Basler ESD 201 User manual

Publication: Rev First Printing 07/96 Page

9 1106 00 991 B Revised 12/02 1

CONFIDENTIAL INFORMATION

OF BASLER ELECTRIC COMPANY,

HIGHLAND, ILL. IT IS LOANED FOR

CONFIDENTIAL USE SUBJECT TO

RETURN ON REQUEST AND WITH THE

MUTUAL UNDERSTANDING THAT IT WILL

NOT BE USED IN ANY MANNER

DETRIMENTAL TO THE INTERESTS OF

BASLER ELECTRIC COMPANY.

Publication:

9 1106 00 991

Revision: B 12/02

INSTRUCTION MANUAL

FOR

ENERGY STORAGE DEVICE

Model: ESD 201

Part Number: 9 1106 00 101

BASLER ELECTRIC BOX 269, HIGHLAND, IL 62249 USA PHONE 618/654-2341 FAX 618/654-2351

INTRODUCTION

The Energy Storage Device ESD 201 is used

where a station battery source is not

available to provide circuit breaker trip power.

The ESD 201 converts ac bus voltage to dc

and stores enough energy to trip a circuit

breaker one time for up to 72 hours after ac

power has been interrupted.

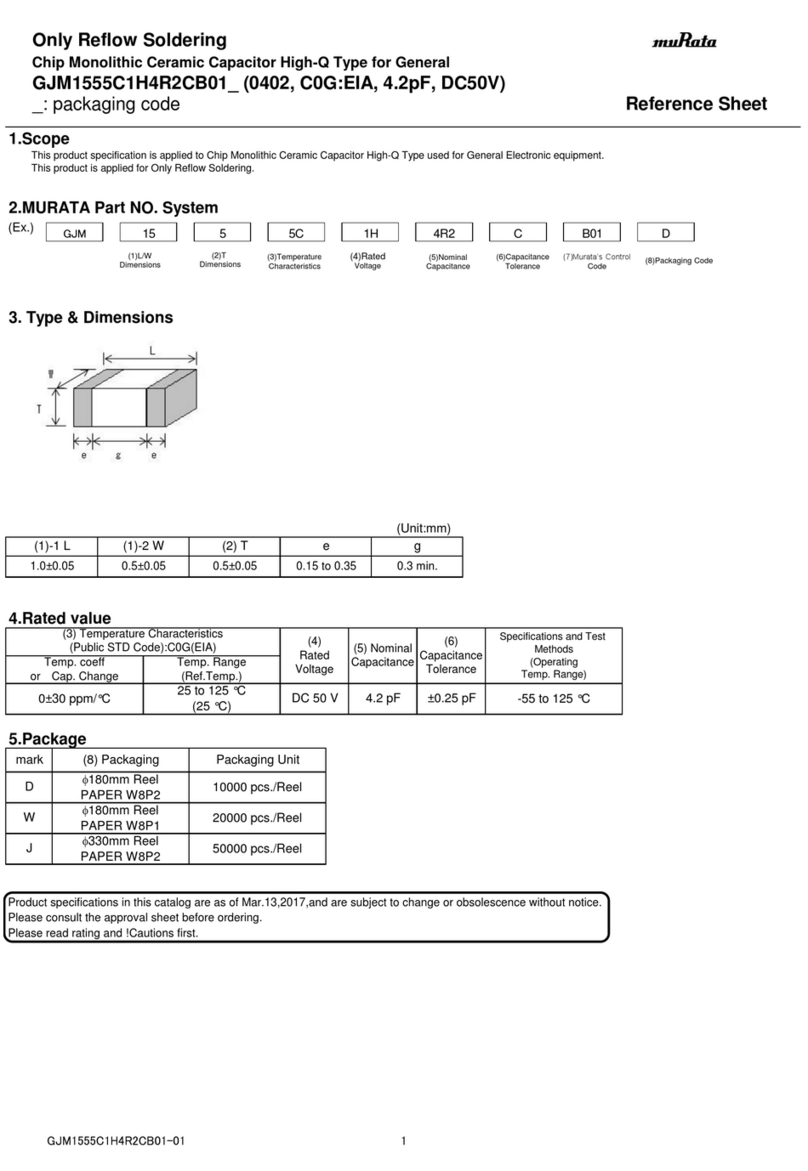

ELECTRICAL SPECIFICATIONS

Output Power

330 to 450 Vdc

27 joules minimum at 330 Vdc

36 joules minimum at 380 Vdc

50 joules minimum at 450 Vdc

This output is maintained for 72 hours after

the internal battery is fully charged.

