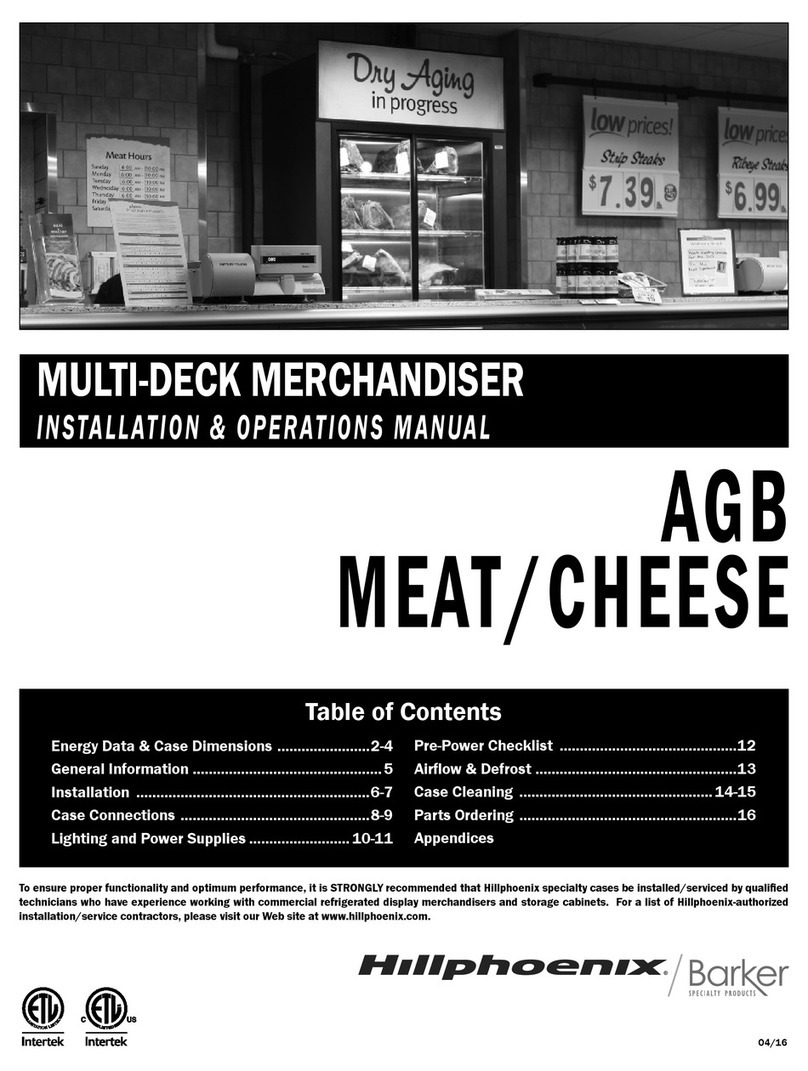

Barker PTD-RGC User manual

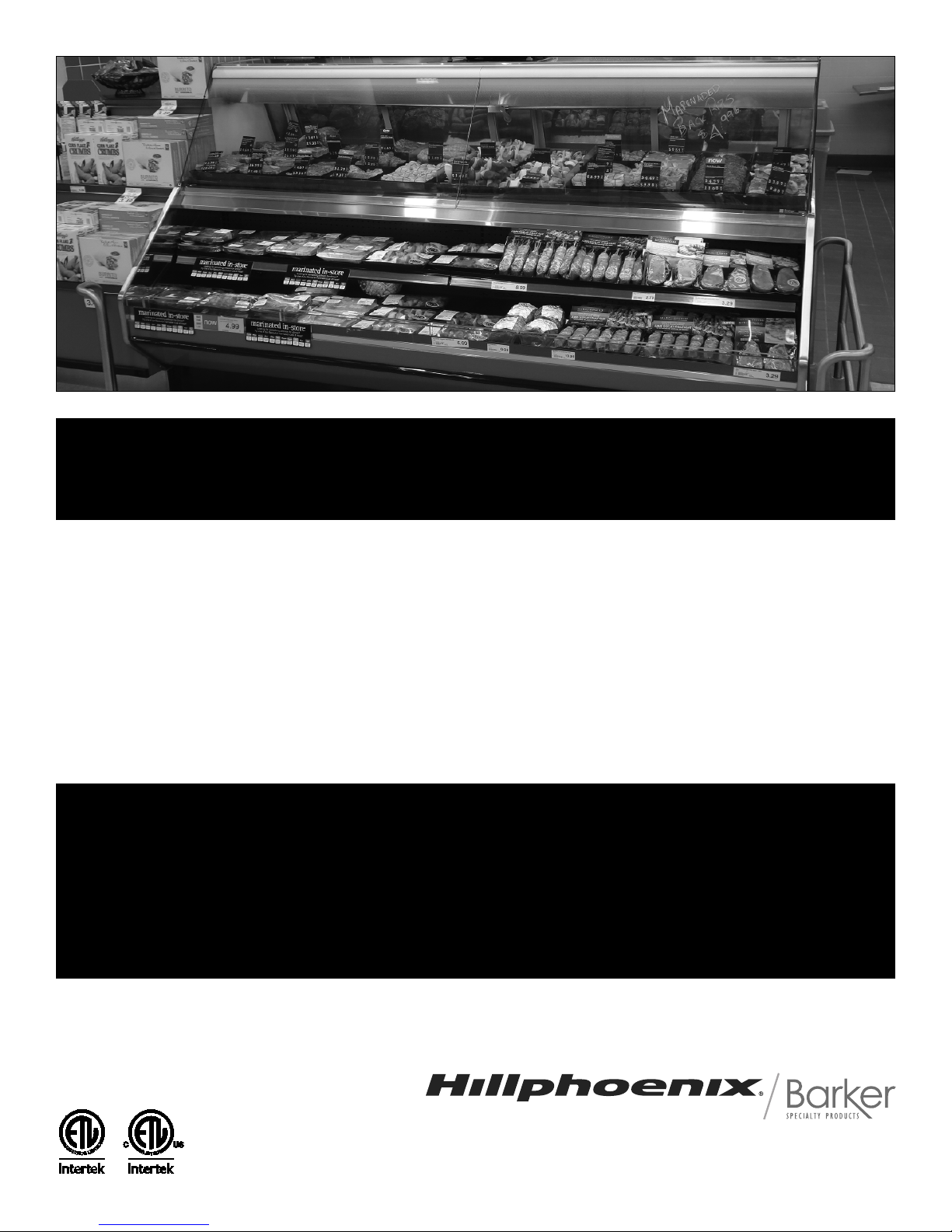

PTD-RGC

DELI/MEAT/SEAFOOD

09/16

MULTI-DECK MERCHANDISER

I N S TA L L AT I O N & O P E R AT I O N S M A N U A L

Energy Data & Case Dimensions ......................2-4

General Information ............................................... 5

Installation ..........................................................6-8

Case Connections ............................................ 9-12

Lighting and Power Supplies ......................... 13-14

Pre-Power Checklist ............................................15

Airflow & Defrost ..................................................16

Case Cleaning ................................................ 17-24

Parts Ordering ......................................................25

Appendices

Table of Contents

To ensure proper functionality and optimum performance, it is STRONGLY recommended that Hillphoenix specialty cases be installed/serviced by qualified

technicians who have experience working with commercial refrigerated display merchandisers and storage cabinets. For a list of Hillphoenix-authorized

installation/service contractors, please visit our Web site at www.hillphoenix.com.

ii

R-744 (CO2) NOTICE

For Systems Utilizing R-744 (CO2) Refrigerant

For refrigeration units that utilize R-744 (CO2), pressure relief and pressure-regulating relief valves may need

to be installed based on the system capacity. The valves need to be located such that no stop valve is posi-

tioned between the relief valves and the parts or section of the system being protected.

When de-energizing refrigeration units containing R-744 (CO2), venting of the R-744 (CO2) refrigerant may

occur through the pressure regulating relief valves. These valves are located on the refrigeration system

and not on the case model. If venting does occur, the valve must not be defeated, capped, or altered by any

means.

WARNING: Under no circumstances should any component be replaced or added without consulting

Hillphoenix Field Service Engineering. Utilizing improper components may result in serious injury to

persons or damage to the system.

LIABILITY NOTICE

For Cases with Shelf Lighting Systems

Hillphoenix does NOT design any of its shelf lighting systems or any of its display cases with shelf lighting

systems for direct or indirect exposure to water or other liquids. The use of a misting system or water hose

on a display case with a shelf lighting system, resulting in the direct or indirect exposure of the lighting

system to water, can lead to a number of serious issues (including, without limitation, electrical failures,

!re, electric shock, and mold) in turn resulting in personal injury, death, sickness, and/or serious property

damage (including, without limitation, to the display itself, to the location where the display is situated

[e.g., store] and to any surrounding property). DO NOT use misting systems, water hoses or other devices

that spray liquids in Hillphoenix display cases with lighted shelves.

If a misting system or water hose is installed or used on a display case with a shelf lighting system, then

Hillphoenix shall not be subject to any obligations or liabilities (whether arising out of breach of contract,

warranty, tort [including negligence], strict liability or other theories of law) directly or indirectly resulting

from, arising out of or related to such installation or use, including, without limitation, any personal injury,

death or property damage resulting from an electrical failure, !re, electric shock, or mold.

P079211M, REVO

iii

Important

D A N G E R

•

Indicates an immediate threat of death or seri-

ous injury if all instructions are not followed

carefully.

At Hillphoenix®, the safety of our customers and employees, as well as the ongo-

ing performance of our products, are top priorities. To that end, we include impor-

tant warning messages in all Hillphoenix installation and

operations handbooks, accompanied by an alert symbol paired with the word

"DANGER", "WARNING", or "CAUTION".

All warning messages will inform you of the potential hazard; how to reduce the

risk of case damage, personal injury or death; and what may happen if the in-

structions are not properly followed.

W A R N I N G

Indicates a potential threat of death or serious

injury if all instructions are not followed care-

fully.

•

C A U T I O N

Indicates that failure to properly follow instruc-

tions may result in case damage.

•

iv

Revision History

• new manual format_12/13

• energy data_01/14

• energy data_03/14

• endviews_09/14

• support diagram and parts page_02/15

• warranty_04/16

• energy data_09/16

v

ENERGY DATA

Numbers are based on standard case sizes. Consult engineering.

All measurements are taken per ARI 1200 - 2002 specifications.

Engineered for stores with ambient conditions not to exceed 75o and 55% relative humidity.

Due to engineering improvements specifications may change without notice.

PTD-RGC COOLGENIX

Electrical Data

1 NOTE: “- - -” indicates data not applicable.

2 RRS - Refrigerated Rear Storage.

3,4 Listed BTUH indicates unlighted shelves. Add the following for lighted shelves:

4’ Fluorescent: 80 BTUH

3’ Fluorescent: 60 BTUH

4’ Shelf LED: 36 BTUH

4’ Canopy LED: 72 BTUH

3’ Shelf LED: 27 BTUH

3’ Hi-Output LED: 54 BTUH

5 Average discharge air velocity at peak of defrost.

6,7 Time-off duration for defrost with no termination control.

