Barker AGB User manual

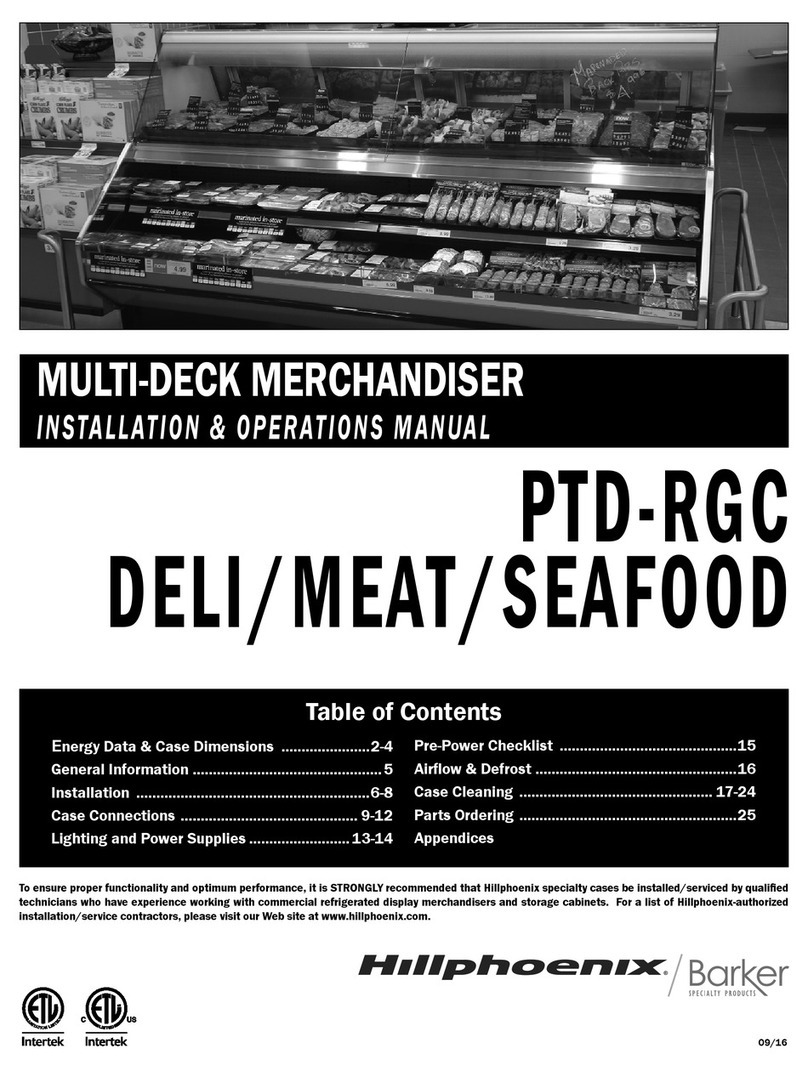

AGB

MEAT/CHEESE

04/16

MULTI-DECK MERCHANDISER

I N S TA L L AT I O N & O P E R AT I O N S M A N U A L

Energy Data & Case Dimensions .......................2-4

General Information ............................................... 5

Installation ..........................................................6-7

Case Connections ...............................................8-9

Lighting and Power Supplies ......................... 10-11

Pre-Power Checklist ............................................12

Airflow & Defrost ..................................................13

Case Cleaning ................................................ 14-15

Parts Ordering ......................................................16

Appendices

Table of Contents

To ensure proper functionality and optimum performance, it is STRONGLY recommended that Hillphoenix specialty cases be installed/serviced by qualified

technicians who have experience working with commercial refrigerated display merchandisers and storage cabinets. For a list of Hillphoenix-authorized

installation/service contractors, please visit our Web site at www.hillphoenix.com.

ii

R-744 (CO2) NOTICE

For Systems Utilizing R-744 (CO2) Refrigerant

For refrigeration units that utilize R-744 (CO2), pressure relief and pressure-regulating relief valves may need

to be installed based on the system capacity. The valves need to be located such that no stop valve is posi-

tioned between the relief valves and the parts or section of the system being protected.

When de-energizing refrigeration units containing R-744 (CO2), venting of the R-744 (CO2) refrigerant may

occur through the pressure regulating relief valves. These valves are located on the refrigeration system

and not on the case model. If venting does occur, the valve must not be defeated, capped, or altered by any

means.

WARNING: Under no circumstances should any component be replaced or added without consulting

Hillphoenix Field Service Engineering. Utilizing improper components may result in serious injury to

persons or damage to the system.

LIABILITY NOTICE

For Cases with Shelf Lighting Systems

Hillphoenix does NOT design any of its shelf lighting systems or any of its display cases with shelf lighting

systems for direct or indirect exposure to water or other liquids. The use of a misting system or water hose

on a display case with a shelf lighting system, resulting in the direct or indirect exposure of the lighting

system to water, can lead to a number of serious issues (including, without limitation, electrical failures,

fire, electric shock, and mold) in turn resulting in personal injury, death, sickness, and/or serious property

damage (including, without limitation, to the display itself, to the location where the display is situated

[e.g., store] and to any surrounding property). DO NOT use misting systems, water hoses or other devices

that spray liquids in Hillphoenix display cases with lighted shelves.

If a misting system or water hose is installed or used on a display case with a shelf lighting system, then

Hillphoenix shall not be subject to any obligations or liabilities (whether arising out of breach of contract,

warranty, tort [including negligence], strict liability or other theories of law) directly or indirectly resulting

from, arising out of or related to such installation or use, including, without limitation, any personal injury,

death or property damage resulting from an electrical failure, fire, electric shock, or mold.

P079211M, REVO

iii

Important

D A N G E R

▲

Indicates an immediate threat of death or seri-

ous injury if all instructions are not followed

carefully.

At Hillphoenix®, the safety of our customers and employees, as well as the ongo-

ing performance of our products, are top priorities. To that end, we include impor-

tant warning messages in all Hillphoenix installation and

operations handbooks, accompanied by an alert symbol paired with the word

"DANGER", "WARNING", or "CAUTION".

All warning messages will inform you of the potential hazard; how to reduce the

risk of case damage, personal injury or death; and what may happen if the in-

structions are not properly followed.

W A R N I N G

Indicates a potential threat of death or serious

injury if all instructions are not followed care-

fully.

▲

C A U T I O N

Indicates that failure to properly follow instruc-

tions may result in case damage.

▲

iv

Revision History

• new manual format_08/12

• parts list_09/12

• energy data and parts list_01/13

• endviews_03/13

• text update and airflow diagram_06/13

• energy data_07/13

• energy data_02/14

• endviews and energy data_09/14

• support diagram and parts page_02/15

• energy data and warranty_04/16

v

AGB REMOTE GRAVITY

ENERGY DATA

Numbers are based on standard case sizes. Consult engineering.

All measurements are taken per ARI 1200 - 2002 specifications.

Engineered for stores with ambient conditions not to exceed 75o and 55% relative humidity.

