Bass EMD-RM Series Quick guide

EMD-RMTR.. User’s Manual

1

Installaton and Instructon

Manual

“Transmtter”

Electromagnetc Flowmeter

Type : EMD-RM...

Rv : 01

EMD-RMTR.. User’s Manual

2

Contents

1.General............................................... 3

2.Installaon.......................................... 3

3.Basic Circuit......................................... 9

4.Specificaons...................................... 10

5.Operaon and Setup........................... 11

6.Parameters and Setng....................... 12

7.Alarms.................................................. 22

8.Troubleshoong.................................. 22

EMD-RMTR.. User’s Manual

3

1. General

1.1. Intended Use

The electromagnetic flowmeters are designed exclusively to measure the flow and conducvity

of electrically conducve, liquid media.

1.2. Cerficaon

The device fulfils the statutory requirements of the following EC direcves:

• Low Voltage Direcve 2006/95/EC

• EMC Directive 2004/108/EC

• EN 61010

• EMC specification acc. to EN 61326/A1

The manufacturer cerfies successful tesng of the product by applying the CE marking.

2. Installaon

2.1 Dimension and mounng

mm

A B C D

214 164 234 70

300 mm

300 mm

EMD-RMTR.. User’s Manual

4

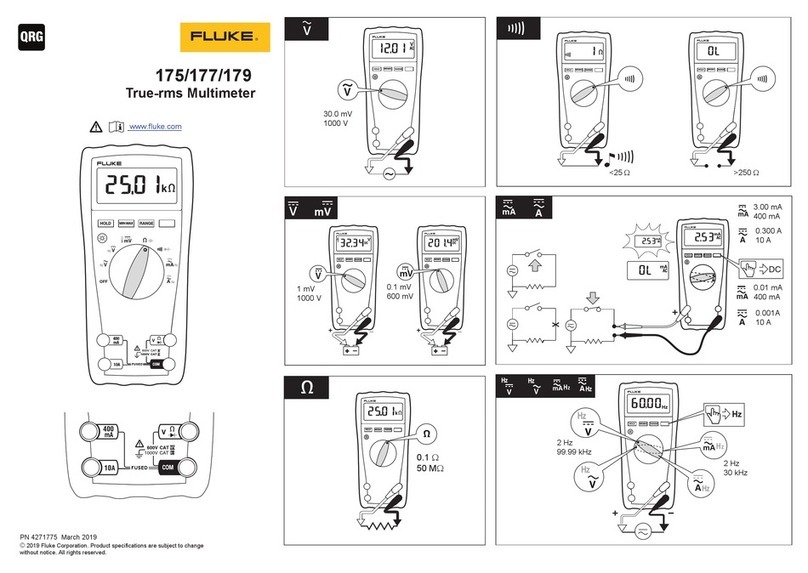

2.2 Terminal Wiring

Funcon Symbol Descripon

Pulse Output POUT Frequency (pulse) output

PCOM Pulse output Ground

Alarm Output ALMH Alarm Output for Upper Limit

ACOM Alarm Output Ground

Alarm Output ALML Alarm Output for Low Limit

ACOM Alarm Output Ground

RS485 (Optional) TRX+ Communicaon RS485+

TRX- Communicaon RS485-

Analog Current Output

VDIN 24V Pull Power Supply

IOUT Analog Current Output

ICOM Analog Current Output Ground

Power Supply

L or (-) 230VAC live or 24V DC (-)

N or (+) 230VAC notr or 24V DC (+)

Ground

Signal from Sensor

SIG1 Signal 1

SGND Signal Ground

SIG2 Signal 2

TCOM

EXT+ Excing Current+

EXT- Excing Current-

DS1 Shielded Excing1

MTSR

DS2 Shielded Excing2

EMD-RMTR.. User’s Manual

5

2.3 Sensor Wiring

2.4 Signal Outputs

2.4.1 Analog Output

Analog output wiring 4 to 20 mA (main connecon)

Blue : Signal 2

Red : Signal 1

Black : Signal GND

Red : EXT +

Black : EXT -

EMD-RMTR.. User’s Manual

6

There are two signal system:0 to 10mA and 4 to 20mA, it can be selected from parameter seng.