Model

Fans

per

Case

High Ef!ciency

Fans

Anti-Condensate

Fans

Drain

Heaters

Optional Defrost

Heaters

RRS2

Fans

per

Case

Unit Cooler Fans

120 Volts 120 Volts 120 Volts 208 Volts 120 Volts

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

PTD-RGC (BASE) 6’ 2 0.6 72 - - -1- - - - - - - - - - - - - - - - - - - - - - - -

8’ 3 0.9 108 - - - - - - - - - - - - - - - - - - - - - - - - - - -

10’ 4 1.2 144 - - - - - - - - - - - - - - - - - - - - - - - - - - -

12’ 4 1.2 144 - - - - - - - - - - - - - - - - - - - - - - - - - - -

Defrost Controls

Model

Defrosts

per Day

Run-Off

Time (min)

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(min)

Termination

Temp (oF)

Fail-Safe

(min)

Termination

Temp (oF)

Fail-Safe

(min)

Termination

Temp (oF)

PTD-RGC (BASE) DX 4 - - - - - - - - - 65/636 42 - - - - - -

RRS 4 - - - - - - - - - 65/736 42 - - - - - -

Model

Lights

per

Row

Light

Length

(ft)

Fluorescent Lighting

(Per Light Row)

Clearvoyant LED Lighting

(Per Light Row)

Standard Power

(Cornice or Shelf)

High Power

(Cornice)

120 Volts 120 Volts 120 Volts

Amps Watts

Maximum

Allowable

Rows Amps Watts

Maximum

Allowable

Rows Amps Watts

Maximum

Allowable

Rows

PTD-RGC (BASE) 6’ 2 3 0.34 40.8 - - - 0.14 16.8 - - - 0.24 28.8 - - -

8’ 2 4 0.47 56.4 - - - 0.20 24.0 - - - 0.36 43.2 - - -

10’ 2 5 0.61 73.2 - - - 0.24 28.8 - - - 0.44 52.8 - - -

12’ 3 4 0.69 82.8 - - - 0.30 36.0 - - - 0.54 64.8 - - -

Lighting Data

Guidelines & Control Settings (DX)

Model

Conventional

3BTUH/ft

Parallel

4BTUH/ft

Superheat

Set Point @ Bulb

(oF)

Evaporator

(oF)

Discharge

Air

(oF)

Discharge Air5

Velocity

(FPM)

PTD-RGC (BASE) DX 485 445 6-8 26 29 250

RRS 109 100 10 26 29 200

2

ENERGY DATA

PTD-RGC COOLGENIX

Numbers are based on standard case sizes. Consult engineering.

All measurements are taken per ARI 1200 - 2002 specifications.

Engineered for stores with ambient conditions not to exceed 75o and 55% relative humidity.

Due to engineering improvements specifications may change without notice.

Electrical Data

1 NOTE: “- - -” indicates data not applicable.

2 Semi Self-Contained is NOT available in a 4’ case.

* Listed data is based on the factory recommended default fresh meat temperature settings.

* Shelves are not recommended for fresh meat applications.

Model

Defrosts

per Day

Run-Off

Time (min)

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(min)

Termination

Temp (oF)

Fail-Safe

(min)

Termination

Temp (oF)

Fail-Safe

(min)

Termination

Temp (oF)

PTD-RGC (DOME) 1 5 - - - - - - 60 45 - - - - - -

Guidelines & Control Settings (Remote Secondary/Semi-Self Contained2)

Defrost Controls

Model

Fans

per

Case

High Ef!ciency

Fans

Anti-Condensate

Fans

Drain

Heaters

Optional Defrost

Heaters

120 Volts 120 Volts 120 Volts 208 Volts

Amps Watts Amps Watts Amps Watts Amps Watts

PTD-RGC (DOME) 4’ - - -1- - - - - - - - - - - - - - - - - - - - - - - -

6’ - - - - - - - - - - - - - - - - - - - - - - - - - - -

8’ - - - - - - - - - - - - - - - - - - - - - - - - - - -

10’ - - - - - - - - - - - - - - - - - - - - - - - - - - -

12’ - - - - - - - - - - - - - - - - - - - - - - - - - - -

Model

Lights

per

Row

Light

Length

(ft)

Fluorescent

Lighting

(Per Light Row)

Clearvoyant LED Lighting

(Per Light Row)

Standard Power

(Cornice or Shelf)

High Power

(Cornice)

120 Volts 120 Volts 120 Volts

Amps Watts

Maximum

Allowable

Rows Amps Watts

Maximum

Allowable

Rows Amps Watts

Maximum

Allowable

Rows

PTD-RGC (DOME) 4’ - - - - - - - - -

6’ 2 3 0.37 44.0 - - - 0.14 16.6 - - - 0.24 29.8 - - -

8’ 2 4 0.47 56.0 - - - 0.20 23.8 - - - 0.36 43.0 - - -

10’ 3 3 0.71 85.0 - - - 0.21 25.2 - - - 0.40 48.0 - - -

12’ 3 4 0.71 85.0 - - - 0.30 35.7 - - - 0.54 64.5 - - -

Lighting Data

Cut-In/Cut-Out

Model

Cut-In

Temp (oF)

Cut-Out

Temp (oF)

PTD-RGC (DOME) Pans 33 29

Top Coil 36 31

Model

Conventional

BTUH/ft

Parallel

BTUH/ft

Glycol

Supply Temp.

(oF)

DX SST

Chiller

Temp. (oF)

Glycol

Flow Rate

GPM/ft

Glycol

Charge

GAL/ft

Glycol

Max. Working

Pressure (PSIG)

Max. Static

Pressure

(PSIG)

PTD-RGC (DOME) 250 240 26 20 0.25 0.20 50 - - -

3

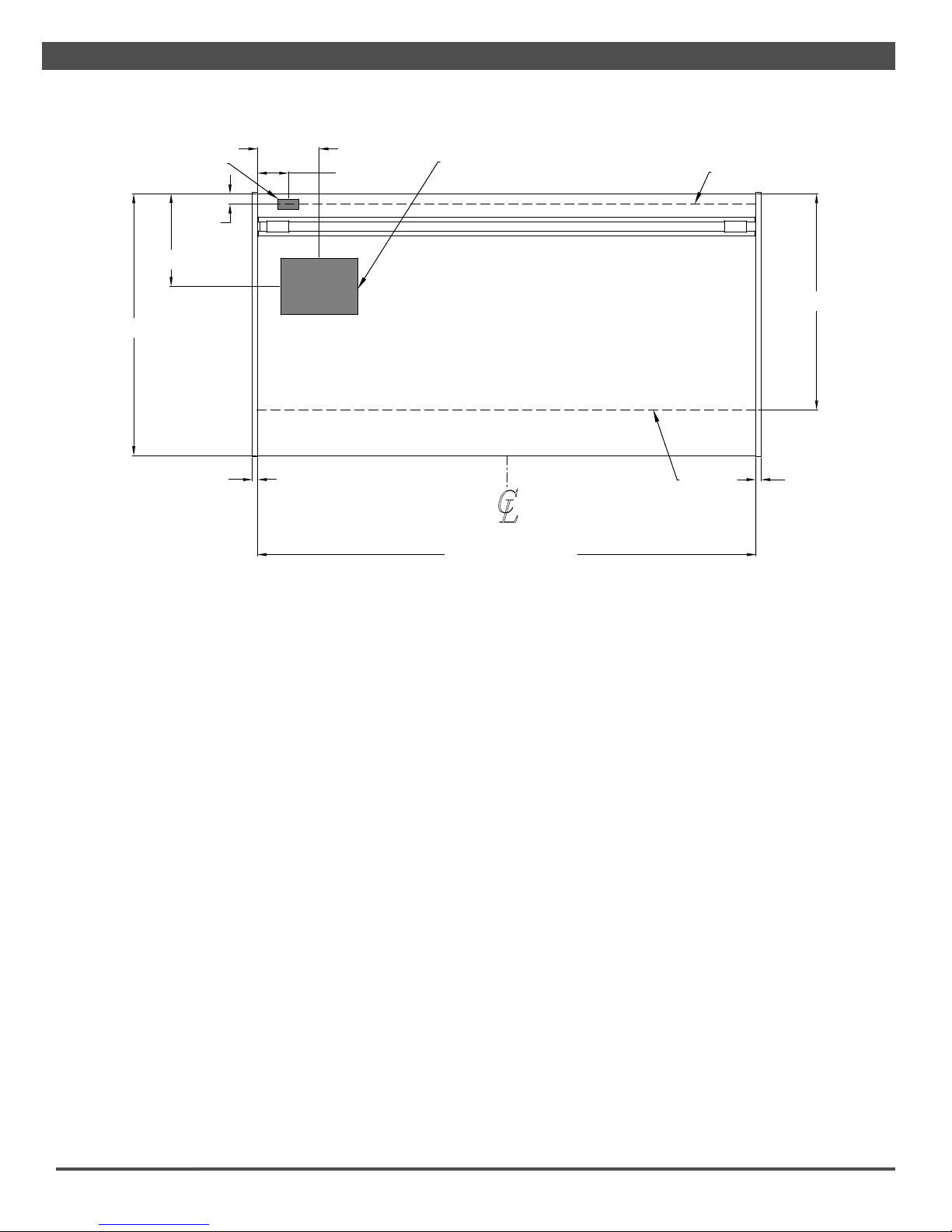

PTD-RGC COOLGENIX

CASE DIMENSIONS

POWER SUPPLY

2 1/16 in

[5.2 cm]

18 in

[45.7 cm]

51 in

[129.6 cm]

6 in

[15.2 cm]

12 in

[30.5 cm]

1 in

[2.5 cm]

1 in

[2.5 cm]

15" x 11" MECHANICAL ACCESS

FOR ELECT. ,REFRIG. ,AND DRAIN CONNECTIONS TOEKICK

42 in

[106.7 cm]

TOEKICK

72 1/2 in [184.2 cm] {6’ case}

L

C

FRONT OF CASE

26 in

[66.0 cm]

96 1/2 in [245.1 cm] {8’ case}

120 1/2 in[306.1 cm] {10’case}

144 1/2 in[367.0 cm] {12’ case}

ELECTRICAL RACEWAY

LOWER REAR STORAGE

WITH DOORS

6 1/4 in

[15.9 cm]

42 in

[106.7 cm]

51 in

[129.5 cm]

1 1/2 in

[3.7 cm]

34 5/16 in

[87.2 cm]

20 3/8 in

[51.7 cm] 9 1/4 in

[23.5 cm]

13 7/8 in

[35.2 cm]

22 3/4 in

[57.8 cm]

14 in

[35.6 cm]

LOAD LIMIT LINE

16 3/4 in

[42.5 cm]

14 5/8 in

[37.2 cm]

REFLECTIVE

REAR LOAD DOORS

16 13/16 in

[42.7 cm]

14 3/16 in

[36.0 cm]

14 13/16 in

[37.7 cm]

[123.2 cm] {4’ case}48 1/2 in

4

Hillphoenix Barker Specialty Products

703 Franklin Street, PO Box 478

Keosauqua, IA 52565

Tel: (319) 293-3777/Fax: (319) 293-3776

Web site: www.hillphoenix.com

GENERAL INFORMATION

Thank you for choosing Hillphoenix for your food merchandising needs. This handbook contains important technical information

and will assist you with the installation and operation of your new Hillphoenix specialty cases. By closely following the instruc-

tions, you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel free to

contact our Marketing Services group at the number listed below. Thank you for choosing Hillphoenix, and we wish you the very

best in outstanding food merchandising.

CASE DESCRIPTION

This manual specifically covers the PTD-RGC beverage, deli,

meat and seafood application, self-service open multi-deck

merchandiser with service dome.

STORE CONDITIONS

Hillphoenix cases are designed to operate in an air-condi-

tioned store that maintains a 75°F (24°C) store temperature

and 55% (max) relative humidity (ASHRAE conditions). Case

operation will be adversely affected by exposure to excessively

high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation for

efficient performance. Machine-room temperatures must be

maintained at a minimum of 65°F in winter and a maximum

of 95°F in summer. Minimum condensing temperatures

should be no less than 70°F.

