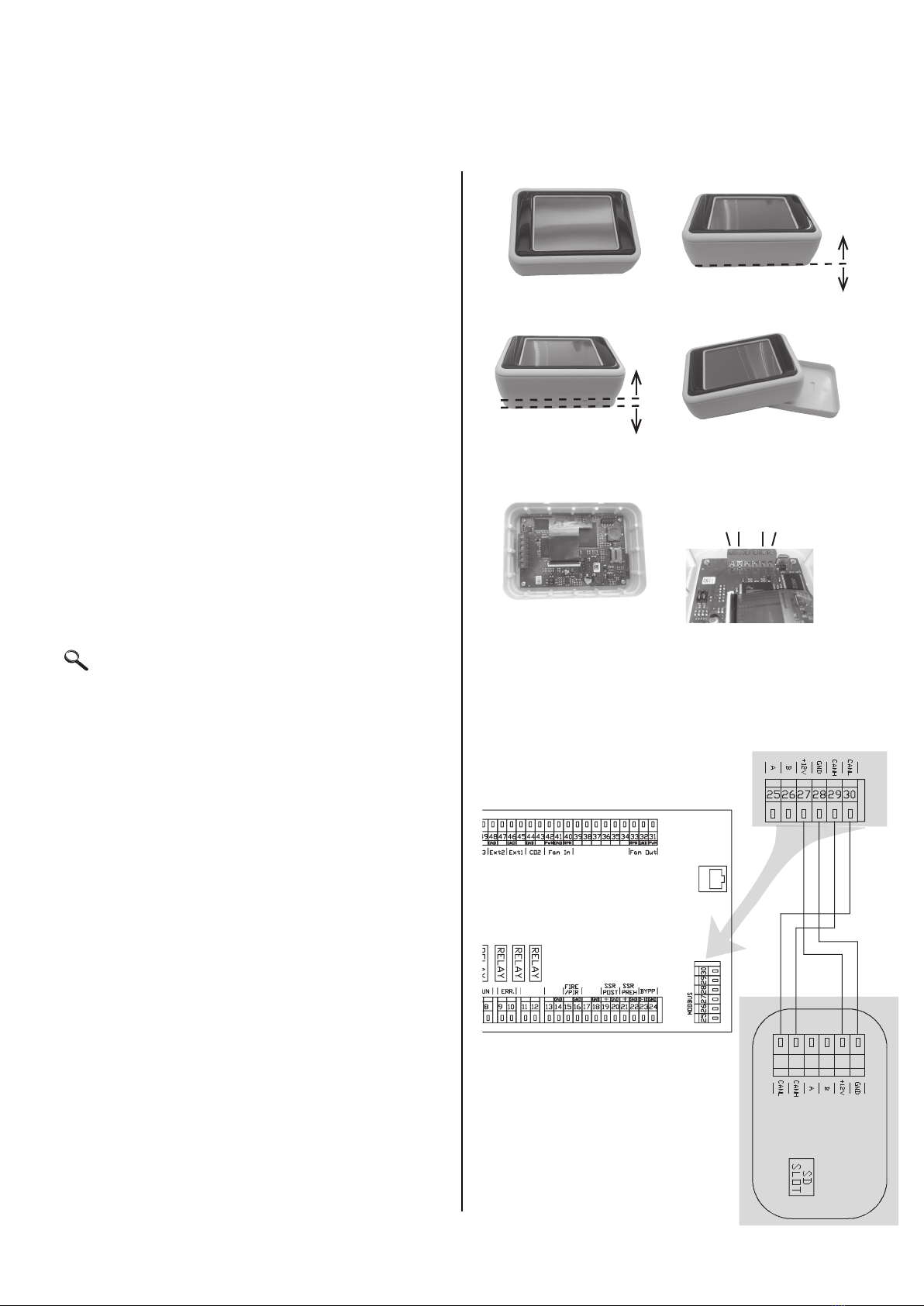

6.5-3 Touchscreen controller

Tostarttheunit,connecttheremotecontroltothe

unitwiththecontrolcable(datacable).

NOTE: Cable not supplied. UTP cable

recommended. The cable length should not exceed

50 m (0.5 mm2)

6.5-2.5 PIR motion sensor

Low voltage switching contact - maximum

possible contact load 12 V, 0.4 A.

CABLE: Cable with two conductors of cross section

min. 0.5 mm2 Maximum length 50 m. The con-

tact is normally open.

When the contact closes, the unit operates

according to the settings in menu 1616.

1.

3.

5.

2.

4.

6.

CANL (30)

CANH (29)

+12 V (27)

GND (28)

PREHEAT

W. PUMP BOOST EXT

Produced in EU

REGULATION REGULATION

The company reserves the right of change without previous announcement. ©2VV, spol. s r.o.

