1

Contents

Greeting ............................................................................................................2

Introduction .......................................................................................................2

Warning Symbols ..............................................................................................2

Purpose.............................................................................................................3

Safety ................................................................................................................3

Safe Operating Practices ..................................................................................3

Training .............................................................................................................3

Preparation........................................................................................................3

Operation ..........................................................................................................4

Maintenance and Storage .................................................................................5

About the Waste Disposal.................................................................................5

Before Long-Term Storage................................................................................5

1. Precautions for Safe Operation.....................................................................6

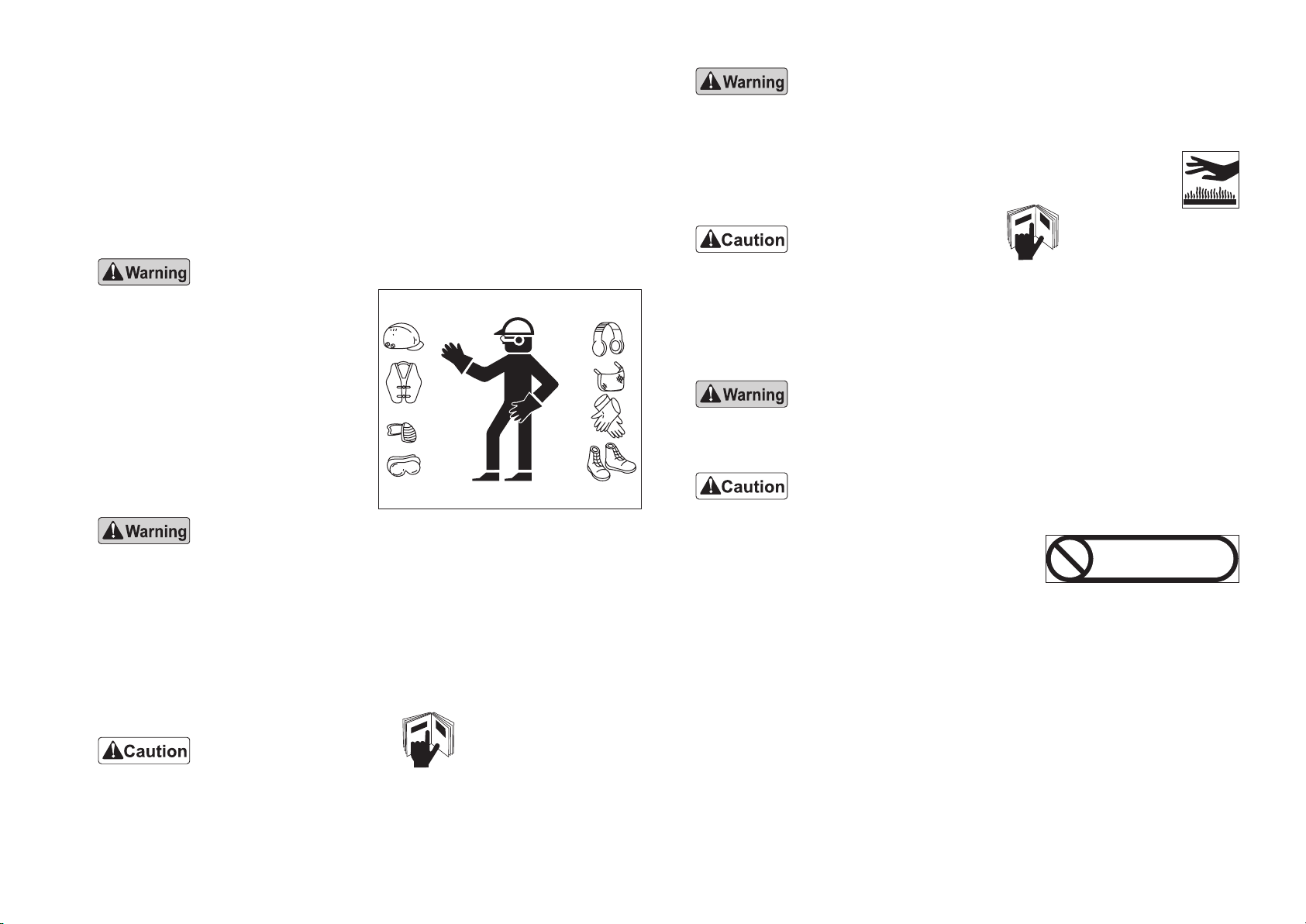

1-1 Clothes for Safe Operation .......................................................................6

