Bartell Global Innovatech PREDATOR P32N User manual

Predator 32N

Owner’s Manual

OIPB-I02001 Predator32N_V1.0 1 | P a g e 01/ 0 7 / 19

INNOVATECH PRODUCTS 4701 Allmond Ave, Louisville, Kentucky, USA 40209

Telephone: 1-425-405-9100 Toll Free: 1-800-267-6682 Fax: 1-425-405-9108

PREDATOR GRINDER POLISHER

P32N

OWNER’S MANUAL

www.BARTELLGLOBAL.com

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 2 | P a g e 01/ 0 7 / 1 9

ORIGINAL LANGUAGE OPERATING MANUAL FOR

P32N GRINDER POLISHER

© 2015 Innovatech Products

No part of this work may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying and recording, or by any information storage or retrieval

system without the prior written permission of Innovatech unless such copying is permitted by

federal copyright laws.

Address inquiries or reference permissions care of:

INNOVATECH PRODUCTS 4701 Allmond Ave, Louisville, Kentucky, USA 40209

REV.

DATE

DESCRIPTION

APPROVED BY:

-

01/7/19

Manual created

EC

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 3 | P a g e 01/ 0 7 / 1 9

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an explosive

atmosphere, near combustible materials, or

where ventilation does not clear exhaust fumes.

WARNING

BURN HAZARD

Never come into contact with the engine or

muffler when engine is operating or shortly after it

is turned off. Serious burns may occur.

CAUTION

MOVING PARTS

Before starting the machine, ensure that all

guards and safety devices are in place and

functioning properly.

ATTENTION

READ OWNER’S MANUAL

Read and understand owner’s manual before

using this machine. Failure to follow operating

instructions could result in serious injury or death.

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 4 | P a g e 01/ 0 7 / 1 9

TABLE OF CONTENTS

1.INTRODUCTION 5

2.SPECIFICATIONS 5

3.WARRANTY INFORMATION 6

4.SAFETY PRECAUTIONS 7

5.OPERATION INSTRUCTIONS 8

6.MAINTENANCE 9

7.TROUBLESHOOTING 9

8.FAULTS WHICH CANNOT BE AUTOMATICALLY RESET 10

9.PARTS DRAWINGS & DIAGRAMS 12

10.DECLARATION OF CONFORMITY 42

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 5 | P a g e 01/ 0 7 / 1 9

1.INTRODUCTION

Innovatech Products and Equipment Company specializes in the manufacturing and distribution

of surface preparation equipment and supplies. From our early origins as a flooring removal

company, and a foundation based upon the success of our Terminator line of flooring removal

machines, Innovatech has transformed itself into an industry leader over a twelve-year period.

Our continued growth can be attributed to our pledge to offer only premium products, our

commitment to stand behind what we sell, and a staff well known throughout the industry for

their knowledge and commitment to our valued customers. Based on customer need,

Innovatech has proudly diversified our offerings to include a complete line of surface

preparation products including Shot Blasters, Scarifiers, Floor Grinders, Dust Collectors,

Diamond Abrasives, and other products.

2.SPECIFICATIONS

P32N

Cutting Width

32” (812mm)

Dimensions (Operating

Conditions)

57” x 33” x 52”

Weight

950lbs (431kg)

Tank Capacity

7 Gal (27L)

Cutter Heads/Tool Plates

Diameter

10.5” (270mm)

RPM

0 –1010rpm

Motor

15hp (11kW)

0-1765RPM

Power Source

Phase

3 Phase

Voltage

414 –504V

Hz

60Hz

Amps

25A

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 6 | P a g e 01/ 0 7 / 1 9

3.WARRANTY INFORMATION

Innovatech warrants to original retail purchaser of the equipment:

A. LIMITED WARRANTY

The equipment, when first delivered, will conform to the specifications set forth in the

Owner’s Manual and will be without defect in material or workmanship. For a period of

one (1) year after delivery to the original retail purchaser, or 300 clock hours of

operation, whichever occurs first; or in the case of replacement parts other than belts, for

a period of ninety (90) days after the part is installed or within the warranty period

described above, whichever is later, if the original retail purchaser notifies Innovatech

(either directly or through one of Innovatech’s authorized dealers) of a defect in material

or workmanship or of a non-conformity to the specifications, then, upon confirmation of

the defect of non-conformity and confirmation that the defect or nonconformity is covered

within these Limited Warranty conditions, Innovatech will, at it’s election and at it’s

expense, either (i) repair or correct the defect and/or non-conformity, or (ii) replace the

part.

