Selectronic SelectCell Ultimate 280 Series User manual

SelectCell Manual

3

SelectCell Manual

Revision

Control

03 22/07/2021

14/11/2022

REV. DATE REASON / RESPONSIBLE

Revision Warnings

04 08/04/2022 Manager - Worker

05 Review of new PCC/PCM codes

Limitation of Warranty and Liability

The limitation of warranties and liabilities as per SelectCell full warranty terms and conditions described

in the product warranty document.

The information included in this manual has been written for the purpose of providing the user with

more detail and clarity in terms of content. Nonetheless, Selectronic Australia reserves the right to

modify the contents of this manual through future revisions at any time and without prior notice.

Confidentiality

All information provided by Selectronic Australia by virtue of this User Manual and any data or

features that may be disclosed by such shall be completely confidential and may not be shared with

third parties or used for purposes other than that for which is was intended without prior and express

written authorization from Selectronic Australia.

Limitations on the use of this equipment

This equipment may not be used in applications for recharging electric vehicles. Selectronic

Australia shall not be held liable for use with these types of application. The buyer shall be wholly

responsible.

Contact

Selectronic Australia

80 Lewis Road

Wantirna South Vic 3152

Australia

Tel. +61 3 9727 6600

Technical Support:

www.selectronic.com.au/support

4

SelectCell Manual

Contents

1 Introduction .............................................................................................................................. 06

1.1 Purpose ............................................................................................................................ 06

1.2 Acronyms .......................................................................................................................... 06

2 Safety .......................................................................................................................................... 07

2.1 General information ........................................................................................................ 08

2.2 Safety Instructions– Potential hazards ...................................................................... 08

2.3 Electrical safety .............................................................................................................. 08

2.4 Mechanical safety ........................................................................................................... 09

2.5 User requirements .......................................................................................................... 09

2.6 Lockout-tagout of machines and installations (L.O.T.O) ....................................... 09

2.7 Switching, measurements and checks ..................................................................... 10

3 General description ................................................................................................................ 10

4 Specifications .......................................................................................................................... 11

4.1 Summary ........................................................................................................................... 11

4.2 11

11

eBick PRO 280 Series ...................................................................................................

4.2.1 Physical characteristics ...............................................................................

4.2.2 Electrical characteristics .............................................................................. 11

4.3 12

12

PCC SERIES 150V 300A / 500A ..................................................................................

4.3.1 Physical characteristics ...............................................................................

4.3.2 Electrical characteristics ............................................................................... 12

4.4 12

12

PCC SERIES 800V 300A ................................................................................................

4.4.1 Physical characteristics ...............................................................................

4.4.2 Electrical characteristics .............................................................................. 13

4.5 13

13

PCM SERIES SLAVE ....................................................................................................

4.5.1 Physical characteristics ...............................................................................

4.5.2 Electrical characteristics ............................................................................. 14

4.6 14

14

PCC SERIES 150V 300A / 500A SLAVE ...................................................................

4.6.1 Physical characteristics ...............................................................................

4.6.2 Electrical characteristics ............................................................................. 14

4.7 14

PCM MASTER C/CAN .....................................................................................................

4.7.1 Physical characteristics ............................................................................... 14

4.8 15PCM MASTER S/CAN ....................................................................................................

4.8.1 Physical characteristics ............................................................................... 15

4.9 15

15

PCC MASTER ..................................................................................................................

4.9.1 Physical characteristics ...............................................................................

4.9.2 Electrical characteristics ............................................................................. 15

4.10 Hardware ............................................................................................................................ 15

4.10.1 Battery module ................................................................................................ 15

4.10.2 PCC ................................................................................................................... 16

4.10.3 PCM .................................................................................................................. 16

4.10.4 Master Busbar Cabinet ................................................................................. 16

5 Operating modes and processes ....................................................................................... 17

5.1 State machine .................................................................................................................. 17

5.2 Start-up and shut-down processes .......................................................................... 18

5.3 Connection process ....................................................................................................... 18

5.4 Ultra-low consumption mode ...................................................................................... 18

5.5 Pre-charge process ....................................................................................................... 19

5.6 Passive equalisation ....................................................................................................... 19

6 System monitoring .................................................................................................................. 20

6.1 State of Charge (SoC) calculation ............................................................................... 20

6.2 Ideal charging conditions ............................................................................................... 20

6.3 State of Function (SoF) and nal battery use ........................................................... 21

5

SelectCell Manual

6.4 Calculation of battery integrity (SoH) .......................................................................... 21

6.5 Extending battery life and end use ............................................................................. 21

7 Electrical safeguards .............................................................................................................. 21

7.1 Parameters involved in the protection functions ..................................................... 21

7.2 Reclose ............................................................................................................................. 22

7.3 Under-temperature .......................................................................................................... 22

7.4 Over-temperature ............................................................................................................. 22

7.5 Undervoltage .................................................................................................................... 22

7.6 Overvoltage ........................................................................................................................ 23

7.7 Temperature difference ................................................................................................... 23

7.8 Voltage difference ............................................................................................................ 23

7.9 PCC charge and discharge currents ............................................................................ 23

8 Data display ................................................................................................................................ 23

8.1 HMI display ........................................................................................................................ 24

8.2 Remote display ................................................................................................................. 25

8.3 Master Screen .................................................................................................................. 25

8.3.1 Contactor switching ....................................................................................... 26

8.3.2 Reset strings .................................................................................................... 26

9 Communications ...................................................................................................................... 27

9.1 IIntroduction ...................................................................................................................... 27

9.2 CAN protocol ....................................................................................................................... 27

9.3 Modbus protocol ................................................................................................................. 27

9.4 Type of data ......................................................................................................................... 27

10 Installation requirements and recommendations ......................................................... 28

10.1 Applicable regulations .................................................................................................... 28

10.1.1 Requirements for Electrical installations ................................................... 28

10.1.2 Requirements for Battery Installations ...................................................... 28

10.2 Environmental requirements ........................................................................................... 30

10.3 Maintenance and storage procedure .......................................................................... 30

10.4 Layout .................................................................................................................................. 30

11 Installation .................................................................................................................................. 30

11.1 Electrical and component verication ........................................................................ 30

11.2 Steps to follow .................................................................................................................. 31

11.3 Different possible congurations .................................................................................. 31

11.4 eBick installation .............................................................................................................. 31

11.5 Communication connections ........................................................................................ 32

11.5.1 Connections between batteries .................................................................. 32

11.5.2 Battery connections with PCC or PCM ..................................................... 33

11.6 Power connection ........................................................................................................... 33

11.6.1 Power connections between batteries ...................................................... 33

11.6.2 Battery connections with PCC or PCM .................................................... 35

11.7 Master/Slave systems ..................................................................................................... 37

11.7.1 PCM Slave and PCC Master system .......................................................... 37

11.7.2 PCC Slave and PCM Master system........................................................... 38

12 Transportation requirements and recommendations ................................................... 41

13 Maintenance plan ..................................................................................................................... 41

13.1 Predictive maintenance ................................................................................................. 41

13.1.1 Verifying voltages, warnings and alarms .................................................. 41

13.2 Preventive maintenance .................................................................................................. 41

13.2.1 Preventative maintenance schedule .......................................................... 41

13.3 Corrective maintenance ................................................................................................ 42

13.4 Maintenance requirements ........................................................................................... 42

6

SelectCell Manual

1.

Introduction

1.1

Purpose

The following document represents the complete manual for the installation, use and maintenance of the SelectCell energy

storage system, comprising SelectCell Ultimate 280 Series modules and PCC protection and control cabinet.

