11-8865-7D0001_A-03/2019-288307

DTL III Ex Type 17-8865-4.22/2200 3000 Operating manual

4.2. Installation

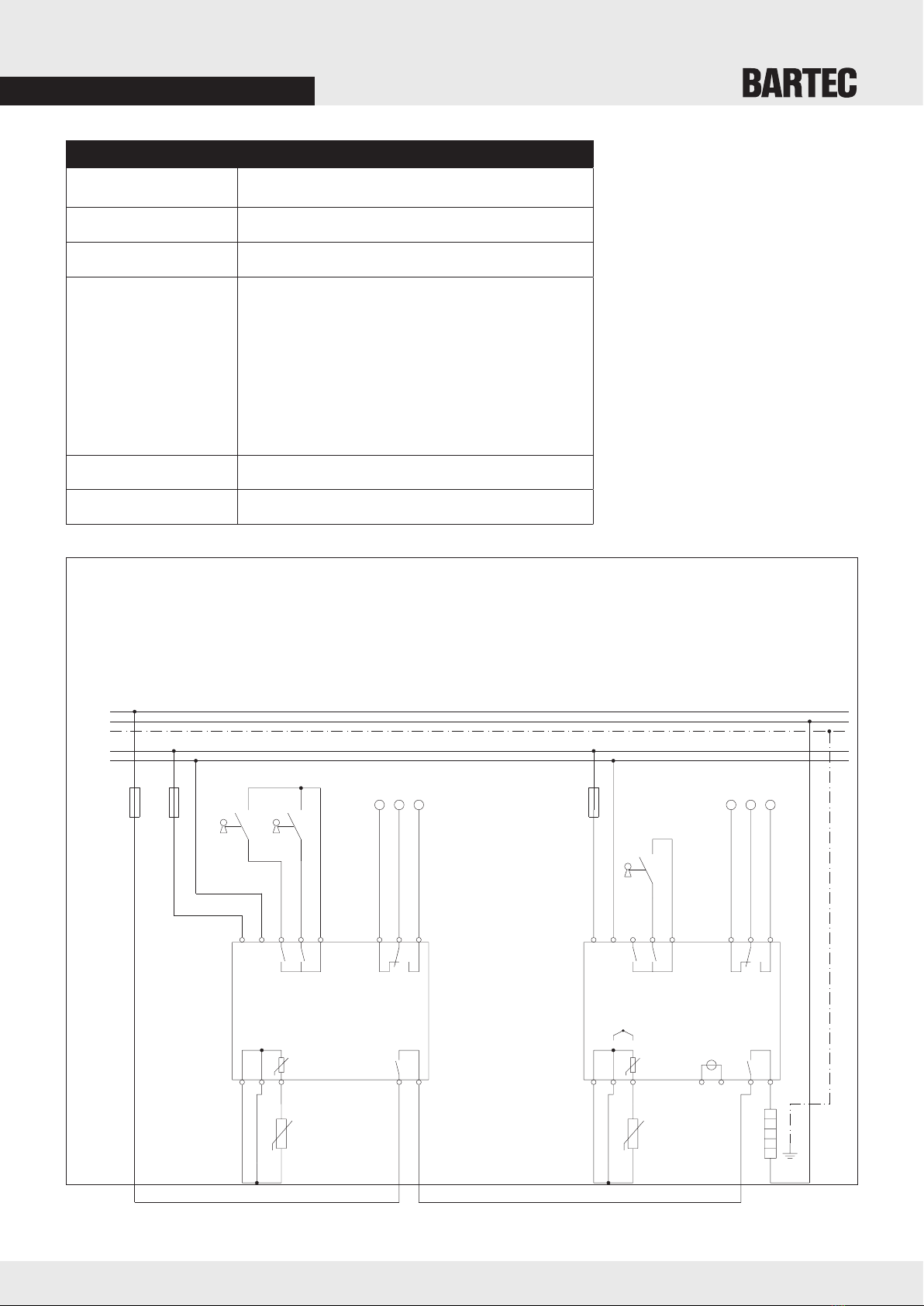

The device must be connected in accordance with the wiring diagram with due consideration to

thecurrent/voltagespecications.Itisessentialtoobservethespecicationsonthetypelabel.