Due to engineering improvements specifications may change without notice.

Electrical Data

Lighting Data

Guidelines & Control Settings (DX)

Guidelines & Control Settings (Glycol)

Model

Fans

per

Case

High Efficiency

Fans

Anti-Condensate

Fans

Drain

Heaters

Optional Defrost

Heaters Humidification2

120 Volts 120 Volts 120 Volts 208 Volts 120 Volts

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

AGB 4’ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

6’ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

8’ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Model

Lights

per

Row

Light

Length

(ft)

Fluorescent

Lighting

(Per Light Row)

Clearvoyant LED Lighting

(Per Light Row)

Standard Power

(Cornice or Shelf)

High Power

(Cornice)

120 Volts 120 Volts 120 Volts

Amps Watts Amps Watts Amps Watts

AGB 4’ 1 4 0.27 32.4 0.24 30 - - - - - -

6’ 1 4 0.27 32.4 0.24 30 - - - - - -

8’ 1 4 0.27 32.4 0.24 30 - - - - - -

Model

Conventional

4BTUH/ft

Parallel

5BTUH/ft

Superheat

Set Point @ Bulb

(oF)

Evaporator

(oF)

Discharge

Air

(oF)

Discharge Air7

Velocity

(FPM)

AGB Gravity Coil 1527 500 12 15 28 - - -

Serpentine 255 50 8-10 336- - - - - -

RRS3255 200 8-10 - - - 28 - - -

Model

Conventional

BTUH/ft

Parallel

BTUH/ft Supply Temp. (oF)

Flow Rate

GPM/ft

Charge

GAL/ft

Cut-In

Temp (oF)

Cut-Out

Temp (oF)

AGB Gravity Coil 1527 500 20 0.8 0.5 - - - - - -

Serpentine 255 50 20 0.1 0.5 - - - - - -

RRS 255 200 20 0.1 0.5 28 26

2

ENERGY DATA

Numbers are based on standard case sizes. Consult engineering.

All measurements are taken per ARI 1200 - 2002 specifications.

Engineered for stores with ambient conditions not to exceed 75o and 55% relative humidity.

Due to engineering improvements specifications may change without notice.

Defrost Controls

AGB REMOTE GRAVITY

1 NOTE: “- - -” indicates data not applicable.

2 Optional humidification system available to boost humidity. Humidity levels are determined by store aged beef programs.

3 RRS - Refrigerated Rear Storage.

4,5 Listed BTUH indicates unlighted shelves. Add the following for lighted shelves:

4’ Fluorescent: 80 BTUH

3’ Fluorescent: 60 BTUH

4’ Shelf LED: 36 BTUH

4’ Canopy LED: 72 BTUH

3’ Shelf LED: 27 BTUH

3’ Hi-Output LED: 54 BTUH

6 EPR valve is factory installed.

7 Average discharge air velocity at peak of defrost.

8 Defrost is tied to gravity coil.

9 DX units equipped with RH systems require 2 defrosts per day with a fail-safe of 120 minutes.

10 Glycol units equipped with RH systems require 3 defrosts per day with a fail-safe of 120 minutes.

Model

Defrosts9,10

per Day

Run-Off

Time (min)

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(min)

Termination

Temp (oF)

Fail-Safe

(min)

Termination

Temp (oF)

Fail-Safe

(min)

Termination

Temp (oF)

AGB Gravity Coil 4 0 - - - - - - 90 47 - - - - - -

Serpentine8- - - - - - - - - - - - - - - - - - - - - - - -

RRS 6 0 - - - - - - 20 47 - - - - - -

3

CASE DIMENSIONS

AGB REMOTE GRAVITY

T8 VERTICAL

LIGHTING

T8 VERTICAL

LIGHTING

2 in

[5.1 cm]

28 in

[71.1 cm]

30 in

[76.2 cm]

6 in

[15.2 cm]

32 in

[81.3 cm]

19 7/8 in

[50.5 cm]

19 7/8 in

[50.5 cm]

20 13/16 in

[52.8 cm]

11 11/16 in

[29.7 cm]

49 13/16 in

[126.5 cm]

30 in

[76.2 cm]

25 13/16 in

[65.6 cm]

21 13/16 in

[55.4 cm]

2 in

[5.1 cm]

34 in

[86.4 cm]

36 in

[91.4 cm]

6 in

[15.2 cm]

32 in

[81.3 cm]

26 13/16 in

[68.1 cm]

11 11/16 in

[29.7 cm]

36 in

[91.4 cm]

31 13/16 in

[80.9 cm]

21 13/16 in

[55.4 cm]

49 13/16 in

[126.5 cm]

93 1/2 in

[237.5 cm]

93 1/2 in

[237.5 cm]

49 1/4 in

[125.1 cm]

49 1/4 in

[125.1 cm]

REFLECTIVE

REAR LOAD DOORS

REFLECTIVE

REAR LOAD DOORS

30" PROFILE 36" PROFILE

48 in

72 in

96 in

[121.9 cm] {4’ case}

[182.9 cm] {6’ case}

[243.8 cm] {8’ case}

28 in [71.1 cm] (30")

34 in [86.4 cm] (36")

26 in [66.0 cm] (30")

32 in [81.3 cm] (36")

TOEKICK

15" x 15" MECHANICAL ACCESS

FOR ELECT. ,REFRIG. ,AND DRAIN CONNECTIONS

TOEKICK

L

C

FRONT OF CASE

18 in

[45.7 cm]

14 in

[35.6 cm]

30 in [76.2 cm]

36 in [91.4 cm]

6 in

[15.3 cm]

POWER SUPPLY

2 in

[5.1 cm]

25 7/8 in

[65.7 cm]

25 7/8 in

[65.7 cm]

LOWER STORAGE WITH

REAR LOAD DOORS

LOWER STORAGE WITH

REAR LOAD DOORS

4

Hillphoenix Barker Specialty Products

703 Franklin Street, PO Box 478

Keosauqua, IA 52565

Tel: (319) 293-3777/Fax: (319) 293-3776

Web site: www.hillphoenix.com

GENERAL INFORMATION

Thank you for choosing Hillphoenix for your food merchandising needs. This handbook contains important technical information

and will assist you with the installation and operation of your new Hillphoenix specialty cases. By closely following the instruc-

tions, you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel free to

contact our Marketing Services group at the number listed below. Thank you for choosing Hillphoenix, and we wish you the very

best in outstanding food merchandising.

CASE DESCRIPTION

This manual specifically covers the AGB-RG aged meat and

cheese application, service multi-deck merchandiser.

STORE CONDITIONS

Hillphoenix cases are designed to operate in an air-condi-

tioned store that maintains a 75°F (24°C) store temperature

and 55% (max) relative humidity (ASHRAE conditions). Case

operation will be adversely affected by exposure to excessively

high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation for

efficient performance. Machine-room temperatures must be

maintained at a minimum of 65°F in winter and a maximum

of 95°F in summer. Minimum condensing temperatures

should be no less than 70°F.

