HIMA HIQuad X User guide

Manual

HIQuad®X

System Manual

HI 803 211 E Rev. 1.01.00 (1847)

All of the HIMA products mentioned in this manual are trademark protected. This also applies for other

manufacturers and their products which are mentioned unless stated otherwise.

HIQuad®, HIQuad®X, HIMax®, HIMatrix®, SILworX®, XMR®, HICore®and FlexSILon®are registered

trademarks of HIMA Paul Hildebrandt GmbH.

All of the technical specifications and information in this manual were prepared with great care and effective

control measures were employed for their compilation. For questions, please contact HIMA directly. HIMA

appreciates any suggestion on which information should be included in the manual.

Equipment subject to change without notice. HIMA also reserves the right to modify the written material

without prior notice.

All the current manuals can be obtained upon request by sending an e-mail to: documentation@hima.com.

© Copyright 2018, HIMA Paul Hildebrandt GmbH

All rights reserved.

Contact

HIMA Paul Hildebrandt GmbH

P.O. Box 1261

68777 Brühl

Phone: +49 6202 709-0

Fax: +49 6202 709-107

E-mail: info@hima.com

Document designation

Description

HI 803 210 D, Rev. 1.01 (1844)

German original document

HI 803 211 E, Rev. 1.01.00 (1847)