SHIPPING CASES

Transportation companies assume all liability from the time a

shipment is received by them until the time it is delivered to

the consumer. Our liability ceases at the time of shipment.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping dam-

age and/or shortages, please contact the Service Parts

Department at the number listed below.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carrier's

agent; otherwise, the carrier may refuse the claim. If damage

becomes apparent after the equipment is unpacked, retain all

packing materials and submit a written request to the carrier

for inspection within 14 days of receipt of the equipment.

Failure to follow this procedure will result in refusal by the

carrier to honor any claims with a consequent loss to the

consumer.

If a UPS shipment has been damaged, retain the damaged

material, the carton and notify us at once. We will file a

claim.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the highest

level of quality. Any claim for lost/missing items must be

made to Hillphoenix within 48 hours of receipt of the equip-

ment. When making a claim please use the number listed

below.

SERVICE & TECHNICAL SUPPORT

For service or technical questions regarding specialty cases,

please contact our Specialty Products Division Service

Department at 1-319-293-3777. For questions regarding our

refrigeration systems or electrical distribution centers, please

contact our Systems Division Customer Service Department at

1-770-388-0706.

CONTACTING THE FACTORY

If you need to contact Hill PHOENIX regarding a specific fix-

ture, be certain that you have both the case model number

and serial number (this information can be found on the data

tag, located on the top-left interior of the case). When you

have this information, call the number below and ask for a

Service Parts Representative.

PRESSURE TESTING

Standard practice for pressure testing secondary systems is to

pressurize the system to 100 psi. This case must be limited to

70 psi or damage to the deck pans and micro-channel coolers

may occur. If the cases are piped to racks not supplied by

Hillphoenix ensure that a properly sized pressure regulator is

installed upstream of the cases.

GYLCOL

Glycols used in Hillphoenix secondary-coolant cases should

NEVER be mixed between different manufacturers. Each

manufacturer may have different additives or inhibitors that will

congeal when mixed with other manufacturers materials. For

more detailed information, please refer to the Secondary

Nature manual located on our web site.

5

CASE INSTALLATION

FLOOR PREP

1. Ask the general contractor if your current copy of the build-

ing dimensions are the most recently issued. Also, ask for

the points of reference from which you should take dimen-

sions to locate the cases.

2. Using chalk lines or a laser transit, mark the !oor where

the cases are to be located for the entire lineup. The lines

should coincide with the outside edges of the case feet.

3. Move case as close as possible to its permanent location.

Remove all crating and shipping braces above the ship-

ping pallet. Loosen the plastic dust cover from the pallet,

but leave cover over the case to protect it while removing

the case from the pallet. Carefullly, lift case up and off the

pallet. Remove dust cover. Istallation hardware ships in a

marked packet located inside the case.

4. Leveling is necessary to ensure proper operation of the

refrigeration system and drainage of the condensate.

Locate the highest point on the positioning lines as a ref-

erence for determining the proper height of the shim-pack

levelers. A laser transit is recommended for precision and

requires just one person. Level adjustable feet by twisting,

if appliacble, or shim as necessary under vertical supports

as this will help ensure that the case is not settling over

time.

5. Locate horizontal support (Fig. 1) positions along the chalk

line. Spot properly leveled shim packs at each support

location.

LOCATION

This refrigerated display case has been designed for displaying

and storing perishable food product. It is engineered for air-

conditioned stores with a maximum ambient of 75°F and 55%

relative humidity.

When selecting the location for placement of this case, avoid

the following conditions:

Excessive Air Movement

1. Doors

2. Air-conditioned vents

3. Other air sources

Excessive Heat

1. Windows

2. Sun

3. Flood lamps 8 feet or less from the product

4. Other heat sources

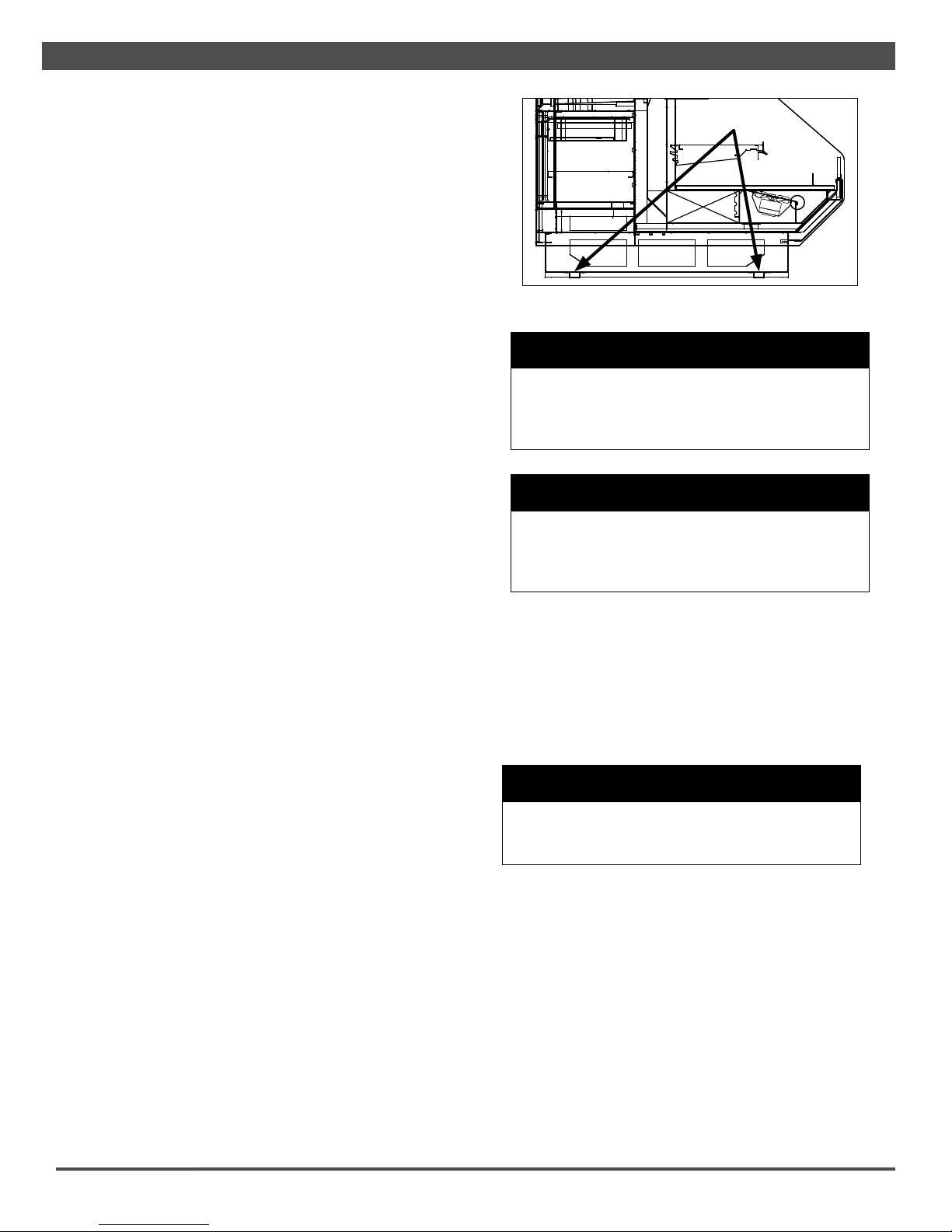

C A U T I O N

Locate the horizontal supports under unit before

removing from pallet. Failure to do so will dam-

age the "nished metal if correct lift points are

not identi"ed prior to removal.

•

C A U T I O N

These cases are not designed for excessive

external weight. Do not walk on top or inside

of cases. Doing so may result in case damage

and/or personal injury.

•

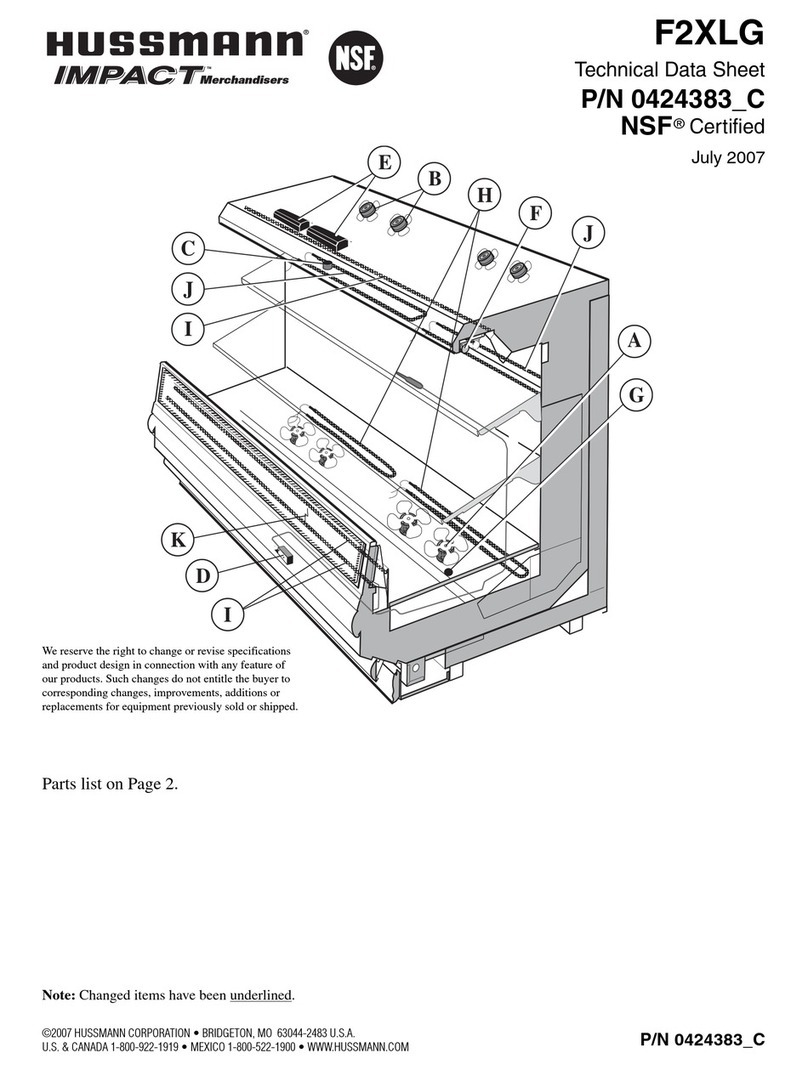

Fig. 1 Horizontal supports

SUPPORTS

LINE-UP & INSTALLATION

Single Case

1. Move the case into position. Using a “J” bar, raise the end

of the case (under cross support), and lower the horizontal

support on to the shim packs. Repeat on the other end of

the case.

2. Once the case is properly placed on the shim packs,

check the vertical plumb of the case by placing a bubble

level on the rear wall. Add/remove shim packs as needed.

For the horizontal level, repeat this process after placing

the bubble level on the front sill.

3. Install the bumper, if applicable, into pre-attached bumper

track and snap into place.

4. After suf"cient time has passed to allow for bumper

shrinkage, cut away the excess bumper for "nal "t and "n-

ish. Be certain to use an appropriate cutting tool (tubing-

or PVC-cutter) to ensure a smooth cut.

5. Install case shelves and reconnect lights. Be aware that

W A R N I N G

Be certain that your hands and feet are out of

the way before lowering the case. Failure to do

so may result in serious injury.