1.2 Acronyms

FAT

Factory

Acceptance

Tests

BMS

Battery

management

system

SelectCell Ultimate Series

Battery

pack

48V

280Ah

EMS

Energy

management

system

PCC

Power

Control

Cabinet

SoC

State

of

charge. Amount

of

energy

in

battery

State of function. Maximum admissible amount of charge or

discharge current at any moment

SoF

STRING

Cabinet

containing

various

modules

and

a

PCC

7

SelectCell Manual

2.

Safety

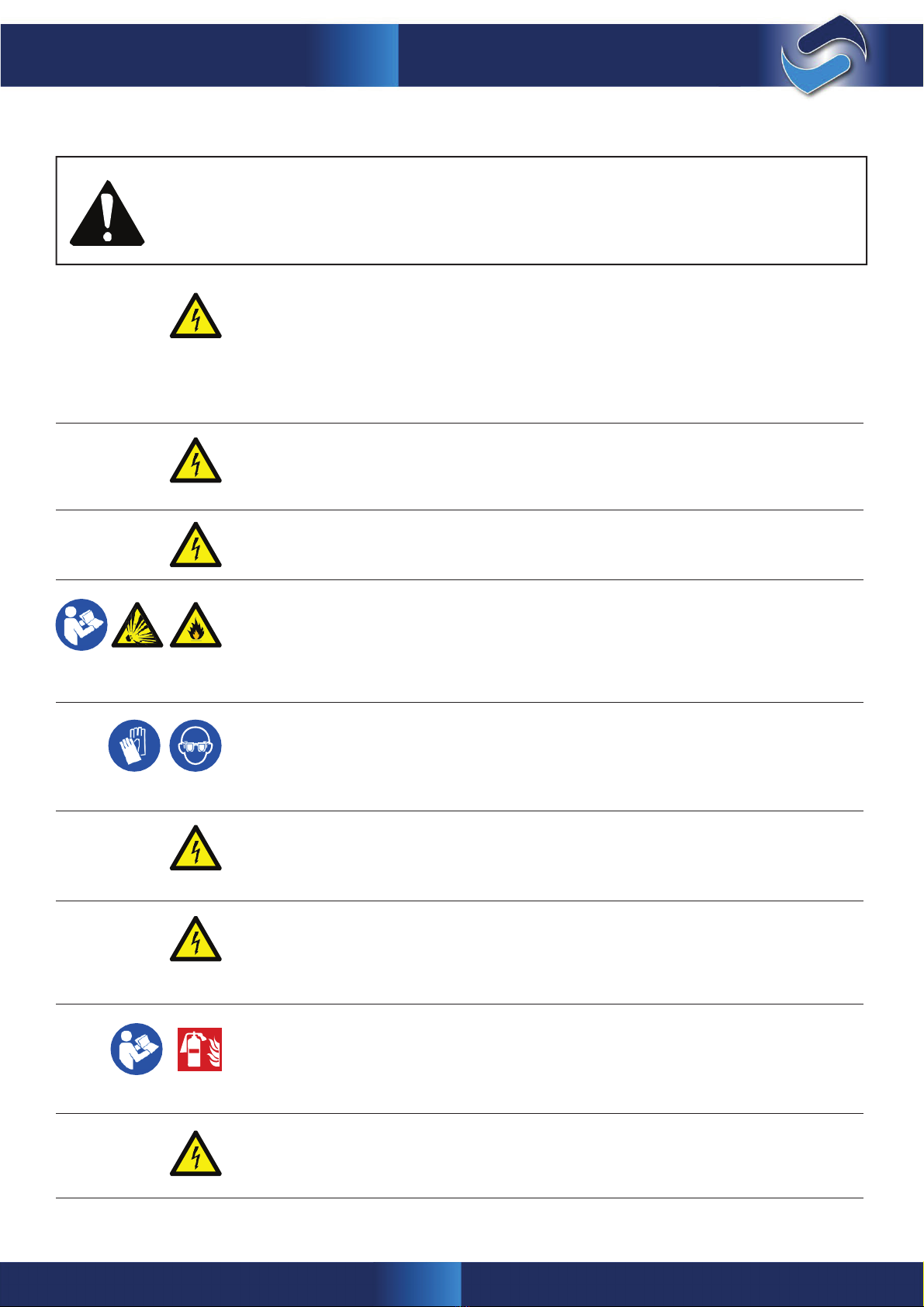

DANGER!

Always use the SelectCell Ultimate 280 module with a PCC protection and control

system. Never connect the module without the PCC.

To prevent high inrush currents, a bus pre-charge is required. A direct connection may result

in damage to the system. This pre-charge is managed from the PCC.

DANGER!

Check that the voltage is within range before connecting the equipment to the inverter.

NEVER connect the string if the voltage is out of range or NULL.

DANGER!

NEVER remove or bypass PCC switching and protection systems.

DANGER!

Do not short-circuit the current circuit terminals of the SelectCell Ultimate 280 module or the

PCC. The short-circuit current may be several thousand amperes. Prolonged short-circuiting

will destroy the battery module and electrolyte may leak out of the cells, causing a fire and/or

explosion.

DANGER!

SelectCell installation and maintenance personnel shall wear protective apparel, special

gloves and safety glasses. All personal metal objects such as wristwatches, rings, jewelry,

etc., shall NOT be worn while working with the SelectCell Ultimate 280 modules.

DANGER!

To avoid short-circuits and electric shock, use safety tools (EN 60900) and protection devices

when installing and servicing the equipment.

DANGER!

Do not connect or disconnect the load when the main contactor is closed. This may cause an

electric arc and expose personnel to high DC voltage. The electric arc might also destroy

connectors, due to a welding effect.

DANGER!

In case of fire, disconnect the circuit from the battery and use a CO2 extinguisher to extinguish

the fire. The batteries contain flammable materials. Always inform fire-fighters about the

lithium batteries.

DANGER!

Do not open the covers on the SelectCell Ultimate 280 modules. Do not place or drop

conductive objects inside the battery module or between the module’s terminals.

WARNING: RISK OF FIRE OR EXPLOSION

Failure to comply with safety messages may cause serious injury, death or damage to property

8

SelectCell Manual

DANGER!

Do not expose to temperatures above 65ºC. The equipment will not be operational beyond these

temperatures, however, even with non-operational equipment exposing the cells to high

temperatures may cause fire and/or explosion.

DANGER!

Do not immerse the SelectCell Ultimate 280 module in water or any other liquid.

DANGER!

Never drop or knock the SelectCell Ultimate 280 modules.

DANGER!

If chargers/converters are used, use only those authorised by Selectronic. Misuse of the battery

module during charging or discharging may cause the equipment to age prematurely leading to

fire and/or explosion. Both units have complex communications and these need to be carried

out by authorised specialists.

DANGER!

In the event of an emergency, read the MSDS (Material Safety Data Sheet) for the cells before

proceeding.

2.1 General information

The SelectCell Ultimate is a smart energy storage system with

Li-ion cells.

The whole system contains a high energy capacity. To minimize

the risk of electric shock, short-circuit, explosion and/or fire,

follow the relevant procedures and local guidelines, as well as

the instructions that are included with the system.

Only qualified personnel should perform the installation, in ac-

cordance with the applicable regulations. Systems with visible

electrical connections have to be isolated from public access.

For safety purposes, cover all direct connections and terminals.

Carefully read, understand and apply all requirements present-

ed in this section.

•

Do not use the module if any of its parts have been im-

mersed in water. A water damaged cell is potentially dan-

gerous. Any attempts to use the system could cause a fire

or an explosion. In such cases, contact Selectronic to have the

battery pack inspected.