If the resistance thermometer that is connected to the device is brought into Dust Ex areas, it must

be ensured that it has the appropriate approval.

In principle, the resistance thermometer must be mechanically and temperature-stably attached to the

point to be measured in order to ensure reliable thermal coupling. This should be carried out by using

temperature-resistant aluminium adhesive tape or similar materials.

All output circuits connected to the device must be protected by suitable over current protection

devices (e.g. CB).

4.3. Commissioning

The device may only be operated in a clean and undamaged condition. In case of visible damage, the device

must be deactivated and appropriate repair actions initiated.

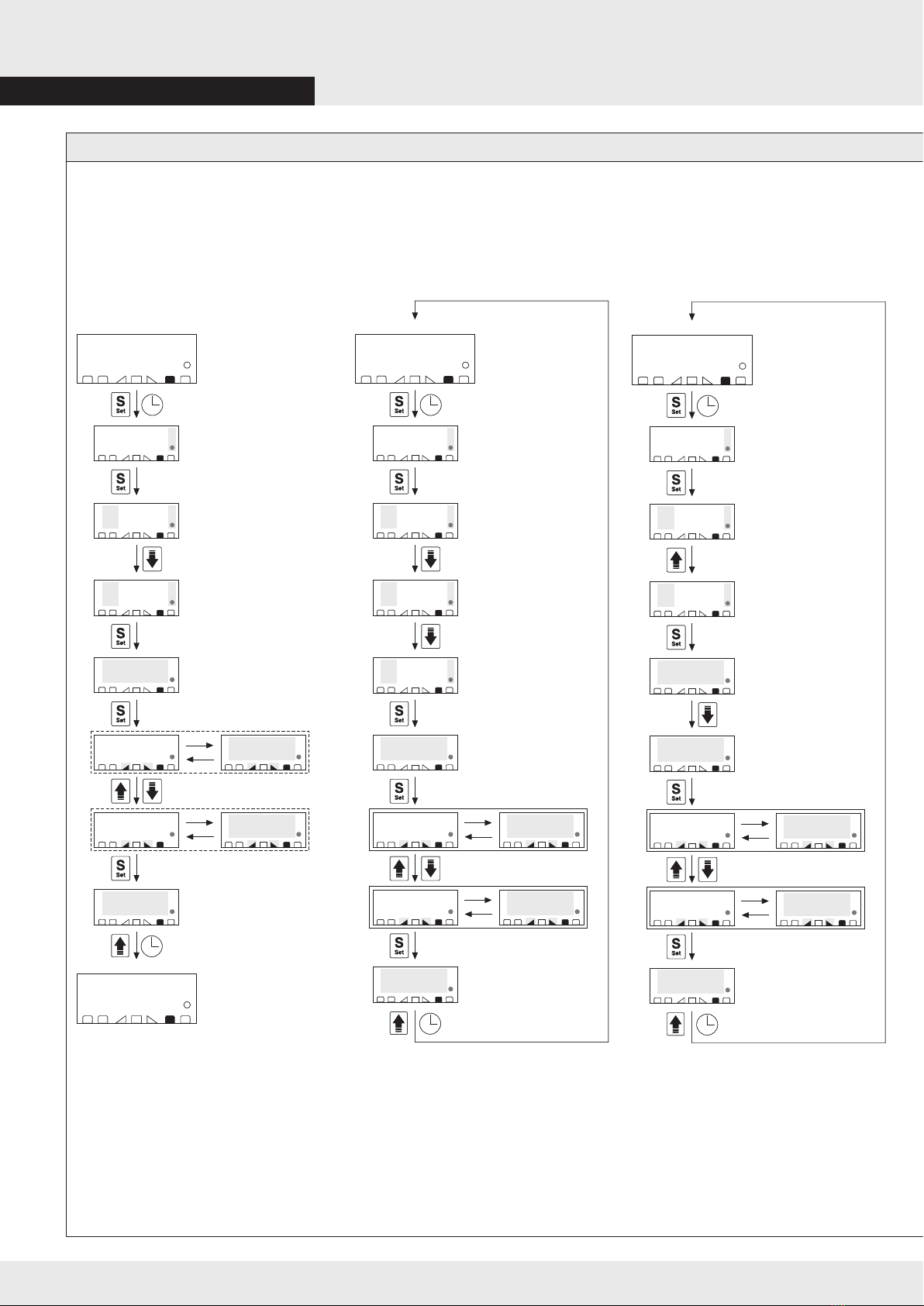

Commissioning must be carried out in the following steps:

Connect the device to electric power

Set the limiter alarm setpoint and the pre-alarm setpoint that suits the application.

Set the access password for the system parameters (incl. the setpoint for the limiter alarm).

If required, set the password for resetting the limiter alarms

Note: When controlling Ex heating circuits, the access password for the setpoint limit alarm and the

password for resetting limiter alarms must be set, since the setting of the DTL III Ex in accordance with

EN 60079-7 or EN 60079-30-1 must be “secured” and “sealed” for interaction with explosion-protected

heating circuits.

With the DTL III Ex, this is achieved by using separate passwords for

- Resetting limiter alarms

- Setting the set point Limiter alarm