1-2 Do Not Operate Under the Following Conditions......................................6

1-3 Do Not Modify Machine ............................................................................6

1-4 Removing Debris From Around Muer and Engine .................................6

1-5 When Lending to Others...........................................................................6

1-6 Do Not Drive or Operate at Night..............................................................6

1-7 Do Not Travel on Public Roads.................................................................6

2. Specications ................................................................................................7

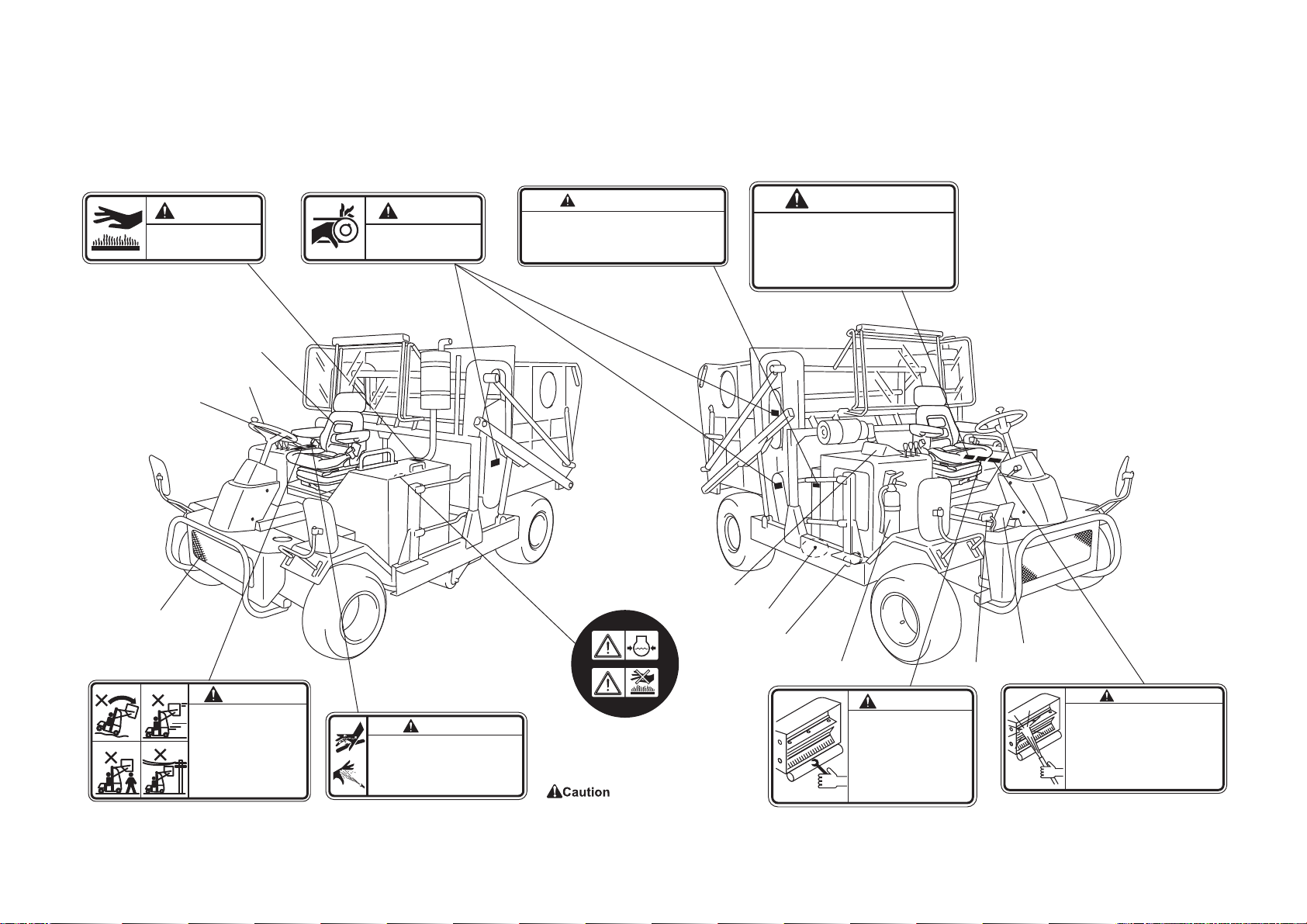

3. Names of Parts and Decal Positions.............................................................8

4. Inspection Before Use...................................................................................9

4-1 Cleaning of Radiator and Oil Cooler.........................................................9

4-2 Inspection of Radiator and Coolant Quantity............................................9

4-3 Inspection and Supply of Engine Oil.......................................................10

4-4 Inspection of Hydraulic Oil......................................................................10

4-5 Cleaning of Air Cleaner...........................................................................10

4-6 Inspection of Engine-Related Parts ........................................................11

4-7 Inspection of Tires...................................................................................11

5. Tightening the Parts ....................................................................................12

5-1 Tightening Torque ...................................................................................12

5-2 Tightening Torque by Model....................................................................13

6. Operation of Each Section ..........................................................................14

6-1 Precautions for Operating the Machine ..................................................14

6-2 Before Starting the Engine......................................................................14

6-3 Starting/Stopping the Engine..................................................................14

6-4 Precautions for Handling Fuel ................................................................15

6-5 Precautions When Leaving the Machine ................................................15

6-6 Control Box.............................................................................................15

6-7 Parking Brake .........................................................................................15

6-8 Adjustment of Seat..................................................................................16

6-9 Tilt Steering.............................................................................................16

7. Basic Operation...........................................................................................16

7-1 Traveling .................................................................................................16