•

The following instructions shall always be followed:

•

Any air inlet or outlet within the room shall be kept

clear and free of obstacles.

•

The floor shall be capable of bearing the weight of

all equipment, keeping in mind the weight of each

battery is 105kg.

•

There shall be no obvious signs of wear on any

STRING element.

•

As this is a battery, there is voltage on the cabinet’s

+/- output terminals whenever the PCC contactor is

closed.

2.2 Safety Instructions– Potential hazards

•

The area around the SelectCell Ultimate shall be kept

clear and free of combustible materials, gasoline and/or other

flammable fumes, vapours and liquids.

2.3 Electrical safety

•

Never remove safety guards or devices that protect against

live parts.

•

Do not reach inside the STRING or the modules, nor touch

any internal component.

•

Do not use or handle any SelectCell component when

accidentally wet, or with wet hands or feet.

•

In the event of a failure or incident, as a first step cut off the

current. To rescue a person being electrocuted, do not touch

them but immediately stop the current.

•

The area defined by safety margins for the necessary supply

and venting of air shall be respected.

In the event of an emergency, the SelectCell has electrical

safety cut-off elements (fuses and contactors). It is

advisable to install an element that protects against over-

current and possible short-circuiting. It is also advisable that

the cut-off element can be manually operated if necessary.

Remember, because this is a battery, the STRING’s internal

DC bus will always be live.

•

DANGER!

Battery terminals are live – DO NOT TOUCH. DO NOT BREAK UNDER LOAD.

+

9

SelectCell Manual

2.6

Lockout-tagout

of

machines

and installations

(L.O.T.O.)

To perform operations, absent of voltage (L.O.T.O.), the device

shall be locked and tagged to non-hazardous voltage values.

The following section is based on the lockout-tagout at several

points according to:

1.Restrict access to the work area to prevent entry of unauthor-

ised personnel.

2.It shall be disconnected and isolated from the supply network

or connection to the converter.

3.Once disconnected, the STRING shall be sectioned into parts

with voltages below 75 VDC.

4.The terminals of these parts shall be protected by insulating

caps designed for this purpose.

5.Given that the batteries are an energy storage system, it is

impossible to make certain points of the system free of volt-

age. If there is any exposed point where the voltage cannot be

eliminated, the terminals will have to be tagged, indicating the

voltage value at that point.

6.Prior to conducting any work, the voltage shall be measured

at the point where the work is to be done. Some points may

be energised directly from the batteries.

•

If it is not possible or takes too long to cut the current, try to

disengage them by means of an insulating element (wooden

strip or board, rope, wooden chair ...).

Whenever a battery is not installed on the STRING, make sure

that the power terminals at the front are protected against

accidental contact given that the terminals are energised.

Make sure that the output and input connection cables are not

short-circuited.

Make sure there is no short circuit between positive and neg-

ative terminals at any point.

Make sure there is always protective insulation on the output

and input cables and a reliable connection.

Never use cables that are visibly damaged or that may be

suspected of being damaged.

Minimise conductivity, avoiding surfaces in contact with wa-

ter. Hands and clothes have to be dry.

Do not use, install or store the system under wet or damp

conditions.

•

•

•

•

•

•

•

2.4

Mechanical

safety

•

Due to the weight of the battery modules (>100 kg), mechan-

ical means have to be employed to install them.

•

Do not stack SelectCell Ultimate modules more than 4 high.

•

•

Use only 600V insulated tools

If terminals are exposed during the sectioning process,

use 600V rated insulating gloves.

Use a face shield during the work.

Should it be necessary to perform an operation on a bat-

tery pack, place the modules on insulating matting.

Use insulating footwear.

To avoid possible short-circuiting, do not carry any con-

ductive device (e.g. pens, tape measures, etc.) during the

work.

Do not wear any metal, conductive or sharp edged

accessories.

2.5

User

requirements

In addition to personnel who work with the module, workplace

users should also implement safety measure by applying the

minimum provisions on the protection of the health and safety of

workers exposed to electrical risk in the workplace, refer to your

local jurisdiction.

Hazards related to electrical risk are specifically identified dur-

ing the work process with this equipment. This does not exclude

the possible existence of other risks present during handling and

use, such as overexertion, posture, or other measures against

health risks. Operators shall receive the necessary training,

sufficient to be able to prevent and avoid any risks arising from

use of the equipment.

By design the equipment protects against these risks under

normal operating conditions, however, it is with operations that

differ from normal ones (installation, maintenance, ...) where

special precautions have to be taken.

Particular care should be taken when handling modules, due

to their weight. Respect guidelines according to current regu-

lations regarding ergonomics in the. Use appropriate handling

equipment.

•

•

•

•

•

10

SelectCell Manual

2.7 Switching, measurements and checks

The regulation permits operations and interventions without

lockout-tagout, provided that an equivalent level of safety is

guaranteed.

These interventions are called switching, trials and checks. They

have to be carried out by authorised personnel with protection

devices and personal protective equipment appropriate for the

voltages in question.

Special protection against short-circuits should be ensured. In-

structions to follow:

•

No terminal with an electrical charge should be left uncov-

ered. If, after removing the connections, the terminals are

exposed, then they have to be protected with the terminal

covers supplied.

All tools shall be insulated and rated up to 600V

Operators shall not wear or carry any metal elements or de-

vices.

The work area shall be free of obstacles.

If necessary, when there are exposed terminals nylon slings

shall be used instead of chains.

The operator shall wear a face shield or safety glasses to pro-

tect against short-circuits

•

•

•

•

•

The operations shall

trained, personnel.

only be carried by authorised, duly

•

•

Safety apparel that covers the whole body (long sleeves) shall

be used. Fireproof or flame retardant, with protection against

chemicals and arc flash.

•

The work shall be done from a solid, stable support

•

If a work table is used, it shall be insulated or covered with

Insulating matting.

Occasionally, depending on the operation, there should be a

preventive resource worker present.