B. LIMITATIONS

This Limited Warranty does not apply to damage caused by (i) misuse of the equipment

including, with limitation, use of the wrong power source, striking an imbedded object

such as a bolt, electrical outlet box, expansion joint or steel reinforcing rod; or (ii)

unauthorized alteration, modification, repair or tampering; or (iii) use of replacement

parts not supplied by Innovatech; or (iv) normal wear, discoloration, surface corrosion,

deterioration of finishes or paint surfaces, or (v) other appearance deterioration caused

primarily by use. Innovatech shall not be responsible and this Limited Warranty shall not

apply to damage caused by improper maintenance or failure to inspect and maintain the

equipment as recommended in the Owner’s Manual.

C. BELTS

The Drive Belt is covered as set out at paragraph A., above, but for the period of six (6)

months after delivery or 250 clock hours of operation, whichever occurs first.

D. TRANSPORTATION

Purchaser will pay the cost of transporting defective or non-conforming parts to

Innovatech and the cost of returning repaired or replacement parts to purchaser. Each

party will safely package the parts it sends to the other in accordance with good

commercial practice. If purchaser requests and Innovatech agrees, Innovatech may

perform covered warranty work where the equipment is located. If Innovatech performs

the work at the location, purchaser will pay the cost of business class transportation and

good quality meals and lodging for Innovatech’s technicians.

E. ABUSE

Innovatech is not responsible for damage, defect, breakage, or malfunction of the

equipment that is caused by abuse or by operation of the equipment in a manner which

is not recommended or approved by Innovatech.

F. EXCLUSIVE WARRANTY

Except as is expressly set out in this limited warranty: (i) Innovatech makes no promise

or warranty, expressed or implied, with respect to the equipment; (ii) Innovatech makes

no promise or warranty that the equipment is fit for any particular purpose; (iii)

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 7 | P a g e 01/ 0 7 / 1 9

Innovatech will have no obligation or liability to the purchaser or to any third party with for

any damage caused by the equipment or as a result or consequence of any claimed

defect in the equipment, any failure to warn or notify, or any claimed non-conformity to

the specifications; and (iv) Purchaser will have no other remedies in respect of such

defect, non-conformity, damage or condition except those set out in this limited warranty.

4.SAFETY PRECAUTIONS

1. Only persons who have received training are permitted to operate or repair the grinder.

2. Use personal safety equipment such as steel toe shoes, safety glasses, and earplugs.

3. Do not use grinder in area where there is a risk of explosion or fire.

4. Do not start the machine with heads off the ground.

5. Make sure the splashguard is on before stating machine.

6. Before you start grinding, check the floor for bolts, large holes and uneven joints. Hitting

these things can damage machine, tools, and cause personal injury.

7. Make sure all power supply is connected with the right voltage.

8. Use only cold water in water tank. Do not use chemicals in water tank.

9. When filling water tank, to avoid electrical hazards and injury, do not spill water onto the

machine motor and electrical box.

10.Switch off the machine power before changing grinding tools.

11.Disconnect power supply before working or repairing machine.

12.Be very careful with rolling machine on any sloping floors or ramps. The machine can roll

very quickly. Two people may be needed to handle and control the machine.

13.Use caution with removing the grinding tools after finished grinding. Tools can be very

hot. Use gloves to remove the plates.

14.When grinding glues, epoxy paints, or coatings, leaving the machine down on floor could

cause the head to stick to the floor. Always tip back machine as soon as the head comes

to a complete stop.

15.Always store machine in a dry place.

16.Only use Innovatech recommended tooling.