Simulaon signal output inner is 24V for 0 to 20mA, it can drive 750Ω resistance.

The percent flux of simulation signal output:

Iout : Measuring Value

Full Scale

For example ;

Measuring Value : 168 m3/h Full Scale : 200 m3/h Current Range : 20 – 4 mA : 16 mA I0 : 4 mA

(168/200)x16+4 : 17,44 mA

Current – Zero Point Calibraon

Enter “Parameter Seng”, and select “Analog Zero”. The standard of signal fountain geng to “0”. Adjust

parameter to ensure that the value of Amperometer is 4mA (±0.004mA).

Current – Full Scale Calibraon

Enter “Anlg Range”. Adjust parameter to ensure that the value of Amperometer is 20mA (±0.004mA)

2.4.2 Frequency,Pulse or Digital output

Frequency or pulse output wiring (main connecon)

x Current Range + I0

Counter,rate indicator

or PLC

EMD-RMTR.. User’s Manual

7

Pout

Pcom

P n

Com

User

equ pment

Vol t age nput

+

-

E

R

I ns de

The connection of digital voltage output

Table of digital output parameter: POUT

Parameter Test Condion Mini Typical Max Unit

Voltage IC=100 mA 3 24 36 V

Current Vol≤1.4V 0 300 350 mA

Frequency IC=100mA Vcc=24V 0 5000 7500 HZ

High voltage IC=100mA V

Low Voltage IC=100mA 0.9 1.0 1.4 V

User Side

Pout

Pcomm

24V-

24V+

24V-

24V+

DI

Com

24V-

24V+

1 K Ω

24V-24V+

Pull-up No Resstor;

EMD PLC (Elar, Setex, Sedomat)

Pout

Pcomm

24V-

24V+

24V-

24V+

DI

Com

24V-

24V+

24V-24V+

Pull-up wth Resstor;

EMD PLC (Elar, Setex, Sedomat)

EMD-RMTR.. User’s Manual

8

Frequency output

Digital output means frequency output and pulse output, and both of them use the same output point, so user

can choose only one type of them but not both.

Frequency output range is 0 to 5000Hz, and corresponding the percent of flux

f : Measuring Value

Full Scale

The up limit of frequency output can be adjusted. It can be chosen from 0 to 5000Hz, and also can be chosen

low frequency: such as 0 to 1000Hz or 0 to 5000Hz.

Frequency output mode can be used in control applicaon, because it responses the percent flux. Users can

choose pulse output when the equipment is applied to count.

Pulse Output

Pulse output mainly applies in count mode. A pulse output delegates a unit flux, such as 1L or 1 M3 etc. Pulse

output unit divide into 0.001L, 0.01L, 0.1L, 1L, 0.001 M3, 0.01 M3, 0.1 M3, 1 M3 .When the pulse unit is

selected, please noce the match of the flux range of flowmeter and pulse unit. For volume flux, count

formula as follows:

Q (l/sec) : 0,0007854 x ID2 x V

Q (m3/sec) : 0,0007854 x ID2 x V x 10-3

Where ; ID : Inside diameter (mm) V : Velocity ( m/sec)

The oversize flux and too small pulse unit will be made the pulse output over the up limit.

Generally, pulse output should be controlled below 3000 Pulses/Sec.

Otherwise, pulse output is different from frequency output. When pulse output cumulates a pulse unit, it

exports a pulse. Therefore, pulse output is not equality. Generally, measure pulse output should choose to

count instrument, but not frequent instrument.

Grounding

Contact area of copper Connector PE on Converter Cabinet for grounding should be larger than 1.6mm2.