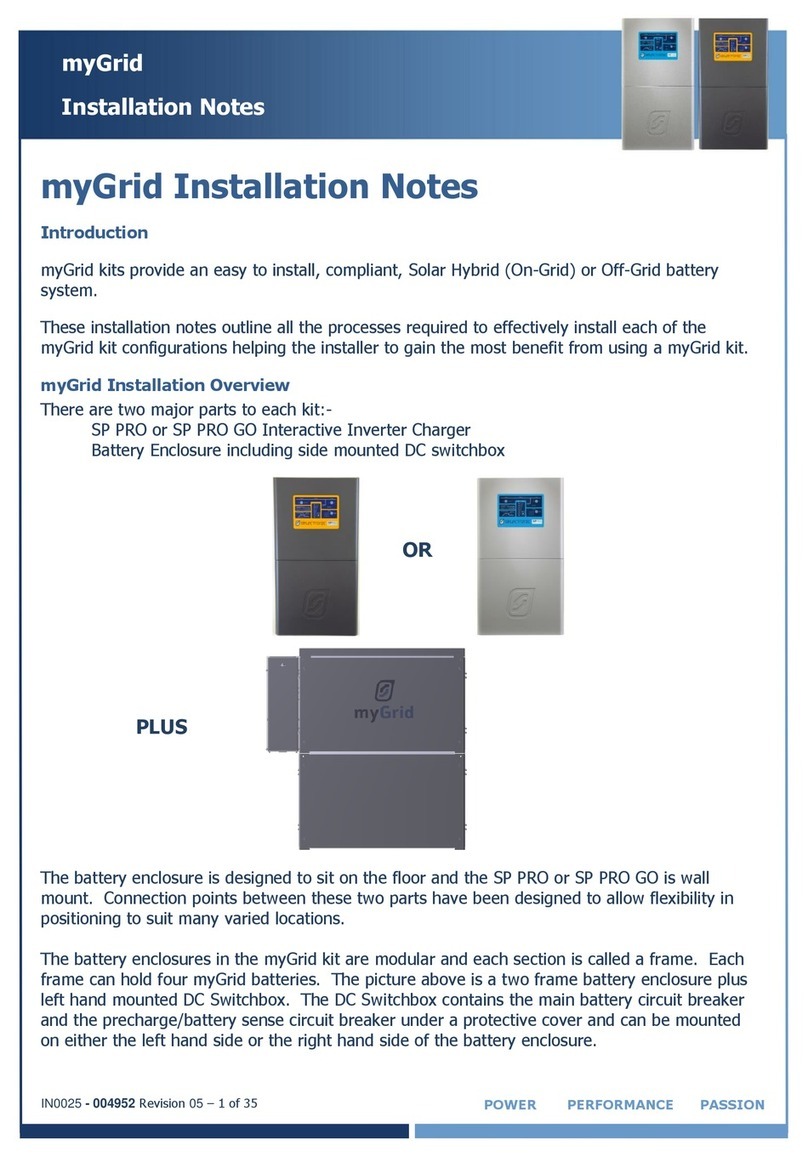

General description

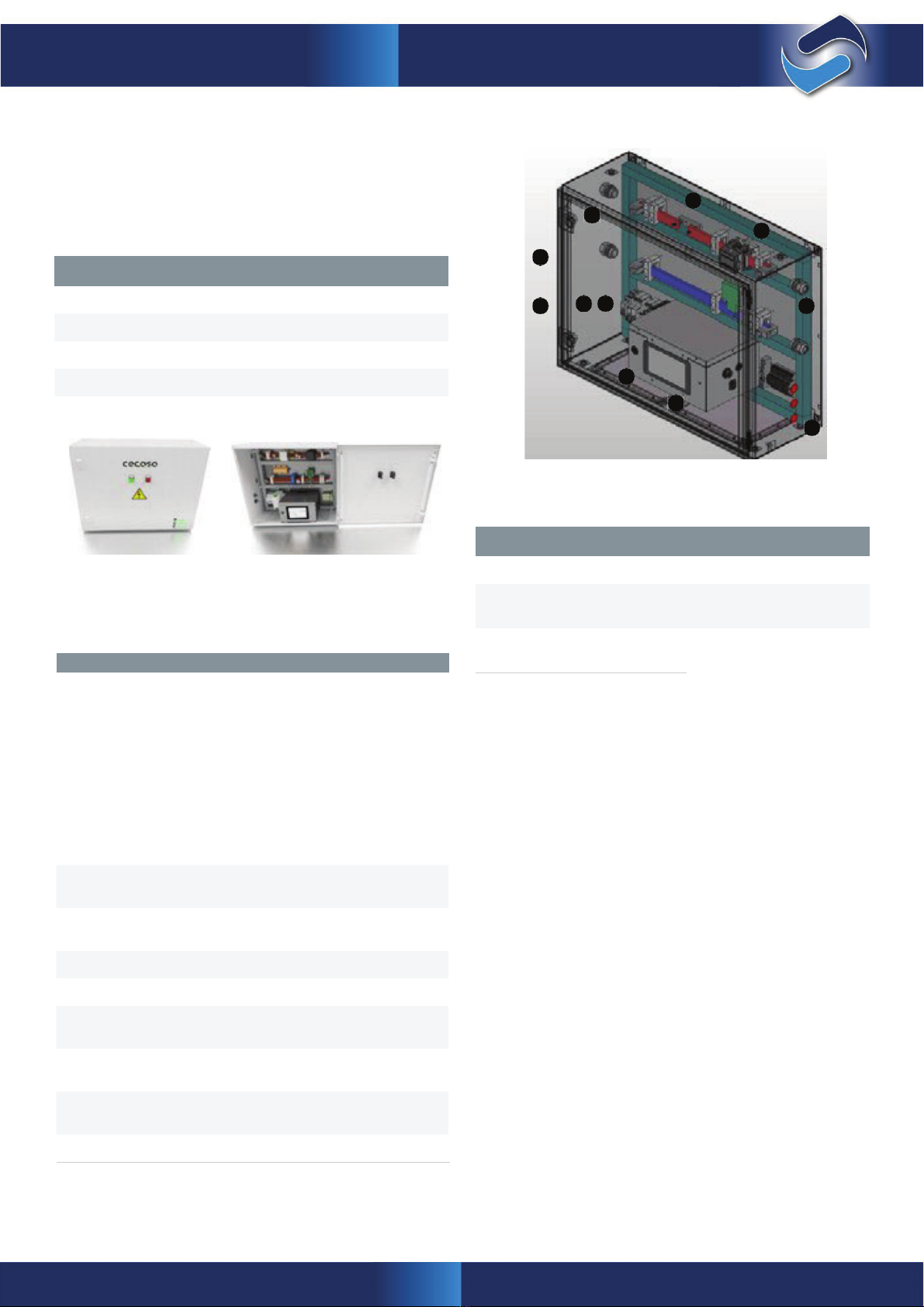

The Selectronic SelectCell Ultimate 280 Series is a lithium-ion

battery, 48VDC nominal and 280Ah capacity.

Each one of the modules or batteries comprises 15 x 3.2V cells

in series welded using laser technology. The voltage of each of

these cells and the temperature of the module is continuously

monitored by its own local card (BMS), developed by

Selectronic.

Each module is fitted with a 300A single-pole fuse, accessible

via a cover on the side of the module, enabling a quick change

in the event of electrical failure on the installation. See corrective

maintenance instruction in section 13.4.

The SelectCell Ultimate 280 Series modules can be connected

in Series in towers up to 3 high. In turn, each group of batteries

can be connected in parallel by using the Manager-Worker

configuration, making it possible to increase the system’s energy

and total power.

The system requires a PCC protection and control body in order

to operate. These control bodies contain the system’s protection

elements, as well as a card responsible for managing them

(EMS).

This EMS card acts as the Manager for the system, receiving all

the information from the BMS found in the system’s battery

modules via ISO SPI communications. To complete the

information needed, a reading of the current passing through the

circuit is made, as well as several voltage readings at string level.

Via an independent communications channel, the EMS also

manages the exchange of information with a higher order

system; be it an inverter, PC or SCADA. The EMS uses all of

this information to operate the protection systems, collect

statistical data and send critical information to external systems

(measurements, states, alarms, ...).

In turn, there is a system Manager in the Manager/Worker systems,

in charge of centralising the information from all of the Workers

and managing the opening of their respective contactors. This

equipment is the one that communicates with the inverter in

order to transmit both the necessary information and the

system’s alarms. This communication is done via the CAN or

Modbus TCP/IP protocol.

11

SelectCell Manual

4. Specifications

4.1 Summary

4.2

SelectCell Ultimate 280

Series

4.2.1 Physical characteristics

The following table gives the specifications of the SelectCell

Ultimate 280 SERIES module:

The following table lists the SelectCell Ultimate 280

Series module interfaces, with a short description of each.