English translation of the German original document

System Table of Contents

HI 803 211 E Rev. 1.01.00 Page 3 of 110

Table of Contents

1Introduction 7

1.1 Structure and Use of the Document 7

1.2 Target Audience 7

1.3 Writing Conventions 8

1.3.1 Safety Notices 8

1.3.2 Operating Tips 9

1.4 Safety Lifecycle Services 10

2Safety 11

2.1 Intended Use 11

2.1.1 Application in Accordance with the De-Energize to Trip Principle 11

2.1.2 Application in Accordance with the Energize to Trip Principle 11

2.1.3 Use in Fire Alarm Systems 11

2.1.4 Explosion Protection 11

2.2 ESD Protective Measures 12

2.3 Residual Risk 12

2.4 Safety Precautions 12

2.5 Emergency Information 12

3Concept for HIQuad X 13

3.1 Safety and Availability 13

3.2 Concept for HIQuad H51X 14

3.2.1 The H51X Mono System 15

3.2.2 The H51X Redundancy System 17

3.3 Concept for HIQuad H41X 20

3.3.1 The H41X Mono System 21

3.3.2 The H41X Redundancy System 23

3.4 Extension Rack 25

3.5 Ventilation Concept 26

3.5.1 Measures for Reducing the Temperature 26

3.5.2 Engineering Support 26

3.5.2.1 Installing the HIQuad X System in the Control Cabinet 26

3.5.2.2 Heat Dissipation 28

3.5.2.3 Installation Type 28

3.5.2.4 Natural Convection 28

3.5.2.5 Note on the Standard 28

4Product Description 29

4.1 Backplane 29

4.2 19-Inch Frame 29

4.2.1 H51X Backplane 31

4.2.1.1 Supply of the H51X Base Rack 31

4.2.1.2 Buffered Voltage for LS1+ and LS2+ in F-PWR 02 Buffer Modules 32

4.2.1.3 5 V Power Supply for Extension Racks 32

4.2.1.4 Signaling Relay for F-PWR 02 Buffer Module, XG6 32

4.2.2 H41X Backplane 33

4.2.2.1 Supply of the H41X Base Rack 33

Table of Contents System

Page 4 of 110 HI 803 211 E Rev. 1.01.00

4.2.2.2 5 V Power Supply for Extension Racks 34

4.2.2.3 24 V Auxiliary Voltages for I/O Modules and I/O Processing Module 35

4.2.3 Extension Rack Backplane 36

4.2.4 Temperature Monitoring 37

4.3 Power Supply 38

4.3.1 Mono H51X Base Rack (24 VDC) 41

4.3.2 Redundant H51X Base Rack (24 VDC) 42

4.3.3 Redundant H51X Base Rack and I/O Level (24 VDC) 43

4.3.4 H51X Base Rack (24 VDC) I/O Level via F-PWR 02 Buffer Modules (Optional) 44

4.3.5 Mono H41X Base Rack (24 VDC) 45

4.3.6 Redundant H41X Base Rack (24 VDC) 46

4.3.7 24 V Distribution for HIQuad X 47

4.3.7.1 5 V Distribution for HIQuad X 48

4.3.7.2 5 VDC Distribution for H51X 48

4.3.7.3 5 VDC Distribution for H41X 50

4.3.8 5 VDC Additional Power Supply (H51X) 51

4.4 System Bus 51

4.5 I/O Bus 52

4.6 I/O Watchdog (WD) 52

4.7 Modules 53

4.8 F-CPU 01 Processor Module 53

4.8.1 Operating System 53

4.8.1.1 General Cycle Sequence 53

4.8.1.2 Operating System States 53

4.8.2 Behavior in the Event of Faults 56

4.9 F-IOP 01 I/O Processing Module 57

4.10 F-COM 01 Communication Module 57

4.11 I/O Modules 58

4.11.1 Scope of Application of the I/O Modules 58

4.11.2 Mounting Position 58

4.12 Noise Blanking 59

4.12.1 Effects of Noise Blanking 59

4.12.2 Configuring Noise Blanking 59

4.12.3 Noise Blanking Sequence 60

4.12.4 Effective Direction of Noise Blanking 62

4.12.4.1 Effective Direction from the Input Module to the Processor Module (3) 62

4.12.4.2 Effective Direction from the Processor Module to the Output Module (4) 62

4.12.4.3 Effective Direction from the Processor Module to the Output Module (7) 62

4.13 Communication 63

4.13.1 Licensing 63

4.14 Connecting the PADT to the System 63

4.15 Licensing 64

5Redundancy 65

5.1 Processor Module Redundancy 65

5.1.1 Reducing Redundancy 65

5.1.2 Increasing Redundancy 65

System Table of Contents

HI 803 211 E Rev. 1.01.00 Page 5 of 110

5.2 Redundancy of I/O Modules 65

5.2.1 Module Redundancy 66

5.2.2 Channel Redundancy 66

5.3 System Bus Redundancy 66

5.4 Communication Redundancy 66

5.4.1 safeethernet 66

5.4.2 Standard Protocols 66

6Programming 67

6.1 Using Variables in a Project 67

6.1.1 Variable Types 68

6.1.2 Initial Value 68

6.1.3 System Variables and System Parameters 69

6.1.3.1 Resource System Parameters 70

6.1.3.2 Use of the Parameters Target Cycle Time and Target Cycle Time Mode 73

6.1.3.3 Maximum Communication Time Slice 74

6.1.3.4 Calculating the Maximum Duration of Configuration Connections [ms] 75

6.1.3.5 The Minimum Configuration Version Parameter 76

6.1.3.6 Rack System Variables 77

6.1.3.7 Locking and Unlocking the Resource 81

6.2 Forcing 82

6.2.1 Time Limits 83

6.2.2 Restricting the Use of Forcing 83

6.2.3 Force Editor 83

6.2.4 Automatic Forcing Reset 84

6.2.5 Forcing and Scalar Events 84

6.3 Cycle Sequence 84

6.4 User Management 85

6.4.1 PADT User Management 85

6.4.2 PES User Management 86

6.4.3 Default User 86

6.4.4 Setting up PES User Accounts 88

7Diagnostics 89

7.1 Light Emitting Diodes 89

7.2Diagnostic History 89

7.2.1 Diagnostic Messages 90

7.3 Online Diagnosis 91

8Product Data, Dimensioning 93