7-2 Collection Work.......................................................................................17

7-3 Bucket Dumping .....................................................................................18

8. Instruments .................................................................................................19

8-1 Water Temperature Gauge .....................................................................19

8-2 Tachometer/Hour Meter ..........................................................................19

8-3 Fuel Gauge.............................................................................................20

8-4 Oil Pressure Lamp..................................................................................20

8-5 Charge Lamp..........................................................................................20

9. Maintenance/Inspection of Parts.................................................................20

9-1 Replacement of Engine Oil.....................................................................20

9-2 Greasing .................................................................................................21

9-3 Replacement of Hydraulic Oil .................................................................22

9-4 Inspection of Oil Leakage .......................................................................22

9-5 Inspection of Battery...............................................................................22

9-6 NTN Constant Velocity Joints .................................................................23

9-7 Opening/Closing of Hood........................................................................23

9-8 Jacking Up the Machine .........................................................................23

10. Maintenance Precautions..........................................................................24

10-1 Maintenance Precautions .....................................................................24

10-2 Preventing Injuries Caused by High-Pressure Oil ................................24

10-3 Maintenance Schedule .........................................................................24

11. Towing When the Machine Does Not Travel ............................................25

11-1 Towing When the Machine Does Not Travel .........................................25

12. Operating Precautions ..............................................................................25

12-1 Preparations Before Use ......................................................................25

12-2 Precautions for Rotating Parts..............................................................25

12-3 Precautions for Hot Parts......................................................................25

13. Operating on Slopes .................................................................................26

13-1 Precautions for Operating on Slopes....................................................26

14. Option ......................................................................................................26

14-1 Rear-view Monitor.................................................................................26

14-2 Hood .....................................................................................................26