SelectCell Ultimate

Series module Interfaces

Power

Positive (1):

Left side of module

HARTING 1000VDCc 200A Fast

Connector

Negative (2):

Right side of module

Physical

characteristics

Height

448

mm

Depth

405

mm

4.2.1 Electrical characteristics

Electrical

specifications

Nominal volta

g

e

(

VDC

)

48

Maximum static voltage, SOC 100% (VDC)

52,2

Maximum current during charge/discharge: (A)*

200

Rated capacity (Ah)

280Ah

Rated energy (Kwh)

13,4

kWh

Nominal current during charge/discharge: (A)*

<140

Minimum static voltage, SOC 0% (VDC)

42

Weight

§k

g

Width

762

mm

Communications

2 Fast Connectors RJ45 Right side

(3)

12

SelectCell Manual

4.3 PCC WORKER / SINGLE / 150V

4.3.1 Physical characteristics

The physical dimensions of PCC WORKER 150V / 500A are

as

following:

1

1

1

5

Height

1000mm

4

3

62

Depth

300mm

8

7

1

4.3.2 Electrical characteristics

Maximum voltage (Vdc)

150VDC

The following table lists the interfaces with a short description

of each.

Maximum peak current

DISCHARGE

600A (1-2 min)

PCC 150V / 500A Interfaces

Power

OUTPUT (1) - Left side of cabinet:

Depending on the number of outputs

needed;

Max cable 185mm

2

1 Output as standard

INPUT (2) - Right side of cabinet:

Depending on the number of inputs needed;

Minimum cable 50mm

2

4 inputs as standard

ULTRA-LOW MODE

breaker

(4)

Front panel for switching on after entering

ULTRA LOW MODE

Modbus/TCP

Communications (6)

RJ45 connector on left side of PCC;

non-crossover Cat5e SERIES cable

User access (8)

USB connector on the PCC

ISO

SPI

Communications

(10)

Female RJ45 connector for

SelectCell Ultimate

modules

on the right side; Own COM cable incl.

Contactor

On positive terminal

On and Error LED (9)

RED to show a system error on the PCC’s front

panel; GREEN system ON

Maximum current during

CHARGE/DISCHARGE

500A

Electrical

characteristics

Weight

~90

Kg

Width

800mm

Physical

characteristics

Fuse

On positive terminal 150VDC / 500A

continuous

HMI

(7)

Touch screen on the PCC

CAN communications

(5)

RJ45 connector on left side of PCC;

non-crossover Cat5e SERIES cable

13

SelectCell Manual

4.5

PCM SINGLE 200A

4.5.1 Physical characteristics

The physical dimensions of the PCM Single are as

follow:

Physical

characteristics

Height

165mm

Depth

250mm

2

7

8

5

6

1

4

3

9

The following table lists the interfaces with a short description

of each.

PCM 150V / 800V 200A Interfaces

11

1

12

5

Power

OUTPUT (1) – Back of equipment:

M12 cable gland; Minimum cable 50mm

2

INPUT (2) – Front of equipment:

Harting Han S connectors;

Minimum cable 50mm

2

62

8

7

Modbus/TCP

Communications (4)

RJ45 connector at the rear of PCM;

non-crossover Cat5e SERIES cable

10

User access (6)

USB connector on the PCM

ISO SPI Communications

(8)

Female RJ45 connector for SelectCell Ultimate

modules

on the front; Own COM cable included

Contactor

On positive terminal

24Vdc Bus (9)

24Vdc Bus to power the Manager’s electronics

Weight

§

Kg

Width

762mm

Error LED (7)

RED to show a system error on the PCM’s front

panel;

HMI

(5)

Touch screen on the PCM

ON/OFF switch (3)

Back panel for switching on/off

Notes:

14

SelectCell Manual

11

1

12

5

6

2

8

7

10

Notes:

15

SelectCell Manual

4.5.2 Electrical characteristics

5

8

63

7

4

12

PCC Manager 1000A Interfaces

Power

OUTPUT (1) –

Left

of equipment:

Bare wire terminal block;

Max cable 120mm

2

6 outputs standard

INPUT (2) – Right of equipment:

Bare wire terminal block;

Max. cable 185mm

2

4 inputs standard

4.9

PCC

MANAGER 1000A

4.9.1 Physical characteristics

The physical dimensions of the PCC Manager Busbar

Cabinet son Worker are as follow:

Internal switch used to connect communication

with workers. Detachable cable gland used

to pass cables inside the cabinet

Modbus/TCP

Communications (4)

Physical

characteristics

User access (6)

USB connector on the PCC

Height

1,300mm

Bus 24Vdc (8)

24Vdc Bus to power the manager’s

Depth

300mm

4.9.2 Electrical characteristics

Maximum voltage (Vdc)

1000V

4.10

Hardware

4.10.1

Battery module

Each battery module consists of:

•

Cells 3.2V – 280 Ah; forming a final array of 48V – 280 Ah

•

BMS: Card that takes the direct voltage reading for each one

of the cells and temperature reading for the module

•

Fuse: Each module has a fuse interposed between the cell

links. The acts in the event of an internal short-circuit or short-

Maximum current during

c

ontinuous Charge/Discharge

1000A

Electrical

characteristics

Weight

§120

Kg

Width

800mm

Error Led (7)

RED to show a system error on the PCC’s front

panel

HMI

(5)

Touch screen on the PCC

Door Isolator Switch (3)

Door Isolator sw

itch

16

SelectCell Manual

circuit on one of the modules’ terminals, opening the string

and preventing adjacent modules (depending on the position

data, acts on protection elements and communicates with

equipment at a higher level.

•

HMI: Touch screen, connected directly to the EMS. This

shows data on the state of the system, allowing manual

intervention if required.

•

Error LED: This LED flashes when the EMS detects a fault on

the system, whether it be an electrical or hardware fault.

•

Contactor: Safety element that cuts the current in the event

of the shorted module) from feeding

4.10.2 PCC

the fault

The protection module comprises the following elements:

•

EMS: This collects the data from all the BMS, manages these

data, acts on protection elements and communicates with

equipment at a higher level.

•

HMI: Touch screen, connected directly to the EMS. This

shows data on the state of the system, allowing manual

intervention if required.

•

Error LED: This LED flashes when the EMS detects a fault on

the system, whether it be an electrical or hardware fault.

•

On LED: This LED stays lit green when connected.

•

Contactor: Safety element that cuts the current in the event

of a system alarm. Located just before the protection

module’s output terminals, it is used to isolate the cabinet

before conditions that guarantee correct connection to the bus

are established, as well as protecting the string against

external faults.

•

Current transformer: Transformer that reads the system’s

total input and output currents to calculate the charge

remaining in the battery, as well as protection functions.

•

Power supply: One a stationary battery’s applications is

to be used as an uninterruptible power supply. To achieve this,

the electronics that manage the batteries cannot stop

receiving energy, so the only way to ensure this is to feed it off

the batteries themselves.

•

On/Off switch: Circuit breaker inside PCC used to start the

PCM once the power connections have been made. Should

the PCM have to be put out of operation, this switch is also

used to switch it off and isolate the electronics from the power

supply.

•

Power terminals: Access for the customer’s power cables is

located on the front of the module

of a system alarm. Located just before the protection

module’s output terminals, it is used to isolate the cabinet

before conditions that guarantee correct connection to the bus

are established, as well as protecting the string against

external faults.

•

Current transformer: Transformer that reads the system’s

total input and output currents to calculate the charge

remaining in the battery, as well as protection functions.

•

Power supply: One a stationary battery’s applications is

to be used as an uninterruptible power supply. To achieve this,

the electronics that manage the batteries cannot stop

receiving energy, so the only way to ensure this is to feed it off

the batteries themselves.

•

On/Off switch: Used to start the PCC once the power

connections have been made. Should the PCC have to be put

out of operation, this switch is also used to switch it off and

isolate the electronics from the power supply.