8.1 Environmental Conditions 93

8.2 Dimensioning 93

9Lifecycle 94

9.1 Installation 94

9.1.1 Mechanical Structure 94

9.1.2 Connecting the Field Level 94

9.1.3 Grounding 94

9.1.3.1 CE-Compliant Structure of the Control Cabinet 95

9.1.3.2 Surges on Digital Inputs 95

Table of Contents System

Page 6 of 110 HI 803 211 E Rev. 1.01.00

9.1.4 Grounding Connectors 96

9.1.5 Grounding and Shielding Concept of HIMA Control Cabinets 98

9.1.6 Grounding Several Control Cabinets 99

9.1.7 Ungrounded Operation 99

9.1.8 Grounded Operation 99

9.1.9 Shielding within the Input and Output Areas 100

9.1.10 Lightning Protection for Data Lines in HIMA Communication Systems 100

9.1.11 Cable Colors 100

9.1.12 Connecting the Supply Voltage 100

9.2 Start-Up 101

9.2.1 Starting up the Control Cabinet 101

9.2.1.1 Test of All Inputs and Outputs 101

9.2.1.2 Voltage Connection 101

9.2.2 Starting up the PES with Processor Modules (F-CPU 01) 101

9.2.2.1 Faults 102

9.3 Maintenance and Repairs 103

9.3.1 Connecting the Power Supply after a Service Interruption 103

9.3.2 Connecting the Redundant Power Supply 103

9.3.3 Loading Operating Systems 103

10 HIQuad X Documentation 104

Appendix 105

Glossary 105

Index of Figures 106

Index of Tables 107

Index 108

System Introduction

HI 803 211 E Rev. 1.01.00 Page 7 of 110

1 Introduction

This manual describes the configuration and mode of operation of the safety-related

programmable electronic system HIQuad X. The system is designed for safety-related

applications up to SIL 3 (IEC 61508), PL e (EN ISO 13849) and for high availability.

HIQuad X can be used for various control tasks within the process and factory automation

industry, in particular in process facilities.

1.1 Structure and Use of the Document

This system manual is composed of the following main chapters:

Introduction

Introduction to this manual.

Safety

Information on how to safely use the HIQuad X system.

Concept for HIQuad X

Concept of the innovative high-performance HIQuad X

system.

Product description

Structure of the HIQuad X system.

Redundancy

Options for increasing availability.

Programming

Important instructions on how to create a user program.

Diagnostics

Summary of the diagnostic options.

Product Data,

Dimensioning

Specifications related to the entire system. Specifications for

the individual components are included in the corresponding

manual.

Lifecycle

Phases of a HIQuad X system lifecycle:

Installation

Start-up

Maintenance and repairs

HIQuad X Documentation

Overview of the documentation:

Appendix

Glossary

Index of tables and index of figures

Index

1.2 Target Audience

This document is aimed at the planners, design engineers and programmers of automation

systems as well as the persons authorized to start up, operate and maintain the devices and

systems concerned. Specialized knowledge of safety-related automation systems is required.

All specialist staff (planning, installation, start-up) must be instructed concerning the risks and

the associated possible consequences which can arise as a result of modifications to a safety-

related automation system.

Planners and configuration engineers must have additional knowledge about the selection and

use of electrical and electronic safety systems in automated plants, e.g., to prevent improper

connections or faulty programming.

The operator is responsible for qualifying the operating and maintenance personnel and

providing them with appropriate safety instructions.

Only staff members with knowledge of industrial process measurement and control, electrical

engineering, electronics and the implementation of PES and ESD protective measures may

modify or extend the system wiring.

Introduction System

Page 8 of 110 HI 803 211 E Rev. 1.01.00

1.3 Writing Conventions

To ensure improved readability and comprehensibility, the following writing conventions are

used in this document:

Bold

To highlight important parts.

Names of buttons, menu functions and tabs that can be clicked and used

in the programming tool.

Italics

Parameters and system variables, references.

Courier

Literal user inputs.

RUN

Operating states are designated by capitals.

Chapter 1.2.3

Cross-references are hyperlinks even if they are not specially marked.

In the electronic document (PDF): When the cursor hovers over a

hyperlink, it changes its shape. Click the hyperlink to jump to the

corresponding position.

Safety notices and operating tips are specially marked.

1.3.1 Safety Notices

Safety notices must be strictly observed to ensure the lowest possible risk.

The safety notices are represented as described below.

Signal word: warning, caution, notice.

Type and source of risk.

Consequences arising from non-observance.

Risk prevention.