SHIPPING CASES

Transportation companies assume all liability from the time a

shipment is received by them until the time it is delivered to

the consumer. Our liability ceases at the time of shipment.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping dam-

age and/or shortages, please contact the Service Parts

Department at the number listed below.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carrier's

agent; otherwise, the carrier may refuse the claim. If damage

becomes apparent after the equipment is unpacked, retain all

packing materials and submit a written request to the carrier

for inspection within 14 days of receipt of the equipment.

Failure to follow this procedure will result in refusal by the

carrier to honor any claims with a consequent loss to the

consumer.

If a UPS shipment has been damaged, retain the damaged

material, the carton and notify us at once. We will file a

claim.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the highest

level of quality. Any claim for lost/missing items must be

made to Hillphoenix within 48 hours of receipt of the equip-

ment. When making a claim please use the number listed

below.

SERVICE & TECHNICAL SUPPORT

For service or technical questions regarding specialty cases,

please contact our Specialty Products Division Service

Department at 1-319-293-3777. For questions regarding our

refrigeration systems or electrical distribution centers, please

contact our Systems Division Customer Service Department at

1-770-388-0706.

CONTACTING THE FACTORY

If you need to contact Hillphoenix regarding a specific fixture,

be certain that you have both the case model number and

serial number (this information can be found on the data tag,

located on the top-left interior of the case). When you have

this information, call the number below and ask for a Service

Parts Representative.

5

CASE INSTALLATION

FLOOR PREP

1. Ask the general contractor if your current copy of the build-

ing dimensions are the most recently issued. Also, ask for

the points of reference from which you should take dimen-

sions to locate the cases.

2. Using chalk lines or a laser transit, mark the floor where

the cases are to be located for the entire lineup. The lines

should coincide with the outside edges of the case feet.

3. Move case as close as possible to its permanent location.

Remove all crating and shipping braces above the ship-

ping pallet. Loosen the plastic dust cover from the pallet,

but leave cover over the case to protect it while removing

the case from the pallet. Carefullly, lift case up and off the

pallet. Remove dust cover. Istallation hardware ships in a

marked packet located inside the case.

4. Leveling is necessary to ensure proper operation of the

refrigeration system and drainage of the condensate.

Locate the highest point on the positioning lines as a ref-

erence for determining the proper height of the shim-pack

levelers. A laser transit is recommended for precision and

requires just one person. Level adjustable feet by twisting,

if appliacble, or shim as necessary under vertical supports

as this will help ensure that the case is not settling over

time.

5. Locate horizontal support (Fig. 1) positions along the chalk

line. Spot properly leveled shim packs at each support

location.

LINE-UP & INSTALLATION

Single Case

1. Move the case into position, leaving a minimum of 2"

between the wall and back of case. Using a “J” bar, raise

the end of the case (under cross support), and lower the

horizontal support on to the shim packs. Repeat on the

other end of the case.

LOCATION

This refrigerated display case has been designed for displaying

and storing perishable food product. It is engineered for air-

conditioned stores with a maximum ambient of 75°F and 55%

relative humidity.

When selecting the location for placement of this case, avoid

the following conditions:

Excessive Air Movement

1. Doors

2. Air-conditioned vents

3. Other air sources

Excessive Heat

1. Windows

2. Sun

3. Flood lamps 8 feet or less from the product

4. Other heat sources

C A U T I O N

Locate the horizontal supports under unit before

removing from pallet. Failure to do so will dam-

age the finished metal if correct lift points are

not identified prior to removal.

▲

C A U T I O N

These cases are not designed for excessive

external weight. Do not walk on top or inside

of cases. Doing so may result in case damage

and/or personal injury.

▲

W A R N I N G

Be certain that your hands and feet are out of

the way before lowering the case. Failure to do

so may result in serious injury.

▲

Fig. 1 Horizontal supports

SUPPORTS

2. Once the case is properly placed on the shim packs,

check the vertical plumb of the case by placing a bubble

level on the rear wall. Add/remove shim packs as needed.

For the horizontal level, repeat this process after placing

the bubble level on the front sill.

3. Bolt the horizontal base brackets to the bottom outside-

front and back of both line-up cases (Fig. 2). Repeat this

with the domino brackets to the top of the cases ensuring

that brackets are fastened to both cases securely (Fig. 3).

4. Properly align the front panels as needed, then install, if

applicable, front panel trim (supplied).

5. Install the bumper, if applicable, into pre-attached bumper

6

CASE INSTALLATION

Fig. 2 Horizontal base bracket

Fig. 3 Domino bracket

BOLT

DOMINO

track and snap into place.

6. After sufficient time has passed to allow for bumper

shrinkage, cut away the excess bumper for final fit and fin-

ish. Be certain to use an appropriate cutting tool (tubing-

or PVC-cutter) to ensure a smooth cut.

7. Install case shelves and reconnect lights. Be aware that

differing shelf configurations will affect energy consump-

tion and case performance.

8. Snap toekick back onto the base of case.

C A U T I O N

Installation of 3rd-party materials may result in

diminished case performance.

▲

7

CASE CONNECTIONS

REFRIGERATION

Refrigeration connections will be made through the refrigera-

tion stub up location on the customer left side of the case.

Refrigeration lines may be headed together for all cases in a

line-up, if necessary, by lines through the access holes with a

high grade silicon to prevent recirculation. All lines must be

correctly sized. See diagram on page 9 for access locations.

If it becomes necessary to penetrate the case bottom for any

reason, make certain it is sealed afterward with canned-foam

sealant and white RTV.

ELECTRICAL

Electrical hookups are made through the power supply box

that can be accessed by removing the back panel.

For case-to-case wiring, run conduit between the power supply

boxes or run wiring through the raceway. When connecting to

the power supply on the case, field wiring should exit box from

the side furthest away from case wiring to allow more room in-

side for wiring connections. Always check the data tag located

on left end exterior panel or top interior of the case. The case

must be grounded. For more detailed electrical wiring infor-

mation, see Appendices A1-A2.

C A U T I O N

Be certain that all plumbing connections are

compliant with local codes.

▲

C A U T I O N

Be certain that all electrical connections are

compliant with local codes.

▲

C A U T I O N

Be sure to remove all styrafoam shipping blocks

from piping and refrigerant lines. Failure to do

so may result in case damage.