Power Input

Operating Range: 120 or 240 Vac, ±10%,

1-phase, 50/60 Hz

Burden: 10.0 VA maximum

Charging Rate

Varies nonlinearly from 90 volts/cycle down

to 2.8 volts/min. as capacitor approaches

90% full charge after breaker trip event.

Power Dissipation

2.0 W, maximum continuous

PHYSICAL SPECIFICATIONS

Operating Temperature

–25°C to 65°C (–13°F to 149°F)

Storage Temperature

–40°C to 85°C (–40°F to 185°F)

Vibration

Withstands 2 G at 10 to 200 Hz in each of

three mutually perpendicular axes.

Shock

Withstands 15 G in each of three mutually

perpendicular axes.

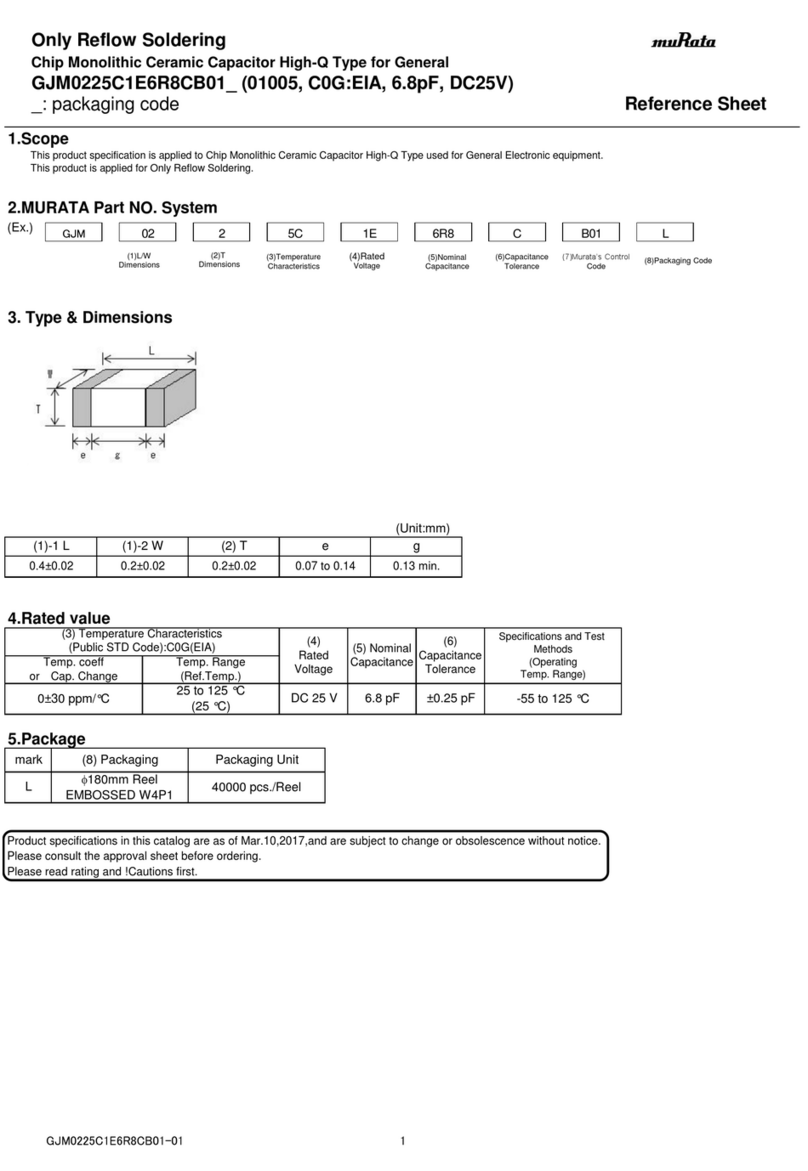

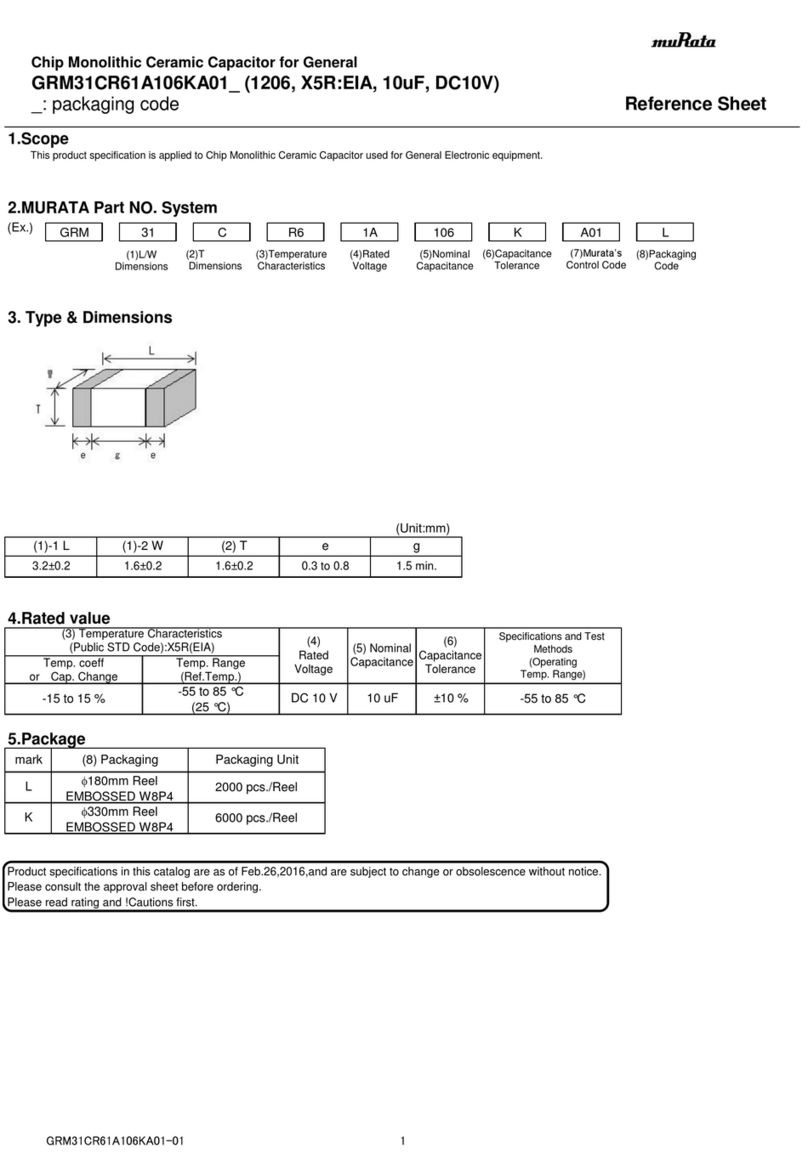

Dimensions

Refer to the

Outline Drawing

.

Weight

0.59 kg (1.3 lb)

Agency Certification/Recognition

Meets CSA C22.2, Number 14,

Industrial

Control Equipment

.

Meets UL 508,

Industrial Control Equipment

as tested by CSA NRTL.