The signal words have the following meanings:

Warning indicates hazardous situations which, if not avoided, could result in death or serious

injury.

Caution indicates hazardous situation which, if not avoided, could result in minor or

moderate injury.

Notice indicates a hazardous situation which, if not avoided, could result in property damage.

SIGNAL WORD

Type and source of risk!

Consequences arising from non-observance.

Risk prevention.

NOTICE

Type and source of damage!

Damage prevention.

System Introduction

HI 803 211 E Rev. 1.01.00 Page 9 of 110

1.3.2 Operating Tips

Additional information is structured as presented in the following example:

i

The text giving additional information is located here.

Useful tips and tricks appear as follows:

TIP

The tip text is located here.

Introduction System

Page 10 of 110 HI 803 211 E Rev. 1.01.00

1.4 Safety Lifecycle Services

HIMA provides support throughout all the phases of the plant's safety lifecycle, from planning

and engineering through commissioning to maintenance of safety and security.

HIMA's technical support experts are available for providing information and answering

questions about our products, functional safety and automation security.

To achieve the qualification required by the safety standards, HIMA offers product or customer-

specific seminars at HIMA's training center or on site at the customer's premises. The current

seminar program for functional safety, automation security and HIMA products can be found on

HIMA's website.

Safety Lifecycle Services:

Onsite+ / On-Site

Engineering

In close cooperation with the customer, HIMA performs changes or

extensions on site.

Startup+ / Preventive

Maintenance

HIMA is responsible for planning and executing preventive

maintenance measures. Maintenance actions are carried out in

accordance with the manufacturer's specifications and are

documented for the customer.

Lifecycle+ / Lifecycle

Management

As part of its lifecycle management processes, HIMA analyzes the

current status of all installed systems and develops specific

recommendations for maintenance, upgrading and migration.

Hotline+ / 24 h

Hotline

HIMA's safety engineers are available by telephone around the clock

to help solve problems.

Standby+ / 24 h Call-

Out Service

Faults that cannot be resolved over the phone are processed by

HIMA's specialists within the time frame specified in the contract.

Logistics+/ 24 h

Spare Parts Service

HIMA maintains an inventory of necessary spare parts and

guarantees quick, long-term availability.

Contact details:

Safety Lifecycle

Services

https://www.hima.com/en/about-hima/contacts-worldwide/

Technical Support

https://www.hima.com/en/products-services/support/

Seminar Program

https://www.hima.com/en/products-services/seminars//

System Safety

HI 803 211 E Rev. 1.01.00 Page 11 of 110

2 Safety

All safety information, notes and instructions specified in this manual must be strictly observed.

The product may only be used if all guidelines and safety instructions are adhered to.

For further information on safety, observe the instructions provided in the HIQuad X safety

manual (HI 803 209 E).

2.1 Intended Use

This chapter describes the intended use of the safety-related automation system HIQuad X.

The automation system is designed for controlling and regulating industrial process plants.

SILworX, HIMA's programming tool, is used for programming, configuring, monitoring, operating

and documenting the HIQuad X system.

2.1.1 Application in Accordance with the De-Energize to Trip Principle

The HIQuad X system is designed in accordance with the de-energize to trip principle.

If a fault occurs, a system operating in accordance with the de-energize to trip principle enters

the de-energized state to perform its safety function.

2.1.2 Application in Accordance with the Energize to Trip Principle

The HIQuad X system can also be used in applications that operate in accordance with the

energize to trip principle.

A system operating in accordance with the energize to trip principle switches on, for instance,

an actuator to perform its safety function.

When designing the automation system, the requirements specified in the application standards

must be taken into account. For instance, line monitoring (SC/OC) for inputs and outputs or

message reporting a triggered safety function may be required.

If the components are defective, the de-energized state is entered irrespective of whether the

system is operating in accordance with the energized to trip or with the de-energized to trip

principle.

2.1.3 Use in Fire Alarm Systems

The HIQuad X systems with analog inputs are tested and certified for use in fire alarm systems

in accordance with DIN EN 54-2 and NFPA 72.