•

Breaker: In the event of entering ultralow mode this device

switches off the entire system to ensure there is no

consumption.

•

Power terminals: Access for the customer’s power cables is

located on the right side of the electric cabinet.

•

Communications connector:

Both

Communications

connectors are located on the back side of the PCM, identified

as “CANbus” and “Modbus”

•

Communications connector:

Both

Communications

connectors are located on the right side of the PCC, identified

as “CANbus” and “Modbus”

The Modbus/TCP connector uses a standard TCP cable.

The pinout for the CAN Communications cable can be

checked in chapter 9.2 CAN protocol. If a different pinout is

required, please contact Selectronic for assistance.

4.10.3 PCM

The protection module comprises the following elements:

•

EMS: This collects the data from all the BMS, manages these

17

SelectCell Manual

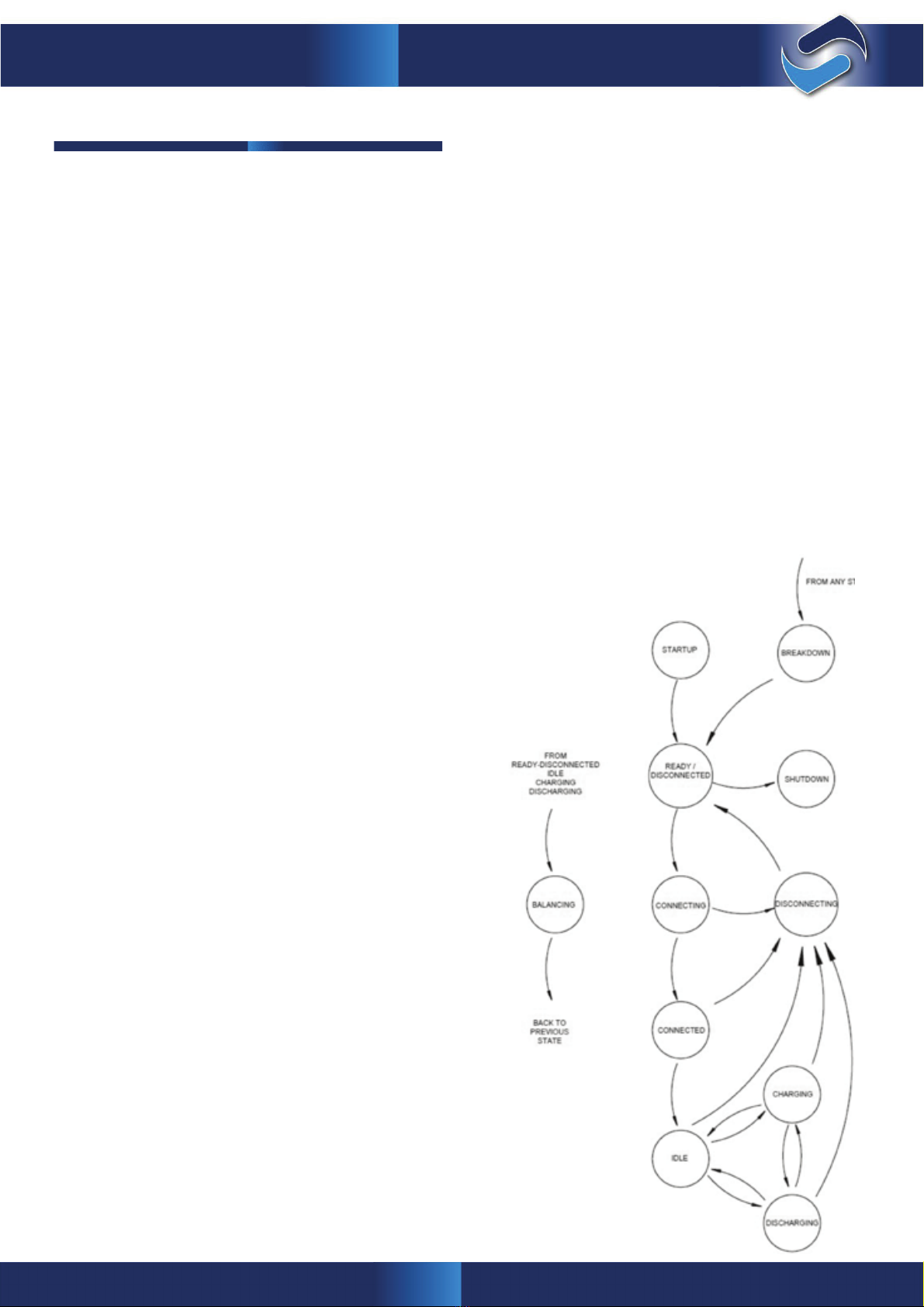

5. Operating modes and processes

5.1 State machine

The string is controlled by a sequential state machine. This state

machine is managed by the EMS located inside the PCC. The

user can check the state of the string both from the HMI and by

communications at address 0x3000 - 1 via CAN or at address

3001 via Modbus.

•

Discharging: Value at memory location = 35

In this state the current is being drawn from the string. The

SoC value will decrease proportionally to the current read

and the protection functions with the “discharge” suffix will

be enabled.

•

Disconnecting: Value at memory location = 6

Transition state. As soon as a disconnection command is

received or an error occurs during the connection sequence,

the system will change to this state as a step prior to open-

ing the contactor.

•

Breakdown: Value at memory location = 1

If the system experiences a critical fault (any error that

prevents safe use of the batteries), the EMS will change to

the Breakdown state, in which the contactor opens. It will

remain in this state until the errors are cleared, either via the

local HMI or by receiving a communications command to

reset errors.

•

Shutdown:

This state appears when a software reset is performed on

the EMS, either due to a settings change or a firmware

update. During this state, the EMS saves the system’s state

to memory, to continue under the same

conditions once the restart has finished.

The EMS state machine has the following states:

•

Start-up:

This starts the card, communications, and each of the BMS

located inside the battery packs. System settings anderror-

free check.

•

Ready / Disconnected:

Value at memory location = 2

Once the start-up sequence has finished, the system

remains in this state until the connection sequence starts,

whether due to a command, if the battery works together

with a manager or after a standby period, if the battery

works independently.

•

Eq Balancing: Value at memory location = 3

If the EMS detects that the charge difference between cells

is too high, and that system conditions are suitable for the

string to enter equalization, the EMS automatically orders

the equipment to this state. In this state any excess energy

in cells with the most charge will be dissipated until all the

cells have approximately the same stored energy.

•

Connecting: Value at memory location = 4

Transition state. the state machine changes to this state

once the connection command has been received and the

pre-charge has been performed (pre-charge is optional,

described in its own chapter). If the bus voltage reading is

correct, it orders the contactor to close and then changes to

the connected state.

If the voltage reading is not correct, the sequence is aborted

and it changes to the disconnecting state.

•

Connected: Value at memory location = 5

Transition state. After receiving the close command and

running the connection sequence, the string will have the

contactor closed. If no errors occur within a specific time, it

changes to the idle state.

•

Idle:

Value at memory location = 15

Once the string is connected, it remains in this state until a

through-current is detected. If the current value read has a

positive sign, it changes to the charging state, but if it is a

negative sign, then it changes to the discharging state.

•

Charging:

Value at memory location = 25

In this state the current is being fed to the string, so the SoC

value will grow proportionally to the current read and the

protection functions with the “charge” suffix will be enabled.

18

SelectCell Manual

To stop the system, via the touch screen, press the switch icon.

The string should never be switched off while current is flowing

through the system.

The contactor has to be opened from the screen (connect

button) prior to switching off the PCC.

