Bartell Global DFG280 User manual

DFG280

OWNER’S MANUAL

DFG280

Operating Manual

V1.05

2

WWW.BARTELLGLOBAL.COM

Bartell Morrison Inc.

170 Traders Boulevard East

Mississauga, Ontario, Canada

L4Z 1W7

Tel: (647) 953-4100

Fax: (647) 953-4101

Bartell Morrison USA LLC

200 Commerce Drive, Unit A

Freehold, NJ, USA

07728

Tel: (848) 225-8100

Fax: (848) 225-8101

SPE International Ltd.

Honeyholes Lane

Dunholme, Lincoln, England

LN2 3SU

Tel: 01673 860709

Fax: 01673 861119

Innovatech

4701 Allmond Ave

Louisville, Kentucky, USA

40209

Tel: (425) 405-9100

Fax: (425) 405-9101

DFG280

Operating Manual

V1.05

3

This manual is provided to persons purchasing an SPE machine and may not be

reproduced in part or full without written permission of SPE International Ltd.

This manual provides the basic information required and is only to be used as a guideline.

The SPE machines are manufactured and covered by SPE design registrations granted and

pending.

SPE International Ltd reserves the right to alter the equipment design and specification as

required without notice.

DFG280

Operating Manual

V1.05

4

INDEX

Page No

5

Safety

6

Safety Precautions

7

Operating Manual

8

Starting Work

9

General Operation

10 Changing the Grinding Head

11 Electrical Instructions

12 Maintenance

13-18 Spare Parts Breakdown

19-21 Wiring Diagrams

22 Electrical Requirements

23-24 Noise and Vibration Assessment

26 Warranty

27 Declaration of Conformity

28

Conditions of Sale

DFG280

Operating Manual

V1.05

5

SAFETY

Only trained operatives should be allowed to work the DFG280 floor grinder.

All operatives should wear ear defenders, goggles and an effective dust mask. Note: It is

possible that the noise level produced by the DFG280 could exceed 90dbA. Personal noise

protection must be worn and the equipment must be used in line with guidelines laid down

by the Health & Safety Executive.

Never leave the DFG280 unattended whilst in use. Always stop the motor prior to leaving

the machine.

Keep the electric lead away from the grinding head.

Always use the correct voltage for the machine and RCD protection.

Always ensure that all power leads are disconnected before attempting to service the

machine. The service of electrical components should be carried out by authorised

personnel. Never tip the machine completely backwards until the grinding plates have

stopped rotating, just raise slightly.

Vibration will occur at various levels dependent on the attachments and work being

completed. It is recommended that tests are taken on site to provide the operator with

accurate information on using the equipment within the guidelines laid down by the Health &

Safety Executive.

Never operate the machine without a dust skirt.

NOTE:

NEVER OPERATE THE COMPACT FLOOR GRINDER IN WET CONDITIONS AS

ELECTRICAL COMPONENTS ARE NOT WATERPROOF

DFG280

Operating Manual

V1.05

6

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an explosive

atmosphere, near combustible materials, or where

ventilation does not clear exhaust fumes.

WARNING

BURN HAZARD

Never come into contact with the engine or muffler

when engine is operating or shortly after it is turned

off. Serious burns may occur.

CAUTION

MOVING PARTS

Before starting the machine, ensure that all guards

and safety devices are in place and functioning

properly.

ATTENTION

READ OWNER’S MANUAL

Read and understand owner’s manual before using

this machine. Failure to follow operating

instructions could result in serious injury or death.

DFG280

Operating Manual

V1.05

7

DFG280 OPERATING MANUAL

This manual covers, to the best of our knowledge, the operation and maintenance of the

DFG280. Before operation of the equipment the manual should be read and understood by the

operator. The safety regulations must be followed at all times. Service of electrical

components should be carried out by authorised personnel. Failure to follow these instructions

could result in damage to the machine and/or serious personal injury or death.

WARNING

Failure to follow these instructions may result in serious personal injury or death. SPE

disclaims all responsibility for damage to persons or objects arising as a consequence of

incorrect handling of the machine and failure to inspect the machine for damage or other faults

that may influence the operation prior to starting work.