▲

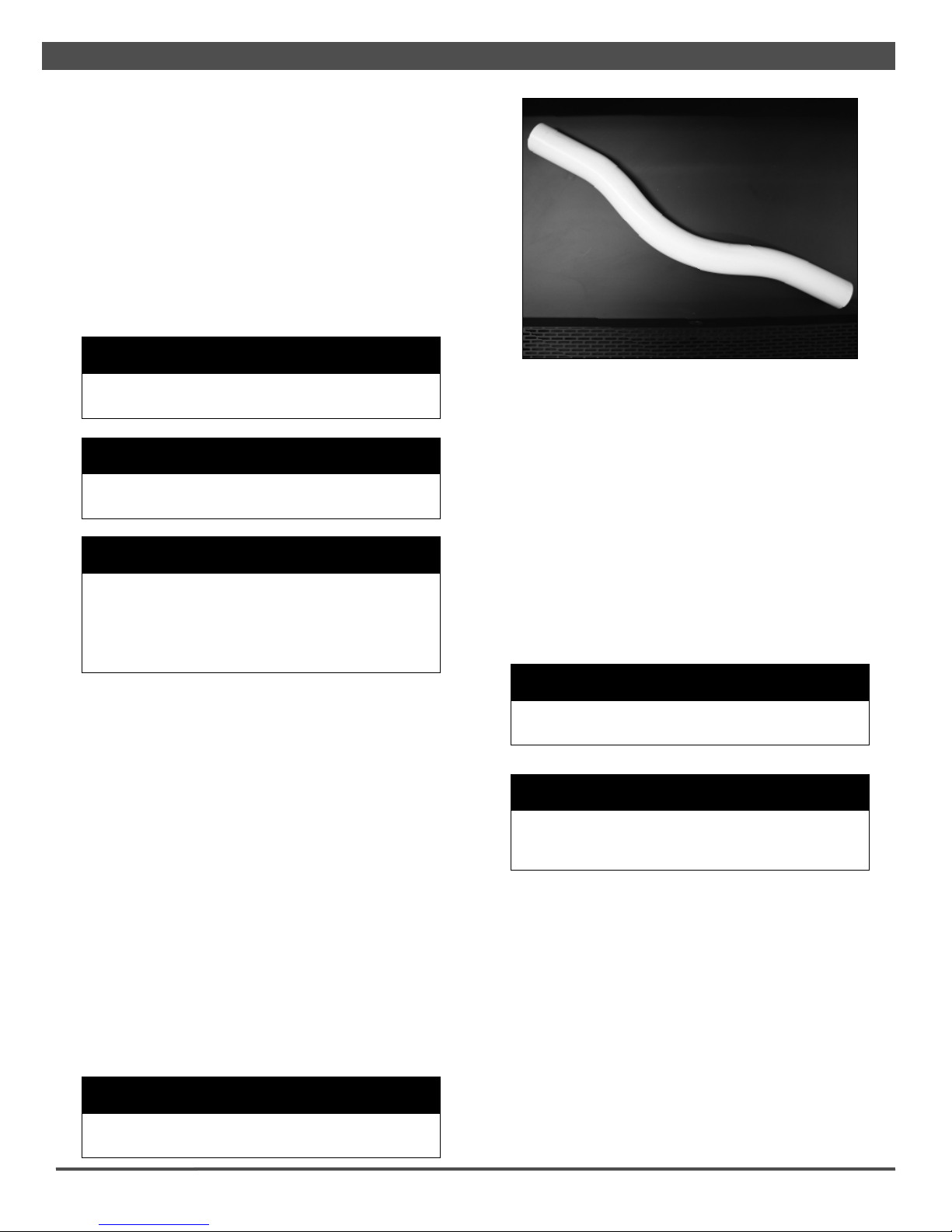

Fig. 4 "P" trap / drain outlet

PLUMBING

The drain outlet or “P” trap (Fig. 4) is shipped loose with the

case and made from a 1 1/2” PVC pipe. Care should be given

to ensure that all connections are water-tight and sealed with

the appropriate PVC or ABS cement.

Drain lines can be run left or right of the tee with the proper

pitch to satisfy local drainage requirements. When connecting

the PVC to the existing "oor drains be sure to provide as much

downhill slope as possible and avoid long runs of drain lines.

Do not install condensate drains in contact with non-insulated

suction lines in order to prevent condensate from freezing.

Install the 1 1/2# PVC trap, which is provided with the case. All

drains must be trapped.

Before operating the case, be certain to remove the styrafoam

shipping block that protects the plumbing lines during ship-

ping.

C A U T I O N

If any brazing is necessary, place wet rags

around the area to avoid tank damage.

▲

C A U T I O N

Be certain that all piping connections are com-

pliant with local codes.

▲

C A U T I O N

If the shelves are removed from the case or other-

wise not utilized, the shelf setpoint (SAA) must be

raised to 90 oF to prevent the pump from running

when only the shelves are calling for refrigeration.

Failure to do so could result in early pump failure.

▲

8

CASE CONNECTIONS

48 in

72 in

96 in

[121.9 cm] {4’ case}

[182.9 cm] {6’ case}

[243.8 cm] {8’ case}

18 in

[45.7 cm]

14 in

[35.6 cm]

28 in [71.1 cm] (30")

34 in [86.4 cm] (36")

30 in [76.2 cm]

36 in [91.4 cm]

26 in [66.0 cm] (30")

32 in [81.3 cm] (36")

TOEKICK

15" x 15" MECHANICAL ACCESS

FOR ELECT. ,REFRIG. ,AND DRAIN CONNECTIONS

TOEKICK

L

C

FRONT OF CASE

MECHANICAL ACCESS LOCATIONS

9

LIGHTING & POWER SUPPLIES

BALLAST/POWER SUPPLY ACCESS

To gain access to the ballasts or power supplies remove the

panel located above the rear toe kick.

Fig. 7 Positive engagement

GENERAL LIGHTING INFORMATION

Hillphoenix cases are equipped with either T-8 lights or LED

luminaires and feature specially designed light reflectors in the

cornice to improve the illumination of products. Depending on

case configuration, T-8 electronic ballasts or LED power sup-

plies operate both the cornice and shelf lights and are located

above the cornice reflectors.

The lighting system in the electrical raceway has an ON/OFF

switch located at the back exterior of the case. Once cases

have been properly positioned in the store and an electrician

has connected the lighting circuit, the lights may be turned on

to verify that they are connected and functioning properly.

To ensure peak performance, it is advisable to run the lighting

systems only when the store climate control is on and case

refrigeration is started. NOTE: it is highly recommended that

the ambient store temperature not exceed 80°F.

D A N G E R

▲

SHOCK HAZARD

Always disconnect power to case when cleaning,

servicing or con!guring components of the light-

ing system. Failure to do so may result in serious

injury or death.

REPLACING T-8 LIGHTS

1. Unplug T-8 lamp power cords located at the inside-back of

the case below the lamp being replaced (Fig. 5).

2. Carefully seperate the cap from the lamp holder on both

ends of the T-8 lamp (Fig. 6). Simultaneously pull down at

both ends of the old T-8 lamp to remove.

Fig. 5 T-8 light power cords

W A R N I N G

▲

Using improper DC power supplies may damage

the luminaires, resulting in sub-standard opera-

tion and increased chances of safety issues/

injury.

W A R N I N G

▲

Never replace a 24V DC power supply with a T8

or T5 ballast of any kind! Ballasts use alternat-

ing current (AC) instead of direct current (DC)

and operate at a much higher voltage than is

used by this LED system. Doing so will damage

the LED system and increases the chance of

safety issues/injury.