The conditions of use provided in this manual must be observed, see also the HIQuad X safety

manual (HI 803 209 E).

2.1.4 Explosion Protection

The HIQuad X automation system is suitable for mounting in zone 2.

The conditions of use provided in the HIQuad X safety manual (HI 803 209 E) must be

observed.

Safety System

Page 12 of 110 HI 803 211 E Rev. 1.01.00

2.2 ESD Protective Measures

Only personnel with knowledge of ESD protective measures may work on the HIQuad X

system.

NOTICE

Damage to the HIQuad X system due to electrostatic discharge!

When performing the work, make sure that the workspace is free of static, and wear a

grounding strap.

If not used, ensure that the modules are protected from electrostatic discharge, e.g.,

by storing them in their packaging.

2.3 Residual Risk

No imminent risk results from a HIMA system itself.

Residual risk may result from:

Faults related to engineering.

Faults in the user program.

Faults related to the wiring.

2.4 Safety Precautions

Observe all local safety requirements and use the protective equipment required on site.

2.5 Emergency Information

A HIMA system is a part of the safety equipment of a plant. If the controller fails, the system

enters the safe state.

In case of emergency, no action that may prevent the HIMA system from operating safely is

permitted.

System Concept for HIQuad X

HI 803 211 E Rev. 1.01.00 Page 13 of 110

3 Concept for HIQuad X

HIQuad X is an innovative, high-performance automation system that is based on the existing

HIQuad system. SILworX, HIMA's tried and tested programming tool, is used for programming,

configuring, monitoring, operating and documenting HIQuad X. All HIMA programmable

systems are thus future-proof and operated with just one programming tool. Additionally,

HIQuad X supports already existing HIQuad I/O modules.

H51X and H41X, the HIQuad X system families, can be equipped with identical modules and

have the following differences:

HIQuad H51X

HIQuad H41X

Structure

Modular

Modular

Base rack

1 (without I/O modules)

1 (with a maximum of 12 I/O

modules)

Extension rack

Max. 16

Max. 1

Processor module (F-CPU 01)

1 or 2

1 or 2

I/O processing module

(F-IOP 01)

1 in each extension rack

1 in the base rack

1 in the extension rack

Communication module

(F-COM 01)

A maximum of 10 in the

base rack

A maximum of 2 in the base rack

I/O modules in each extension

rack

16

16

Total number of I/O modules

Max. 256

Max. 28

Table 1: Differences of HIQuad H51X Compared to H41X

The H51X and H41X system families can be equipped with digital and analog I/O modules. For

details, refer to Chapter 4.9.

The I/O processing module (F-IOP 01) uses the I/O bus to interconnect the I/O modules within

one rack. The F-IOP 01 module safely communicates with the processor modules via one or

two system buses, see Figure 2 and Figure 4.

3.1 Safety and Availability

The HIQuad X systems are designed for safety-related applications operating in accordance

with the energize to trip and de-energize to trip principles up to SIL 3 in accordance with

IEC 61508. Additionally, the HIQuad X system complies with the standards specified in the

certificates.

Refer to the HIQuad X safety manual (HI 803 209 E) and certificates for the standards used to

test the HIQuad X system.

For safety-related application up to SIL 3, the base racks must be equipped with the safety-

related processor modules (F-CPU 01). The safety-related processor module (F-CPU 01)

features a 1oo2 processor system. The 1oo2 processor system includes two microprocessors

that continuously align their data.

Safety-related HIQuad I/O modules can be used to connect to the field level, see Chapter 4.9.

I/O modules and processor modules exchange data via safety-related I/O processing modules

(F-IOP 01) with integrated 1oo2 processor system.

Additional non-safety-related I/O modules can be used for non-safety-related applications.

Depending on the required safety and availability, the H51X and H41X system families can be

structured as mono or redundancy systems, see the following chapters.

Concept for HIQuad X System

Page 14 of 110 HI 803 211 E Rev. 1.01.00

3.2 Concept for HIQuad H51X

The H51X system family has a modular structure which includes an H51X base rack and up to

16 extension racks. The H51X base rack (F-BASE RACK 01) can be equipped as shown in

Figure 1.

