BASE Electronics LV-8S User manual

BASE

LV-8S

Low Voltage

Power Distribution Module

Installation and Operation Manual

BASE Electronics, Inc.

2856-C Janitell Road • Colorado Springs, CO 80906 • (719) 540-9697 • Fax (719) 540-9698

BASE Electronics, Inc.

2856-C Janitell Road • Colorado Springs, CO 80906 • (719) 540-9697 • Fax (719) 540-9698

Limited Warranty

The LV-8S Low Voltage Power Distribution Module is warranted by BASE Electronics against manufactur-

ing defects in materials and workmanship for a period of 2 years from date of purchase. During this period,

any warranty repair required will be made at no charge for parts or labor. This warranty does not apply to any

work or materials provided by any outside persons or technicians involved in the installation, unauthorized

repair, connection, or testing of this product. This warranty does not cover any damage or failure caused by

or attributable to Acts of God, abuse, misuse, improper or abnormal usage, faulty or improper installation

or maintenance, neglect or accident. BASE Electronics is not responsible or liable for any special, conse-

quential or indirect damages resulting from or in connection with the use or performance of this product

as pertaining to economic loss, property loss, costs for removal or installation, or loss of revenues or prot.

Except as provided herein, BASE Electronics makes no expressed or implied warranties. The duration of

product performance for its intended purpose is limited to the duration set forth herein.

For Warranty or other repair, send the product postage prepaid to BASE Electronics and include Sender’s

name, company, address, phone and brief problem description. BASE Electronics will notify sender of any

required repair costs not covered under this warranty prior to making such repairs.

This Warranty gives you specic legal rights. You may have other rights that vary from state to state.

Selectable Series

LV-8S Specications

• Indoor Temperature Range: -25° C. to +70°C.

• Electrical

Maximum Voltage: 30VDC

Maximum Total Current: 8A

Maximum Recommended Current per Output: 2.5A

Maximum Total Relay Coil Current Draw: 100mA

Connections: Captive Screw Terminals for #14 to #22AWG Wire

• Size: 3.75” wide by 8.00” long by 2.50 maximum height (inches) with relays installed.

• Mounting: (4) 3/8 inch high nylon standos included.

• Special Features

Power Disconnect Relay Socket with Auxiliary Contact Terminals

© Copyright 2022 - BASE Electronics, Inc.