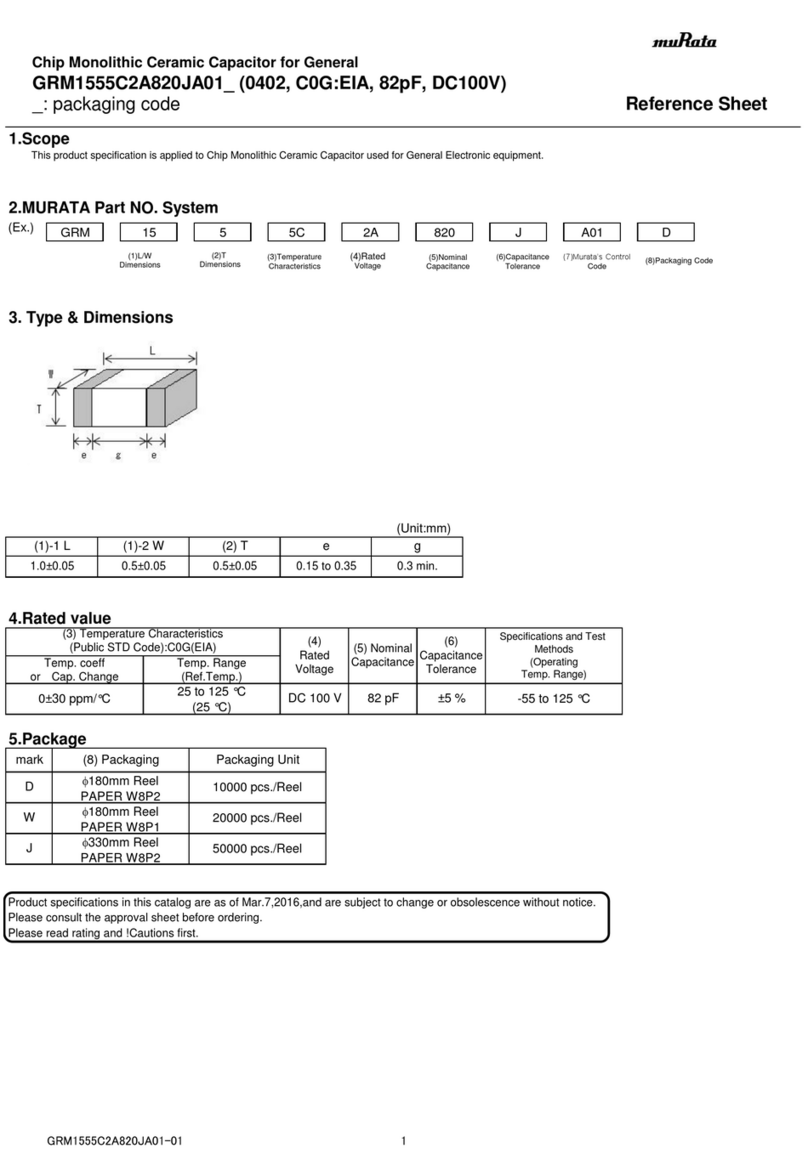

THEORY OF OPERATION

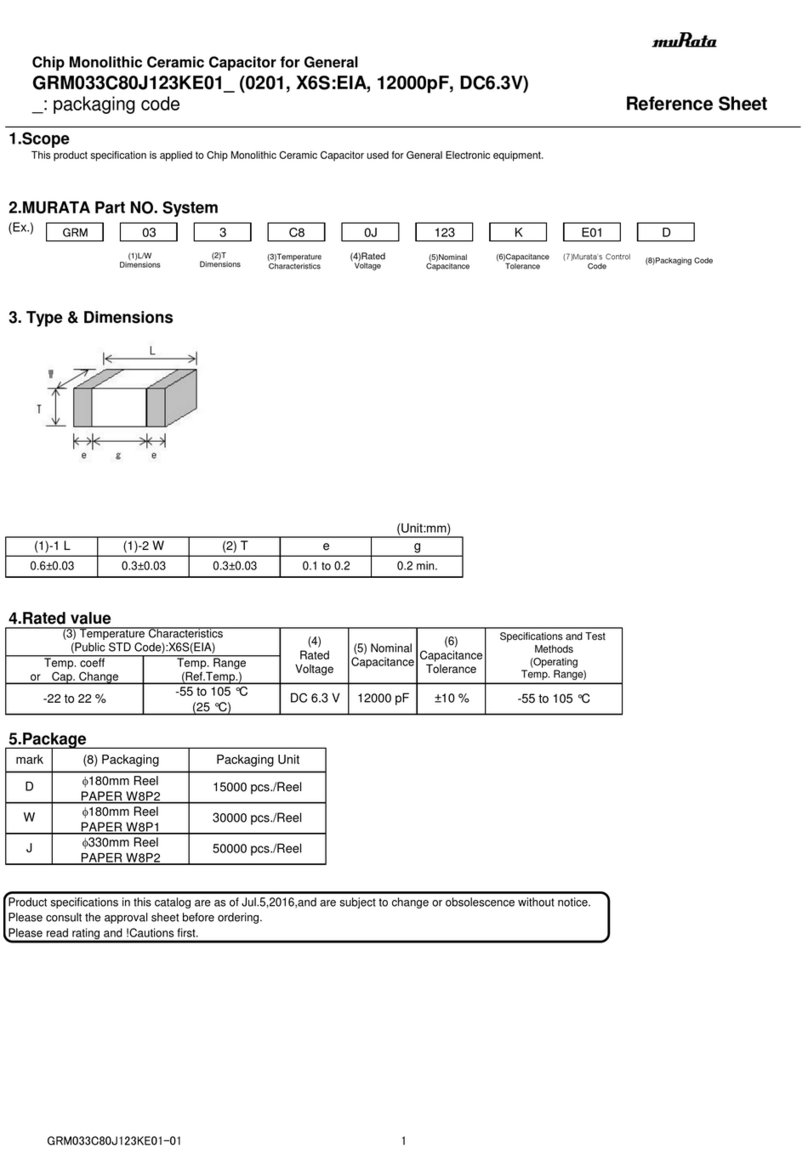

ESD 202 operation is illustrated in the

Function Block Diagram

.

Power input to the ESD 201 is 120 or 240

Vac. This input is rectified and used to

charge the output capacitor (C1) to approx-

imately 170 Vdc for 120 Vac input, 340 Vdc

for 240 Vac input. As long as the ac input is

applied, C1 continues to be charged in this

manner. However, the failure of the ac input

is what the ESD 201 is designed to protect

against. Therefore, when the ac input fails, a

battery powered oscillator circuit and an

associated step-up transformer act as the C1

charging source. (The ESD 201 can be inter-

connected to the system so that the oscillator

circuits function only when the breaker being

controlled is closed. See the

Interconnection

Diagram

.) A battery charger charges the

battery as long as the ac input is applied to

the ESD 201.

CONTROLS AND INDICATORS

The pushbutton and LED indicator are used

to determine if the ESD 201 is operationally

ready. When the button is pushed, the LED

lights if the capacitor has the minimum

charge of 180 Vdc required to trip the

breaker. The pushbutton and LED do not

indicate whether or not the ac input is being

applied.