DFG280

Operating Manual

V1.05

8

STARTING WORK

Check the following prior to starting the equipment.

•Check all nuts and bolts for tightness

•Check the plugs and cables for damage

1.

The machine is fitted with an adjustable handle which can be folded over for ease of

lifting and transportation. The handle can be adjusted by releasing the two locking pins on

the side and moving the handle into one of three positions for preferred operator comfort.

This is then locked in place by re-engaging the locking pins.

2.

Fit a suitable grinding head by tilting the machine backwards on to its handle. The

machine must be secured and supported. Attach the grinding head to the machine using the

four countersunk fixing screws and tighten. Lower the machine back to the upright position.

3.

Connect the vacuum hose to the dust extraction port, if a dust control vacuum is being

used. We recommend the SPE VAC316 3 motor vacuum for dust control.

4.

Ensure that the power supply is correct for the machine (see page 11 for further details).

Connect the machine to the power supply.

5.

To start the machine

•Check that the stop button is out by rotating clockwise.

•Lift the grinding head slightly by tipping the machine onto its rear wheels.

•Press the start button.

•Lower the machine onto the floor, moving the head evenly across the surface to

ensure a smooth ground finish.

6.

To stop the machine, push the red stop button.

7.

The machine is also fitted with two removable panels in the dust shroud which can assist

with edge work. Undo the two thumb nuts and remove the panel to allow the grinding head

to get closer to the vertical surface. Once done, replace the panel and refit and tighten the

two thumb nuts.

Never allow the machine to stop moving whilst grinding head is in contact with the

surface.

DFG280

Operating Manual

V1.05

9

GENERAL OPERATION

Although excessive downward pressure on the cutters may marginally improve the work

rate/finish this would increase the wear rates on the head, components and could result in

overloading the motor.

Tests have shown that two light passes are quicker and more cost effective than one slow

heavy pass and have conclusively shown that heavy downward pressure reduces the life of

the tooling discs used.

The DFG280 is normally operated in a forwards and left to right direction, the operator

varying the speed of travel to determine the final finish. It is permissible to operate the

machine with a backwards and forwards action. Each pass should be overlapped to

produce a uniform finish.

DFG280

Operating Manual

V1.05

10

CHANGING THE GRINDING HEAD

1.

Disconnect from the power supply.

2.

Tilt the machine backwards on to its handle. The machine must be secured and

supported.

3.

Make sure the grinding head is cool to the touch.

4.

Use a hex key to undo the countersunk screws securing the Grinding Head to the adaptor

plate.

5.

Remove the grinding head and replace.

6.

Ensure the grinding head is seated to the adaptor plate correctly prior to tightening the

countersunk screws diagonally.

7.

Lower the machine back to the upright position.

8.

Reconnect to the power supply.

CHECK FOR CORRECT WEAR RATE AFTER QUARTER OF AN HOUR AND AGAIN AT

HALF AN HOUR INTERVALS - THIS WILL GIVE AN IDEA OF WEAR RATE

DFG280

Operating Manual

V1.05

11

ELECTRICAL INSTRUCTIONS

The DFG280 machine is supplied with a specially commissioned 110V electric motor and

starter switch assembly. Each unit is fully tested and the safety overload relays have been

calibrated and set according to the manufacturers specifications. In the event of the malfunction

on a new machine the owner should first check that the power supply on site is suitable and

adequate.

DFG280-5 (110V)

•The 110V motor requires a 32 Amp supply.

•To avoid voltage drop the cable size must be a minimum of 4.0mm 3 core. Maximum

length of cable not to exceed 30 metres.

•If a transformer is used it must have a continuous rated output of at least 3 KVA. In

practice this means that a 5 KVA transformer must be used.

DFG280-1 (415V Three Phase)

DFG280-3 (230V Single Phase)

•The 230V/400V require a 16 Amp supply.

DFG280-6 (115V)

•The 115V motor requires a 15 Amp supply.

All cables should be fully uncoiled and never left wrapped around cable reels or tied in loops.

