BASEWEST 790 Series Installation and operation manual

BASEWEST

Operating & Maintenance Manual

“Smart” Battery Power Unit,

Escape Slide Lighting System

Model 790, 800, & 900 Series

Released

July 9, 2021

BASEWEST INC.

4240 116th Terrace N • Clearwater FL 33762

Tel: 727/573-2700 •Fax: 727/573-4307

E-mail: [email protected]

www.basewest.com

25-60-53

BASEWEST

Operating & Maintenance Manual

“Smart” Series Battery Power Unit

Page 2 of 825-60-53

July 9, 2021

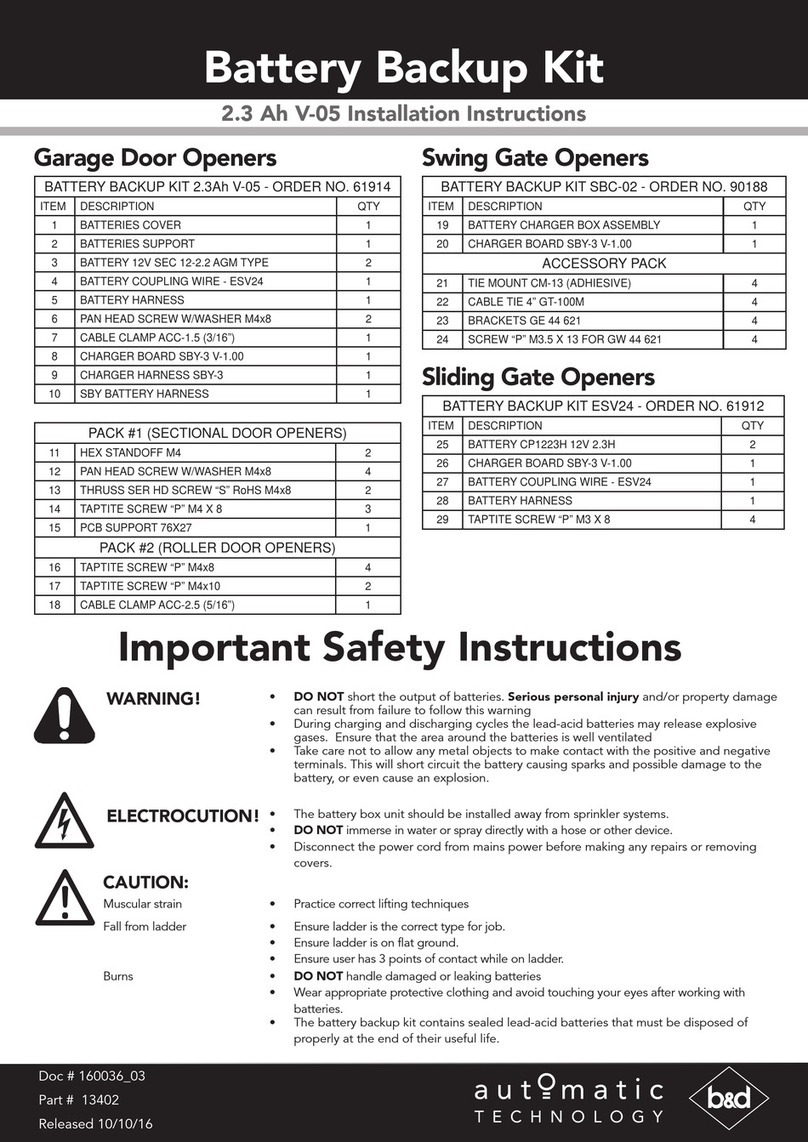

1.0 INTRODUCTION

1.1 Scope

This manual covers the installation, test, and maintenance of the output regulated, non-

rechargeable, alkaline-based Model 790, 800, and 900-Series escape slide lighting bat-

tery power units (batteries) for LED-based non-overwing escape slide lighting systems

manufactured by BaseWest Inc., in the following part number formats:

•Model 790-Series (P/N 7-1089-201 & P/N 7-109X-201)

•Model 800-Series (P/N 7-08XX-201)

•Model 900-Series (P/N 7-09XX-201)

These devices are designed for installation on non-overwing aircraft evacuation slides

and slide/rafts to provide power to integral escape slide lighting systems comprising light

emitting diode (LED) luminaires. For specific instructions relative to operation and instal-

lation on a specific escape slide, please refer to the corresponding OEM escape slide or

slide/raft manual. Batteries for overwing applications have differing activation switching

means that are not covered in this manual.