The communication modules are connected to the processor modules via two system buses (A

and B) in a point-to-point connection. The processor module in slot 8 controls and monitors

system bus A whereas the processor module in slot 10 controls and monitors system bus B.

During redundant operation, the two processor modules align their data.

The RJ-45 interfaces on the rear side of the base rack are used to connect the extension racks

to the processor modules. An I/O processing module (F-IOP 01) must be used in the extension

rack to connect the system buses to the I/O bus, see Figure 2 and Figure 4.

System bus interfaces on the rear side of the base rack

Figure 1: H51X Base Rack Completely Assembled

System Concept for HIQuad X

HI 803 211 E Rev. 1.01.00 Page 15 of 110

3.2.1 The H51X Mono System

Thanks to the use of safety-related modules (I/O modules, the I/O processing module and a

processor module), the HIQuad H51X system can ensure safety-related signal processing in

accordance with SIL 3 already when operating in a mono structure, see Figure 2.

Figure 2: Example of Safe H51X Mono Operation (1oo2)

The input modules of the HIQuad H51X system safely record the values measured by sensors.

Data is exchanged with the processor module via the I/O processing module. The measured

values are cyclically queried by the processor module and processed by the user program. The

user program's results are sent to the I/O processing module, which writes them to the output

modules. The output modules thus control the field level, e.g., the actuators.

During mono operation, the signal is forwarded by the processor module in slot 8 via system

bus A.

Figure 3 shows the example of an H51X mono system with system bus A. Up to 16 extension

racks can be connected to the system bus in any UP loop, DOWN loop, or UP and DOWN loop.

The extension racks are interconnected with system bus A via the I/O processing module, see

the F-IOP 01 manual (HI 803 219 E).

If the system bus connection is interrupted in a mono system, all I/O modules located after the

interruption point are no longer available. After the interruption point, all output modules enter

the safety-related, de-energized state. As for the input modules, the failsafe initial values are

processed in the respective processor module.

Concept for HIQuad X System

Page 16 of 110 HI 803 211 E Rev. 1.01.00

System bus interfaces on the rear side of the base rack

Figure 3: Example of H51X Mono System

The rack IDs do not necessarily have to be arranged as described above, but they must be

unique.

To ensure a clearer overview, HIMA recommends the following:

Arrange the rack IDs in accordance with Figure 3.

Use red patch cables for system bus A if only system bus A is used.

System Concept for HIQuad X

HI 803 211 E Rev. 1.01.00 Page 17 of 110

3.2.2 The H51X Redundancy System

During redundant operation with two processor modules, both system buses are used to

process the signals. This variant with redundant processor modules and system buses

increases the system's availability, see Figure 4. If a processor module fails, it automatically

enters the safe state and the redundant processor module maintains safe operation. The faulty

processor module must be replaced to ensure continued availability. The processor module can

be replaced while the system is operating.

Figure 4: Example of Safe H51X Redundant Operation (1oo2)

In contrast to mono operation, the entire design of a redundant system is intended to ensure

availability. Redundant input modules safely record the values measured by redundant sensors.

They exchange data with the processor modules via the safety-related I/O processing modules.

The measured values are cyclically queried and compared by the redundant processor

modules, and then processed by the user program. The user program's results are sent to the

I/O processing module, which writes them to the redundant output modules. The output

modules thus control the field level, e.g., the actuators. The example in Figure 4 shows a

redundant structure of field level and extension racks.

Concept for HIQuad X System

Page 18 of 110 HI 803 211 E Rev. 1.01.00

During redundant operation, the signal is processed via both system buses A and B. The

system buses A and B between the I/O processing modules are implemented in a patch cable.

Figure 5 shows the example of an H51X redundancy system with system buses A and B. Up to

16 extension racks can be connected to the system buses in a UP loop, DOWN loop, or UP and

DOWN loop. The extension racks are interconnected with system buses A and B via the I/O

processing module, see F-IOP 01 manual (HI 803 219 E).