If the power is to be generated, the DFG280 requires a minimum 8kva generator.

The motor is protected with a safety trip in the panel. Should the trip be activated, it will reset

automatically after cooling down.

If the motor repeatedly cuts out then it will be damaged. The possible causes are

either an inadequate power supply, overloading of the machine, or an electrical fault.

DFG280

Operating Manual

V1.05

12

MAINTENANCE

Prior to any maintenance or adjustment disconnect the machine from the power supply.

AFTER USE:

-

Clean the machine to remove all build-up of dust and surface residue. If using a hose

pipe or pressure washer take care that water is not directed onto electrical components

and switches. (Note: Motors and switches are not waterproof)

-

All components should be checked daily for tightness.

-

Check the plugs and cables for damage.

-

The flexible drive coupling that support the grinding head should be checked on a

weekly basis.

-

Any excess vibration due to uneven head wear should result in the head being changed

to eliminate damage to coupling.

BASIC MAINTENANCE CHECKLIST

DAILY: (or every 8hrs to 10hrs)

•Check all nuts and bolts for tightness.

•Check the condition of the grinding head

•Check the plugs and cables

WEEKLY:

All the above with the following: -

•All of the above with the following.

•Check the flexible drive coupling

•Check the support wheels and grease

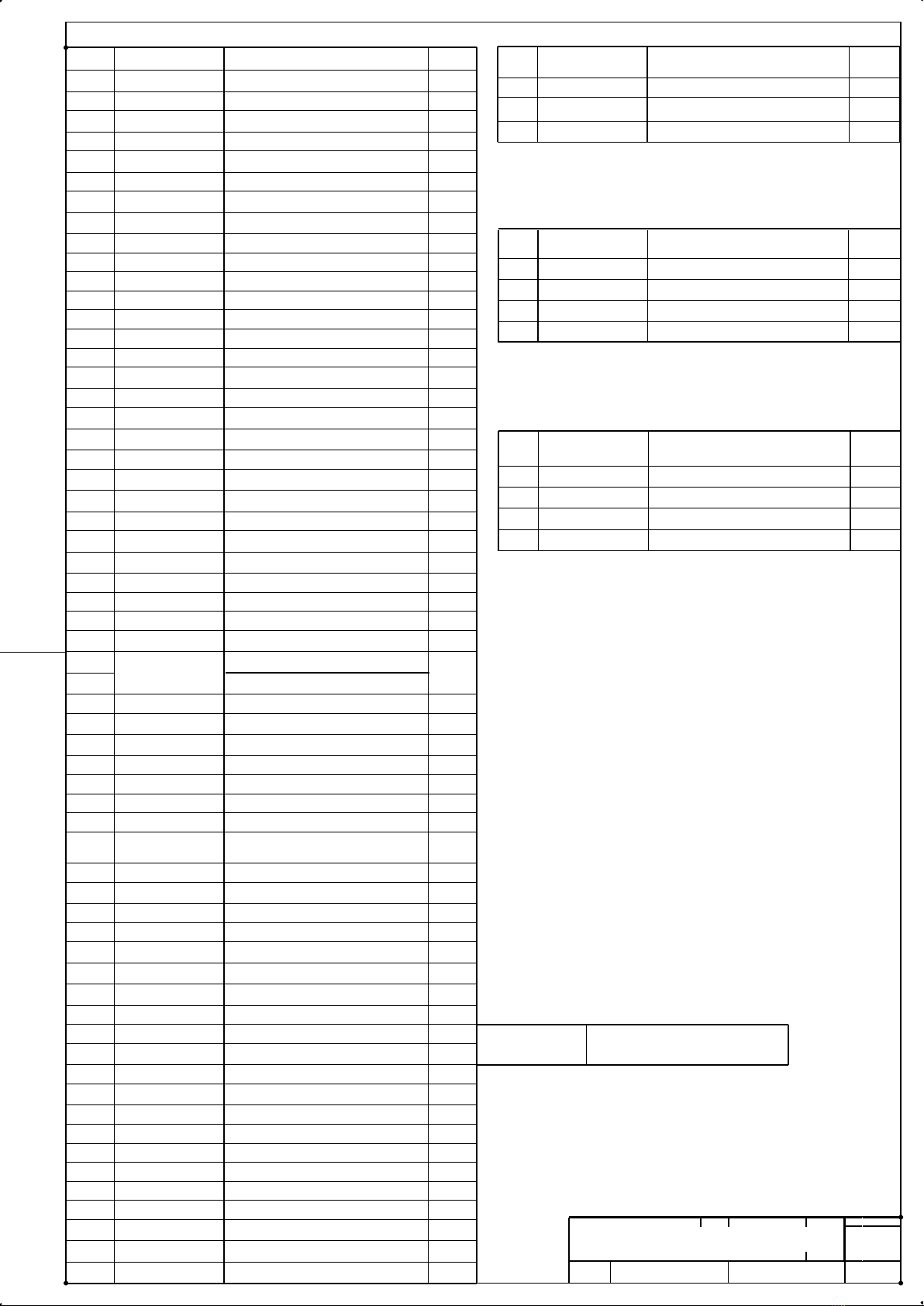

DFG280-5 (110V) DFG280-3 (230V)

ITEM

NO. SPENo DESCRIPTION QTY. ITEM

NO.

11

50

51

DFG280-1 (415V)

.