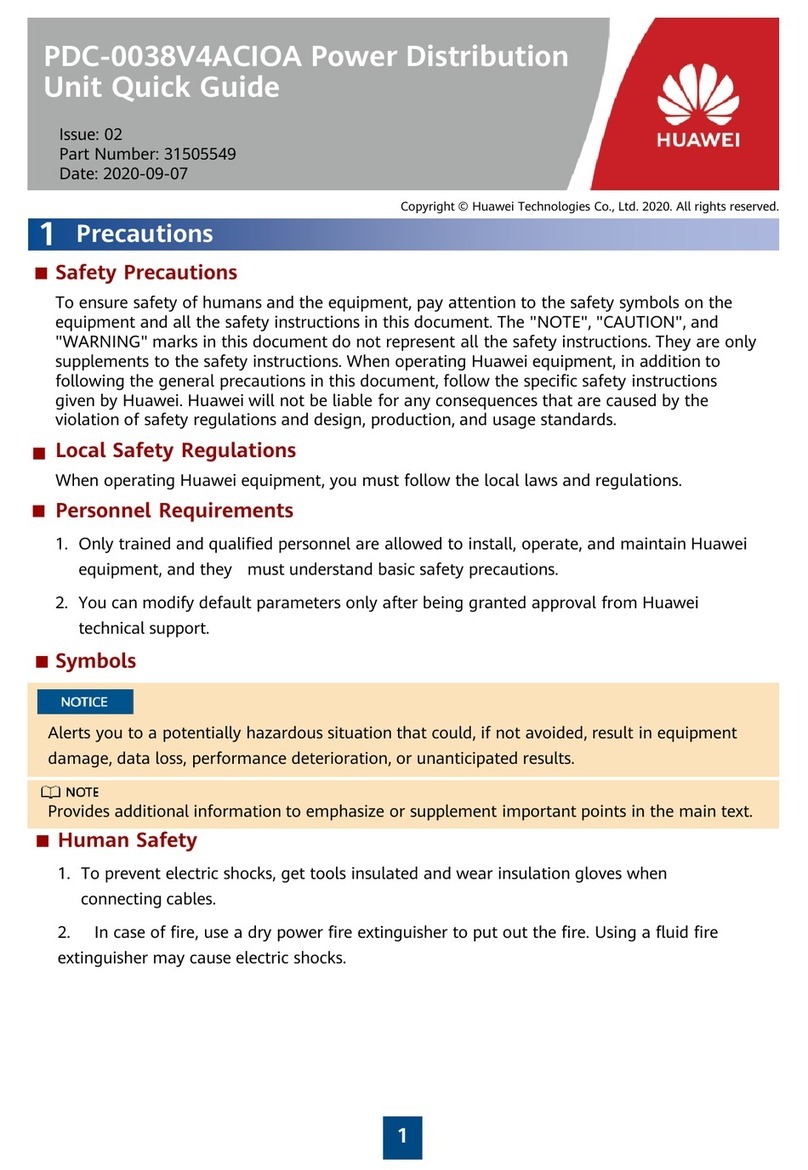

NC

OUTPUTSCONTROLS

DISCONNECT

RELAY

Com

NO

8

C

2

C

1

C

V

C

Power

ST

1

D

C

2

D

C

8

D

C

F

AUX

CONTACT

OUTPUT

Figure 2 - LV-8S Schematic Diagram

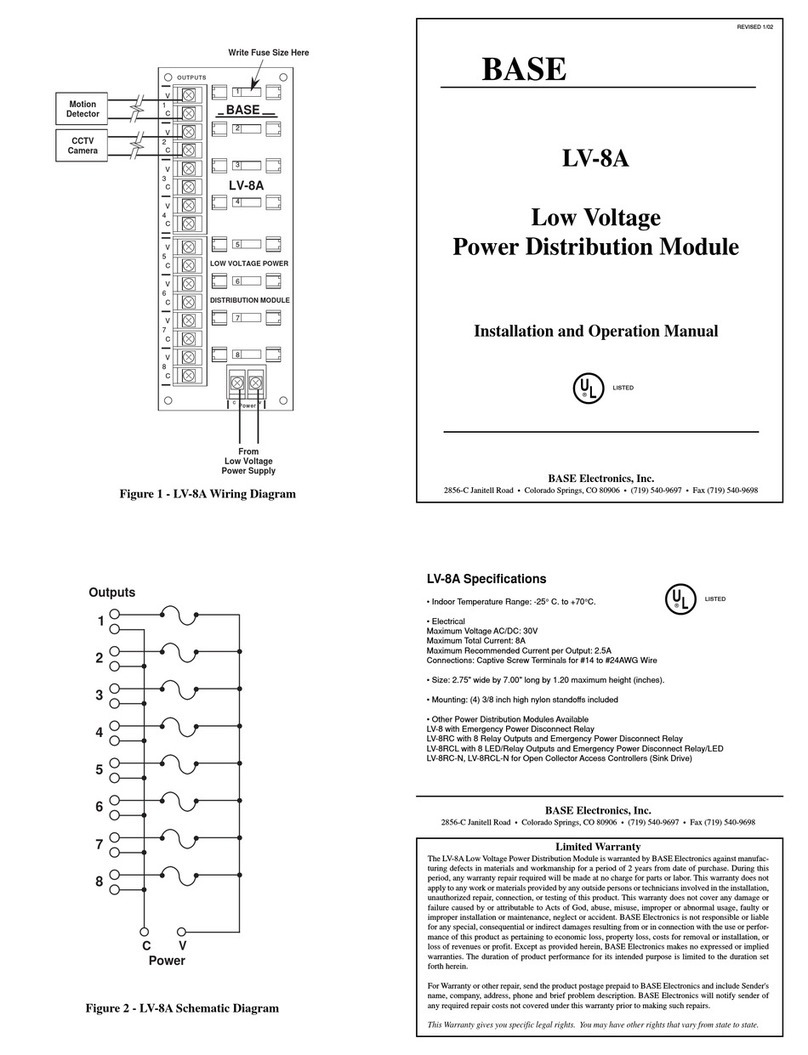

Figure 1 - LV-8S Wiring Diagram

F

INPUT MAX.