3. Push and snap the new T-8 lamp into place on the lamp

holder. When the T-8 is properly seated, the lamp button

- which secures the T-8 to the lamp holder - will be clearly

visible through the lamp button hole. The cap should be

pushed all the way down (Fig. 7) for positive engagement

indicator.

Fig. 6 T-8 cap and lamp holder

LAMP HOLDER

CAP

10

LIGHTING & POWER SUPPLIES

REPLACING LED LIGHTS

Once store power is connected and the light circuit is ener-

gized, the Clearvoyant LED system should operate without

the need for any significant maintenance for several years.

Should a power supply need to be removed and/or replaced,

turn off the power to the case before proceeding. Be certain

to replace the power supply with genuine Hill PHOENIX parts or

a comparable UL-listed Class-2 rated regulated 24V DC power

supply with 100W output capacity.

SHELF LUMINAIRES

Removing shelf luminaires:

1. Unplug the luminaire.

2. Pinching the latching clips inward at the ends of the lumi-

naire, rotate luminaire up at each end until hooks are free,

then remove.

Re-installing shelf luminaires:

1. Place hook into shelf roll form at shelf front and rotate

rear of luminaire toward the shelf.

2. Depress the rear clip so that luminaire can finish rotation

and until clip engages the shelf bracket.

NON-SHELF LUMINAIRES

Removing non-shelf luminaires:

1. Simultaniously squeeze the plastic clips at each end.

2. When the hooks are disengaged, pull the luminaire free.

Re-installing non-shelf luminaires:

1. Align the 4-pole jack with the 4-pole connector on the clip-

in luminaire.

2. Push into place - side clips will engage on the sheet metal

of the case.

3. Fasten anti-tamper bracket into sheet metal of case with

#8 screw at end opposite of the 4-pole in-line connector

D A N G E R

▲

SHOCK HAZARD

Always disconnect power to case when cleaning,

servicing or configuring components of the light-

ing system. Failure to do so may result in serious

injury or death.

11

PRE-POWER CHECKLIST

Have you thoroughly examined the case for shipping damage? (see pg. 5)

Have you checked the vertical plumb of the case? The horizontal level?

(see pg. 6)

Have you installed the toekick? (see pg. 7)

Have you removed the shipping blocks from the refrigeration and plumbing

lines? (see pg. 8)

After powering-up the case, be certain that all of the steps listed below have

been completed to ensure proper case functionality, safety and compliance with

warranty terms.

1. Check all lights to ensure they are all functioning properly.

2. Check case temperature and adjust controller as needed.

Before powering-up the case, be certain that all of the steps listed below have

been completed to ensure proper case functionality, safety and compliance with

warranty terms.

12

AIRFLOW & DEFROST

AIRFLOW & PRODUCT LOAD

Hillphoenix cases provide maximum product capacity within the

refrigerated air envelope. Please keep products within the ap-

propriate load limit.

It is important that you do not overload the food product display

so that it impinges on the air•ow pattern (Fig. 8). Overload-

ing will cause malfunction and the loss of proper temperature

levels, particularly when discharge and return air sections are

covered.

DEFROST & TEMPERATURE CONTROLS

Cases are equipped with either Electric, Hot Gas, or Timed-Off

defrost at the owner's option.

The hot gas defrost termination sensor bulb and probe are

attached to the dump line which is in the front, left-hand side

of the case.

W A R N I N G

Always keep product within the designated air

curtain. Failure to do so may result in case

malfunction and product losing proper tempera-

ture, resulting in sub-standard operation and

increased chances of food contamination.

!

Fig. 8 Airflow pattern

HUMIDIFICATION SYSTEMS

The starting point for proper humidity levels in the AGB display

case are typically around 75% RH when stocked with product.

The RH will vary during defrost or cycling. A humidification

system is recommended to ensure consistent performance in

all store ambient. Several factors to consider are listed below

and adjustments may need to be made to the setting for par-

ticular configurations to maintain humidity levels within a case.

1. Store Conditions - Hillphoenix cases are designed to oper-

ate in an air-conditioned store that maintains a 75°F

(24°C) store temperature and 55% (max) relative humidity

(ASHRAE conditions). Case operation will be adversely

affected by exposure to excessively high ambient tempera-

tures and/or humidity.

2. Desired Case Temperature - Hillphoenix recommends a

set point of 33˚-36˚F. If the meat is too cold the meat may

freeze and the aging process will slow or stop. If the meat

is too warm it will spoil.

3. Dry Aging Process - Dry aged beef is typically stored for

14-21 days in a humidity and temperature controlled envir-

norment. The productmoisture content, desired shrink and

approximate timespent in the aging process all are factors

related to the amountof humidity the product releases into

the case environment.

All set points and parameters are starting point and

must be adjusted to meet ambient conditions and

desired product temperatures.

If store conditions are very dry, an optional humidification sys-

tem is recommended.

If your case is equipped with a Dixell temperature and humidity

controller, see Appendices B1-B4 for operating instructions.

DETERMINING SUPERHEAT

To identify proper superheat settings, complete the following:

1. Obtain suction pressure from access port; obtain suction

line temperature from area near TXV bulb at the outlet of

evaporator coil.

2. Using the suction pressure reading, convert pressure to

temperature using temperature pressure chart (see

Appendix C1).

3. Finally, subtract the converted temperature reading from

the actual temperature reading for superheat setting.

13

CASE CLEANING

CASE CLEANING

A periodic cleaning schedule should be established to maintain

proper sanitation, insure maximum operating efficiency, and

avoid the corrosive action of food fluids on metal parts that are

left on for long periods of time. We recommend cleaning once

a week. Further suggestions for case cleaning include the fol-

lowing:

• To avoid shock hazard, be sure all electrical power is turned

off before cleaning. In some installations, more than one

disconnect switch may have to be turned off to completely

de-energize the case.

• All surfaces pitch downward to a deep-drawn drain trough,

funneling liquids to the center of the case where the waste

outlet is located for easy access. Check the waste outlet to

insure it is not clogged before starting the cleaning process

and avoid introducing water faster than the case drain can

carry it away.

• To clean the LED luminaires, shut off the lights in the case,

then wipe the luminaires down with a soft, damp cloth.

Avoid using harsh or abrasive cleaners as they may dam-

age the lights. Be certain that the luminaires are complete-

ly dry before re-energizing.

• Clean from top to bottom when cleaning the display case to

avoid cross contamination.

• If any potentially harmful cleaners are used, be certain

to provide a temporary separator (e.g., cardboard, plastic

wrap, etc.) between those cases that are being cleaned

and those that may still contain product.

• Avoid spraying any cleaning liquids directly on the electrical

connections.

• Allow cases to be turned off long enough to clean any frost

or ice from coil and pans.

• Remove toekick and clean underneath the case with a

broom and a long-handled mop. Use warm water and a

disinfecting cleaning solution when cleaning underneath

the cases.

D A N G E R

▲

SHOCK HAZARD

Always disconnect power to case when servicing

or cleaning. Failure to do so may result in serious

injury or death.