17.The operator must never leave the machine unattended during operation.

18.When grinding dry, use a suitable vacuum to extract the dust.

19.Innovatech is not responsible for any off gassing of hazardous gas that is generated by

grinding materials. It is the responsibility of the operator. Grinding floors containing

asbestos is especially dangerous and can cause health problems. Contact your state or

country for the proper way to handle it.

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 8 | P a g e 01/ 0 7 / 1 9

5.OPERATION INSTRUCTIONS

Before starting:

1. Check the floor carefully and remove all bolts, nails, as well as any loose material that

could get caught in the machine.

2. Fit the appropriate tools to the machine.

3. Fit splash guard to the right height.

4. Connect the power supply. Make sure you have all the phases. May have to check with

volt meter.

5. If you are grinding dry, connect the appropriate vacuum and start vacuum before starting

the grinder.

Starting machine:

1. Turn main power switch on side of power box to ON.

2. Turn forward or reverse switch left of right.

3. Turn manual speed pot up to get the heads turning for desired speed. (If heads do not

move, you may have to lean on handle to reduce pressure on tools.

4. Always grip handle firmly when starting machine. The machine will always move from

side to side with first start.

5. When finished with grinding, turn off machine and let the heads come to a complete stop

before tilting back the machine.

Changing of Tools:

1. Before working on the grinder, bring the motor to a total stop and disconnect power.

2. Tilt machine back on floor.

3. Use caution! Tools can be very hot from grinding. Use gloves.

4. Use special tool supplied to turn center of tool holder to remove tool plate.

5. Replace with new tool plate and turn to lock in place.

6. Lower machine back down and re-adjust splash guard is necessary.

NOTE: IF THE WRONG POWER IS SUPPLIED TO THE GRINDER, IT WILL DAMAGE

THE ELECTRICAL COMPONENTS IN THE INVERTERS.

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 9 | P a g e 01/ 0 7 / 1 9

6.MAINTENANCE

Clean machine after every use. To clean machine, use a low-pressure water hose or air

pressure. Do not use a high PSI pressure washer. This could force water into areas of the

machine unintentionally and damage parts. A regular inspection of machine for wear and

damage should be done on a regular basis. If any parts have been damaged or have excessive

wear, they should be replaced. If belt is needing replaced, please see separate instructions.

7.TROUBLESHOOTING

1. Check to see if main power supply is on.

2. Check to see if emergency stop is pushed down; if it is, pull up.

3. Check to see if manual speed pot is turned up past 1.

4. Check all cords ends for loose connection.

5. Check fuse in distribution box with test meter.

6. Check to see if all phase are with right voltage (check with voltmeter).

7. Check the converter connector cable to motor.

8. Check for error message on display of the converter.

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 10 | P a g e 01/ 0 7 / 1 9

8.FAULTS WHICH CANNOT BE AUTOMATICALLY RESET

Faults which cannot be automatically reset are listed in the table below. To clear these faults:

1. Remove power from the drive controller.

2. Wait for the display to go off completely.

3. Determine the cause of the fault and correct it.

4. Re-apply power.

FAULT

PROBABLE CAUSE

REMEDY

B L F

Brake Sequence

•Brake release current not

reached

•Check the drive controller and motor

connections

•Check the motor windings

C r F

Precharge Circuit

Fault

•Precharge circuit damaged

•Reset the drive controller

•Replace the drive controller

I n F

Internal Fault

•Internal fault

•Internal connection fault

•Remove sources of electromagnetic

interference

•Replace the drive controller

O C F

Over Current

•Incorrect parameter settings in

the Set- and drC- menus

•Acceleration too rapid

•Drive controller and/or motor

undersized for load

•Mechanical blockage

•Clear the mechanical blockage

S C F

Motor Short Circuit

•Short circuit or grounding at the

drive controller output

•Significant ground leakage

current at the drive controller

output if several motors are

connected in parallel

•Check the cable connecting the drive

controller to the motor and check the

motor insulation

•Reduce the switching frequency

S O F

Over Speed

•Instability

•Overhauling load

•Check the size of the motor, drive

controller, and load

F n F

Aut-Tuning Fault

•Motor or motor power not

suitable for the drive controller

•Motor not connected to the drive

controller

•Check the presence of the motor during

auto-tuning

•If a downstream contractor is being used,

close it during auto-tuning

E P F

External Fault

•User defined

•User defined

L F F

•Loss of the 4-20 mA reference

on input A13

•Check the connection on input A13

•Loss of 4-20 mA follower

O b F

Over voltage

during

deceleration

•Braking too rapidly

•Overhauling load

•Increase the deceleration time

O H F

Drive Overload

•Drive controller or ambient

temperature is too high

•Continuous motor current load is

too high

•Check the motor load, the drive controller

ventilation, and the environment. Wait for

the drive controller to cool before

restarting