INSTALLATION

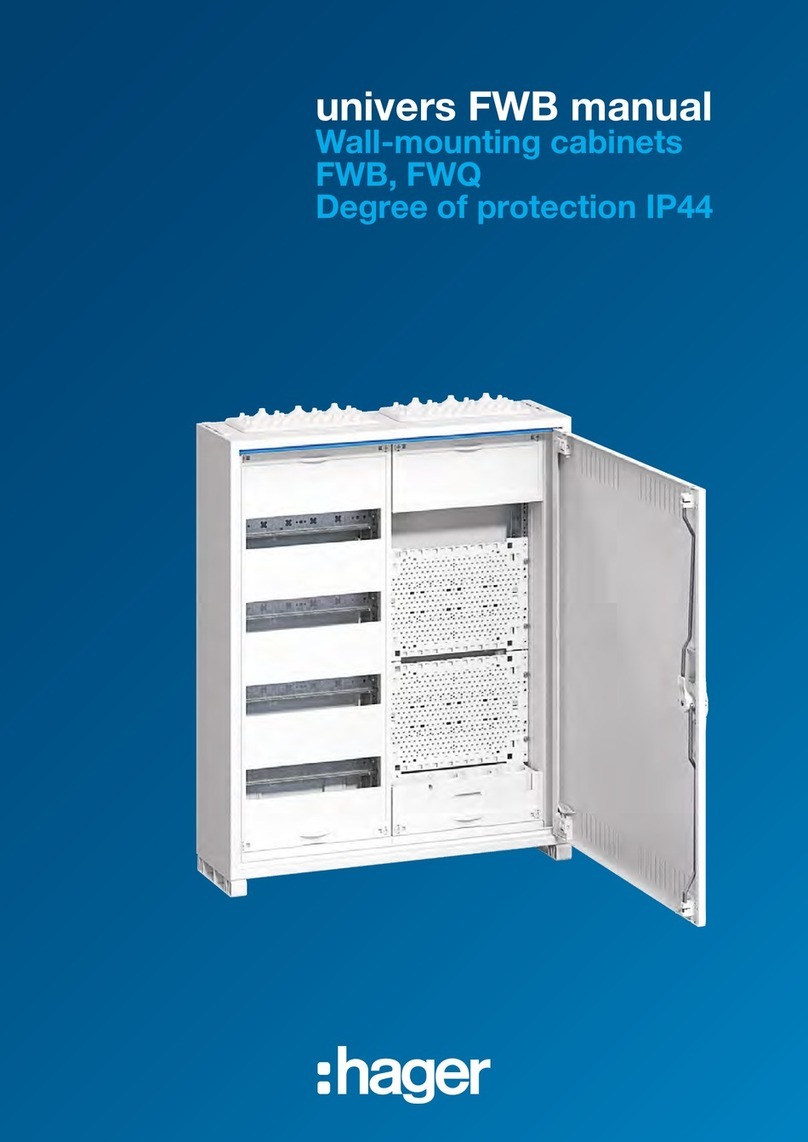

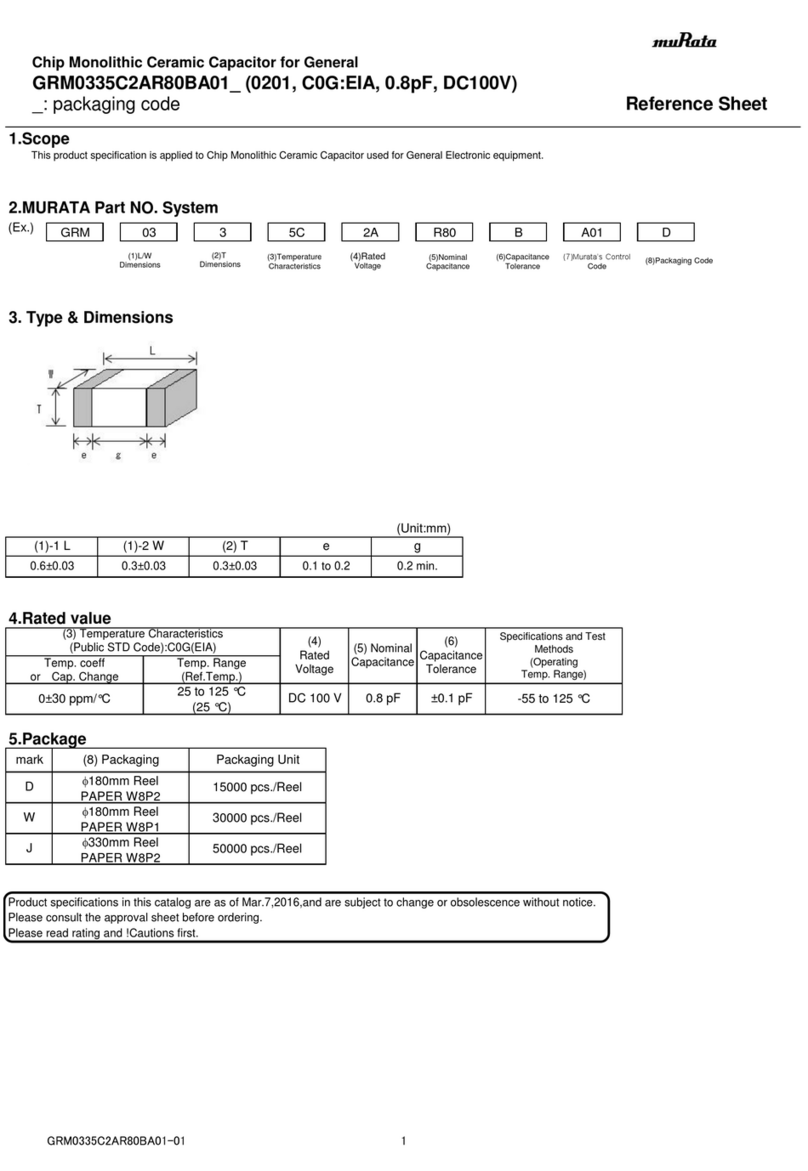

The ESD 201 should be connected as shown

in the

Interconnection Diagram

. In order for

the ESD 201 internal, battery-operated,

capacitor-charging circuits to operate, ter-

minal 1 must be connected to terminal 4.

This can be accomplished by permanently

jumpering the two terminals together. Using

this approach however, the oscillator circuits

will continually be in operation if the battery is

in place. This will result in premature

discharge of the battery if ac input power is

not being applied. An alternate (and pre-

ferable) approach involves the use of the

breaker auxiliary "a" contact. The intent of

the "a" contact is to inhibit operation of the

oscillator circuit (and thereby eliminate

battery drain) until the circuit breaker is

closed.

Each breaker should be provided with its own

ESD 201. The use of a single ESD 201 to

provide a tripping output for more than one

breaker (or other device) is not recom-

mended. Such configurations should only be

considered when it can be demonstrated,

through independent testing, that combi-

nations of breakers (or devices) can be

reliably operated from a single ESD 201.

OPERATION

When the ESD 201 is properly inter-

connected and 120 or 240 Vac input power is

applied, the unit is ready for operation. This

can be verified by using the pushbutton as

described in the

Controls and Indicators

paragraph. No adjustments of any type

should be necessary.

Ac power must be applied continually for a

minimum of two hours before the ESD 201 is

capable of developing full charge on the

output capacitor with a sustained interruption

in ac input.

If the batteries are fully discharged (terminal

voltage of 3.6 volts or less), it will take

approximately 48 hours to recharge the

batteries from the ac source. In such

situations, it is suggested that the battery be

removed and recharged with a high rate

charger (not to exceed a 0.1 ampere