QPN

Your partner in ventilation...

tfofkd=af^do^jp bibhqofp`eb=p`e^iqmi„kb

^ää=ïáêáåÖ=Çá~Öê~ãë=éêçîáÇÉÇ=áå=íÜÉ=íÉÅÜåáÅ~ä=Å~í~äçÖ=

~êÉ=áåÇáÅ~íáîÉ=çåäóK=

tÜÉå= ~ëëÉãÄäáåÖ=íÜÉ=éêçÇìÅíI=

çÄëÉêîÉ=ëíêáÅíäó=íÜÉ=å~ãÉéä~íÉ=ê~íáåÖë=~ë=ïÉää=~ë=

ÇáêÉÅíáçåë=~åÇ=Çá~Öê~ãë=~ÑÑáñÉÇ=ÇáêÉÅíäó=íç= íÜÉ=

éêçÇìÅí=çê=ÉåÅäçëÉÇ=íç=íÜÉ=éêçÇìÅíK

pŽãíäáÅÜÉ=áã= íÉÅÜåáëÅÜÉå=h~í~äçÖ=~åÖÉÑćÜêíÉå=

pÅÜ~äíéäŽåÉ=ëáåÇ=åìê=áåÑçêã~íáîK==_Éá=ÇÉê=jçåí~ÖÉ=

ÇÉë=mêçÇìâíÉë=êáÅÜíÉå=páÉ=ëáÅÜ=~ìëëÅÜäáɡäáÅÜ=å~ÅÜ=

ÇÉå=pÅÜáäÇïÉêíÉå=ìåÇ=pÅÜ~äíÄáäÇÉêåI=ÇáÉ=ÉåíïÉÇÉê=

~ìÑ=ÇÉã= mêçÇìâí=~åÖÉÄê~ÅÜí==çÇÉê=òìã= mêçÇìâí=

ÄÉáÖÉäÉÖí=ëáåÇK

hbv=ql=`lafkd hbkkwbf`ekrkdpp`ei¸ppbi

pbosl=qaJMQJOPMJN

TD-04-230-1

servo drive for controlling the HVAC flaps

TD-04-230-1

Stellantrieb für die Bedienung der lufttech-

nischen Klappen

TD-04-230-1

Type

Тyp

230

Voltage

[V]

Spannung

[В]

2

Standby [W]

Standby

[Вт]

12

Operation

[VA]

Betrieb

[ВA]

4

torque

[Nm]

Drehmoment

[Нм]

90

displacement

time [s]

Verschiebung

Zeit [s]

95°

working angle

max.

Arbeitswinkel

max.

0,5

weight

[kg]

Gewicht

[kg]

Power consumption / Stromverbrauch

Your partner in ventilation...

358

Produced in EU The company reserves the right of change without previous announcement. ©2VV, spol. s r.o.

REGULATION REGULATION

NOTE: Barkell does not supply the above

accessory as standard, it must be ordered

separately.

READ CAREFULLY!

● Thesupplyandthecontrolcableshouldbeasfar

apartfromeachotheraspossible.

● Makesurethatthecablehasbeenproperlyin-

sertedintotheconnector.

● Becarefulnottodamagecableinsulationwhen

xingtheremotecontroltothewallortoother

surface.

● If you do not connect connectors or cables di-

rectly during the unit´s installation, protect

themagainstmechanicaldamageorshortcircuit

byaninsulatingtape.

● Cable connectors must not come into contact

withwaterorotherliquid.

● Parametersettingsaremaintainedthankstothe

batterywiththeservicelifeof3–5years.

20

6.4-4 Connection of the unit to

the BMS control system

The ventilation unit control is normally

equipped with the RS-485 interface.

For connection use a standard communication

cable. Connect the cable to the assigned

MODBUS connectors on the control board.

Connect the other end to the main control unit.

For the protocols details (ModBUS) contact

Barkell.

IMPORTANT NOTICE!

ItispossibletoconnecttheunittotheBMScontrol

systemandtheunitcontrolleratthesametime.

BMScommunicationisonlyavailablethroughthe

RS-485 Modbus interface. Other communication

protocolswillrequireagatewaytranslator.

ForadditionalinformationabouttheMODBUSco-

nnectionpleaseconsultthe THERM-X HRFLMod-

busProtocolmanual.