W A R N I N G

▲

Exercise extreme caution when working in a case

with the coil cover removed. The coil contains

many sharp edges that can result in severe cuts

to the hands and arms.

14

SOVIS ULTRAVISION®tempered glass specialized Anti-Reflective coatings on each surface of the glass.

These coatings reduce the glare from lighting so that the products on display are more visible to your

customers.

While the Anti-Reflective coatings are durable, they are susceptible to scratching if abrasive materials are

used for cleaning. Once the glass surfaces are scratched, it is impossible to restore the original finish.

Special care must be taken to prevent damage when cleaning the glass. SOVIS recommends the

following products for routine cleaning of ULTRAVISION®Anti-Reflective glass:

Cleaning Cloths – two products are recommended…

Scotch-Brite®High Performance Cloth – manufactured by 3M®and available in most grocery

stores under the name Scotch-Brite®Microfiber Cleaning Cloth in a 12” x 14” size. This cloth is

washable and may be reused as long as it remains clean.

Spontex®Microfibre Cleaning Cloth – distributed by Spontex®and available in most grocery stores

under the same name in a 15.75” x 12” size. This cloth is washable and may be reused as long as it

remains clean.

Cleaning Fluid – for more difficult cleaning jobs, these products are recommended…

Windex®- standard product only (extra-strength or specialty products may not be suitable)

Glass-Plus®- standard product only (extra-strength or specialty products may not be suitable)

Exceed®Multi-Surface & Glass Cleaner – from Kay Chemical Company, Greensboro, NC

Warm Water

Note: equivalent store-brand glass cleaning products are normally acceptable substitutes to the brand

name products listed above.

The cleaning cloths named above will normally remove dust, grease, oil, and fingerprints without the need

for cleaning fluids. A light spray of the cleaning fluids listed above will reduce the time required for

cleaning. These materials have been tested and proven to clean ULTRAVISION®glass without

scratching or damaging the Anti-Reflective coatings. If you need assistance with obtaining these

materials, please contact your display case supplier.

Under no circumstances should the following types of materials be used for cleaning glass with

ULTRAVISION®Anti-Reflective coatings.

Coarse Paper Towels

Scouring Pads or Powders

Steel Wool or Steel Fiber Materials

Blades

Acidic or highly Alkaline detergents

Fluorine based detergents

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION ABOUT

CLEANING YOUR ULTRAVISION®ANTI-REFLECTIVE GLASS!

PLEASE READ AND FOLLOW THESE INSTRUCTIONS TO

PREVENT DAMAGE TO THE ANTI-REFLECTIVE COATINGS.

C A U T I O N

Do not use these materials for cleaning glass.

▲

CASE CLEANING

15

PARTS ORDERING

Contact the Service Parts Department at:

319-293-3777

Provide the following information about the part you are ordering:

• Model number and serial number* of the case for which the part is intended.

• Length of the part (if applicable).

• Color of part (if painted) or color of polymer part.

• Whether part is for left- or right-hand application.

• Quantity

*Data tag is located on the left end exterior panel or top interior of the case.

If the parts are to be returned for credit, contact the Parts Department. Do not send parts without

authorization.