1.2 Battery Type

The “smart” battery power units covered by this manual, hereinafter “battery(ies”), con-

tain non-rechargeable alkaline manganese dioxide “AA” and or “AAA” cells manufac-

tured by Energizer® Battery Company. Information on these battery cells is available on

the internet at the Energizer® website.

2.0 THEORY OF OPERATION

2.1 General Description

Batteries covered by this manual comprise a series or series/parallel arrangement of AA

and/or AAA cells connected to an electronic regulation circuit in a cylindrical package

with integral switching means and wire leads provide power output and battery test.

Activation of the battery is accomplished upon inflation of the host device; an activating

lanyard with a switch plug is installed in the switch end of the pack. This switch plug is

captured by a retaining clip secured in a protective annulus. The switch plug, when in-

stalled, depresses the plunger of a normally open snap-action microswitch housed in the

pack, rendering the battery power circuit OPEN, and the system OFF. The lanyard is

short-rigged and tied-off, so that inflation and extension of the escape slide causes the

switch plug to be pulled from the pack, allowing the microswitch to snap to the CLOSED

circuit (ON) condition, providing power to the installed slide light harness. A nylon tie-

cord is provided to secure the battery to its mounting on the escape slide structure.

BASEWEST

Operating & Maintenance Manual

“Smart” Series Battery Power Unit

Page 3 of 825-60-53

July 9, 2021

Fig. 1 General Battery Configuration

Fig. 2 Installation of Switch Plug in Retaining Clip

2.2 “Smart” Batteries

The “smart” series of batteries covered by this manual are designed by BaseWest spe-

cifically for use with LED-based escape slide lighting systems. They include electronic

circuits which regulate battery output and provide for testing of the battery condition.

a) All “Smart”Batteries

•Regulated outputs from this circuitry remain relatively constant throughout the

useful discharge life of the smart battery.

•Testing of a complete escape slide lighting system (a battery connected to a

lighting harness) is accomplished by connecting the battery’s test lead to a

Model TS-420 test set. With this connection two types of tests can be per-

formed: (a) a voltage test of the battery cell stack under a selectable load, or

(b) an electrical current test of the connected LED harness with power pro-

BASEWEST

Operating & Maintenance Manual

“Smart” Series Battery Power Unit

Page 4 of 825-60-53

July 9, 2021

vided by a regulated 5VDC power supply within the TS-420 through the bat-

tery power leads.

b) Model 790-Series Batteries Only

•Power is only available to the power leads only if a load is connected to

the battery at the instant the activating switch is pulled. If the load is per-

manently disconnected from an activated smart battery, the battery will

immediately deactivate and can only be re-activated if the switch plug is

re-inserted and pulled again. This smart battery design feature is intend-

ed to discourage inadvertent activation or electrical shorting when the bat-

tery is not connected to the slide lighting system.