Contact resistance should be less than 10Ω.

x frequency range

EMD-RMTR.. User’s Manual

9

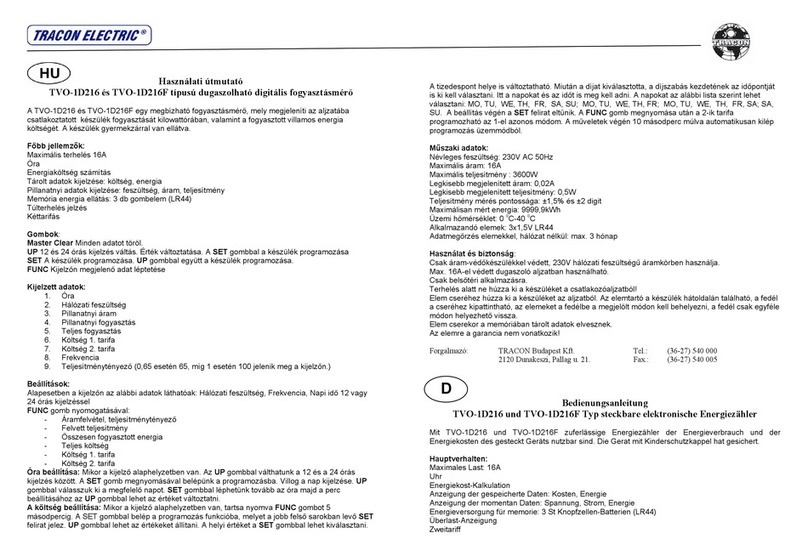

3. Basic Circuit

32 bt

CPU

ROM

EEROM

LCD

Dsplay

Keyboard

A/D

exctng crcut

Swtchng

Power Supply

Current Output

Pulse Output

Status

Control

Communcaton

Interface

85~260V

45~63Hz

4-20mA or

0-10mA

1-5000Hz

Frequency or

Pulse Output

OC Gate Status

Output

RS485 .etc

preampl

fier

Working Principle: the converter supplies excing current to the coil of flowmeter’s sensor (Detector); the

main amplifier amplifies the electromove force from the sensor and converts it into standard signals of

current or frequency so that the signals can be used for displaying, controlling and processing. Structure of

converter circuit is shown in above figure

EMD-RMTR.. User’s Manual

10

4. Specificaons

Excing current can be selected for 125mA、187.5mA;

Velocity range: 0.1 to 15m/s,current speed resoluon: 0.5mm/s;

AC high-frequency switching power, range of voltage: 85VAC to 250VAC

DC 24V switching power, range of voltage: 20VDC to 36VDC

Network funcon: MODBUS、HART Communication (Oponal)

4.1 Especial Funcon

Recording time when power turn-off, to record power broken me of instrument system automatically and

recruit to count the missing flux

Recording function of hour gross, to record the flux gross by hour, fit for timed measure;

4.2 Normal Operang Condions

Ambient Temperature Ranges: –10~+60°C

Relative Humidity: 5%~90%;

Power Supply: 85...250V, 45~63Hz ( single-phase AC) or 20...36VDC

Dissipation Power: < 20W

4.3 Measure Precision

Range (m/s) Accuracy

0,1....0,3 ±0,25 % FS

0,3...1 ±0,5 % R

1...15 ±0,5 % R

EMD-RMTR.. User’s Manual

11

4.4 Digital Frequency Output

Frequency Output Range : 1...5000 Hz

Output Electric Isolate : Photoelectric Isolate > 1000 V

Frequency Output Capacity : Field-effect transistors Output Maximum Voltage: 36V DC

Maximum Current: 250 mA

4.5 Digital Pulse Output

Pulse Output Range : 1... 100 Pulse/s

Pulse Output Value : 0.001-1.000 m3/cp; 0.001-1.000 Liter/cp

Pulse Output Capacity : Field-effect transistors Output Maximum Voltage: 36V DC

Maximum Current: 250 mA

4.6 Alarm output

Alarm Output Juncon : ALMH: Upper Limit; ALML: Lower Limit

Alarm Output Capacity : Field-effect transistors Output Maximum Voltage: 36V DC

Maximum Current: 250 mA

4.7 Digital Communicaon And Protocol

MODBUS interface: RTU; Electric isolate 1000V;

HART interface: be compliant with HART Protocol; Parameters can be set by hand-held device

Profibus

RS232 or RS485

5. OPERATION AND SETUP

5.1 Keys and Display

Compound Down Up Enter

+123,45

FQL m3/h

Σ + 00000524.4 m3

Flow Rate

Flow Rate Unit

Flow Velocity

Percentage

Posive,Negave or Net Total

etc.