16

Table of contents

Other Barker Merchandiser manuals

Popular Merchandiser manuals by other brands

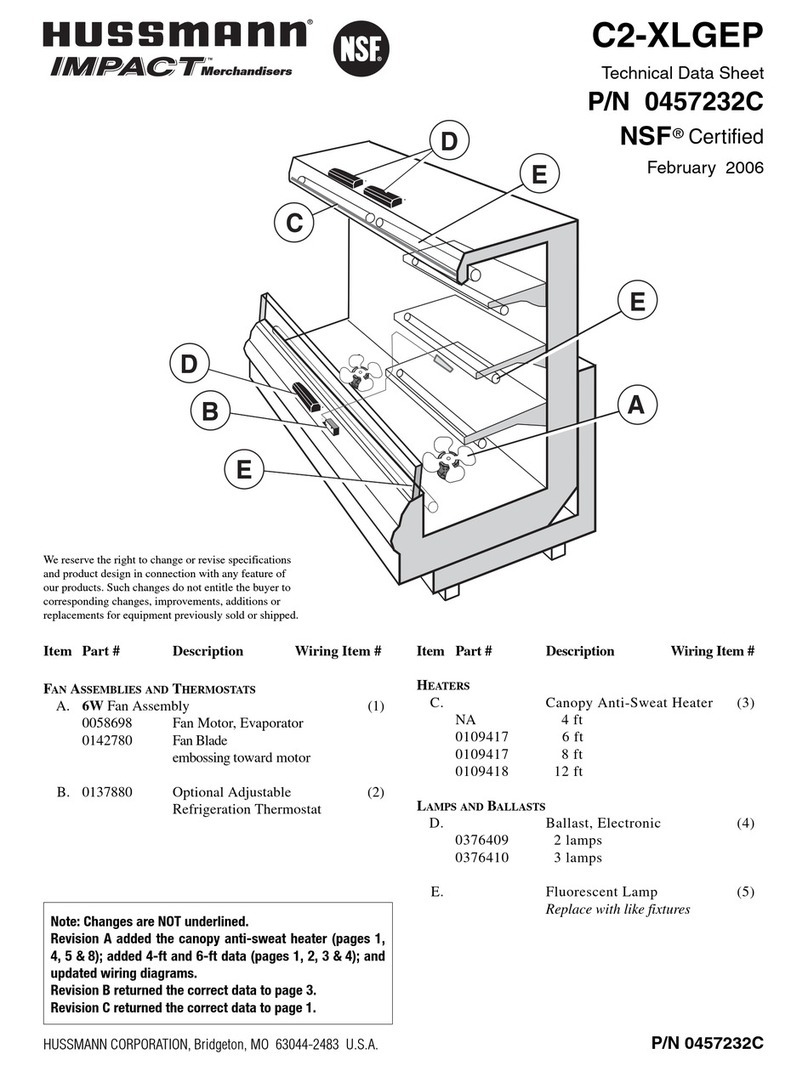

Hussmann

Hussmann Impact Excel C2X-LGEP Technical data sheet

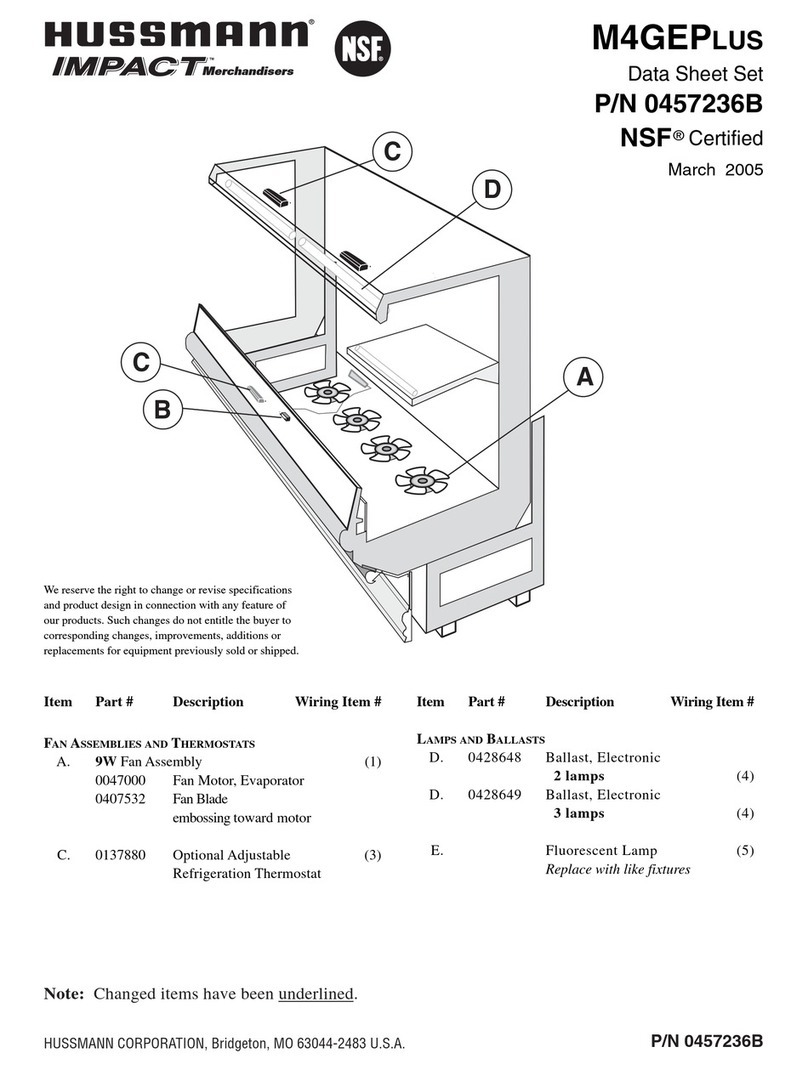

Hussmann

Hussmann M4G-EP datasheet

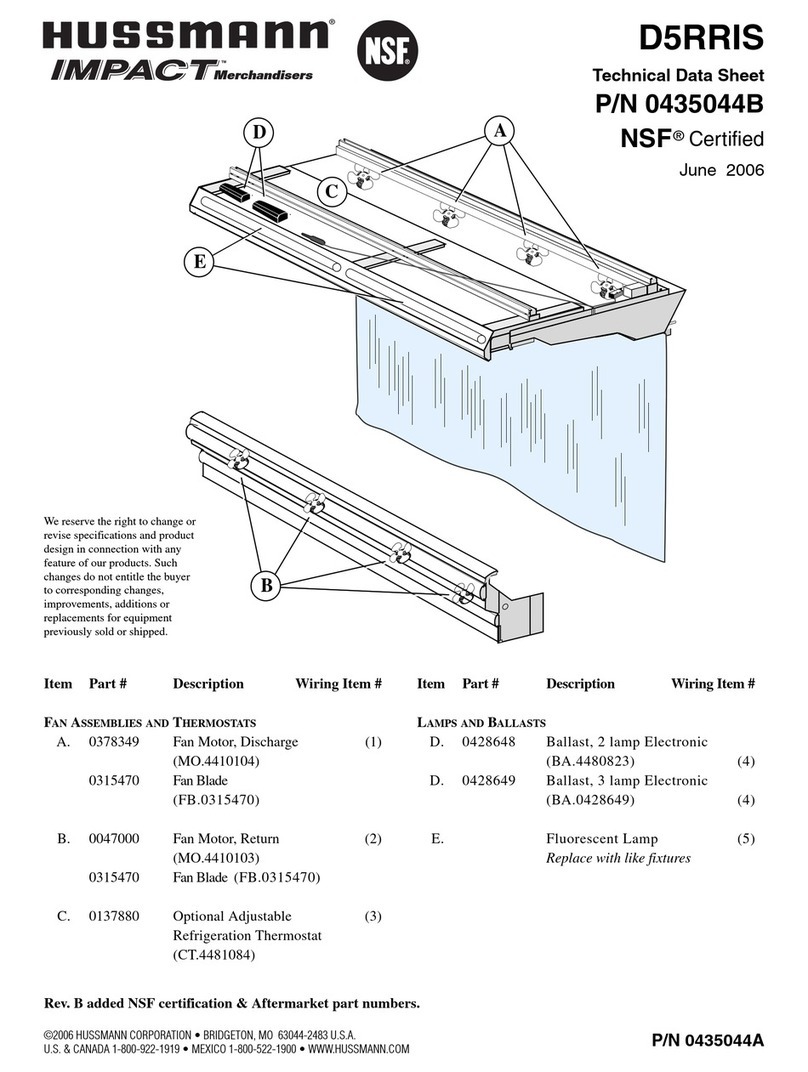

Hussmann

Hussmann IMPACT D5RRIS Technical data sheet

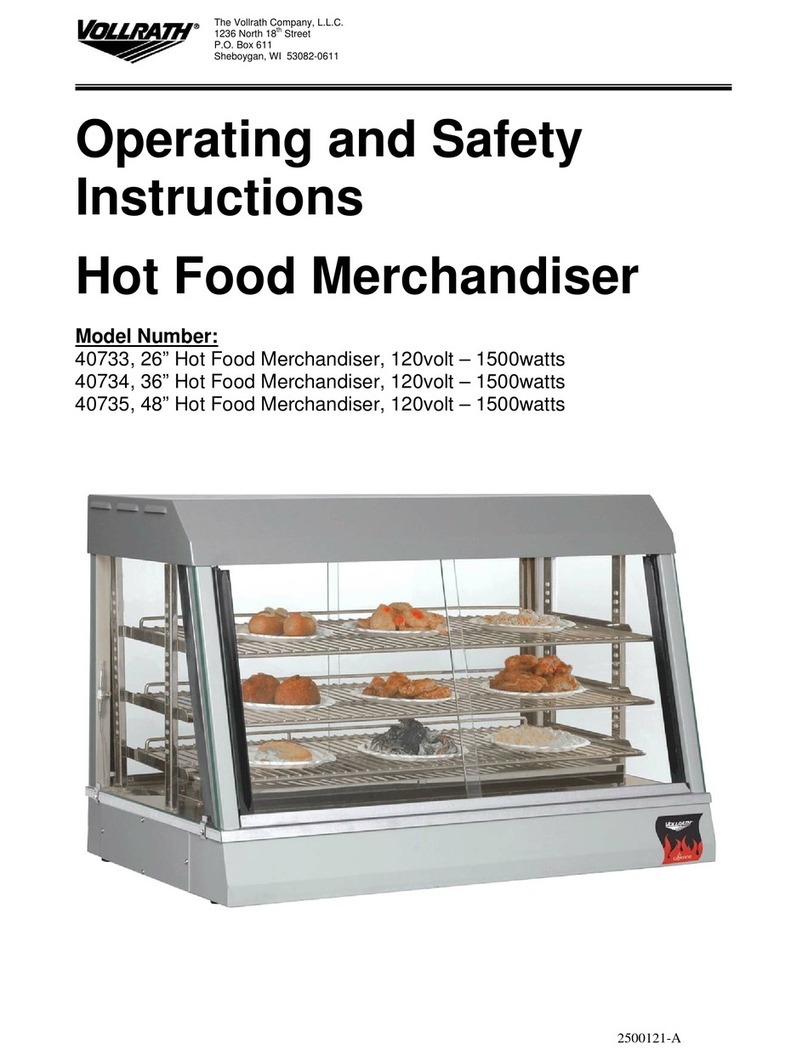

Vollrath

Vollrath 40733 Operating and safety instructions

Avantco