4. Assembly, installation and commissioning3. Safety instructions

Before commissioning, please check the

marking on the DTL III Ex for suitability for

the intended use.

For electrical systems, the relevant installation

and operating regulations as well as other

relevant national regulations must be observed.

The operator of an electrical system in a

hazardous environment must keep the

equipment in good condition, operate and

monitor it properly and do maintenance and

repairs.

All generally valid statutory rules and the other

binding directives on safety at work, accident

prevention and the protection of the

environment must be adhered to.

When using the DTL III Ex to monitor the

temperatures of the heating and heating

circuits in hazardous areas, the following

points must be observed:

- The factory setting of the limiter alarm

setpoint is 190 °C (in Temperature

Class T3). If the application requires another

limit value, this must be set.

- The limiter alarm setpoint setting must be

protected by a password that is accessible

only to authorised people. The factory

setting of the PAS.2 password (“OFF“) must

be altered.

- The resetting of limiter alarms can be

protected by a password, whereby the

factory setting of the PAS.1 password

(“OFF“) must be changed.

- The remote reset use (e.g. by using a

key switch) may only be made possible

to authorised people.

- During commissioning a test of correct

functioning must be conducted in

accordance with EN 60079-30-2.

- The functionality of the DTL III Ex must

be checked in accordance with the

speciedtestintervalsoftheIndustrial

Safety Regulation.