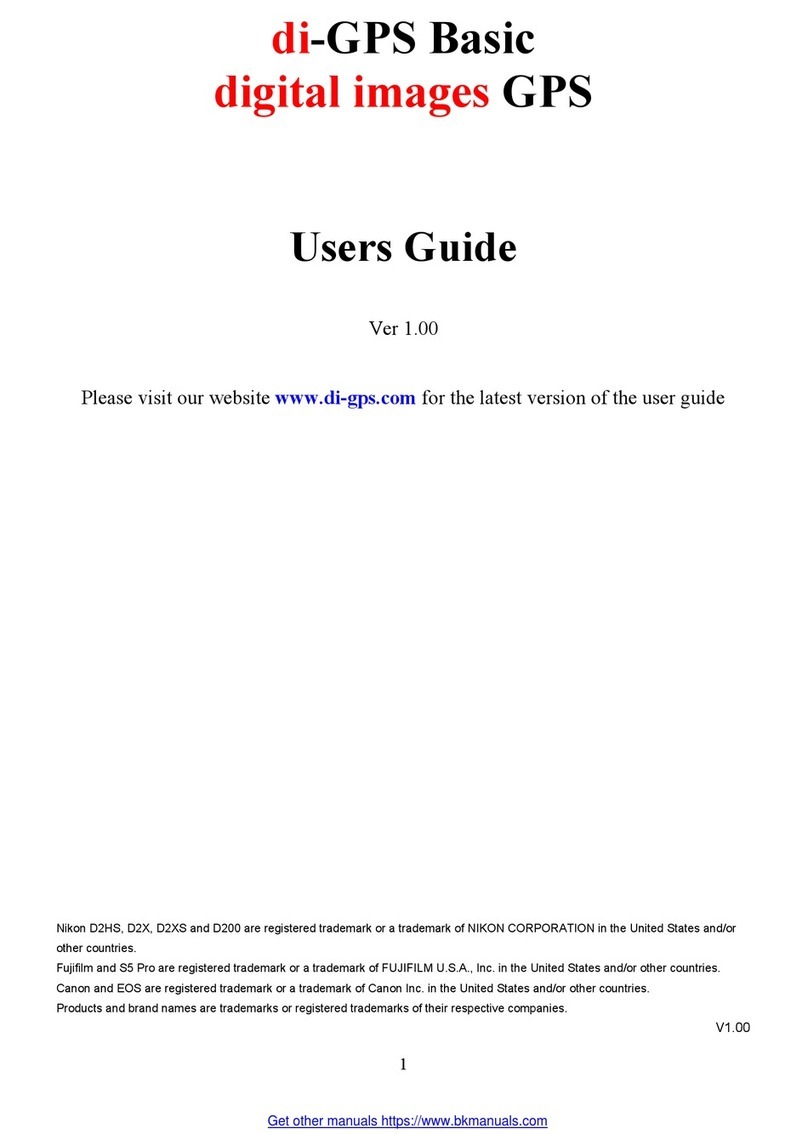

2.3 Schematic

The Model 790-Series batteries utilize a linear mode regulation circuit, and the Model

800- and 900-Series provide output regulation through a switch-mode regulator. The

figures below provide schematics for each of the non-overwing batteries.

Control

Circuit

(Linear

Regulator)

"SMART" BATTERY POWER SUPPLY,

MODEL 789 & 790-SERIES

ESCAPE SLIDE LIGHT HARNESS (LED)

TEST

CONNECTOR

NO POWERLEAD

QUICK

DISCONNECTS

BLU (+)

WHT (-)

R

4

3

1

2

4

3

1

2

TS-420 TEST SET

5VDCPOWER SUPPLY

& AMMETER

VOLTMETER WITH

LOADSELECTOR

ACTIVATING SWITCH

(NORMALLYOPEN)

BLU (+)

WHT (-)

TAPPED CELL

REPRESENTATIVE SERIESCELL STACK

PTC

ACTIVATING SWITCH/PLUG LANYARD

(SWITH ISOPEN WHEN INSTALLED)

Fig. 3 Model 790-Series Battery (Linear Regulator)

Regulator

Circuit

(Switch-Mode

Type)

"SMART" BATTERY, MODEL 800 & 900 SERIES

ESCAPE SLIDE LIGHT HARNESS (LED)

TEST

CONNECTOR

NO POWER LEAD

QUICK

DISCO NNECTS

BLU (+ )

WHT (-)

ACTIVATING SWITCH

(NORMALLY OPEN)

4

3

1

2

4

3

1

2

TS-420 TEST SET

5VDC POWER SUPPLY

&AMMETER

VOLTMET ER WITH

LO AD S EL ECT OR

BLU (+ )

WHT (-)

CELL STACK:COMPRISING

NON-RECHARGEBLE

ENERGIZER

ALKALINE CELLS PTC

ACTIVATING SWITCH/PLUG LANYARD

(SWITH ISOPEN WHEN INSTALLED)

Fig. 4 Model 800- and 900-Series Battery (Switch Mode Regulator)

BASEWEST

Operating & Maintenance Manual

“Smart” Series Battery Power Unit

Page 5 of 825-60-53

July 9, 2021

2.4 Limitations

2.4.1 The batteries covered by this manual are designed only for use with escape slide lighting

systems specifically identified by the escape slide manufacturer’s component mainte-

nance manual (CMM). No other use of the batteries is intended or authorized.

2.4.2 The batteries covered by this manual comprise non-rechargeable AA and/or AAA alka-

line cells, manufactured by Energizer® Battery Company. The user is encouraged to re-

fer to Energizer technical publications on these cells for specific information regarding

limitations, usage, storage, and disposal.

2.4.3 Any battery can pose a potential fire, explosion, or burn hazard. The user is encouraged

to refer to Energizer technical publications on these cells for specific information regard-

ing limitations, usage, storage, and disposal.

3.0 INSTALLATION, RIGGING & OPERATION

3.1 General

Install these batteries in accordance with escape slide manufacturer's component

maintenance manual (CMM) procedures. The following information is provided as gen-

eral guidance only.

3.2 Rigging

Secure the end of the activating lanyard to the escape slide structure and route it to the

battery in accordance with the escape slide manufacturer's CMM. Fully seat the switch

plug (located on the end of the activating lanyard) into the clip at the switch end of the

battery per Fig. 2. DO NOT safety-tie switch plug in place.