•

6

CASE INSTALLATION

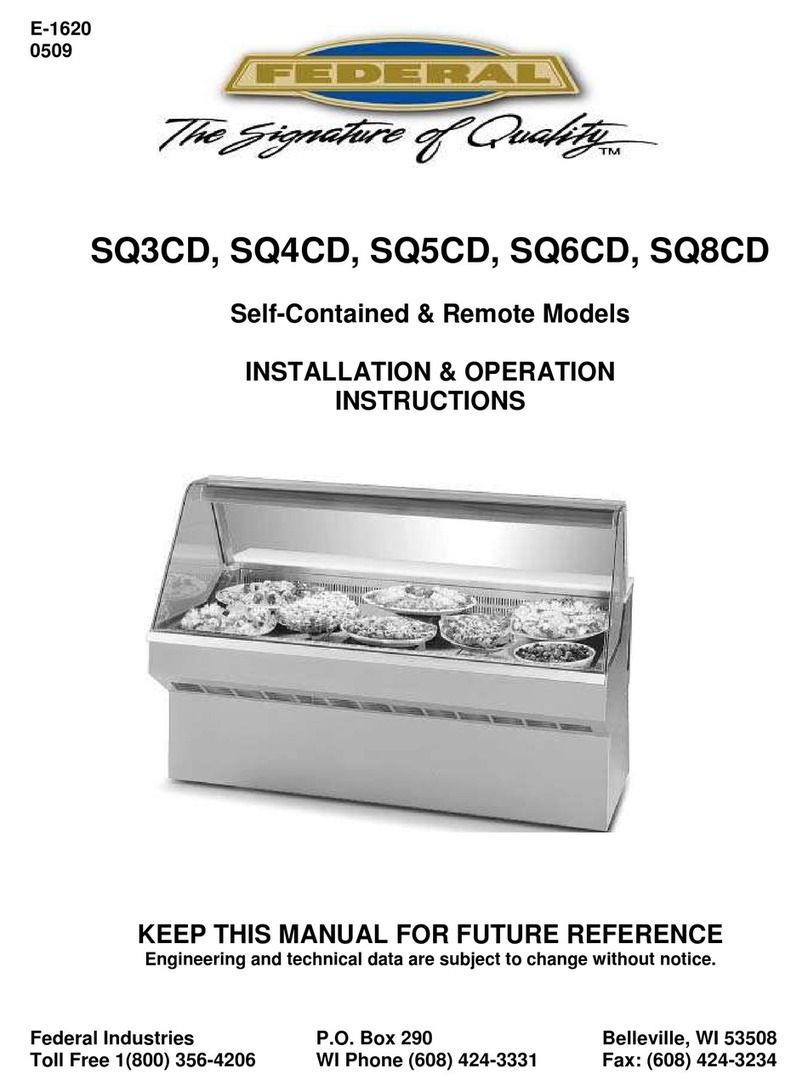

Fig. 2 Sealant, piping, and bolt locations

Multi-Case

1. Remove any shelves (discard the shelf clips) and/or loose

items from the cases that may interfere with case joining.

Keep all loose items as they will be used later in the instal-

lation process.

2. Follow the single-case installation instructions for the •rst

case,excluding #6, then position the next case in the line-

up approximately 3’ away.

3. Apply the foam tape (supplied) to the end breakers of the

•rst case. After this is set apply the sealant to the end of

the case. From the opposite end, push the second case to

a position that is approximately 6" from the •rst case, then

position case on the shim packs.

4. Push the cases tightly together, then lightly bolt them

together through the holes provided (Fig.2). Tighten all the

joining bolts until all margins are equal. Be careful not to

over tighten.

5. Install PVC •tting between cases with case to case piping

(Fig. 2). It is very important for line ups designed with

holes in the pipe chase and equipped with PVC •ttings to

seal between the joints and protect piping.

6. Apply case-to-case watershed (supplied) over the end

frame seam (Fig. 3). The watershed prevents water from

settling in the case joint.

7. Repeat steps 3-6 of this sequence for all remaining cases.

Be certain to properly level all cases.

Fig. 3 Sealing the end frame

WATERSHED

END FRAME

C A U T I O N

Installation of 3rd-party materials may result in

diminished case performance.

•

COOLGENIX PANS

Deck Pans

1. The Coolgenix deck pans are the main source of cooling.

2. All products placed into the Coolgenix case must be at the

appropriate temperature before placing into the case.

3. Warm product should not be placed inside a case.

differing shelf con•gurations will affect energy consump-

tion and case performance.

6. Install toekick back onto the base of case.

8. Properly align the front panels as needed, then install, if

applicable, front panel trim (supplied).

9. Install the bumper into pre-attached bumper track and

snap into place.

10. After suf•cient time has passed to allow for bumper

shrinkage, cut away the excess bumper for •nal •t and •n-

ish. Be certain to use an appropriate cutting tool (tubing-

or PVC-cutter) to ensure a smooth cut.

11. Install case shelves and reconnect lights. Be aware that

differing shelf con•gurations will affect energy consump-

tion and case performance.

12. Install toekick back onto the base of case.

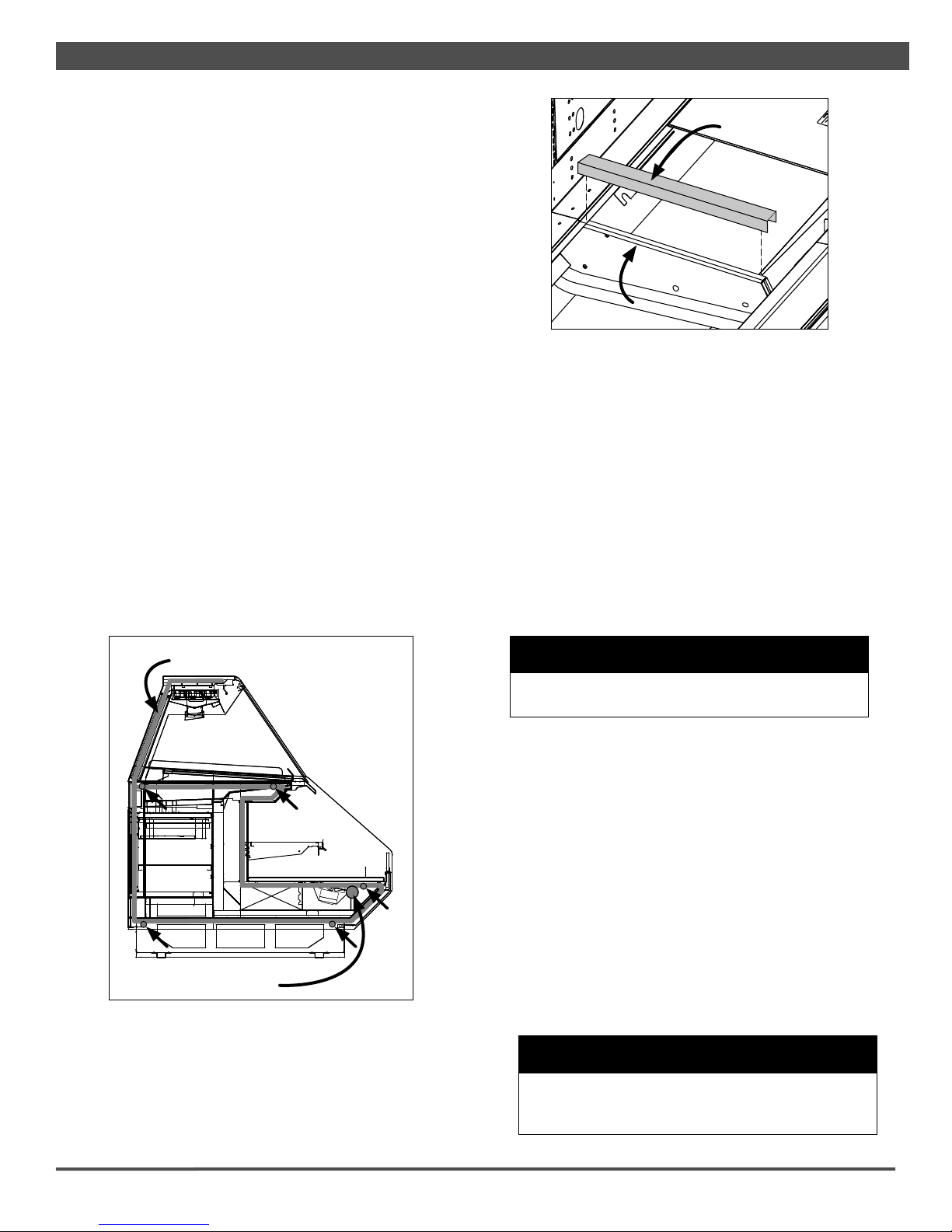

Spanner Bars

1. Spanner bars (Fig. 4) are a very important support for

Coolgenix pans.

2. To prevent warping spanner bars MUST be used under

Coolgenix pans.

CAUTION

Support spanner bars must be under Coolgenix

pans to prevent warping of pans. Failure to use

these bars will void warranty on pans.

•

PIPE LOCATION

SEALANT

7

CASE INSTALLATION

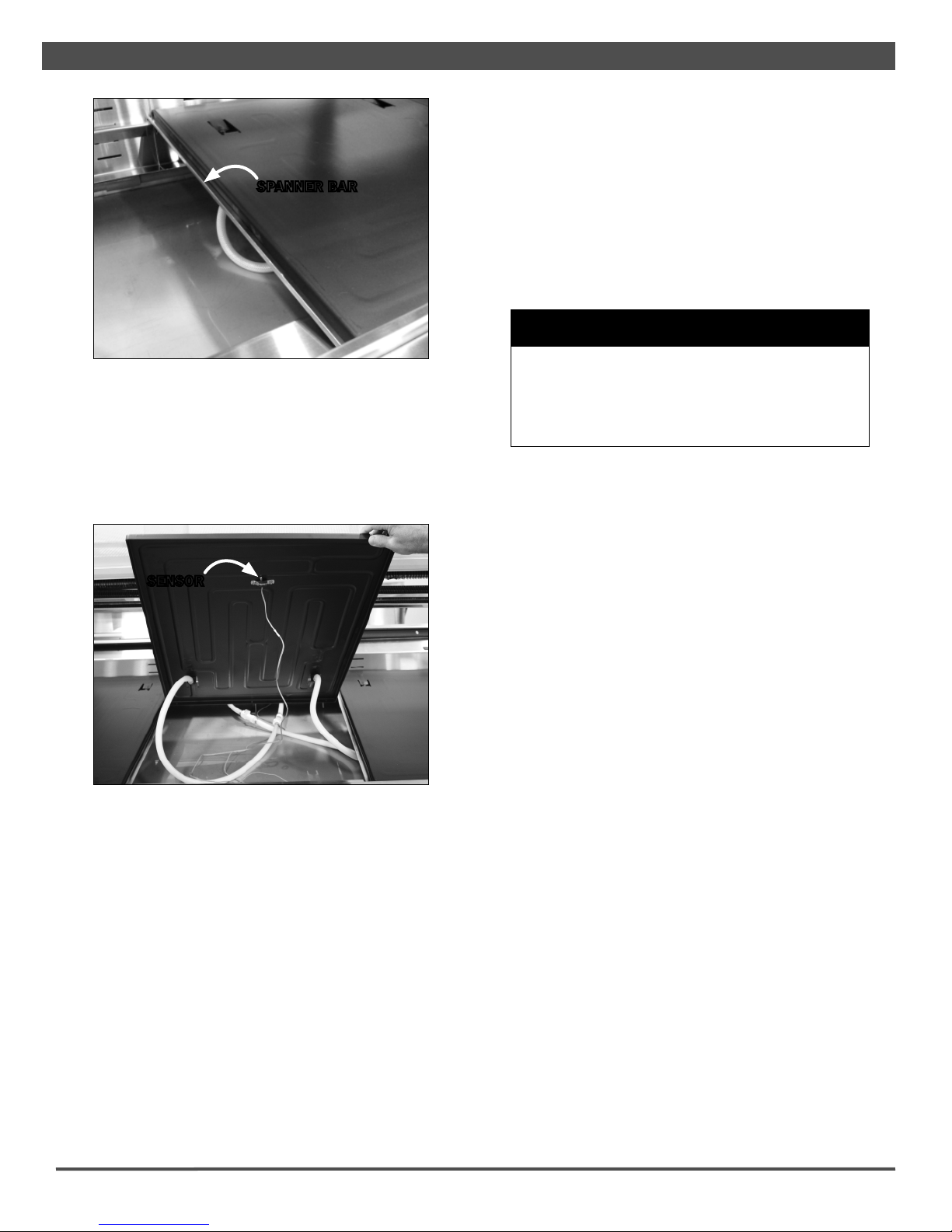

Pan Sensors

1. The center deck pan and shelving (if applicable) have a

pan sensor connected to the underside (Fig. 5). Not every

pan will have this sensor. Check the underside of each

pan to see which pan(s) have this sensor.

