Bastian Solutions RLVAC Manual

Installation and Maintenance Manual

Model: RLVAC

Effective February 2022

Rev. B

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

2

Contributions

ROLE

NAME

TITLE

Author

Ben Baker

Senior Design Engineer

Checker

Brad Paris

Senior Design Engineer

Approver

Sam Osterhout

Design Team Lead

Revisions

DATE

REVISION

DESCRIPTION

AUTHOR

11/18/2021

A

Initial Document Creation

Ben Baker

2/18/2022

B

Document Formatting Edits

Andrew W. Jones

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

3

Term and Acronym Definitions

TERM/ACRONYM DEFINITION

2 Groove

Roller format which uses O-Rings to transfer rotational motion from one roller to

another in DC conveyor.

AC

Alternating current

Accumulation

The collection or staging of multiple cartons, cases, or totes of product on conveyor.

ATO

Assembled to Order; Orders consisting of standard products

Back pressure

Pressure against carton(s) in the direction of carton flow resulting from weight of

densely accumulated cartons.

BF

Between frame; this refers to the distance between conveyor bed side frames.

BHCS

Button head cap screw

BOM

Bill of Materials

Carton or Case

Term for a conveyable item (cardboard box, tote, etc.)

CB

Carriage bolt

CCW

Counter-clockwise

CDAC 1.0

Conveyor Director Control Card 1.0 - Bastian Solutions' dual zone control card designed

for zero pressure control of low-voltage (24V nominal) DC solenoids for belt-under

roller conveyor.

CDDC 1.0

Conveyor Director Control Card 1.0 - Bastian Solutions' dual zone control card designed

for zero pressure control of low-voltage (24V or 48V nominal) DC powered MDRs.

Center Drive

Drive format of AC conveyor where the drive unit is mounted underneath the

conveyor.

CW

Clockwise

DC

Direct current

Diffuse

A photoeye format that houses both the emitter and receiver and senses an object

when the light beam is reflected back to the sensor. This type of photoeye is a

standalone unit and does not use reflectors.

Discharge

The point where cartons, cases, or totes exit a conveyor or similar unit used in a

material handling system.

Divert

(noun) A conveyor unit used to change the direction of a carton, case, or tote in a

controlled manner. (verb) To change the direction of a carton, case, or tote in a

controlled manner.

Double-dispense

Event in which two or more cartons are dispensed when a single carton, case, or tote is

requested. This is generally a result of two cartons, cases, or totes being in full contact

just prior to reaching the dispensing point.

Drive Card

A control card used to power and control the logic of one or more zones of zero

pressure conveyor.

Drive Pulley

A motor-driven pulley used to transmit rotational energy to linear motion in AC belts.

Dutchman

A short, removable section of belt used to take up slack developed in AC belts after

they have stretched from long term use.

End stop

A plate mounted to the end of a conveyor with the intent of stopping and holding a

carton, case, or tote in position until removed by a user or diverted by a conveyor unit.

E-stop

A highly visible button or pull cable designed to shut down equipment in the case of an

emergency.

ETO

Engineered to Order; Orders requiring custom Engineering

FAT

Factory Acceptance Testing

Flange

A feature in sheet metal consisting of a face and bend connected to an existing face

along a straight edge.

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

4

Flash

Excess material left on a part by a molding or forming process, created by material

leaking between the separate parts of the mold.

Gapping

The separation of cartons, cases, or totes. Generally done by progressively increasing

the speed of consecutive zones or belts, forcing cartons, cases, or totes to "pull a gap."

Guide Rail

Mechanism used to maintain the desired position of conveyable cartons, cases, or

totes on their respective conveying surface.

HHCS

Hex head cap screw

ID

Inner diameter of a circular, cylindrical or arced body.

Idler Roller

Conveyor roller that is unpowered and used to support a belt.

Infeed

The point where cartons, cases, or totes enter a conveyor or similar unit used in a

material handling system.

Live

A conveyor or zone which runs in response to a simple “enable” signal or runs

whenever power is applied, without any zero pressure accumulation logic.

LOTO Lockout Tagout

Mark Number

A numeric or alphanumeric term used to uniquely identify a conveyor bed or collection

of beds (of similar model type) within a material handling system.

Match

A mark made on mating conveyor assemblies to assist in identifying orientation and

placement within a system.

MDR

Motorized drive roller; DC powered conveyor roller with an internally mounted motor

which may be controlled via internal or external commutation.

Minimum Pressure

Allows cartons, cases, or totes to lightly touch with up to 2% back pressure while being

conveyed to eliminate product damage.

OAW

Overall width of any given conveyor bed, measured between the outside flanges of the

sideframes.

OD

Outer diameter of a circular, cylindrical, or arced body.

O-Ring

A urethane ring or band with a circular cross section used for power transmission in DC

conveyor applications.

OSHA

Occupational Safety and Health Administration

PE

Photoeye; Device used to detect the presence of an object by sensing a light beam.

Common types are diffuse, retroreflective, and through-beam.

PELV

Protected Extra Low Voltage, a voltage level (less than 60V DC or 25Vrms AC in the

context of EN 60204-1) that is low enough to be safe in the case of indirect or small

area direct contact. PELV circuits are required to be connected to earth ground.