Avantco 178GDW23BB user manual

Alto-Shaam

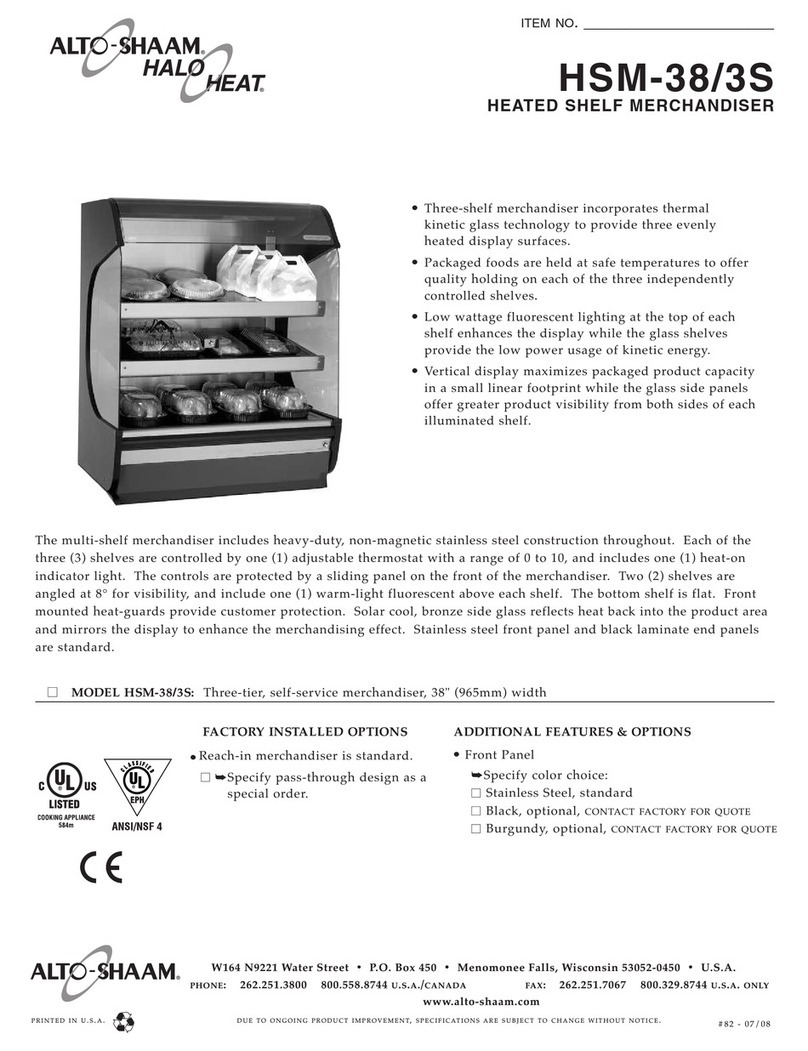

Alto-Shaam HSM-38/3S Installation operation & maintenance

Alto-Shaam

Alto-Shaam HSM-38/3S Specification sheet

Randell

Randell 40024 Series Specifications

Hatco

Hatco GLO-RAY GR3SDS-39DCT Installation and operating manual

Master Bilt

Master Bilt IM-38 Installation and operation manual

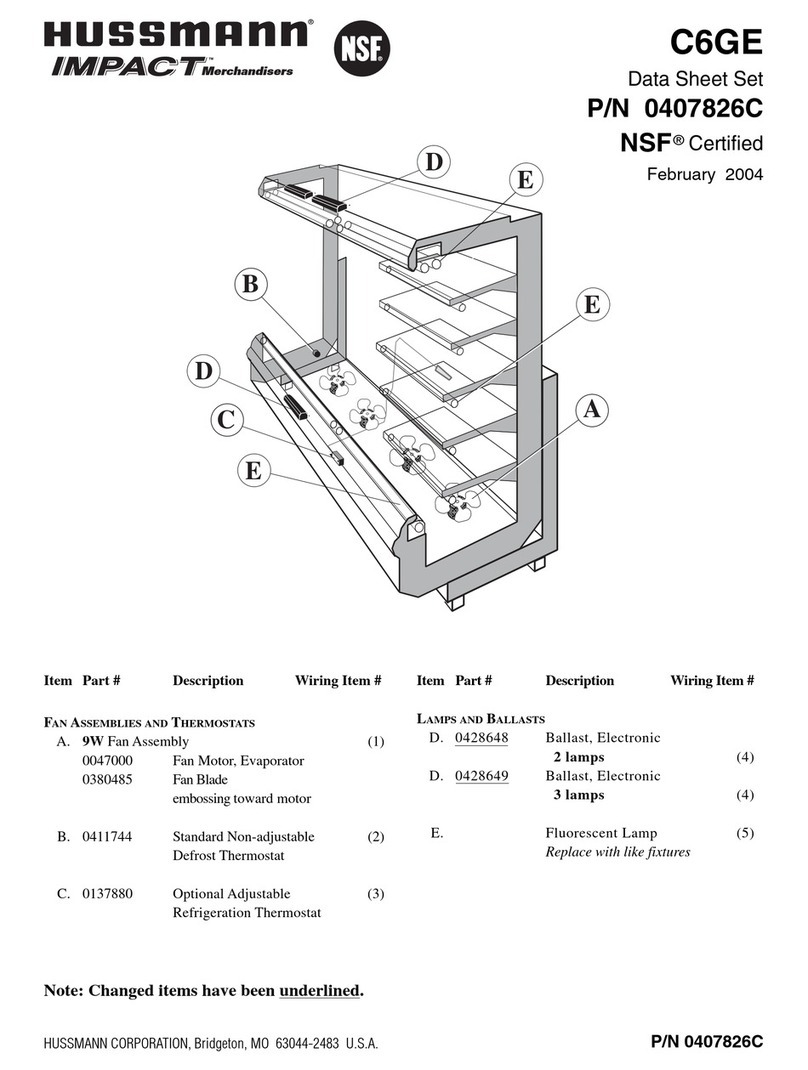

Hussmann

Hussmann Impact C6GE datasheet

Hussmann

Hussmann NEBBDT Installation & service manual