The advantage of a redundancy system is that, if one system bus is disconnected, the system

can continue to operate via the redundant system bus. If an I/O processing module fails, all

output modules in the affected rack enter the safety-related, de-energized state. The failsafe

default values are transmitted for the input modules.

System Concept for HIQuad X

HI 803 211 E Rev. 1.01.00 Page 19 of 110

System bus interfaces on the rear side of the base rack

Figure 5: Example of H51X Redundancy System

The rack IDs do not necessarily have to be arranged as described above, but they must be

unique.

To ensure a clearer overview, HIMA recommends the following:

Arrange the rack IDs in accordance with Figure 5.

Between the base rack and the first F-IOP module, use red patch cables for system bus A.

Between the base rack and the first F-IOP module, use green patch cables for system bus B.

Concept for HIQuad X System

Page 20 of 110 HI 803 211 E Rev. 1.01.00

3.3 Concept for HIQuad H41X

The H41X system family has a modular structure which includes an H41X base rack and can be

additionally equipped with an extension rack. The additional extension rack can be used to

create a redundant I/O structure. The H41X base rack (F-BASE RACK 02) can be equipped as

shown in Figure 6.

The communication modules are connected to the processor modules via two system buses (A

and B) in a point-to-point connection. The processor module in slot 16 controls and monitors

system bus A whereas the processor module in slot 18 controls and monitors system bus B.

During redundant operation, the two processor modules align their data.

The RJ-45 system bus interfaces on the rear side of the base rack are used to connect the I/O

modules in the H41X base rack to the processor modules. An I/O processing module (F-IOP 01)

must be used in the H41X base rack to connect the I/O bus to the system buses. An I/O level

redundant to that in the base rack can be set up by integrating an additional extension rack in

the system bus connection of the H41X base rack.

System bus connection on the rear side

of the base rack

I/O bus

Figure 6: H41X Base Rack Completely Assembled

The rack IDs for the HIQuad H41X system are fixed.

To ensure a clearer overview, HIMA recommends the following:

Between the base rack and the first F-IOP module, use red patch cables for system bus A.

Between the base rack and the first F-IOP module, use green patch cables for system bus B.