Fig. 5 Coolgenix pan sensor

Displaying

1. All display trays must lie !at on the pans without feet.

2. Any space between the display trays and pans will cause

early product deterioration due to insuf"cient contact with

the pans.

3. Making contact with the deck pans and display tray is vital

for keeping product temperature.

4. The use of foam, riders, any type of shelf liners, Dri-Loc

pads or display dividers that raise trays off the deck pans

should not be used.

Loading

1. When loading a case the product should be loaded

through the rear load door opening.

2. The rear doors should never be removed while merchan-

dising. This is recommended to ensure optimum case

operation and to prevent contamination of rear door

surfaces.

3. The front lift glass should only be lifted when cleaning the

inside of the glass.

C A U T I O N

Coolgenix pans are not designed to be used with

ice in direct contact. Doing so may cause damage

to the Coolgenix pans. Ice can only be used as

an accent lightly sprinkled on product, or with a

polycarbonate ice tray.

•

SENSOR

2. The pan sensor monitors and controls the product temper-

ature. It is very important that the sensor not be discon-

nected from the pan while the cases are in use.

3. The pans will not function as designed if the pan sensor is

not attached to the center deck pan.

Fig. 4 Spanner bar

SPANNER BAR

8

SEMI-SELF-CONTAINED

Hillphoenix SSC (Semi-Self-Contained) cases utilize an open-

loop secondary system, supplying independent circuits to the

Coolgenix pans, shelves and the gravity top coils. All circuits

return to a common reservoir tank that is maintained at atmo-

spheric pressure. All cases are tested and shipped with a 35%

mixture of Dowfrost propyleneglycol.

Charging the refrigeration system is imperative to maximizing

case performance by ensuring that excess air is eliminated

from the system - excessive air in the system can reduce

the heat transfer capacity and even block the •ow to one or

more of the heat transfer components (e.g. Coolgenix Pans or

section of the top coils). Also, charging the system •oods the

pump, which helps prevent damage caused by cavitation.

Starting a Newly Delivered SSC Case

Unless otherwise speci!ed, all SSC cases are charged and

tested at the factory. Much of the •uid is drained out of the

reservoir to prevent spillage during shipment and handling.

Before starting the case, the DX (direct expansion) side of the

chiller must be connected to the appropriate refrigerant lines

and the power connected to the case.

Starting the case consists of topping-off the reservoir tank and

ensuring that all hand-valves are open, then supplying power

by turning the main control and pump switches to their respec-

tive "ON" positions. This requires access to the chiller and the

electrical box.

For cases with pedestals, the chiller is located in the right-

hand pedestal while the electrical box is in the left-hand ped-

estal. The !lling tube can be accessed by removing only the

rear of the right hand pedestal. Cases that are fully skirted

require the removal of the lower back panel to access the

chiller and the electrical box.

There are 2 indicator lamps - one red, one blue - located in

the upper back panel. The red lamp indicates that the •uid

level in the reservoir is low and should be topped-off. The blue

lamp indicates that the reservoir is full and that no more glycol

should be added to avoid spills. If neither lamp is lit, the •uid

level is in the operating range. To top-off the reservoir, remove

the !lling tube from its holding position and extend it to insure

that there are no kinks or obstructions. Remove the charging

cap and pour in propyleneglycol (use only 35% Dowfrost) until

the blue lamp lights, indicating that the reservoir tank is full.

Replace the charging cap and return the hose to its holding

position.

Recharging a Drained System

There may be circumstances when the glycol system needs to

be drained, •ushed, and recharged - usually due to contami-

nants being added to the approved propylene glycol. Charging

and air purging should be performed with the hand-valve on

the DX-side of the chiller closed.

Field charging the chiller system requires "bumping the pump".

The pump is capable of emptying the reservoir faster than •uid

can be poured into it. When the system is empty, the reservoir

must be !lled until the blue light is illuminated. The pump

should then be "bumped" on-and-off using the pump switch

until the red light comes on. The reservoir has to be re!lled

and the process repeated until the red light no longer comes

on. The pump can then be left on.

Each circuit in the system may be cycled by adjusting the set-

point values above "AMBIENT" to stop •ow and below "FLUID

TEMPERATURE" to force •ow. This will help force any en-

trapped air out of the pans and top coils. The •ow through the

system is never perfectly silent; however if an obvious gurgling

sound is heard in any of the pans or at the outlet of a top coil,

this indicates air movement at that location.

Increased •ow can be forced by restricting the •ow to the other

components in the circuit. For pans with quick connects, this

can be done by disconnecting one of the hoses to the non-

problem pans. For pans without quick connects, the •ow can

be restricted by pinching the feed hoses on the non-problem

components. Do not use any kind of clamp that could cut or

tear the hoses.

There are also Schrader !ttings in the return headers of each

of the top coils. Entrapped air may be bled off by depressing

the core of the !tting or removing it until a solid •uid stream

is present. While purging air, be certain to make note of the

red indicator lamp - do not allow the reservoir to empty. Once

the majority of the air is purged and the case is performing

acceptably, top-off the reservoir until the blue lamp is on, open

the DX-side hand valve, and close up the case. Any incidental

air in the system will be removed during the normal operation

of the case.

C A U T I O N

Dowfrost propylene glycol is used for pres-

sure testing and system charging. If another

approved glycol is utilized, the case MUST be

•ushed with pure water to remove any residual

glycol before !lling. Failure to do so will void the

manufacturer warrarnty. Never mix manufactur-

ers of glycol.

•

CASE CONNECTIONS

REFRIGERATION

Refrigeration connections will be made through the refrigera-

tion stub up location on the customer left side of the case.

Refrigeration lines may be headed together for all cases in a

line-up, if necessary, by lines through the access holes with a

high grade silicon to prevent recirculation. All lines must be

9

CASE CONNECTIONS

ELECTRICAL

Electrical hookups are made through the power supply box

that can be accessed by removing the back panel.

For case-to-case wiring, run conduit between the power supply

boxes or run wiring through the raceway. When connecting to

the power supply on the case, •eld wiring should exit box from

the side furthest away from case wiring to allow more room in-

side for wiring connections. Always check the data tag located

on left end exterior panel or top interior of the case. The case

must be grounded. For more detailed electrical wiring infor-

mation, see Appendices A1-A4.

C A U T I O N

Be certain that all plumbing connections are

compliant with local codes.

•

C A U T I O N

Be certain that all electrical connections are

compliant with local codes.

•

C A U T I O N

Be sure to remove all styrafoam shipping blocks

from piping and refrigerant lines. Failure to do

so may result in case damage.

•

Fig. 6 "P" trap / drain outlet

PLUMBING

The drain outlet or “P” trap (Fig. 6) is shipped loose with the

case and made from a 1 1/2” PVC pipe. Care should be given

to ensure that all connections are water-tight and sealed with

the appropriate PVC or ABS cement.

Drain lines can be run left or right of the tee with the proper

pitch to satisfy local drainage requirements. When connecting

the PVC to the existing !oor drains be sure to provide as much

downhill slope as possible and avoid long runs of drain lines.

Do not install condensate drains in contact with non-insulated

suction lines in order to prevent condensate from freezing.

Install the 1 1/2" PVC trap, which is provided with the case. All

drains must be trapped.

Before operating the case, be certain to remove the styrafoam

shipping block that protects the plumbing lines during ship-

ping.

C A U T I O N

If any brazing is necessary, place wet rags

around the area to avoid tank damage.

•

C A U T I O N

Be certain that all piping connections are com-

pliant with local codes.

•

C A U T I O N

If the shelves are removed from the case or other-

wise not utilized, the shelf setpoint (SAA) must be

raised to 90 oF to prevent the pump from running

when only the shelves are calling for refrigeration.

Failure to do so could result in early pump failure.

•

correctly sized. See diagram on page 12 for access locations.

If it becomes necessary to penetrate the case bottom for any

reason, make certain it is sealed afterward with canned-foam

sealant and white RTV.

10

C A U T I O N

Dowfrost propylene glycol is used for pressure

testing and system charging. If another approved

glycol is utilized, the case MUST be •ushed with

pure water to remove any residual glycol before

•lling. Failure to do so will void the manufacturer

warrarnty. Never mix manufacturers of glycol.