15

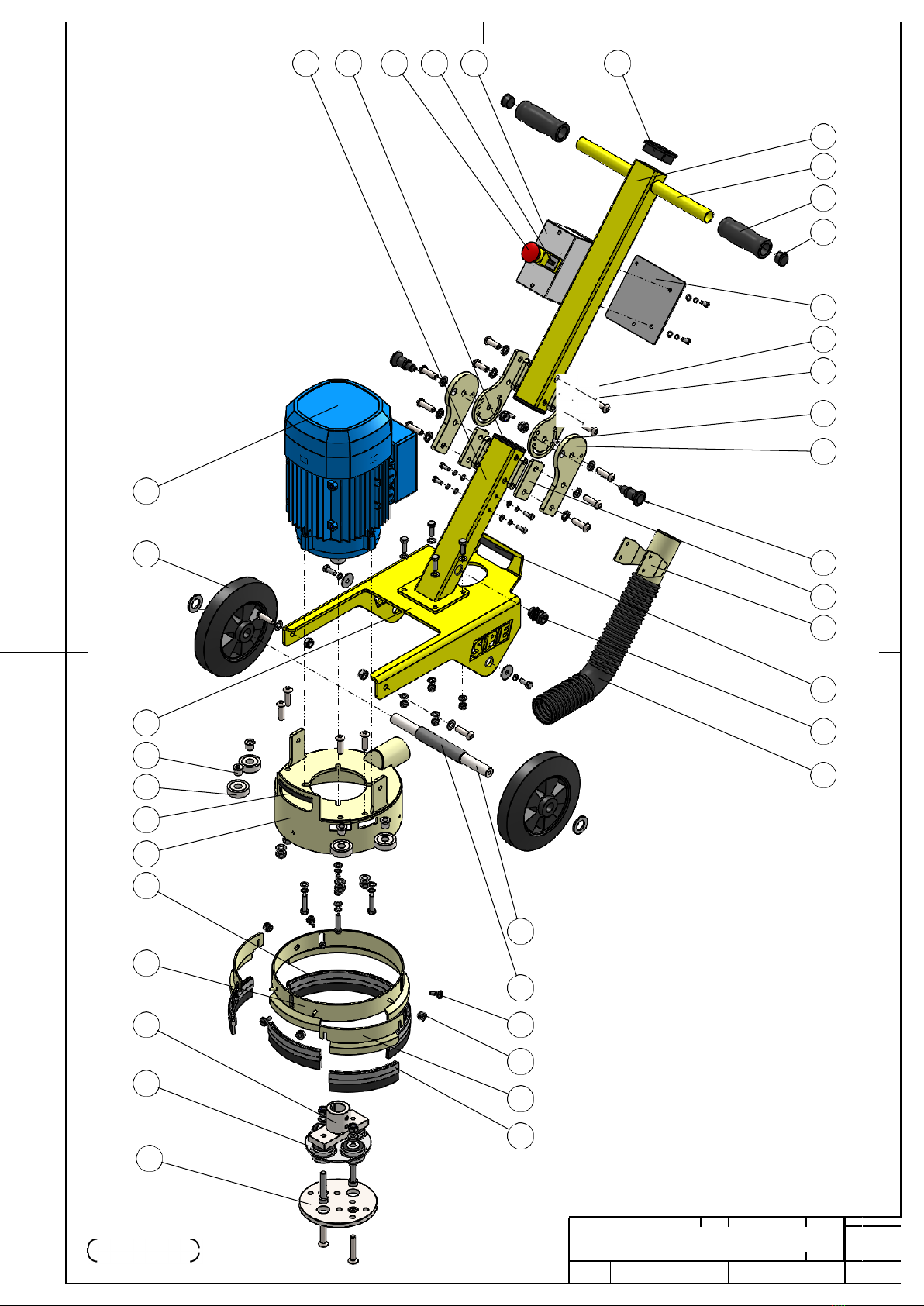

5365

Pivot Plate Packer

2

16

5366 Clamping Bar 4

17

5367

Electrical Box Plate

1

18

5368 End Cap 2

DFG280-6 (115V)

19 5369 End Cap (with hole) 1 ITEM SPENo DESCRIPTION QTY.

Head Screw

SPM1X1702P Enclosure Kit (Enclosure + Stop Button)

PARTS BREAKDOWN

DWG No.

DFG-280-A-(BOM)-0

SCALE

NOT TO SCALE

SHEET

1

of 6

SPENo DESCRIPTION QTY.

5360A

Motor (230V)

1

SPM1P1400 Switch 1

SPM1X14230

Under Voltage Coil

1

ITEM

NO.

SPENo DESCRIPTION

QTY

11 5360B Motor (415V) 1

47 SPCG/LNM25 Cable Gland 2

50

SPM1P065 Switch 1

51

SPM1X14400

Under Voltage Coil

1

20

5370

Roll Pin

2

NO.

21

5371 Bearing 4

4

5382

Connector

1

22 5372 Bearing Spacer 4

11

5360C

Motor (115V)

1

23 5373 Extraction Tube 1

50

SPM1P1800

Switch

1

24

5374 Flexi-Coupling 1

61

5381

Adapter Plate

1

25 5375 Retaining Screw 3