Alarm Codes

C

EMD-RMTR.. User’s Manual

12

When measuring, pushing down “Compound Key + Enter” will appear password of changing state, base on

distinction of secrecy, and change the password as we provide. Then pushing “Compound Key + Enter” again,

and you can inter the state of seng parameter. If want to return to the running state, push “Enter” for

several seconds.

6. PARAMETERS SETTING

6.1.1 Keys funcon

a) Keys’ function for self-tesng

: Selecng displayed data on lower line in turn;

: Selecng displayed data on higher line in turn;

+ : Come into parameter seng

: Press it to come into the picture of select funcon.

At measure status, using “Compound” key + “Up” key or “Compound” key + “Down” key for several seconds to

adjust LCD contrast.

b) Funcon keys for parameters seng

“Down” key: Subtract 1 from the number at cursor area;

“Up” key: Plus 1 to the number at cursor area;

“Compound” key + “Down” key: Cursor turns le;

“Compound” key + “Up” key: Cursor turns right;

“Enter” key: Enter/Exit submenu;

“Enter” key: Press for two seconds under any state to return measure status.

It returns to the measure status automatically aer 3 minutes without any acon under parameter setting

status;

C

EMD-RMTR.. User’s Manual

13

6.1.2 Funcon Keys for Parameters Seng

At measuring status, press “Compound” + “Enter” keys geng to the select of parameter and transfer

password (0000), and then reset the password with one of the new passwords that are provided by

manufacturer. Press the “Compound”+“Enter” keys to work in Parameters Seng Way.

There are 6 Passwords in design and Four Passwords for operators, the other Two Password are fixed

passwords for system operaon.

6.1.3 Funcons Select Menu

Press “Compound”+“Enter” keys to the funcons select menu, push “Up” or “Down” keys to select, there are

three funcons:

Code Funcons Notes

1 Parameters Set Enter Parameters Seng

2 Clr Total Rec Total Flow Reset

3 Fact Modif Rec Check the factor’s Modification Record

6.1.3.1 Parameters Set

Press “Compound”+“Enter” key, it displays “Parameters Set” funcon. Input password. Press

“Compound”+“Enter” key, it geng to Parameters Seng status.

6.1.3.2 Clr Total Rec

To push “Compound”+“Enter” keys geng to the select of parameter, then push “Up” key to “Clr Total Rec”,

input the passwords. When the passwords becomes “00000”, this funcon is done, the gross is 0 in the

instrument.

6.1.3.3 Fact Modif Rec

To push “Compound”+“Enter” keys geng to the select of parameter, then push “Up” key to “Fact Modif

Rec”(Detail consult the AppendixFive)

6.1.4 Seng Parameters in Menu

There are 54 parameters of –RM series, user can set every parameter. The List of Parameters is shown below:

Seing Parameters in Menu

Code Parameter words Setng Way Grades Range

1 Language Select 2 English

2 Comm Addres Set count 2 0~99

3 Baud Rate Select 2 600~14400

4 Snsr Size Select 2 3~3000

5 Flow Unit Select 2 L/h、L/m、L/s、m3/h、

m3/m、m3/s

EMD-RMTR.. User’s Manual

14

6 Flow Range Set count 2 0~99999

7 Flow Rspns Select 2 1~50

8 Flow Direct Select 2 Plus/ Reverse

9 Flow Zero Set count 2 0~±9999

10 Flow Cutoff Set count 2 0~599.99%

11 Cutoff Ena Select 2 Enable/Disable

12 Total Unit Select 2

0.001m3~1m3 、

0.001L~1L、

13 SegmaN Ena Select 2 Enable/Disable

14 Analog Type Select 2 0~10mA /4~20mA

15 Pulse Type Select 2 Freque / Pulse

16 Pulse Fact Select 2 0.001m3~1m3 、

0.001L~1L、

17 Freque Max Select 2 1~ 5999 HZ

18 Mtsnsr Ena Select 2 Enable/Disable

19 Mtsnsr Trip Set count 2 59999 %

20 Alm Hi Ena Select 2 Enable/Disable

21 Alm Hi Val Set count 2 000.0~ 599.99 %

22 Alm Lo Ena Select 2 Enable/Disable

23 Alm Lo Val Set count 2 000.0~599.99 %

24 Sys Alm Ena Select 2 Enable/Disable

25 Clr Sum Key Set count 3 0~99999

26 Snsr Code1 User set 4 Finished Y M

27 Snsr Code2 User set 4 Product number

28 Field Type Select 4 Type1,2,3

29 Sensor Fact Set count 4 0.0000~5.9999

30 Line CRC Ena Select 4 Enable/Disable

31 Lineary CRC1 User set 4 Set Velocity

32 Lineary Fact 1 User set 4 0.0000~1.9999

33 Lineary CRC2 User set 4 Set Velocity

34 Lineary Fact 2 User set 4 0.0000~1.9999

35 Lineary CRC3 User set 4 Set Velocity

36 Lineary Fact 3 User set 4 0.0000~1.9999

37 Lineary CRC4 User set 4 Set Velocity

38 Lineary Fact4 User set 4 0.0000~1.9999

39 FwdTotal Lo Correctable 5 00000~99999

40 FwdTotal Hi Correctable 5 00000~9999

41 RevTotal Lo Correctable 5 00000~99999

42 RevTotal Hi Correctable 5 00000~9999

43 PlsntLmtEna Select 5 Enable/Disable

44 PlsntLmtVal Select 5 0.010~0.800m/s

45 Plsnt Delay Select 5 400~2500ms

46 Pass Word 1 User correct 5 00000~99999

47 Pass Word 2 User correct 5 00000~99999

48 Pass Word 3 User correct 5 00000~99999

49 Pass Word 4 User correct 5 00000~99999

50 Analog Zero Set count 5 0.0000~1.9999

EMD-RMTR.. User’s Manual

15

51 Anlg Range Set count 5 0.0000~3.9999

52 Meter Fact Set count 5 0.0000~5.9999

53 MeterCode 1 Factory set 6 Finished Y /M

54 MeterCode 2 Factory set 6 Product Serial No

Parameters of converters can decide the running status, process and output ways as well as state of output.

Correct opon and seng of parameters can keep the converters running opmally and get higher accuracies

of output bother in display and in measurement.

There are 6 grades of passwords for seng parameters funcon. Grades 1 to grade 5 of passwords are for

users and grade 6 of password is for manufacturer. Users can reset their passwords of grades 1 to 4 in grade 5.

Users can check converters parameters in any grade of password. However, if users want to change

parameters pf converters, deferent grade of parameters have to be used by the users.

Grade 1 of password (set by manufacturer as 00521): users can only read parameter.

Grade 2 of password (set by manufacturer as 03210): users can change 1~24 parameters.

Grade 3 of password (set by manufacturer as 06108): users can change 1~25parameters.

Grade 4 of password (set by manufacturer as 07206): users can change 1~38parameters.

Grade 5 of password (Fixed): users can change 1~52 parameters.

Password Grade 5 can be set by skilled users. Grade 4 is mainly used for reseng total volume in password.

Grades 1~3 can be set by any one who can be chosen by users.

6.2 Details Parameters

6.2.1 Language

There are 2 languages for –RM series converter operaon. They can be set by users according to the users

needs.

6.2.2 Comm Addres

It means this instrument’s address when communicates with many, and has 01~99, holding the 0.

6. 3.3 Baud Rate: 600, 1200, 2400, 4800, 9600, 19200

6.3.4 Snsr Size: 3mm to 3000mm

6.3.5 Flow unit: (L/s、L/m、L/h、m3/s、m3/m、m3/h)

6.2.6 Flow Range (Change this value will affect other parameters or output)

Flow range means upper limit value, and lower limit value is set “0” automacally.

Pulse output will not affect.

EMD-RMTR.. User’s Manual

16

FS = ○ ○ ○ ○ ○

± ○ ○ ○ ○ ○

6.2.7 Flow Rspns

It means me of filter measure value. The long one can enhance the stability of flow display and output

digital, and fits for gross add up of pulse flow; the short one means fast respond rate, and fits for producon

control.

6.3.8 Flow Direct

If users think the direct and design are differ, just change the direct parameter is OK, but not change

excing or signal.

6.2.9 Flow zero

Make sure the sensor is full of flow, and the flow is sllness. Flow zero is shown as velocity of flow, mm/s.