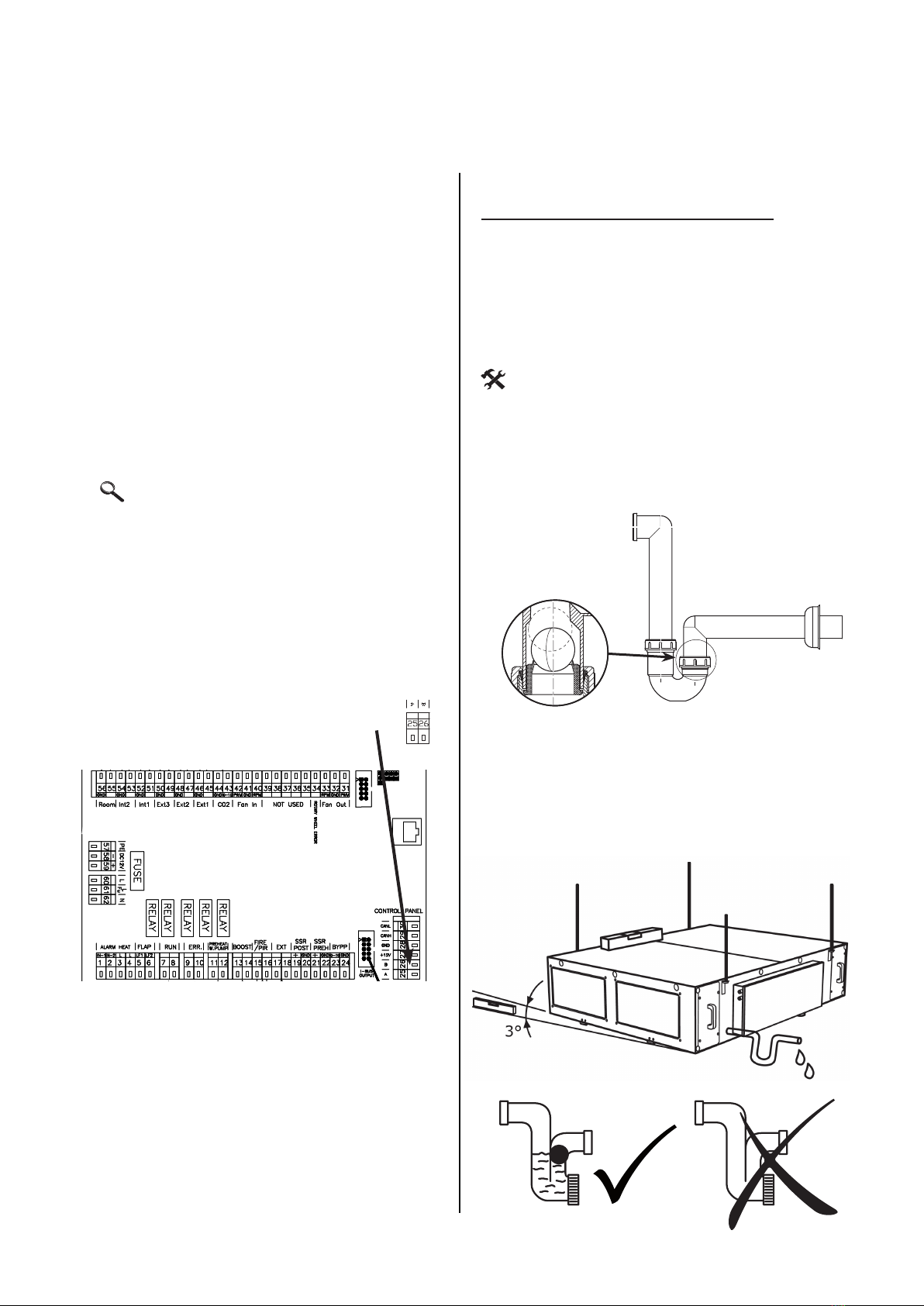

6.5 CONDENSATE DRAIN

CONNECTION

Condensate drain from the unit (either from the

recuperator, the cooling coil (if provided) or both

must be connected to the discharge pipeline.

If the unit has 2 drain connections an additional

trap or pump is required.

Ensure the unit is level or angled slightly towards

the condensate tray outlet to facilitate correct

conden-sate removal from the unit.

YOU WILL NEED

• 1siphon

• PVCdischargepipework

• sealtothedischargepipework

Siphon with a ball

The tube connection on the drain is connected

to the side discharge on the ventilation unit.

Ensure ALL connections are TRAPPED.

6. INSTALLATION

– Makesurethattheunitisinclinedby3°sothat

thecondensatedrainisensured.

Control panel

1

1. 1

5. 1

6.

1

2. 1

7.

1

8.

1

9. 1

10. 1

11. 1

12. 1

13. 1

14. 1

15. 1

16. 1

17.

1

3. 1

4.

1

20. 1

21. 1

22.

1

18. 1

19.