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 11 | P a g e 01/ 0 7 / 1 9

O L F

Motor Overload

•Thermal trip due to prolonged

motor overload

•Motor power rating too low for

the application

•Allow the motor to cool before restarting

O P F

Motor phase

failure

•Loss of phase at drive controller

output

•Downstream contractor open

•Motor not connected

•Instability in the motor current

•Drive controller oversized for

motor

•Check the connections from the drive

controller to the motor

•Test the drive controller on a low power

motor or without a motor: set OPL to nO

O S F

Over voltage

during steady

state operation or

during

acceleration

•Line voltage too high

•Line supply transients

•Check the line voltage. Compare with the

drive controller nameplate rating

•Reset the drive controller

P H F

Input phase failure

•Input phase loss, blown fuse

•Three-phase drive controller

used on a single-phase line

supply

•Input phase imbalance

•Transient phase fault

NOTE: This protection only

operates with the drive controller

running under load

•Check the connections and the fuses

•Verify that the input power is correct

•Supply three-phase power if needed

C F F

Configuration

Fault

•The parameter configurations

are not suited to the application

•Restore the factory settings or load the

backup configuration, if it is valid

U S F

Under Voltage

•Line supply too low

•Transient voltage dip

•Damaged precharge resistor

•Check the line voltage

•Replace the drive controller

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 12 | P a g e 01/ 0 7 / 1 9

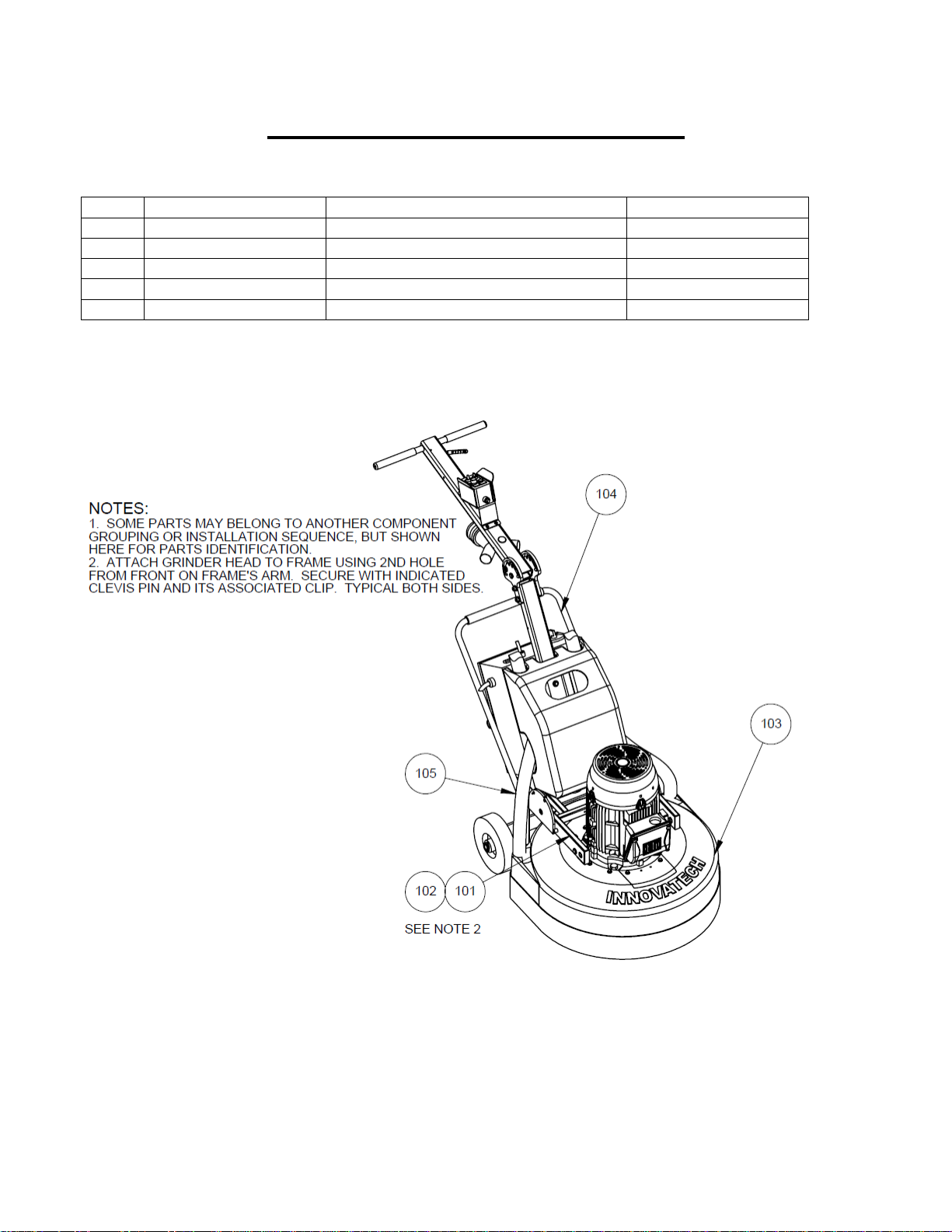

9.PARTS DRAWINGS & DIAGRAMS

P32N Grinder

ITEM

PART NO

DESCRIPTION

QTY

101

11-0082

Adjustable Clevis Pin, 5/8”*2-1/2”L

2

102

11-0052

Cotter Pin

2

103

96-0318

Grinder Head (P32N)

1

104

96-0325

Frame-Complete build-up (P32N)

1

105

825-0003

2”Hose

2

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 13 | P a g e 01/ 0 7 / 1 9

Frame complete build-up(96-0325)

ITEM

PART NO

DESCRIPTION

QTY

201

13-0162

Linch Pin

2

202

54-0031

Wheel (10in)