This manual suits for next models

2

Table of contents

Popular Power Distribution Unit manuals by other brands

Siemens

Siemens SIVACON 8PS LX Series installation instructions

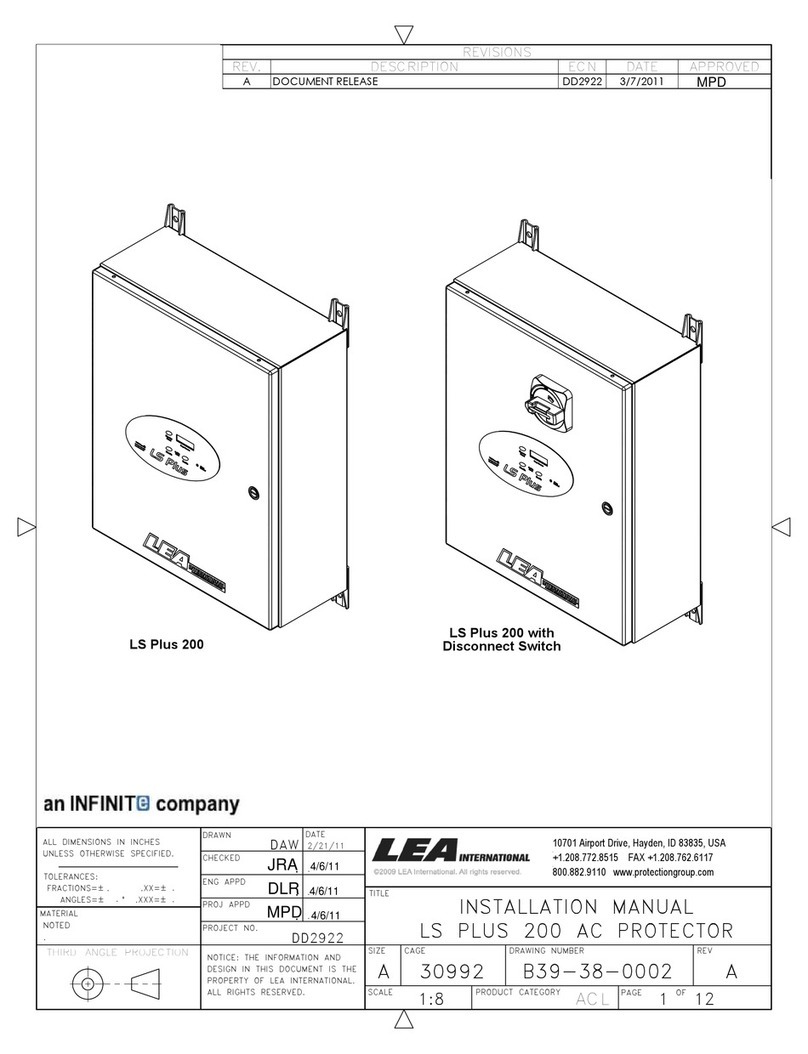

Infinite

Infinite LEA INTERNATIONAL LS Plus 200 installation manual

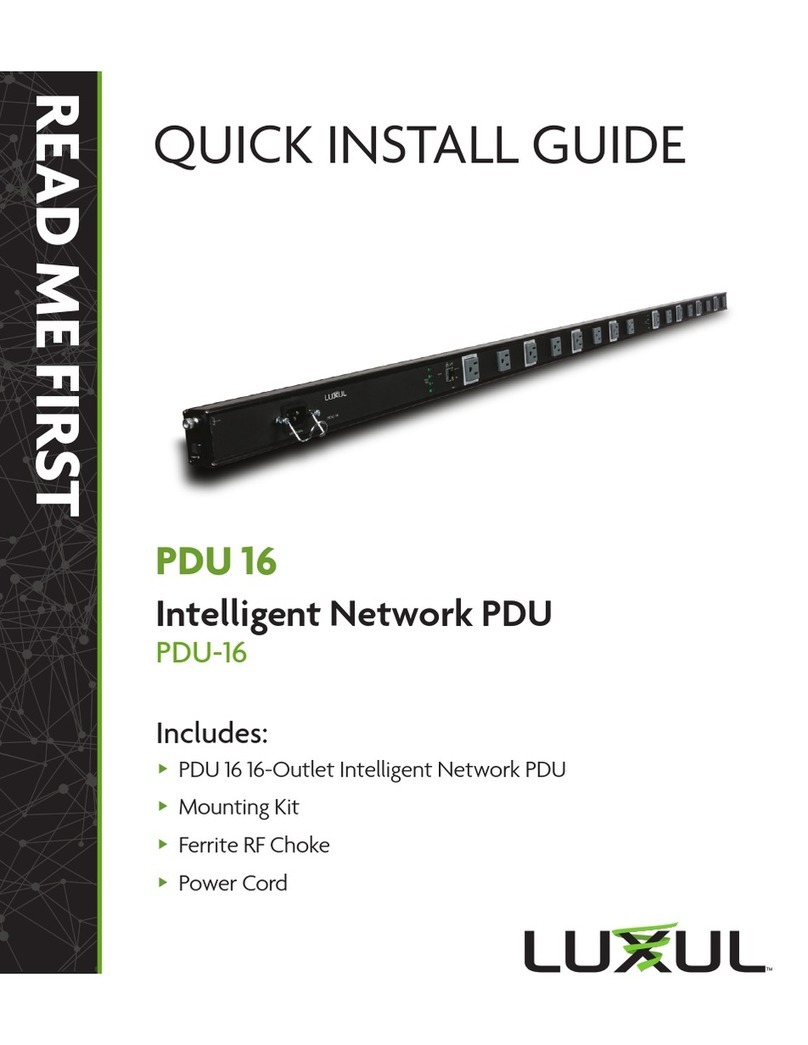

Luxul

Luxul PDU 16 Quick install guide

FEDERAL PIONEER

FEDERAL PIONEER USD instruction manual

Vertiv

Vertiv Geist PDU GU2 Quick installation guide

CTR Electronics

CTR Electronics Pigeon 2.0 user guide