4.1. Assembly

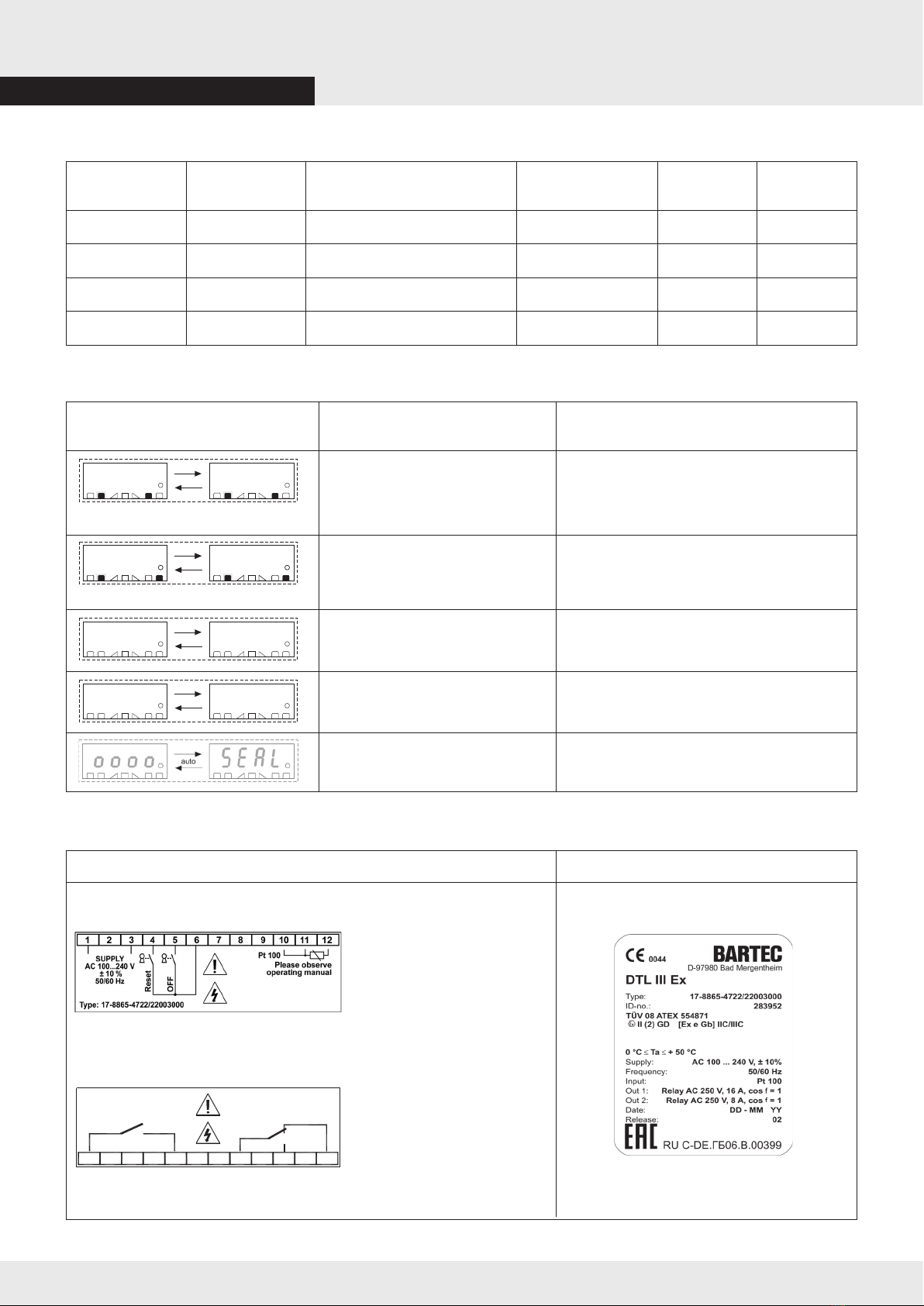

ThedetailsonthetypelabelandintheECTypeExaminationCerticatemustbeobserved.Thecontroller

isttedintoaDINenclosure with 4 HP (horizontal pitch). The device can be latched onto a mounting rail in

any mounting position in a row.

Inprinciple,itmustbeensuredthatthedeviceisproperlyventilatedtoensurethatthespeciedoperating

temperature limits are not exceeded. Avoid use in areas with additional heat sources so that the permissible

ambient temperature of the limiter is not exceeded.

The device must be installed as far away as possible from sources that could cause strong electromagnetic

interference (e.g. from motors).

Whenconnectingstrandedorne-strandedconductors,theconductorendsmustbeadequatelyprepared.

Assembly instructions for assigning the connection terminals

Conductor Min. Max. Minimum length

cross-section cross-section wire end ferrule

rigid 0.2 mm² 2.5 mm²

with wire end ferrule 0.25 mm² 2.5 mm² 10 mm

2 conductors rigid 0.2 mm² 0.75 mm²

2 conductors with

non-insulated wire end ferrule 0.2 mm² 0.75 mm² 10 mm

2 conductors with

TWIN wire end ferrule 0.5 mm² 1.5 mm² 10 mm

EN 5/12