3.3 Packing

Care must be taken during the packing process to ensure that sufficient slack is provided

in the activating lanyard to ensure that folding, packing, and compression will not inad-

vertently place sufficient tension on the activating lanyard to cause it to pull from the re-

taining clip in the end of the battery; such a condition will result in inadvertent activation

of the lighting system within the slide pack and premature depletion of the battery.

Take care to avoid placing the battery in a location that will result in bending stresses, or

point load compression against hard surfaces (e.g., bottles or regulators) within the pack

that could compromise the battery.

3.4 Operation

The battery, when properly installed, secured and rigged in accordance with the escape

slide manufacturer’s instructions, will operate automatically upon inflation of the escape

slide. The activating lanyard is “short-rigged” to the escape slide such that the activating

switch plug will be pulled from the battery when the escape slide is inflated.

BASEWEST

Operating & Maintenance Manual

“Smart” Series Battery Power Unit

Page 6 of 825-60-53

July 9, 2021

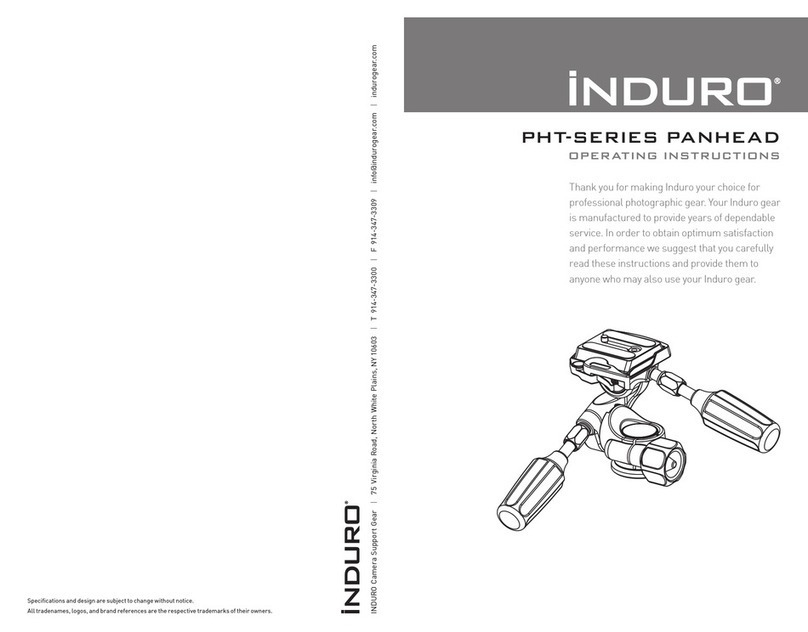

4.0 TESTING

4.1 General

BaseWest escape slide light systems are designed to be tested with BaseWest's Model

TS-420 series test set. Refer to the escape slide manufacturer’s CMM and BaseWest

Technical Manual No. 25-60-41 for specific instructions regarding set-up and use of the

TS-420 series test set. The following general instructions are for guidance only.

Figure 5. TS-420 General Arrangement

4.2 Battery Test

This test is designed to verify the serviceability of the battery only. This test may be

used for receiving inspection, pre-installation and pre- or post-packing tests.

(a) Set the TS-420 Mode Selector to “Voltmeter”, and Load Selector to setting speci-

fied by the slide manufacturer’s CMM (A through F).

(b) Connect battery test lead to the center receptacle on the test set’s connector block.

(c) Ensure the activating switch plug is fully seated in the battery’s switch end cap.

LCD Display

SELF-TEST Indicator

(Green / Red LED)

LOW BATT Indicator

(Amber LED)

Mode Selector

(Voltmeter/Ammeter)

Load Selector

Press to Test

Battery Charger

Receptacle

Receptacle

Connector Block

(See Fig 6)

BASEWEST

Operating & Maintenance Manual

“Smart” Series Battery Power Unit

Page 7 of 825-60-53

July 9, 2021

(d) Press down the RED “Press to Test”button and hold for 3-5 seconds to observe

and record the battery voltage. Compare this reading to acceptance limits noted in

the slide manufacturer’s CMM.

(e) After the voltage reading is taken, release the “Press to Test”button and discon-

nect the battery test lead from the test set.