•

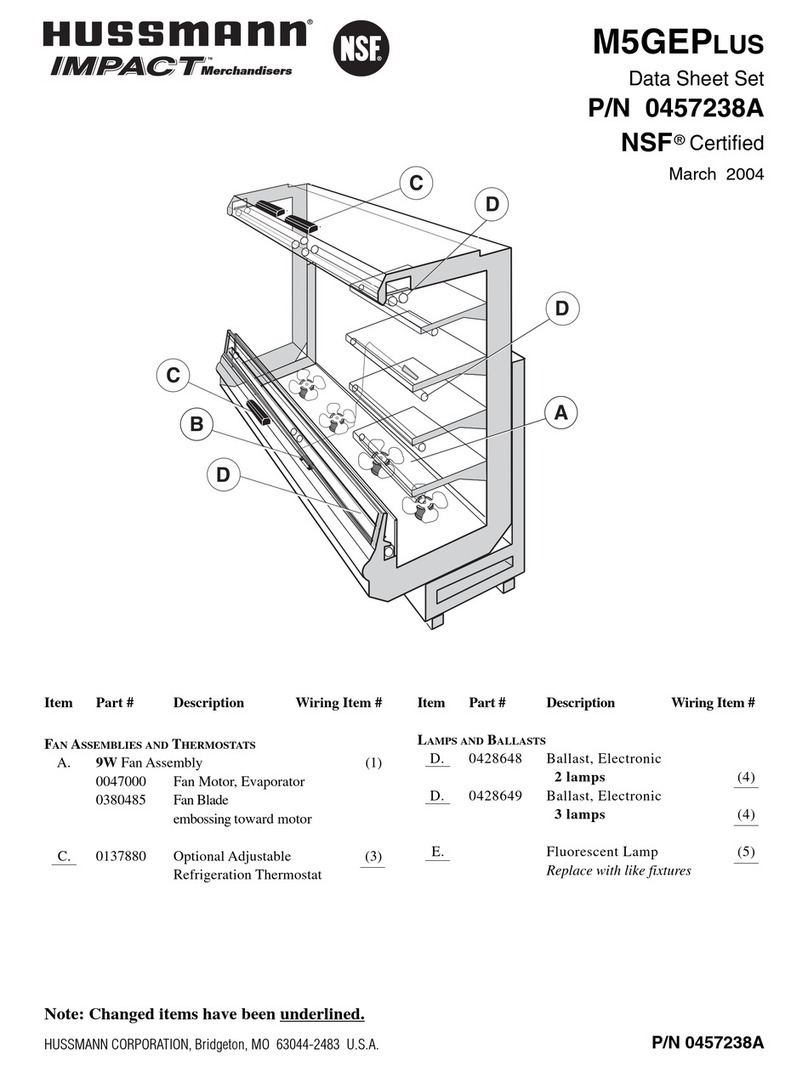

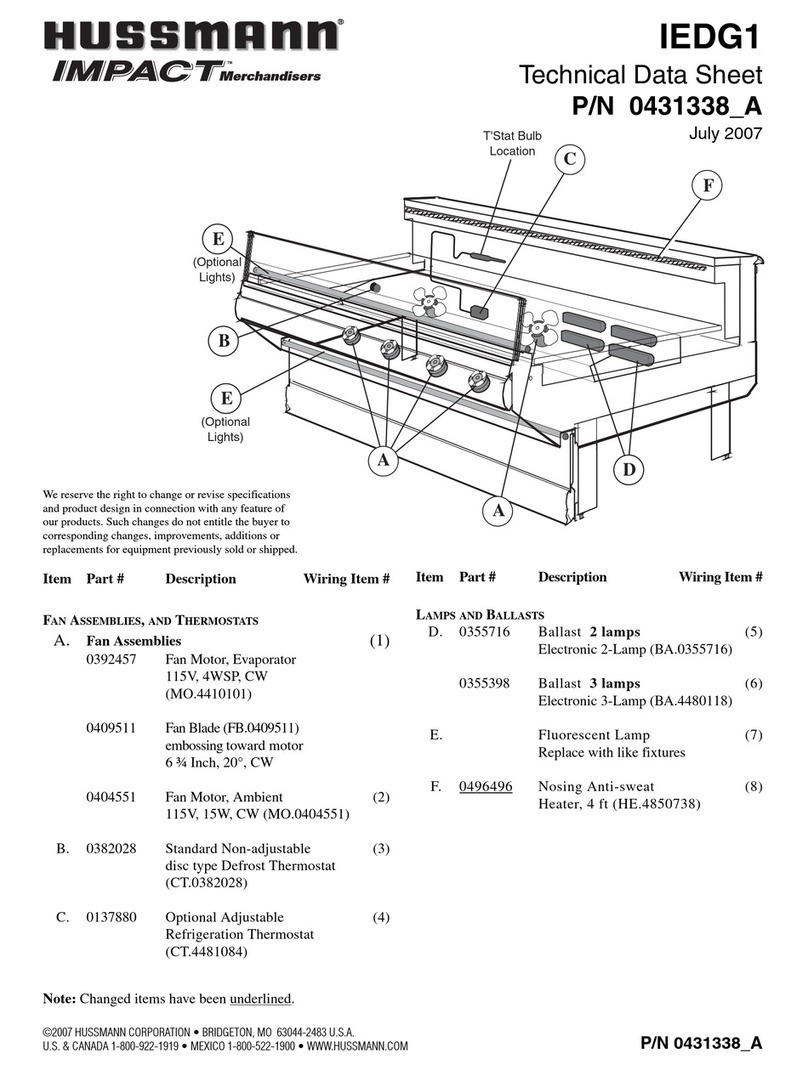

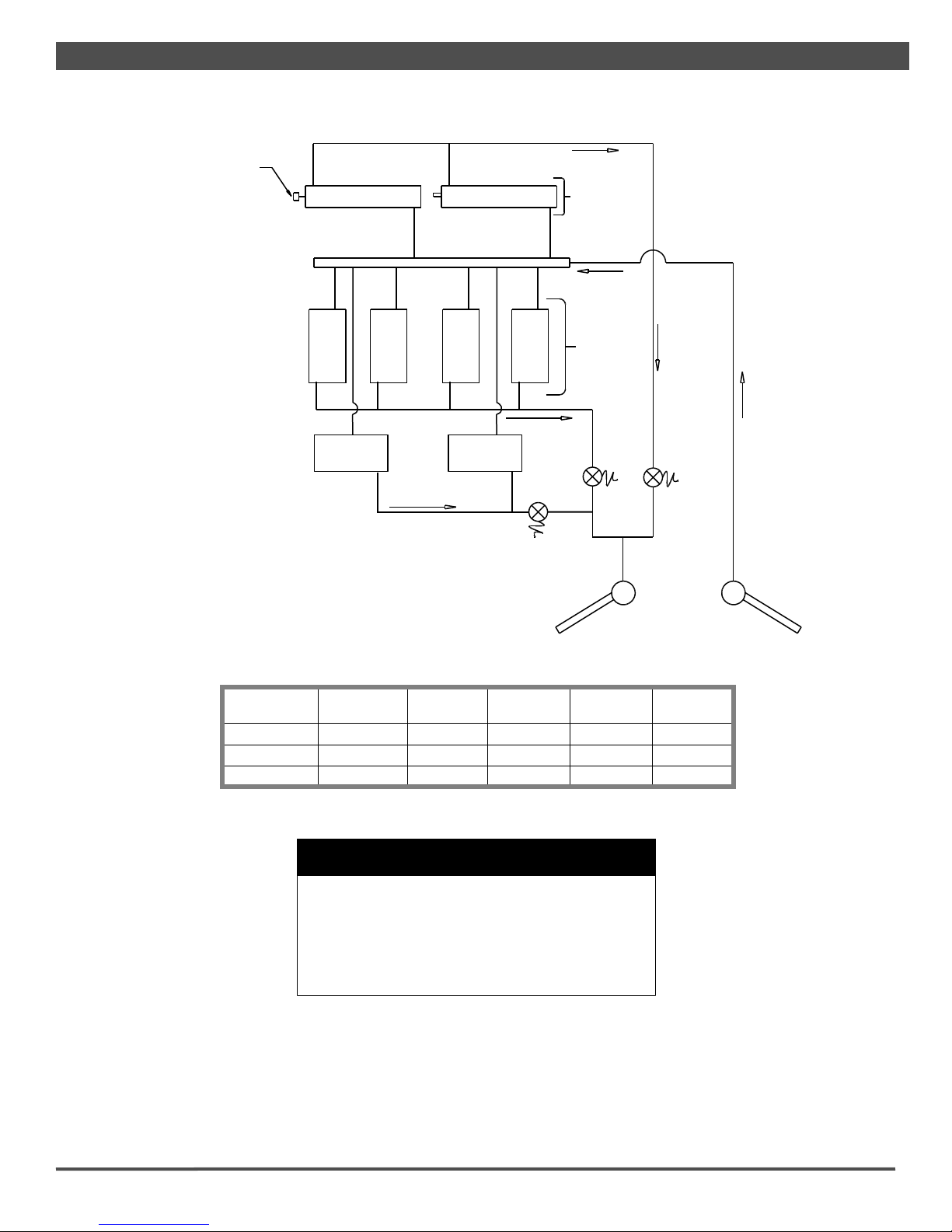

Coil Return Header

Schrader Valve

On Each Coil Return

Top Coils

Refer to

the table

for the

correct

number of

coils

Supply

Header

Coolgenix

Pan

Coolgenix

Pan

Coolgenix

Pan

Coolgenix

Pan

Refer to

the table

for the

correct

number of

pans

Pan

Solenoid

(SV-2)

Top Coil

Solenoid

(SV-1)

Pan Return Header

Hand Valve Hand Valve

Coolgenix

Shelves

Coolgenix

Shelves

(optional) (optional)

Shelf

Solenoid

(SV-4)

Shelf Return Header

CASE CONNECTIONS

Case Length

Number of

Regular Pans

Number of

LH Pans

Number of

RH Pans

Number of

Coils

Number of

Shelves

6' 3 N/A N/A 1 1

8' 4 N/A N/A 2 2

12' 6 N/A N/A 3 3

11

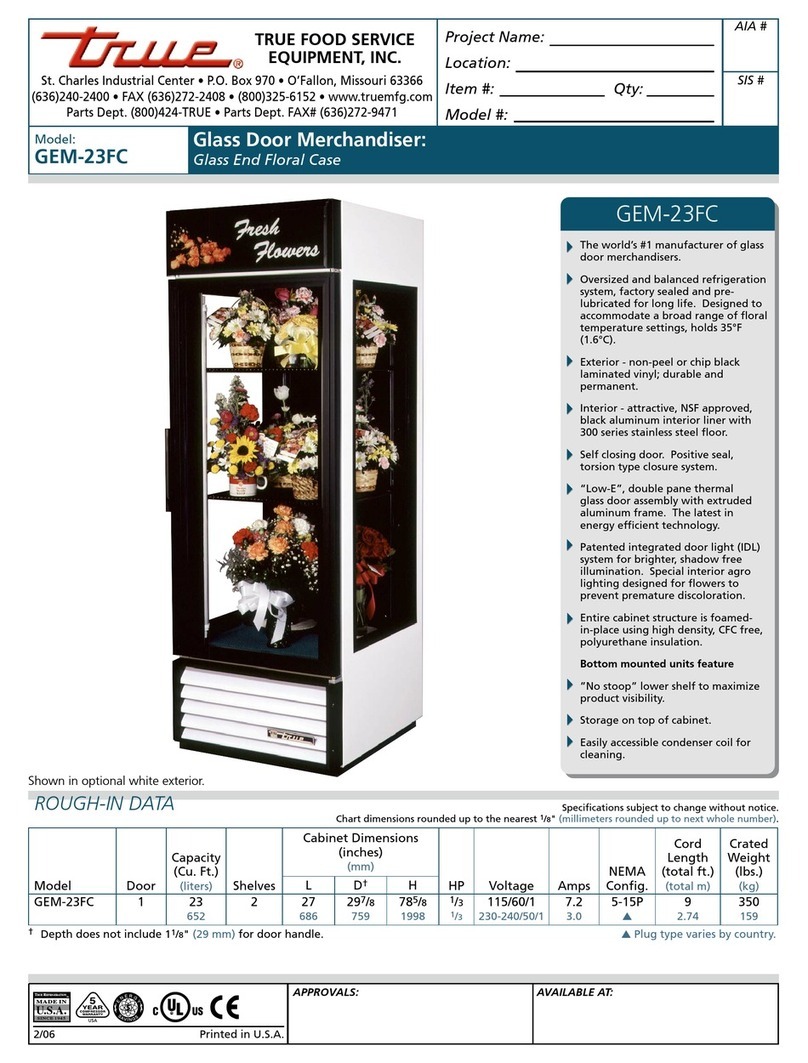

MECHANICAL ACCESS LOCATIONS

CASE CONNECTIONS

POWER SUPPLY

2 1/16 in

[5.2 cm]

18 in

[45.7 cm]

51 in

[129.6 cm]

6 in

[15.2 cm]

12 in

[30.5 cm]

1 in

[2.5 cm]

1 in

[2.5 cm]

15" x 11" MECHANICAL ACCESS

FOR ELECT. ,REFRIG. ,AND DRAIN CONNECTIONS TOEKICK

42 in

[106.7 cm]

TOEKICK

L

C

FRONT OF CASE

72 1/2 in [184.2 cm] {6’ case}

96 1/2 in [245.1 cm] {8’ case}

120 1/2 in[306.1 cm] {10’case}

144 1/2 in[367.0 cm] {12’ case}

[123.2 cm] {4’ case}48 1/2 in

12

LIGHTING & POWER SUPPLIES

GENERAL LIGHTING INFORMATION

Hillphoenix cases are equipped with either T-8 lights or LED

luminaires and feature specially designed light reflectors in the

cornice to improve the illumination of products. Depending on

case configuration, T-8 electronic ballasts or LED power sup-

plies operate both the cornice and shelf lights and are located

above the cornice reflectors.