30VAC/DC, 8A, 60Hz

OUTPUTS

LOW VO LTAGE POWER

DISTRIBUTION MODULE

LV-8S

BASE

CONTROLS

DISC RELA Y

V

PWR

C

1

C

2

C

3

C

4

C

5

C

6

C

7

C

8

C

ST

NO

NC

DC

1

2

3

4

5

7

6

8

P

W

RDC

AC

1

2

D

C

C

C

3

D

D

D

C

4

5

6

D

C

C

C

7

D

D

D

C

8

WARNING - To reduce the risk of fire, replace only with same type and rating of fuse.

OUTPUTS 1 - 8 MAXIMUM FUSE SIZE 2.5A

V

C

Electric

Lock

Com

NC

NO

Spare Terminal -

Aux

Contact

Output

Write fuse size here

Access Control

Panel Dry Contact

Multi-Channel Fail-Secure Wiring

Multi-Channel Fail-Safe Wiring

Write power supply

voltage here

Normally Closed Dry

Contacts of Fire Panel

From Lock

DC Power Supply

-+

Common Positive

LV-8S

Low Voltage Power Distribution Module

The LV-8S distributes power from a low voltage power source to 8 individually fused

outputs. Terminals are provided for control of each output by an Access Control

system. A 2-pole Disconnect Relay socket is provided and easily interfaces with Fire,

Life Safety or Alarm Panels to provide Emergency Power Disconnect. Relay auxilary

contact terminals are provided for alarm monitoring of the Disconnect feature. For

each of the 8 inputs, the user can select a (C) Continuous power bus terminal or a (D)

Disconnect power bus terminal when routing wiring to an Access Controller.

The Disconnect Relay and 3AG-type Fuses are provided separately depending on the

system voltage needed and output device current requirements. To meet UL Listing

requirements, the relay selected should be Idec Corp., P/N RH2B-U, DPDT, 12vdc

or 24vdc.

The module is 3.75” wide x 8.00” long. The installed height with relay is 2.50”. Stand-

os are included for mounting the circuit board in a user-supplied enclosure.

* * * WARNING * * *

Turn o all power feeding the module terminals before servicing or changing input/output wiring, removing

or reinstalling fuses or relays, or cutting jumpers. Failure to observe this warning may cause electrical shock

hazard or may damage internal or external circuit components.

The information in this manual is believed to be accurate in all respects. However, BASE Electronics cannot assume

responsibility for any consequences resulting from the use thereof. The information contained herein is

subject to change and BASE Electronics may issue a revision to incorporate such changes at any time.

INSTALLATION

Locate the unit inside a NEMA 1 enclosure (such as a BASE LVPC Low Voltage Power

Cabinet) close to the source power supply. Drill (4) 0.187” diameter holes to match

the (4) corner holes in the printed circuit board. Push the nylon standos supplied

into each hole and snap the module into place.

POWER SUPPLY WIRING

Connect the low voltage power supply input leads to the terminal strip at the lower right

side of the circuit board as shown in Figure 1. Use a minimum of 18AWG copper con-

ductors for this wiring and keep the length to the power supply as short as possible.

V = +DC voltage (12 or 24)

C = DC Common

POWER DISCONNECT WIRING

A socket is provided for a 2-pole relay that is used to disconnect the output power

during facility emergencies. This relay should be wired to dry contacts of a Fire, Life

Safety or Alarm Panel at the ‘F’ terminals. The emergency alarm contact should be

rated for the current required by the disconnect relay selected.

MONITORING THE RELAY

The auxiliary output contacts of the Disconnect Relay can be monitored by an alarm

system. Note that the terminals designated NO and NC (shown in Figure 1) stand for

Normally Open and Normally Closed when the relay is de-energized. The terminal

marked ST is a Spare Terminal available for termination of an end-of-line resistor if

needed.

OUTPUTS AND CONTROLS

NOTE: The maximum recommended operating current at any single LV-8S output

should not exceed 2.5 Amperes. The maximum recommended total operating current

(all output currents added) should not exceed 8 Amperes. All fuses must be type 3AG.

Output Fuses must be 2.5A maximum or less. Fuses are ordered separately - specify

desired rating when ordering.