26

5376

Dust Skirt (580mm)

1

27

5377

Dust Skirt (140mm)

3

28

5378

Thumb Nut

4

29

5355 T-Mag Plate 1

30

5380

Handle Grip (Back)

2

31

Handle Grip (Front)

32

6013

Wheel (Rear)

2

33

7379 Locking Pin 2

34

9104

Handlebar Grip

2

35

BOLT022

M6x16 Hex Screw

6

36

BOLT042

M8x20 Hex Screw

2

37

BOLT043 M8x25 Hex Screw 4

38

BOLT045

M8x35 Hex Head Set Screw

4

39 BOLT166

M10 x 60 Socket Countersunk

2

40

BOLT268

M10x60 SOK Head Screw

2

41

BOLT305 M8x10 Cup Point Grub Screw 2

42

BOLT325

M10x30 Button Head Skt Screw

4

43

BOLT326 M10x35 Button Head Skt Screw 12

44

NUT043

M6 Nyloc Nut

3

45

NUT044 M8 Nyloc Nut 4

46

NUT045

M10 Nyloc Nut

10

47

SPCG/LNM20

Cable Gland EMC

1

48

SPM1Z1701P

Enclosure

1

49

SPM1Z1740P

Stop Button

1

50

SPM1P2500

Switch

1

51

SPM1X14110

Under Voltage Coil

1

52

TI/009

Tube Insert (Black)