The lighting system in the electrical raceway has an ON/OFF

switch located at the back exterior of the case. Once cases

have been properly positioned in the store and an electrician

has connected the lighting circuit, the lights may be turned on

to verify that they are connected and functioning properly.

To ensure peak performance, it is advisable to run the lighting

systems only when the store climate control is on and case

refrigeration is started. NOTE: it is highly recommended that

the ambient store temperature not exceed 80°F.

D A N G E R

▲

SHOCK HAZARD

Always disconnect power to case when cleaning,

servicing or con!guring components of the light-

ing system. Failure to do so may result in serious

injury or death.

Fig. 7 T-8 light power cords

W A R N I N G

▲

Using improper DC power supplies may damage

the luminaires, resulting in sub-standard opera-

tion and increased chances of safety issues/

injury.

W A R N I N G

▲

Never replace a 24V DC power supply with a T8

or T5 ballast of any kind" Ballasts use alternat-

ing current (AC) instead of direct current (DC)

and operate at a much higher voltage than is

used by this LED system. Doing so will damage

the LED system and increases the chance of

safety issues/injury.

BALLAST/POWER SUPPLY ACCESS

To gain access to the ballasts or power supplies remove the

panel located above the rear toe kick (Fig. 10).

Fig. 8 T-8 cap and lamp holder

LAMP HOLDER

CAP

Fig. 9 Positive engagement

SHELF LUMINAIRES

1. Unplug T-8 lamp power cords located at the inside-back of

the case below the lamp being replaced (Fig.7).

2. Carefully seperate the cap from the lamp holder on both

ends of the T-8 lamp (Fig. 8). Simultaneously pull down at

both ends of the old T-8 lamp to remove.

3. Push and snap the new T-8 lamp into place on the lamp

holder. When the T-8 is properly seated, the lamp button

- which secures the T-8 to the lamp holder - will be clearly

visible through the lamp button hole. The cap should be

pushed all the way down (Fig. 9) for positive engagement

indicator.

13

LIGHTING & POWER SUPPLIES

REPLACING LED LIGHTS

Once store power is connected and the light circuit is ener-

gized, the Clearvoyant LED system should operate without

the need for any signi•cant maintenance for several years.

Should a power supply need to be removed and/or replaced,

turn off the power to the case before proceeding. Be certain

to replace the power supply with genuine Hillphoenix parts or

a comparable UL-listed Class-2 rated regulated 24V DC power

supply with 100W output capacity.

SHELF LUMINAIRES

Removing shelf luminaires:

1. Unplug the luminaire.

2. Pinching the latching clips inward at the ends of the lumi-

naire, rotate luminaire up at each end until hooks are free,

then remove.

Re-installing shelf luminaires:

1. Place hook into shelf roll form at shelf front and rotate

rear of luminaire toward the shelf.

2. Depress the rear clip so that luminaire can •nish rotation

and until clip engages the shelf bracket.

NON-SHELF LUMINAIRES

Removing non-shelf luminaires:

1. Simultaniously squeeze the plastic clips at each end.

2. When the hooks are disengaged, pull the luminaire free.

Re-installing non-shelf luminaires:

1. Align the 4-pole jack with the 4-pole connector on the clip-

in luminaire.

2. Push into place - side clips will engage on the sheet metal

of the case.

3. Fasten anti-tamper bracket into sheet metal of case with

#8 screw at end opposite of the 4-pole in-line connector

D A N G E R

▲

SHOCK HAZARD

Always disconnect power to case when cleaning,

servicing or con•guring components of the light-

ing system. Failure to do so may result in serious

injury or death.

Fig. 10 Clear view of the ballasts

BALLAST

14

PRE-POWER CHECKLIST

Have you thoroughly examined the case for shipping damage? (see pg. 5)

Have you checked the vertical plumb of the case? The horizontal level?

(see pg. 6)

Have you applied the sealant to the end breakers of adjoining cases?

(see pg. 7)

Have you sealed the case-to-case joints by applying caulk and acrylic tape to

the end frame seam? (see pg. 7)

Have you installed the toekick? (see pg. 7)

Have you removed the shipping blocks from the refrigeration and plumbing

lines? (see pg.10)

After powering-up the case, be certain that all of the steps listed below have

been completed to ensure proper case functionality, safety and compliance with

warranty terms.

1. Check all lights to ensure they are all functioning properly.

2. Check case temperature and adjust controller as needed.

Before powering-up the case, be certain that all of the steps listed below have

been completed to ensure proper case functionality, safety and compliance with

warranty terms.

15

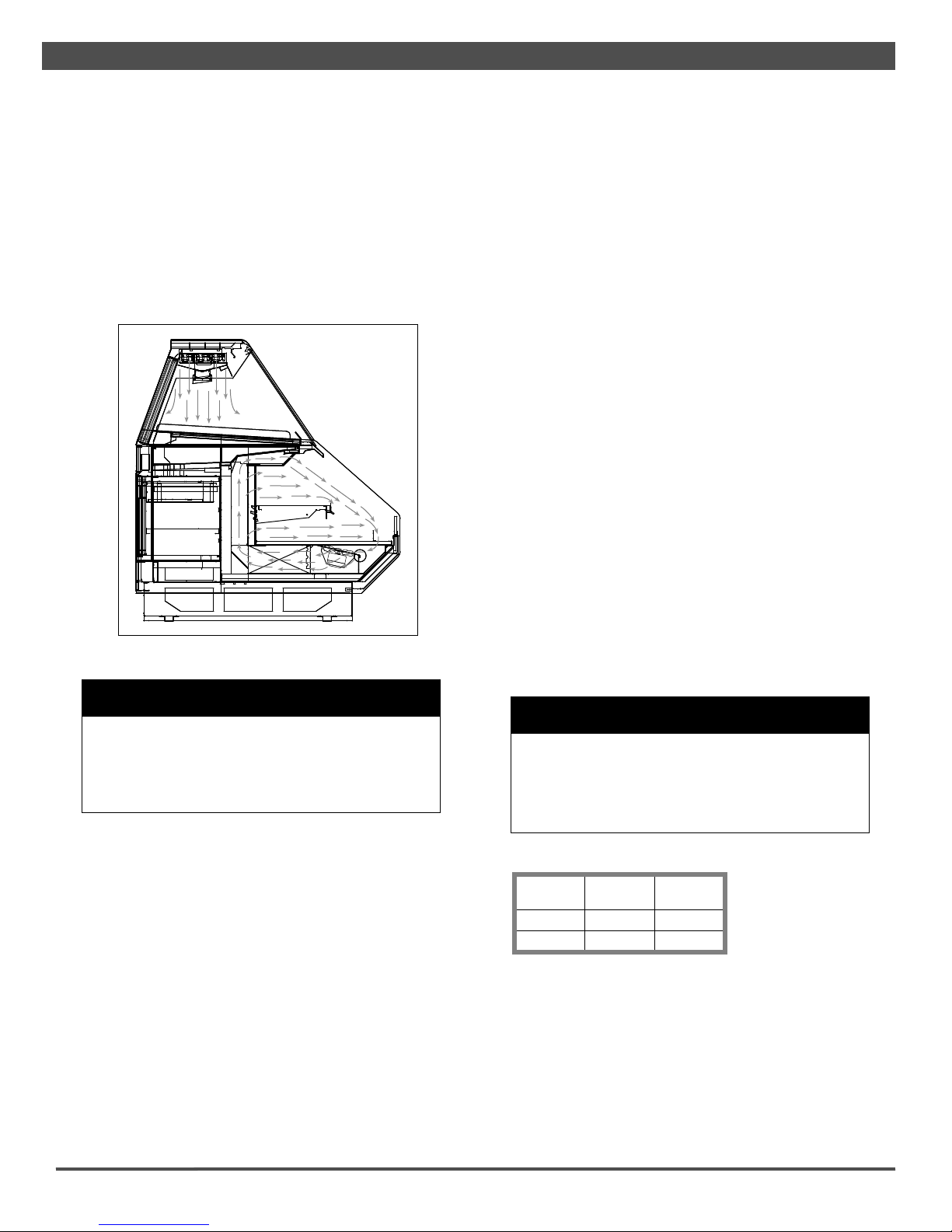

AIRFLOW & DEFROST

Cut-In/Cut-Out

Cut-In

Temp (oF)

Cut-Out

Temp (oF)

Pans 33 29

Top Coil 36 31

AIRFLOW & PRODUCT LOAD

Hillphoenix cases provide maximum product capacity within the

refrigerated air envelope. Please keep products within the ap-

propriate load limit.

It is important that you do not overload the food product display

so that it impinges on the air!ow pattern (Fig. 11). Overload-

ing will cause malfunction and the loss of proper temperature

levels, particularly when discharge and return air sections are

covered.

W A R N I N G

Always keep product within the designated air

curtain. Failure to do so may result in case

malfunction and product losing proper tempera-

ture, resulting in sub-standard operation and

increased chances of food contamination.

•

PTD-RGC cases are available with the defrost and temperature

controls mounted at the case or initiated by the rack controller.

When the controls are mounted at the case, the single time-off

defrost is initiated by the Dixell XR70CX controller mounted in

the slide out control box. During defrost, all valves close and

the pump cycles OFF. When in refrigeration mode, the glycol

!ow to the top coil, shelves and the Coolgenix pans is inde-

pendently controlled by the Dixell controller. If none of these

components requires !ow, all solenoids close (including DX

liquid-line valve) and the pump is cycled OFF.

When defrost and temperature are controlled from the rack,

the time-off defrost is controlled by a set of normally open con-

tacts at the rack controller. When in refrigeration mode, the

top coils, shelf and the Coolgenix pans are controlled as three

independent, temperature-controlled cases. Again, if none of

C A U T I O N

If the shelves are removed from the case or other-

wise not utilized, the shelf setpoint (SAA) must be

raised to 90 oF to prevent the pump from running

when only the shelves are calling for refrigeration.

Failure to do so could result in early pump failure.

•

these components requires !ow, all valves close and the pump

cycles OFF.

Whether the controls are managed at the case or by the rack

controller, the case and product temperatures are maintained

by having the top coils, shelves and the Coolgenix deck pans

cycle through their individual DIFFERENTIAL range. If the

Dixell XR70CX Controller is used, the !ow of the chilled !uid to

the Coolgenix pans, shelves and top coil circuit is controlled by

comparing the temperature readings of the appropriate tem-

perature sensor against either the CUT-IN or CUT-OUT setpoint

to the DIFFERENTIAL control settings. To determine CUT-OUT

temperature, calculate the CUT-IN minus the DIFFERENTIAL.

To determine CUT-IN temperature, calculate the CUT-OUT plus

the DIFFERENTIAL. For example, the factory setting for pan

CUT-OUT is 29°F with a 4°F DIFFERENTIAL which yields a CUT-

IN setting of 33°F.

The factory settings should be considered a guide and may

need to be adjusted based on store conditions. Because

these cases are often installed in stores near a meat prepara-

tion area where standard ASHRAE conditions may not apply,

different settings may be required for optimal operation.

It is important to consult the guidelines and control setting

shown on page 2 before setting defrost times. Further adjust-

ment may be required depending on store conditions.

If your case is equipped with a Dixell temperature and humidity

controller, see Appendices B1-B4 for operating instructions.

If you need to convert pressure to temperature see Appendix

C1 for the Sporlan Temperature-Pressure Chart.

DEFROST & TEMPERATURE CONTROLS

Cases are equipped with either Hot Gas or Timed-Off defrost at

the owner's option.