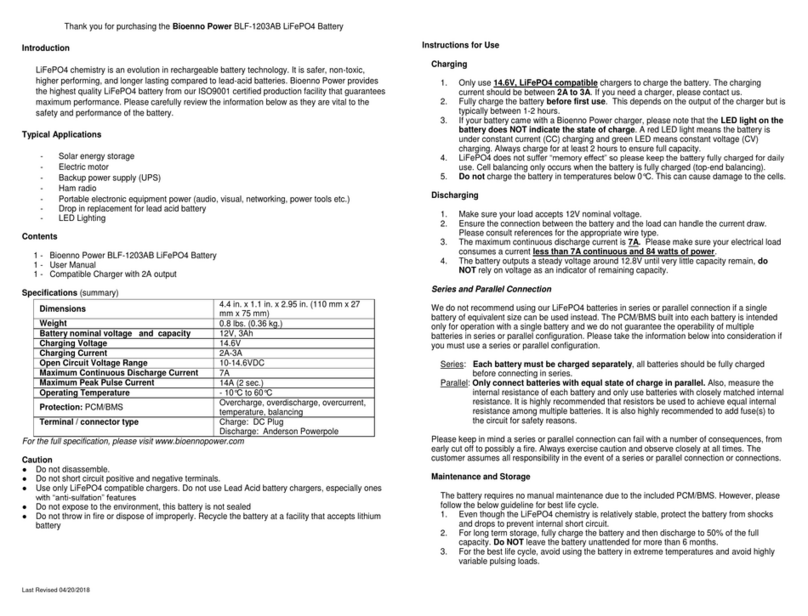

Figure 6. TS-420 Connector Block Arrangement

4.3 Battery and LED Harness System Test

This section provides a functional test of a connected battery and LED harness system

in a pre-pack condition when the LED harness can be observed. This test is not con-

ducted while connected to the TS-420 test set.

a) Ensure the battery power lead is properly connected to the escape slide light har-

ness in accordance with slide manufacturer instructions.

b) With the escape slide laid out fully and the LED harness luminaires visible (inflated

or non-inflated), pull the activating switch plug from the battery. Observe that the

LED harness luminaires function properly. IMMEDIATELY reinstall the switch plug

to de-activate the lighting harness.

NOTE: If the system fails to operate properly, re-install the activating switch plug

into the battery, and verify that the power lead connectors are properly engaged in-

to the mating connectors on the LED lighting harness. Repeat the test.

CAUTION: PROLONGED OPERATION OF THE LIGHTING HARNESS WITH THE INSTALLED

BATTERY CAN DEPLETE THE BATTERY BEYOND SERVICEABLE LIMITS.

4.4 LED Harness Test through Connected Battery

Functional testing of LED harness alone may be conducted before or after packing with

the battery connected to the LED harness. This test requires the TS-420 test set. Follow

instructions in the slide manufacturer’s CMM. The following guidance is provided:

4-Contact Receptacle for

Battery Test Lead Connector

BASEWEST

Operating & Maintenance Manual

“Smart” Series Battery Power Unit

Page 8 of 825-60-53

July 9, 2021

NOTE: Power to the LED harness is provided by a power supply within the TS-

420 test set and not the battery itself. This IS NOT a test of the serviceability of

the battery.

a) Ensure the activating switch plug is fully seated in the switch retaining clip.

b) Ensure the battery power lead is properly connected to the slide light harness.

c) Connect the battery test lead connector to the center receptacle on the TS-420

connector block.

d) Set the TS-420 Mode Selector switch to “Ammeter”.

e) Press and release the “Press to Test”button and record the current (mA) on the

TS-420’s display. Refer to the slide manufacturer’s CMM for acceptable current

levels.

NOTE: In the “Ammeter” mode, the TS-420 will remain ON for approximately 20

seconds and turn OFF automatically. Power can be interrupted at any time after

the readings are recorded by removing the battery test connector from the test set.

5.0 MAINTENANCE

5.1 General

BaseWest's slide lighting batteries are non-repairable, life-limited devices. Repairs are

not authorized.

5.2 Storage

The batteries should be stored inside in a dry, protected area within a temperature range

of -40°C to +60°C (-40°F to +140°F). Always store the battery with the activating switch

plug/lanyard in place. Do not expose the power lead contacts to contact with conductive

materials, or to contact with each other. Maintain connector housings on power lead

wires at all times.

5.3 Service Life

The batteries covered by this manual are approved for a seven (7) year service life from

date of manufacture. The slide manufacturer may specify adjustment of this service life

down to five (5) years for certain batteries. Battery nameplates are marked with replace-

by dates per slide manufacturer instructions.

Care should be taken to use batteries on a first-in-first-out inventory rotation basis to

maximize available service life.

6.0 ACCESSORIES

The TS-420 test set and certain test and calibration cables are available from BaseWest.

TS-420 operating and calibration manuals (25-60-41 and 25-60-42) are available upon

request, or may be downloaded from the BaseWest website at www.basewest.com.

This manual suits for next models

2

Table of contents