2

203

11-0204

Flat washer

4

204

96-0317

Frame-32N, 32ND, 32NDX

1

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 14 | P a g e 01/ 0 7 / 1 9

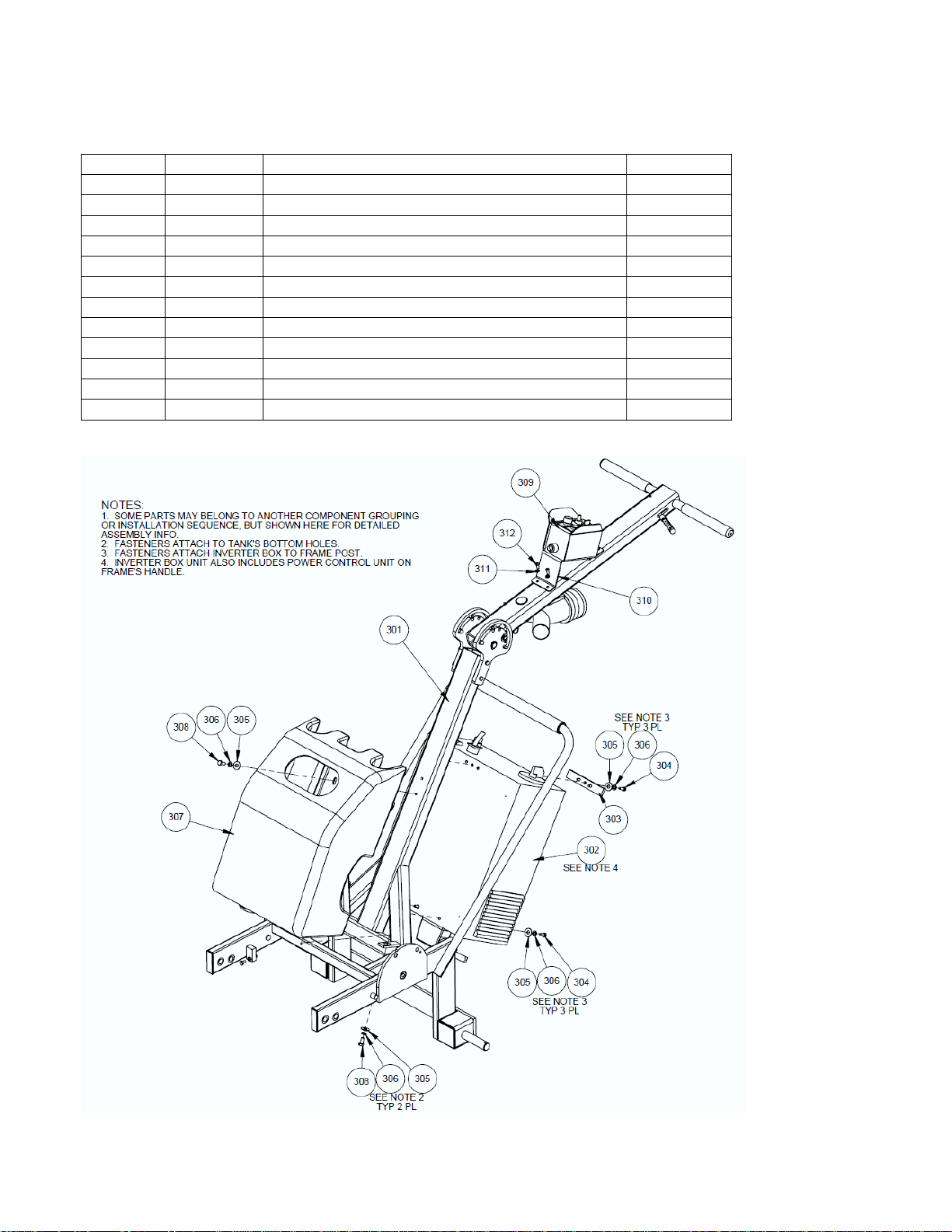

Frame complete build up- P32N, P32ND, P32NDX (96-0317)

ITEM

PART NO

DESCRIPTION

QTY

301

96-0293

Frame-Structure (skeleton) assy

1

302

96-0308

Inverter Box

1

303

51-0898

Inverter box attachment strip

1

304

11-0132

Hex head cap screw, 5/16”-18*1”

6

305

11-0034

Flat washer, 5/16”

10

306

11-0040

Split lock washer, 5/16”

10

307

54-0017

Water Tank

1

308

11-0018

Hex head cap screw, 5/16”-18*3/4”

4

309

23-0052

Power control box

1

310

52-0195

Bracket, Power control box

1

311

11-0069

Lock washer, ¼”

4

312

11-0349

Socket button head, ¼-20-5/8”