charging rate). During this time, standard

"AA" size cells should be substituted in the

ESD 201.

DISCHARGING

Since more than 400 Vdc can be present on

the ESD 201 output terminals, the storage

capacitors should be discharged before

working on the unit. The following procedure

can be used for discharging the storage

capacitors.

WARNING!

To prevent personal injury or equipment

damage, only qualified technicians or

operators should install, operate, or

service this device.

CAUTION

The ESD 201 is not a power supply and

can be damaged by continuous current

draw on the output.

NOTE

The test circuit acts as a discharge path to

the output capacitor. Therefore, the push-

button should be depressed only long

enough to observe if the LED lights.

NOTE

Read the paragraphs under

Discharging

before changing batteries.

WARNING!

Lethal voltage may be present at ESD 201

terminals and within the ESD 201. Only

qualified persons should install, operate,

or service this device.

Publication: Rev First Printing 07/96 Page

9 1106 00 991 B Revised 12/02 2

Outline Diagram

Function Block Diagram

Interconnection Diagram

1. Connect a few inches of 14 AWG, 600 V

insulated wire to each end of a 470 ohm,

5 watt, wire-wound resistor.

2. Remove ac input power from ESD 201

terminals 1, 5, and 2.

3. To discharge the capacitors, carefully

touch one of the resistor wires to terminal

1 and the other wire to terminal 3. Hold

the wires on the terminals for at least five

seconds.

4. Ensure that the capacitors are dis-

charged by connecting a dc voltmeter

across terminals 3 (+) and 1 (–).

REPAIRS

The ESD 201 is not field repairable. Should

the device require repairs, return it to Basler

Electric for service.

FIELD SERVICE AND ADJUSTMENT

Following assembly, every ESD 201 under-

goes a complete operational test. If for any

reason the unit fails to operate properly, it

should be returned to Basler Electric for

repair or replacement.

This manual suits for next models

1

Table of contents