5.3 Connection process

SelectCell Ultimate 280 systems can operate in 2 different ways:

Worker mode and Stand-alone mode

In Worker mode control depends on a higher level system, be

it SCADA, an inverter or operation personnel. In this mode, after

the system is started it remains in the ready/disconnected state

until it receives an external close command.

In stand-alone mode the system automates various opera-

tions, including direct connection. Once the SelectCell is started

in this mode, if no critical errors occur, the contactor will close

in- dependently. This mode is used together with inverters that

do not have communications, or whose communications system

is not suitable for controlling lithium battery pack switches.

The latter (stand-alone) is the default connection mode.

5.4 Ultra-low consumption mode

Should the batteries be left unattended for a prolonged peri- od,

the cabinet has an ultra-low consumption system to protect

them. If the equipment were to be left on without supervision

or use, the electronics in the batteries would consume their en-

ergy, so if the EMS detects a battery voltage value lower than a

desirable level, it follows a series of steps as the voltage de-

creases, until it switches the string off completely.

5.2 Start-up and shut-down processes

Please refer to the Installation Section page 28 prior to starting

the system.

Once the PCC is energized, the control electronics in the PCC

powers up. The EMS then checks hardware integrity (own

hardware and that of the BMS distributed by communications)

and that the cabinet distribution set-up corresponds with that

read. If no error is detected, the EMS allows work with batteries

to commence. The time required for start-up is less than 1

minute.

Prior to starting normal battery operation, it is advisable to

charge the modules up to 100% SoC.

In the case of the PCC, there is a circuit breaker to switch off

consumption definitively. To switch the equipment back on, it is

necessary to use the switch again. Contact Selectronic for

information on how to do this safely, because when the system

restarts there should be an energy source available to charge

the batteries (grid, generator, renewable...)

Input conditions for this ULTRA-LOW CONSUMPTION mode:

Current less than 2A AND minimum cell value <2975mV for 2h

The actions that occur are as follows:

DANGER:

ELECTRONICS SELF-CONSUMPTION

The electronics inside the cabinet are powered by

the batteries. If the batteries are not going to be used for a

prolonged period, the PCC has to be switched off.

Worker PCC

Contactor Switches

Manager PCC

Contactor Switch

19

SelectCell Manual

5.5 Pre-charge process

The pre-charge process is designed to be used with commercial

inverters. It requires specific custom-built hardware for this

application.

Power inverters, MPPT controllers and most of the power

electronics equipment work with a set of capacitors, coils and

transistors to modify the input signal to achieve the desired

output signal for the application.

To solve this problem, a DC bus soft-start is used.

In this instance, instead of initially closing the circuit with the

main contactor; an auxiliary contactor is used, which is con-

nected in series with a resistor that limits the current. This

resistor decreases the capacitors’ energization current and once

the DC bus is energized, the main contactor closes while this

auxiliary contactor is disconnected, as long as the bus pre-

charge has been done safely by reaching the desired bus

voltage level.

5.6 Passive equalisation

As the string charges and discharges, slight differences in the

chemistry of the cells produce different resistive values, leading

to differing losses during use of the battery and different

amounts of energy stored in each cell.

The end of the charging process is determined by the cell that

has the highest amount of stored energy in the whole string

(when a cell reaches 100% charge, the process stops regard-

less of the charge stored in the rest of the string’s cells), while

the end of the discharge process is determined by the cell with

the least amount of charge.

The differences in stored energy increase as the number of

cycles in the string increases; making the system increasingly

less efficient. To solve this problem, the EMS monitors the

difference between cells, initiating the equalisation process

whenever necessary.

Cell imbalance is due to different factors, the most common

being:

xDepth of Discharge (DoD): Higher DoD, greater im-

balance.

xCharge and discharge cycles: More cycles, greater

imbalance.

xOperating temperature: Working at temperatures

other than the optimum one produces greater

imbalance for the same charge/discharge cycle.

xCharge/discharge current: Higher currents, greater

imbalance.

The charge in a cell is partially related to the voltage in that

cell. SelectCell constantly controls the voltage in each of its

cells. If a high imbalance between cells is detected at any

point, then the EMS enters passive equalisation mode,

assuming the string is not being used.

During this process, any excess energy in cells with the

largest amount of charge is dissipated. By doing this, the

charge value of each cell begins to decrease slowly until each

cell reaches the charge value of the least charged cell.

There are two passive equalisation modes: Normal mode and

extreme mode.

A typical equalisation process, where a set of lithium-ion

cells with initially spread voltages is reduced over time as

the process is executed.

DANGER:

ULTRA-LOW CONSUMPTION MODE

If the user detects that the string has disconnected itself

and that the screen is off, charging battery should be

avoided.

If the battery tries to charge normally in this state; in the

best of cases, it would lead to a severe loss of capacity

for the equipment; in the worst case it would cause a

short circuit.

Under these conditions the battery has to be recharged

in a specific way.

Please contact Selectronic’s technical support department

so that it can analyse the situation and provide additional

instructions.

1. Contactor opens due to undervoltage

2. BMS switched off on each of the batteries

3. Screen and EMS switched off.

If the battery does reach any of these points it may still be

re- covered, however, it requires a specific charging method.