4

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 15 | P a g e 01/ 0 7 / 1 9

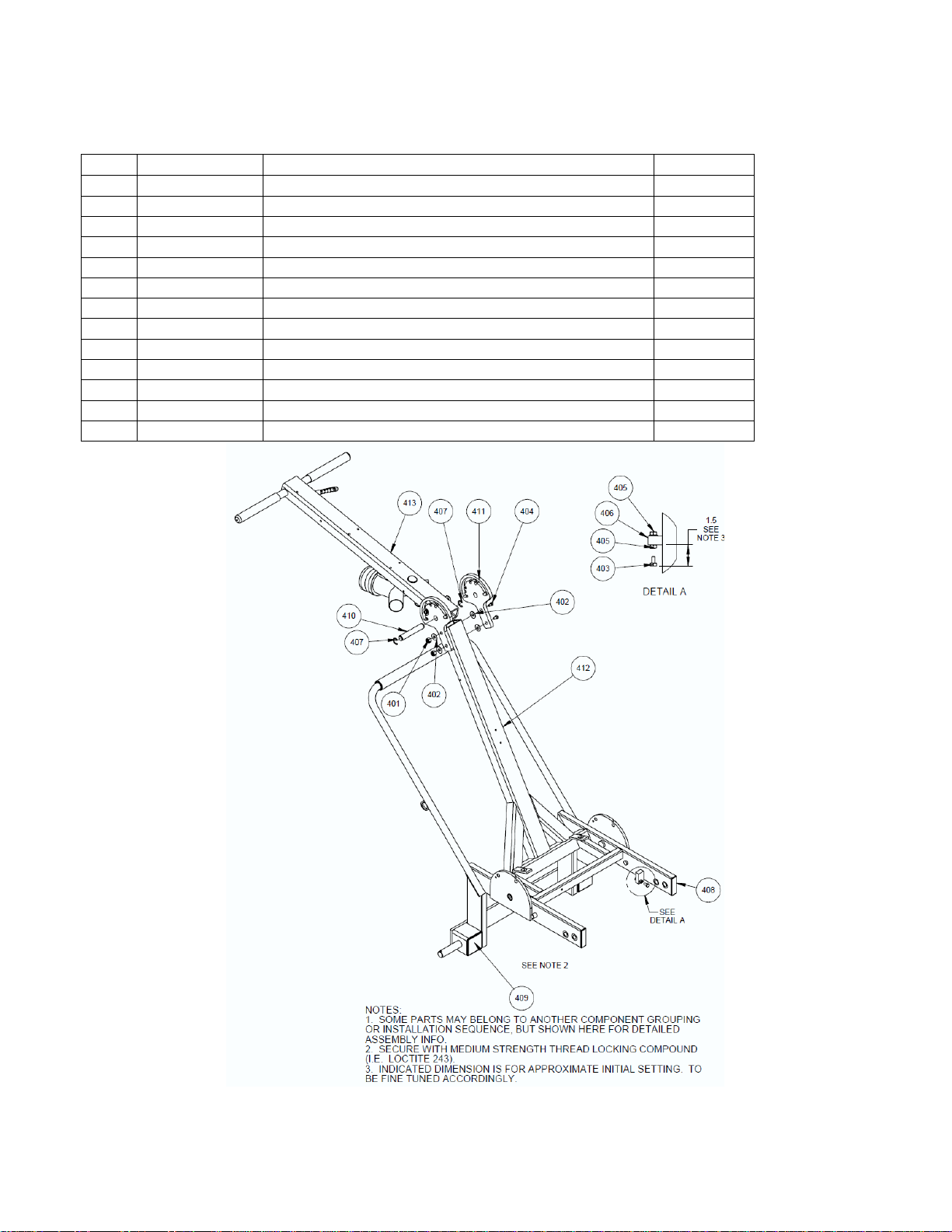

Frame- Structure (skeleton) assy (96-0293)

ITEM

PART NO

DESCRIPTION

QTY

401

11-0027

Steel Nylon-Insert Lock Nut, 7/16”-14 ZP

2

402

11-0036

Washer, 7/16”

4

403

11-0253

Hex head cap screw, 7/16”-14*3"

2

404

11-0219

Hex head cap screw, 7/16”-14*5”

2

405

11-0254

Nut, 7/16”-14

4

406

11-0320

Washer (split-lock), 7/16”

2

407

13-0144

Retaining Ring (E-Style)- for 3/4" shaft

2

408

13-0170

End cap, 1”*3”

2

409

13-0338

End cap, 2-3/4” square

2

410

51-0187

Handle hinge pin

1

411

53-0278

Handle tilt angle selection plate

2

412

53-0308

Frame-Base and post structure

1

413

96-0304

Frame- Handle Assy

1

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 16 | P a g e 01/ 0 7 / 1 9

Frame Handle Assembly (96-0304)