Converter’s zero-flow correction displays as below:

Upper small words: FS means measure value of zero;

Lower large words: correcon value of zero.

When FS is not “0”, please set FS = 0.

Note: if change the value on next line and FS increases, please change the “+, -” to correct FS to zero.

Flow zero is the compound value of the sensor, and should be recorded in sensor list and band. The unit

will be mm/s, and the sign will be opposite with correcon value.

6.2.10 Flow cutoff

Flow cutoff is set in percentage of Upper Limit Range of flow, and users can delete all Negligible Small

Signals of flow volume, velocity and percentage out of displaying and outpung them. Somemes user can

delete output of current output signal and frequency (pulse) output signal only to have flow, velocity and

percentage being displayed.

6.2.11 Total Unit

Converter display is counter with 9 bits, and the max is 999999999.

Flow integrator value: 0.001L, 0.010L, 0.100L, 1.000L

0.001 m3, 0.010m3, 0.100 m3, 1.000 m3;

EMD-RMTR.. User’s Manual

17

6.2.12 SegmaN Ena

When “SegmaN Ena” is “enable”, if the flow flows, the sensor will export pulse and current。When it is

“disable”, the sensor will export pulse as “0” and current as “0”(4mA or 0mA) for the flow flows reversals.

6.2.13 Output currents

0~10mA or 4~20mA is available

6.2.14 Analog Type

Frequency Output and Pulse Output.

Frequency Output is connuous square waveform and Pulse output is a serial wave of square wave. Frequency

Output is mainly used for instant flow and total integrated flow in short me measurement. Frequency output

can be chosen in equivalent frequency unit and volume of integrated flow can be displayed. Frequency Output

can be used in long me measurement for total integrated flow with volume units.

6.2.15 Pulse Type

Frequency output and pulse output are usually from OC gates so that DC power supplies and load resistors

have to be required

6.2.16 Pulse Fact

Equivalent pulse Unit is referred to one pulse for corresponding flow. The range of pulse equivalent can be

chosen:

Pulse Equivalent Flow Pulse Equivalent Flow

1 0.001L/cp 5 0.001m3/cp

2 0.01L/cp 6 0.01m3/cp

3 0.1L/cp 7 0.1m3/cp

4 1.0L/cp 8 1.0m3/cp

Under the same flow, the smaller pulse, the higher frequency output, and the smaller error will be. The highest

pulse output is 100cp/s, and mechanism electromagnec counter can get 25 frequency/s.

6.2.17 Freque Max

Frequency output range is as the upper limit of flow measure, just the percent flow 100%. Frequency output

upper limit can be selected between 1~5000Hz.

6.2.18 Mtsnsr Ena

The state of empty pipe can be detected with the funcon of converter. In the case of Empty Pipe Alarm, if the

pipe was empty, the signals of analog output and digital output would be zero and displayed flow would be

zero.

EMD-RMTR.. User’s Manual

18

6.2.19 Mtsnsr Trip

When the pipe is full of liquid (whether flowing or not), the parameter of “Mtsnsr” could be modified more

easily. The parameter displayed upper line is real MTP, and the parameter displayed bellow is the “Mtsnsr

trip” that should be set. When seng “Mtsnsr trip”, you could be according to the real MTP, the value that

should be set is usually three to five mes of real MTP.

6.2.20 Alm Hi Ena

Users can choose “Enable” or “Disable”.

6.2.21 Alm Hi Val

The parameter of upper limit alarm is percentage of flow range and can be set in the way of seng one

numerical value between 0%~199.9%.When the value of flow percentage is larger than the value of seng

value, the converter outputs the alarm signal.

6. 2.22Alm Lo Val

The same as upper limit alarm.

6.2.23 Sys Alm Ena

Selecng Enable will have the funcon, and selecng Disable will cancel the funcon.

6.2.24 Clr Sum Key

User use more than 3 byte code to enter ,Then set this password in Clr Total Rec.

6.2.25 Snsr Code

It is referred to the produced date of sensor and the serial number of product that can keep the sensors

coefficient right and accurate.