Suggested wiring methods for OUTPUTS and CONTROLS are shown in Figure

1. Wiring to the access control devices connects to the Controls terminals. Three

terminals are provided for each LV-8S control input. A control contact wired from

the ‘D’ terminal loses power when the Disconnect Relay is de-energized. A control

contact wired from the ‘C’ terminal is continuously powered and not aected by the

Disconnect Relay.

Wiring to the output devices connects to the Output terminals. Two terminals are

provided for each LV-8S output.

V = the fused output terminal

C = the DC Common terminal

Add the expected operating current ratings for each device to be powered from one

LV-8S output to determine the expected operating current ow. Install a fuse for the

output that will trip when this value is exceeded. The value of the fuse selected for each

output may be written on the white area below the fuse for easy future reference.

Example A: Output 1 - (1) magnetic lock

operating current = 0.29A at 12 VDC

Install fuse rated just greater than 0.29A = 3/8A or 1/2A

Example B: Output 2 - (4) deadbolt locks

operating current = (4 x 0.40A) = 1.6A

Install fuse rated just greater than 1.6A = 2A

When powering devices over considerable distances, the cabling resistance may be

so high that the voltage available at the device drops to an unacceptable level. To

prevent this from occuring, the system cabling should be designed with adequate sized

conductors. Use the Low Voltage System Cabling Design Guide in this manual for

help in obtaining the desired results.

LIGHTNING, TRANSIENT AND NOISE SUPPRESSION

Lightning or transient suppression devices may be installed at the LV-8S output terminals to protect control equip-

ment from induced voltages. A multi-screw, solid ground bar should be installed vertically next to the output side

of the module for connection of metal oxide varistors, transient suppression diodes, etc. If shielded cable is used

for output wiring, shield drain wires can be connected to the ground bar for line noise suppression. Run a minimum

#14AWG green stranded ground wire from the ground bar to the closest Service Ground. Grounding bars of the

type mentioned above can be separately supplied by BASE Electronics.

LOW VOLTAGE SYSTEM CABLING DESIGN GUIDE

With an improperly designed cabling system, the resistance of wire conductors may cause a voltage drop that

could signicantly aect the performance of the powered device. The resistance of a given length of cabling and

its voltage drop at the given operating voltage can be calculated. This allows the aect on the powered device to

be estimated with adjustments in conductor size implemented in the design stage.

Example:

A CCTV camera requires 0.29A at 24 VAC and the estimated cable length from the power supply is 800 feet.

The camera specications state that the camera will operate properly down to 21.0 VAC (a voltage drop of 3.0

volts maximum). What should be the size of the power cable conductors? From the chart below, we observe that

a pair of 18AWG stranded copper conductors will have a resistance of 2 x 800 feet x 6.48 ohms/1000 feet. Using

Ohm’s Law: E = I x R

E (voltage dropped) = I (the required current) x R (the cabling resistance)

E = (0.29) x (2 x 800 x (6.48/1000)) = 3.007 volts

Subtracting 3.007 volts from 24VAC leaves 20.993 volts available at the camera, an unacceptable level. When

16AWG conductors are used in the equation: E = (0.29) x (2 x 800 x (3.67/1000)) = 1.703 volts

Subtracting 1.703VAC from 24VAC leaves 22.297VAC available at the camera. Taking future expansion of a second

camera into account, the estimator may decide to increase the conductors to #14AWG as follows:

E = (2 x 0.29) x (2 x 800 x (2.31/1000)) = 2.14VAC dropped

When powering inductive devices (relay coils, electric strikes, magnetic locks, etc.), remember to install reversing

diodes (DC powered) or metal oxide varistors (AC powered) at the device terminals or as recommended by the

device manufacturer to counter the aect of Counter Magnetic Force (CMF).

Resistance of Copper Conductors

Solid Conductors Stranded Conductors

Wire Gage Resistance Wire Gage Stranding Resistance

(AWG) (Ω/1000’) (AWG) (#/AWG) (Ω/1000’)

10 1.00 10 37/26 1.11

12 1.59 12 7/20 1.45

14 2.53 14 7/22 2.31

16 4.02 16 7/24 3.67

18 6.39 18 16/30 6.48

20 10.15 20 10/30 10.32

22 16.14 22 7/30 14.74

24 25.67 24 7/32 23.30

Other BASE Electronics Power Distribution Unit manuals