ITEM

PART

DESCRIPTION

QTY

501

11-0007

Hex head cap screw, GR5, 3/8”-16*1”ZP

2

502

11-0139

Steel USS Flat Washer, 5/16”, ZP

3

503

11-0124

Steel hex nut, GR8: 3/8”-16, ZP

3

504

11-0129

Steel split lock washer, 3/8”, ZP

2

505

11-0234

Hex head cap screw, GR5:1/4”-20*2”L, ZP

1

506

11-0349

Button head socket cap screw, ¼”-20*5/8”

1

507

11-0351

Steel shoulder screw, 1/2”*3/8L, 3/8”-16 Thread

1

508

13-0147

Clevis Spring Pin

1

509

13-0150

Retaining ring (E-style, for 3/8" dia shaft)

2

510

13-0152

Steel Compression Spring: 4"Lx7/8"ODx0.08"WD

1

511

13-0155

3/8" ID Grip Cover

1

512

13-0212

Yoke end, 3/8"-16 threads, 3/8 pin holes

2

513

13-0285-05

Clamp (P-style, 5/8" dia.)

1

514

13-0347

Handle grip, 1" ID x 7-7/8" L

2

515

51-0170

Quick change lever

1

516

51-0173

Handle lock rod

1

517

51-0174

Spring Tension Block

1

518

51-0999

Rod (fully-threaded), 3/8"-16 x 2 ft long

1

519

53-0330

Y-coupler unit, pivotable

1

520

53-0331

Handle post (with handle bar)

1

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 17 | P a g e 01/ 0 7 / 1 9

Grinder head- Complete unit (with shroud)- P32N (96-0318)

ITEM

PART NO

DESCRIPTION

QTY

601

11-0069

Split lock washer, ¼”

10

602

11-0234

Hex head cap screw, ¼”-20 x2”

10

603

11-0259

Flat washer, ¼”

10

604

54-0027

Splash Guard

1

605

54-0039

Shroud (cut-out panel)

1

606

96-0027

Cutter head-Floating Assy

4

607

96-0319

Shroud (main cover)

1

608

96-0321

Drum drive unit

1

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 18 | P a g e 01/ 0 7 / 1 9

Cutter Head, Floating Head Assembly (96-0027)

ITEM

PART NO

DESCRIPTION

QTY

701

11-0036

Washer, 7/16”

2

702

11-0079

Hex head cap screw, 7/16”-14 x 1-1/4”

1

703

11-0147

Socket head cap screw, 3/8”-24 x 2”

4

704

11-0162

Washer (Belleville, serrated), 3/8” (0.413ID

X 0.630 OD)

4

705

11-0320

Washer (split-lock), 7/16”

1

706

11-0348

Flat head socket screw, 5/16-18 x ½”

3

707

13-0056

Flexible coupling

1

708

13-0186

Velcro mat

1

709

51-0139

Cutter head floating head bottom plate

1

710

51-0140

Cutter head floating head top plate

1

711

96-0025

Cutter head triangle holder assy

1

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 19 | P a g e 01/ 0 7 / 1 9

Shroud (main cover, built-up) assy- P32N (96-0319)

ITEM

PART NO

DESCRIPTION

QTY

801

13-0156

P-clamp, ½”dia, black plastic

12

802

13-0161

Steel blind rivet w/ mandrel dom: 3/16 diax

0.251”-0.375”Thk

4

803

13-0172

Adhesive backed Velcro strip, 3”W X 112”L

1

804

13-0174

Rivet, 5/32dia, 1/4-3/8Thk

12

805

31-0078

Clear PVC tubing 3/8ID, 1/2OD, 1/16”Thk

4

806

32-0012

Adapter T-connector, 3/8 Nylon tube

4

807

51-0218

Grinder Shroud

2

808

54-0038

Shroud, main cover

1

Predator 32N

Owner’s Manual

OIPB-I02001-PREDATOR32N_V1.0 20 | P a g e 01/ 0 7 / 1 9

This page is left blank intentionally.

Table of contents