2

53

WASHER003

M6 Plain Washer

9

54

WASHER004 M8 Plain Washer 12

55

WASHER005

M10 Plain Washer

14

56

WASHER005

M10 Plain Washer

8

57

WASHER009

M20 Plain Washer

2

58

WASHER023 M6 Spring Washer 6

59

WASHER024

M8 Spring Washer

6

60 WASHER052 M8x30 Repair Washer 2

1

5350

Main Body Plate

1

2

5351

Handle (Bottom Section)

1

3

5352 Handle (Top) 1

4

5353

Connector

1

5

5354 Adapter Plate 1

6

5356

Shroud

1

7

5357 Floating Shroud 1

8

(5358)

Shroud Edging

2

9

5359 Exhaust Bracket 1

10

5360

Motor (110V)

1

11

5361

Axle (Rear)

1

12

5362 Axle Sleeve 1

13

5363

Pivot Plate (10mm)

2

14

5364

Pivot Plate

2

DFG280

.

2 19 49 50 48 18

3

3

34

(J.

52

17

16

14

20

13

10

y

32 y I

().

1

22

21

31

..

"

..

:,

'

e

d,

J,

, ,

I

I

I

.

I

.

y

I

11

11

I

'v

33

15

9

30

47

23

"'o

6

i-

I

d, d,

I

I

I

26

'------

7

4

.

I

I

.

!

"'

"'

11

12

'-------

25

28

24

8

27

5

Ass

P

e

A

m

R

b

T

ly

S

DWG No.

DFG-280-A-(ME)-1

I

SCALE

•

NOT TO SCALE

SHEET

2

of 6

I

I

I

'

°

I

7

"'-

G.--.

---

'

-

...

53 58 35

'y

56 42

"'-------._.._

"-

'-

"-'-

'

'

'

0-

0-

46 55 55 43

..

"-'-

'-----._

"

'

>--.

'-

"'-

0- 56 43

.

' '

.

'- '-

'

'-----._

0-

'-

'-

.

'

,

'-----._

-

. ,

"

"

y "·

37

54

54 "'-

"-,

'-

I

;,

y

I

y

I

y

I

I

I

45 jl

0

I

I

ll

I

I

0----._

'-

-y.

43

55

46

d:,

-

-

d:,

d, d,

d,

-y

- -

"'-------._

53 58 35

l

54

59

38

28

"'

-

I

I

..

I

d:,

!

.

I

.

,

1

I

I

.

I

.

d:,

"'-o

60 59 36

46 55 43

57

40

l

46

55

39

fDWG No.

I

I

l

r=

-

-

r

DFG280

) DFG-280-A-(ME)-2

I

FASTENERS

SHEET

3

of

6

-

25

NOT TO SCALE

I

SCALE

4

"

'

.

10

31

22 43

55

46

21

54

59

38

6

(DFG280-6 Only)

61

44 53 25

7

28

8

26

27

28 41

25

24

4

DFG280

DWG No.

DFG-280-A-(SA)-2

HEAD

SCALE NOT TO SCALE

SHEET

4

of 6

41 ADAPTER PLATE

(Standard Fitment)

46

55

24

55

40

5

39

DFG280

DWG No.

DFG-280-A-(SA)-3

COUPLING

SCALE NOT TO SCALE

SHEET

5

of 6

OPTIONAL TOOLING PLATES

SPENo.

DESCRIPTION

5355

T-Mag Plate

5381 Slide Mag Plate

T-MAG PLATE

SLIDE MAG PLATE

DWG No.

DFG-280-A-(OE)-4

TOOLING

SCALE

NOT TO SCALE

SHEET

6

of 6

DFG280

Operating Manual

V1.05

19

WIRING DIAGRAM

DFG280-1

DFG280-6

DFG280

Operating Manual

V1.05

20

WIRING DIAGRAM

DFG280-3

Table of contents

Other Bartell Global Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Altrad

Altrad ATIKA RLC 40-10 Original instructions

Unimi Solutions

Unimi Solutions 1baseHPC installation manual

Skid Pro

Skid Pro QC605-SKD Setup instructions

Toro

Toro 22806 Operator's manual

Broderson

Broderson IC-35-2F Operating and maintenance manual

Epiroc

Epiroc HM Series Safety and operating instructions