EN RU CZ

1. A (5-6) LF1 - FLAP INLET (output L-open), LF2 - FLAP OUTLET ( output L-open) LF1 ( L-), LF2 - ( L-) LF1 - KLAPKA PŘÍVOD (výstup L-open), LF2 - KLAPKA ODVOD ( výstup L-open)

2. A (7-8) RUN CONTACT (output -NO/NC settable) RUN ( - NO/NC ) RUN KONTACT (výstup -NO/NC nastavitelné)

3. A (9-10) ERROR CONTACT (output NO) ( NO) ERROR KONTACT (výstup NO)

4. A (11-12) PREHEATER WATER PUMP (11 - Lint, 12 - Lout) (11 - Lint,12 - Lout) VODNÍ ČERPADLO PŘEDEHŘEVU (11 - Lint, 12 - Lout)

5. A (13-14) BOOST (input NO) BOOST ( NO) BOOST (vstup NO)

6. A (15-16) FIRE (input NC) FIRE - ( NC) FIRE (vstup NC)

7. A (17-18) EXTERNAL CONTROL ON/OFF (input NC) ON/OFF ( NC) EXTERNÍ OVLÁDÁNÍ ON/OFF (vstup NC)

8. A (18-19) AQS SENSOR 0-10V (input) 0-10 () ČIDLO KVALITY VZDUCHU 0-10V (vstup)

9. B (1-2) WATER PUMP (1 - Lint, 2 - Lout) (1 - Lint, 2 - Lout) VODNÍ ČERPADLO (1 - Lint, 2 - Lout)

10. B (3-4) HEAT PUMP CONTROL settable (output - ON/OFF) ( - ON/OFF) ŘÍZENÍ TEPELNÉHO ČERPADLA nastavitelné (výstup - ON/OFF)

11. B (5-6) ADIABATIC MODULE output - ON/OFF ( - ON/OFF) ADIABATICKÝ MODUL výstup - ON/OFF

12. B (7-8) COOL / HEAT settable (CO = NC/NO - DX = output settable) / (CO = NC/NO - DX = ) CHLAZENÍ / TOPENÍ nastavitelné (CO = NC/NO - DX = výstup nastavitelné)

13. B (9-10) ADIABATIC MODULE ERROR input NO ERROR ( NO) ADIABATICKÝ MODUL ERROR vstup NO

14. B (11-12) HEAT PUMP DEFROST settable (input NC/NO) ( NC/NO) ODMRAŽOVÁNÍ TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

15. B (13-14) HEAT PUMP ERROR settable (input NC/NO) ( NC/NO) CHYBA TEPELNÉHO ČERPADLA nastavitelné (vstup NC/NO)

16. B (15-16) PIR (input NC) PIR ( NC) POHYBOVÉ ČIDLO PIR (vstup NC)

17. B (17-18) CONDENSATE OVERFLOW (input NC) ( NC) ČIDLO PŘETEČENÍ KONDENZÁTU (vstup NC)

18. B (46-47) EXTERNAL TEMPERATURE SENSOR (external postheater - input) ( - ) EXTERNÍ TEPLOTNÍ ČIDLO (externí dohřev - vstup)

19. B (44-45) EXTERNAL TEMPERATURE SENSOR (adiabatic module / recirc. chamber - input) ( / - ) EXTERNÍ TEPLOTNÍ ČIDLO (adiabatický modul / recirkulační komora - input)

20. B (38-39) EXTERNAL PREHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ PŘEDEHŘEV (výstup - vodní=0-10V, elektrický=PWM)

21 B (36-37) EXTERNAL POSTHEATER (output - Water= 0-10V, electric=PWM) ( - =0-10, =PWM) EXTERNÍ DOHŘEV (výstup - vodní=0-10V, elektrický=PWM)

22 B (34-35) RECIRCULATION CHAMBER (output 0-10V) ( 0-10) RECIRKULAČNÍ KOMORA (výstup 0-10V)

A

B

MODBUS connection

Table of contents

Popular Fan manuals by other brands

Create

Create WINDLIGHT MINIMAL DC user manual

Casablanca

Casablanca Panama Gallery 55059 Owner's guide and installation manual

RenewAire

RenewAire DN-Series Installation, operation and maintenance manual

Westinghouse

Westinghouse WFF16 user manual

DELTA BREEZ

DELTA BREEZ RAD80L manual

Gallet

Gallet VEN 73T Blizzard instruction manual

Progress Lighting

Progress Lighting AirPro P250062 installation manual

Envirovent

Envirovent energiSava 300 installation guide

CFM

CFM AeroFan Brochure & specs

LEGRAND

LEGRAND HPM RCFTRI12H4WE instruction sheet

Gaggenau

Gaggenau VL 414 712 use and care manual

TemperZone

TemperZone IMDL 40Y Installation & maintenance