6.2.26 Sensor Fact

“Sensor Coefficient” is printed on the Label of the sensor when it is made in factory. The “sensor coefficient”

has to be set into Sensor Coefficient Parameter when it runs with converter.

6.2.27 Field Type

affords three excing frequency types: 1/16 frequency (type 1), 1/20frequency (type 2), 1/25 frequency (type

3)。 The small-bore one should use 1/16 frequency, and large-bore one should use 1/20 or 1/25 frequency.

When using, please select type 1 first, if the zero of velocity is too high, select the type 2 or type 3.

Note: Demarcate on which excing type, working on it only.

EMD-RMTR.. User’s Manual

19

6.2.28 FwdTotal Lo, hi

Posive total volume high byte and low byte can change forthcoming and reverse total value, and be used to

maintenance and instead.

User use 5 byte code to enter, and can modify the posive accumulang volume (∑+). Usually, it is unsuitable

to exceed the maximum the counter set(999999999).

6.2.29 RevTotal Lo、hi

User use 5 byte code to enter, and can modify the negave accumulang volume (∑-). Usually, it is unsuitable

to exceed the minimum the counter set(999999999).

6.2.30 PlsntLmtEn

For paper pulp, slurry and other serosity, the flow measure will have "cuspidal disturb", because the solid grain

friction or concussion the measure electrode. -RM converters

use variaon restrain arithmec to conquer the disturbing by designing three parameters to select disturb

character .

Set it "enable", start variaon restrain arithmetic; set it "disable", close variaon restrain arithmetic.

6.2.31PlsntLmtVl

This coefficient can disturb the variaon of cuspidal disturb, and calculate as percent of flow velocity, thus ten

grades: 0.010m/s, 0.020m/s, 0030m/s, 0.050m/s, 0.080m/s, 0.100m/s, 0.200m/s, 0.300m/s, 0.500m/s,

0.800m/s, and the smaller percent, the higher delicacy of cuspidal restrain.

Note: when using it, must test for select by the fact, and somemes it is not the higher delicacy is good.

6.2.32 PlsntDelay

This coefficient can select the width of me of restrain cuspidal disturb and the unit is ms. If the duraon is

shorter than flow change in some me, –RM series will think it is cuspidal disturb, and if it is longer, –RM series

will think it is natural. It also needs to select parameter in fact.

6.2.33User’s password 1~4

Users can use 5 grades of passwords to correct these passwords.

6.2.34 Analog Zero

When the converters are made in the factory, output current has been calibrated to zero scale, that is,

accurate 0mA or 4mA output.

6.2.35 Anlg Range

When the converters is made in the factory, output current have been calibrated to full scale, that is, accurate

10mA or 20mA output.

6.2.36Meter Fact

This fact is the special one of sensor-made-factory and the factory use this fact to unite –RM series

electromagnec flowmeters converters to make sure all the instruments can interchange by 0.1%.

EMD-RMTR.. User’s Manual

20

7. ALARM INFORMATION

–RM series intelligent converters have self-diagnose funcon. Without trouble of power and hardware circuit,

the normal trouble can be alarmed correctly. This informaon displays on the le of LCD. The explanaon

of Alarm as below:

FQH: High flow limit alarm;

FQL: low flow limit alarm;

FGP: empty pipe alarm;

SYS: System excing alarm

8. TROUBLESHOOTING

Symptom Probable Cause Soluon

No Display

1. No power Apply correct power

2. Fuse blown Replace a fuse with same parameter

3. Contrast of LCD is too low Increase the contrast

Empty Pipe Alarm

1. Fluid is not full filled the pipe Increase the flow rate

2. Electrode was polluted Clean the electrode if voltage of DS1 and DS2 > 1V.

3. Fluid’s conducvity is too small

If connect three terminals SIG 1, SIG 2, SIGGND. and

the alarm disappears, which means the fluid’s

conducvity is small.

Replace other kind of flowmeter

Flow rate indication is

unstable

1. Grounding issue Make sure meter is properly grounded to a good

earth ground

2. Air Make sure fluid does not contain air bubbles

3. Converter locaon – outside electrical

interference

Make sure Converter is not too close to sources of

electrical interference

Table of contents

Other Bass Measuring Instrument manuals