The hot gas defrost termination sensor bulb and probe are

attached to the dump line which is in the front, left-hand side

of the case.

Fig. 11 Airflow pattern

16

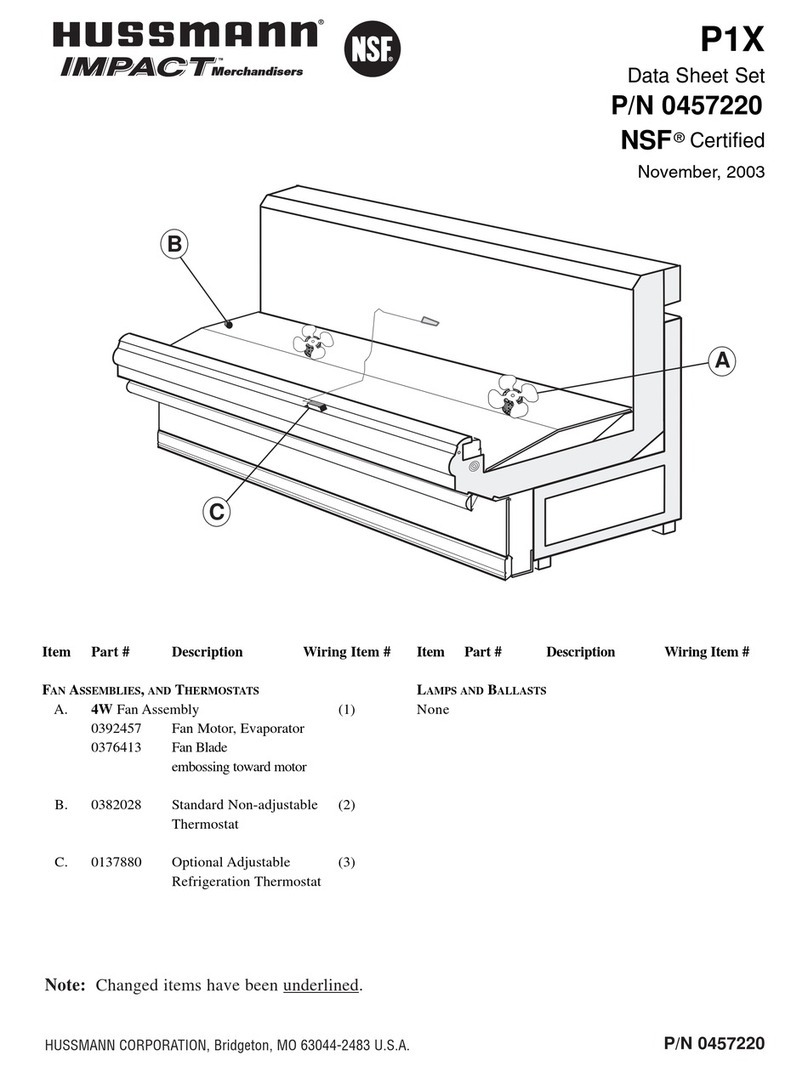

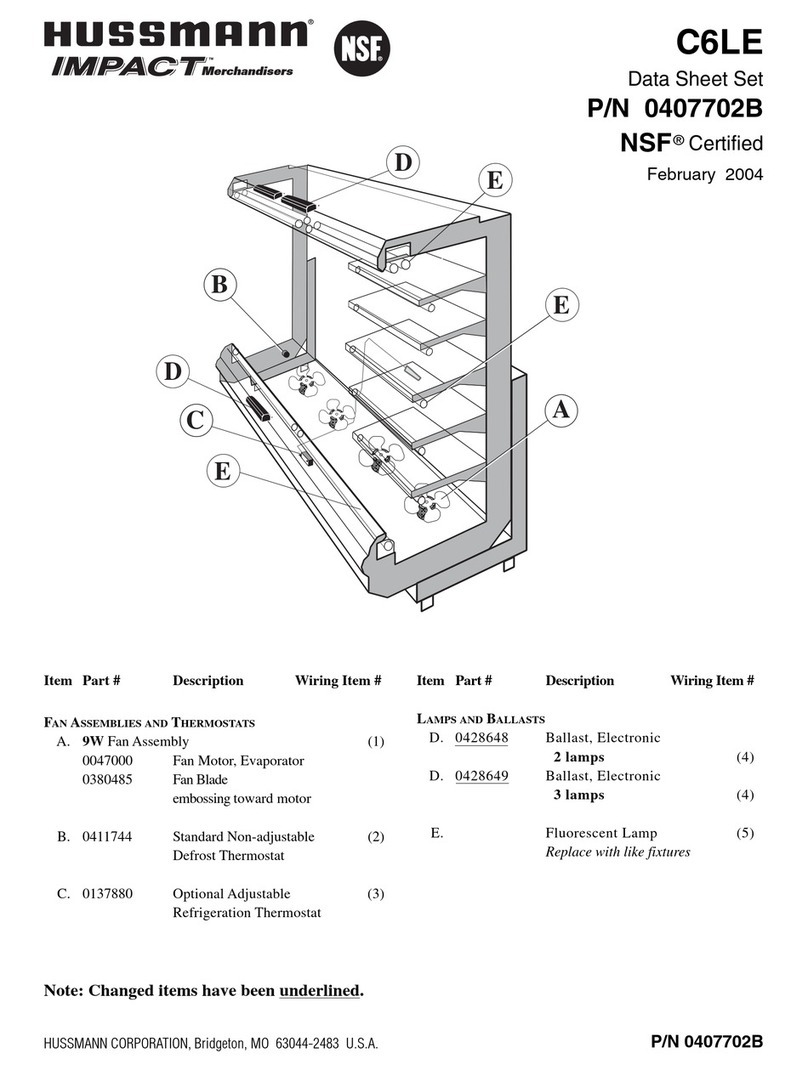

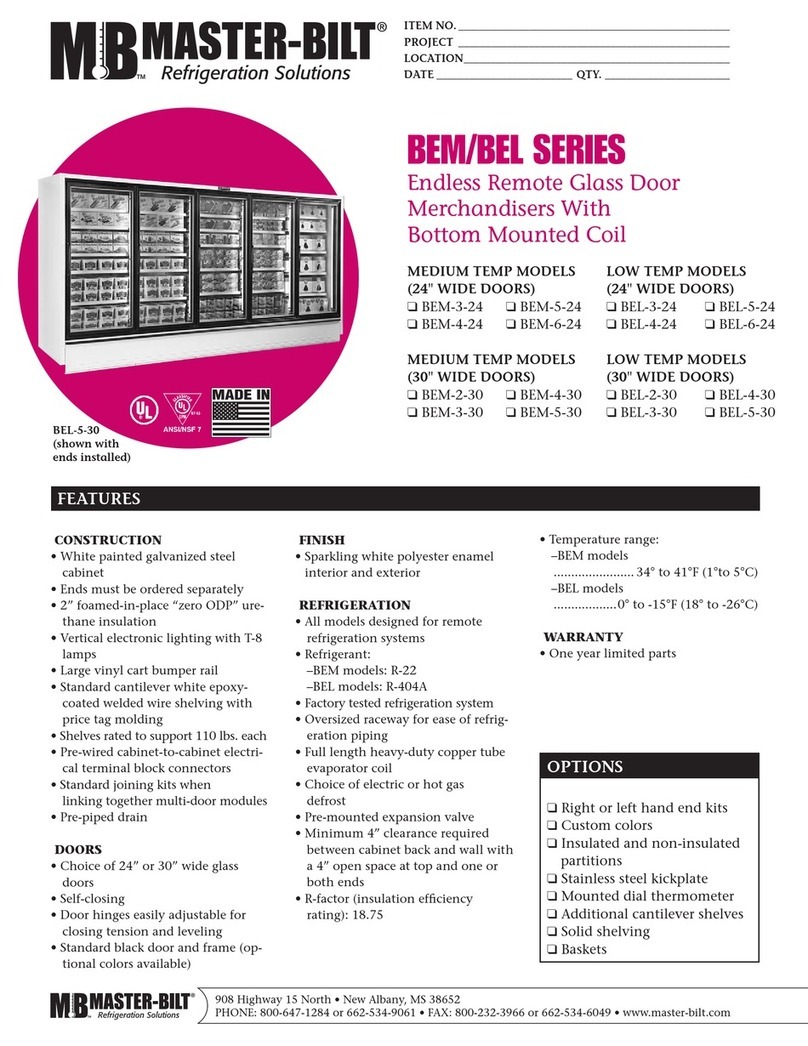

This manual suits for next models

1

Table of contents

Other Barker Merchandiser manuals

Popular Merchandiser manuals by other brands

True

True GDM-7-S-LD installation manual

Master Bilt

Master Bilt BEL-2-30 Specification sheet

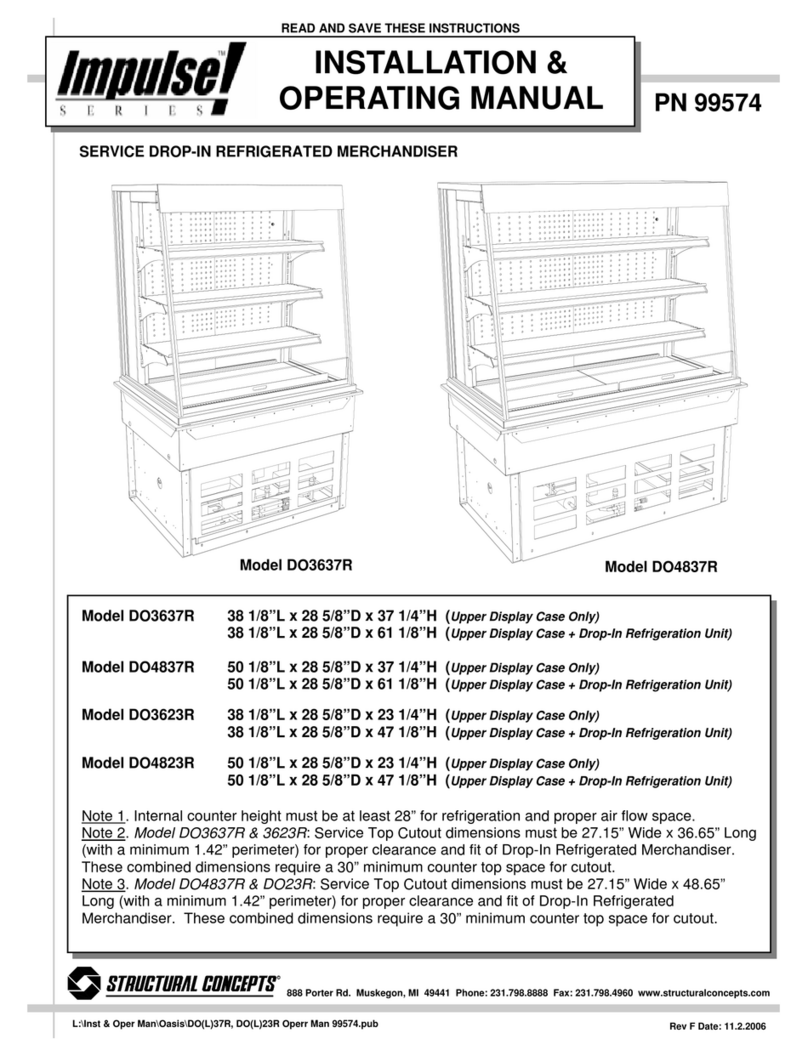

Structural Concepts

Structural Concepts DO3623R Installation and operating manual

True

True GDIM-26 installation manual

Winco

Winco EDM-1K Operating instructions manual

Hatco

Hatco FLAV-R-FRESH FDW-1 Installation & operating manual