20

SelectCell Manual

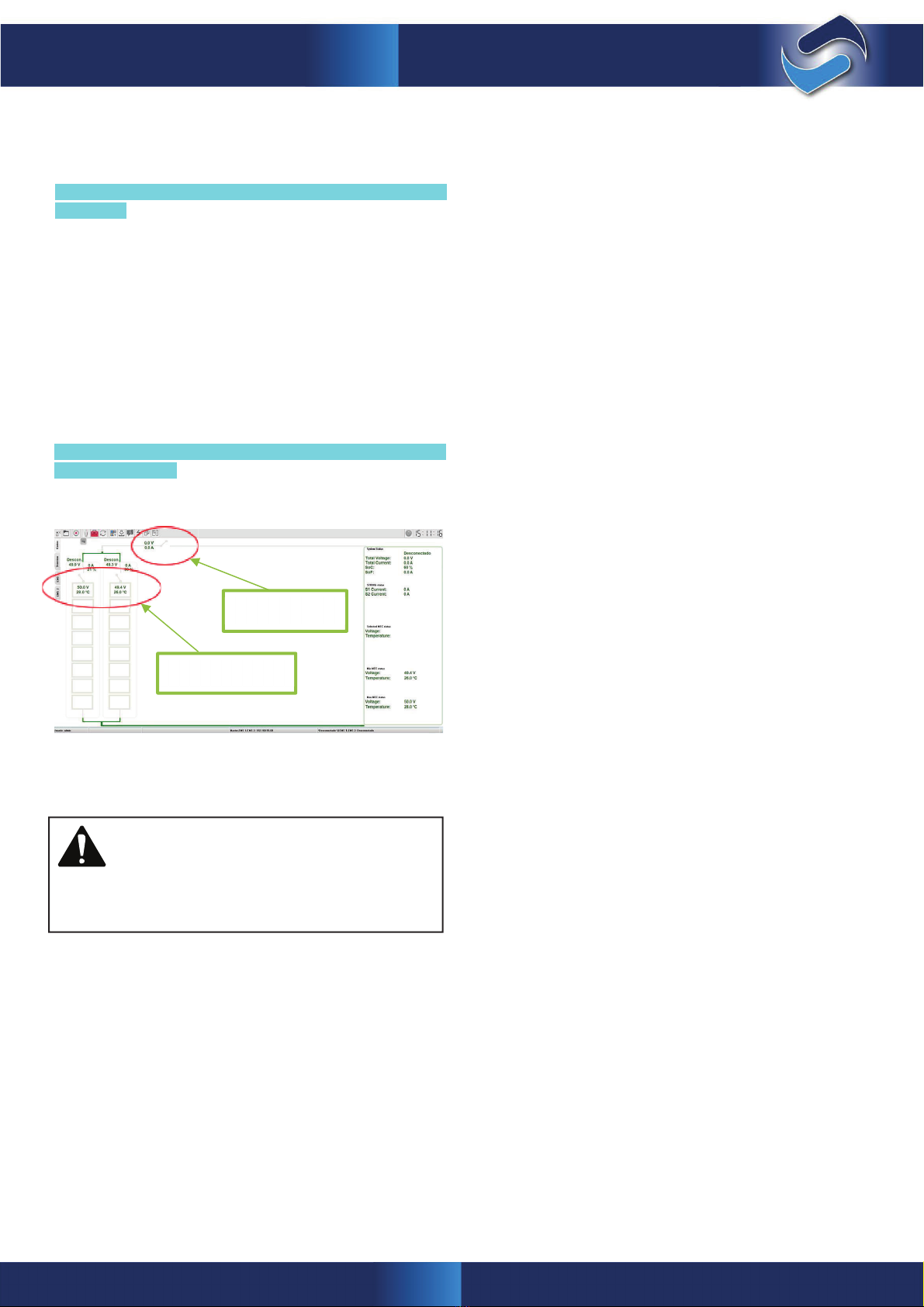

6. System monitoring

6.1 State of Charge (SoC) calculation

One of the most important aspects in a battery is to know how

much stored energy remains in it, in order to determine how the

battery can be used.

This is quite simple with lead acid batteries, given that the sys-

tem voltage is practically proportional to the charge remaining in

the batteries.

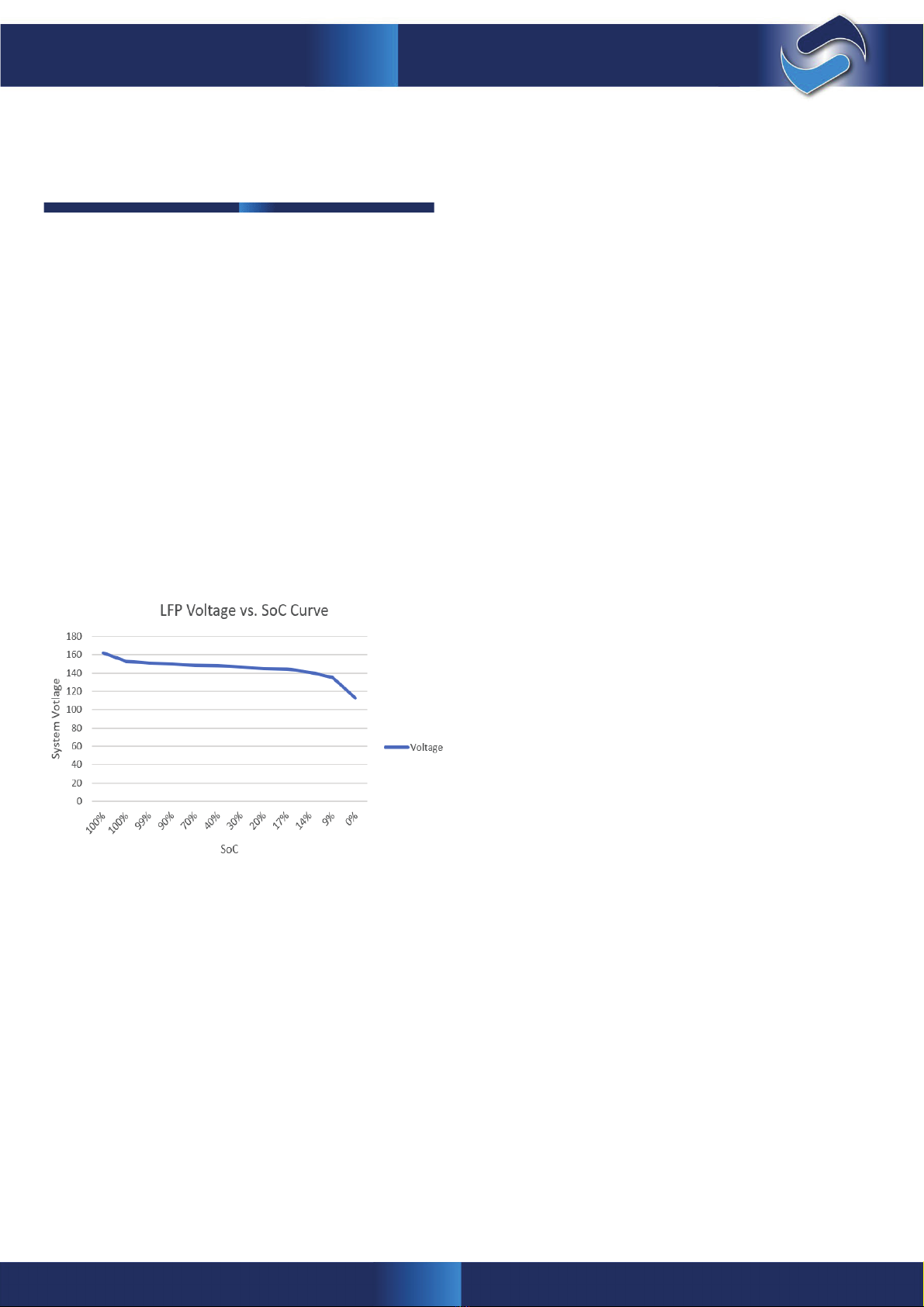

However, LFP-type batteries have a characteristic discharge

curve in which the voltage is flat for most of its utilization range,

and where a variation of 1-2 mV could represent a 10-20% er-

ror when estimating the charge. Only the voltage extremes vary

enough to be able to relate directly to the charge remaining in

the battery.

This, coupled with the fact that the shape of the characteris-

tic varies with different factors (discharge current, temperature

...), makes direct measurement of the voltage to represent the

charge remaining in the battery infeasible.

During most of the utilisation range the EMS continuously cal-

culates the batteries’ SoC using a coulometric based algorithm.

A reading is taken of the output current during discharge and

input current during charge, and the SoC is then updated by

adding or subtracting this energy.

An update of the estimated charge is performed at the ends of

the curve (0-20% and 95-100% charge), where the voltage can

be more precisely related to the remaining charge; updating the

SoC to this voltage under certain physical conditions.

•

100% update; given the SW defined voltage and current

conditions to interpret that the battery is fully charged.

Similarly, if one of the series reaches a value of 3575mV

for 10 seconds.

•

Idle update; The EMS electronics use their own algo-

rithms to update the SOC when idle (ZERO current after

a period of inactivity) depending on the voltage of cells

only within the range from 0 to 20%.

•

0-20% update based on discharge current; The EMS

electronics use their own algorithms to update the SOC

based on the discharge current of each module con-

nected in parallel and minimum cell voltage; this SOC

value is only updated with current within the range from

0 to 20%

6.2 Ideal charging conditions

The EMS system constantly controls the SOC conditions, tem-

perature, voltages of the entire system and uses communications

to send the inverters/chargers the optimum charge voltage and

charge current values in order to ensure correct control of the

charging process.

-Charge voltage based on cell temperature:

•

Between 0 and 5ºC

•

Between 6 and 10ºC

51.5V

52V

To solve this problem and attain a faithful representation of the

system’s state of charge, a mixed solution has been applied.

This manual suits for next models

1

Table of contents

Other Selectronic Camera Accessories manuals