PM

Project Management (or Project Manager)

PO

Purchase Order

Polytier

Heavy duty floor support with a wide stance, capable of supporting multiple levels and

types of conveyor.

PPE

Personal protective equipment

Prox Sensor

A sensor able to detect the presence of nearby objects without any physical contact.

Pulley

Mechanical device used to change the direction of the belt in a conveyor system, to

drive and/or tension the belt.

Reflector

A reflective component needed for retroreflective photoeyes to receive transmitted

light or radiation when no object is in front of the photoeye.

Retroreflective

Of or relating to a surface or device that reflects light or other radiation back to its

source.

Return Idlers

Belt-routing rollers on the underside of any given AC conveyor.

RLCAC

Roller Live Curve AC

RLSAC

Roller Live Spur AC

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

5

Roller

Powered or unpowered cylindrically-shaped material handling component used for

mechanical power transmission, a conveying surface, and/or support for a belted

conveying surface.

Shingling

Event in which surfaces of adjacent cartons, cases, or totes are forced to lift off the

conveyor due to elevated uneven carton, case, or tote back pressure.

Side Frame

Structural member used to support rotating components needed for conveyor beds.

Singulation

The active separation of cartons, cases, or totes.

Skatewheel

Small unpowered wheels used to replicate nearly frictionless guidance or support of

conveyable cartons, cases, or totes.

Skew

A format of conveyor where one end of all rollers are shifted to provide an angled

conveying surface for left or right justification of cartons, cases, or totes.

SKU

Stock Keeping Unit; Product and service identification code for a product (i.e. bar

code).

Slug Release

See Train Release.

Snub Roller

A roller or pulley mounted to increase the arc of contact between a belt and drive

pulley. Additionally, this can be used to change the direction of the return belt travel.

Splice Assembly

A five-component assembly-consisting of a plate (or formed plate), two bolts, and two

nuts-that is used to secure a piece of guide rail to an adjacent piece of guide rail, or a

side frame to an adjacent side frame. This is used to provide additional structural

rigidity and ensure relative position of components is maintained.

Spur

A format of DC conveyor used to create linear transitions into intersecting lines of

conveyor positioned at a non-perpendicular angle. Typically includes 30deg and 22deg

configurations.

Tail Pulley

A non-driven pulley located at the tail end of the conveyor.

Takeup Pulley

Pulley with an adjustable position used to eliminate unnecessary slack in a belt.

Takeup Screws

Adjustment screw used to adjust the position of a takeup pulley.

TOR

Top of roller; this refers to the elevation of the conveying surface with respect to the

floor on which the conveyor is sitting.

Track

To adjust the position of conveyor components in such a way that engourages proper

belt alignment on a system.

Tracking Bands

Thin plastic bands installed on head or secondary drive roller to help keep DC format

conveyor belts tracked.

Train Release

The release or activation of all zones in a line of accumulating conveyor at the same

time.

UHMW

Ultra-high molecular weight polyethylene plastic, used to reduce friction and wear.

Waterfall

Method of overlapping guide rail such that cartons, cases, or totes cannot catch on

downstream guide rail.

Wiz Nut

A serrated flange nut used to cut into the surface of the component it is tightened

against.

Zero Pressure

Condition where adjacent cartons, cases, or totes are not in contact with one another.

Zone

A section of conveyor that can be independently controlled for the purposes of zero

pressure accumulation.

ZPA

Zero Pressure Accumulation; a method of collecting, staging, and/or transporting

multiple cartons, cases, or totes on zoned conveyor without the products touching

each other.

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

6

Table of Contents

1Introduction........................................................................................................... 10

2OSHA and Safety .................................................................................................. 10

3Model: RLVAC....................................................................................................... 11

3.1 Overview ...............................................................................................................................11

3.2 Belt........................................................................................................................................11

3.3 Drive Section ........................................................................................................................11

3.4 Tails ......................................................................................................................................13

3.5 Intermediate Beds ................................................................................................................13

3.6 Skew Beds............................................................................................................................ 14

4Receiving............................................................................................................... 15

4.1 Mark Numbers ...................................................................................................................... 15

4.2 Skid Contents.......................................................................................................................15

4.3 Skid Documentation............................................................................................................. 16

5Installation............................................................................................................. 17

5.1 Layout................................................................................................................................... 17

5.2 Setting the Conveyor ...........................................................................................................17

5.3 Pressure Assembly Installation........................................................................................... 18

5.4 Leveling and Straightening.................................................................................................. 19

5.5 Installing the Belt .................................................................................................................20

5.5.1 Belt Routing: Screw Takeup Drive ...................................................................................... 21

5.5.2 Belt Routing: Pneumatic Takeup Drive................................................................................ 23

5.5.3 Belt Routing: Skewed Beds ................................................................................................24

5.5.4 Belt Hot Splicing ................................................................................................................. 25

5.6 Installing Return Rollers ......................................................................................................30

5.7 Belt Tracking Zones ............................................................................................................. 31

5.8 Drive Pressure Adjustment.................................................................................................. 34

5.9 Power Take-Off..................................................................................................................... 35

5.10 Electrical Installation............................................................................................................35

5.10.1 AC Motor Installation ..........................................................................................................35

5.11 Accessories.......................................................................................................................... 36

5.12 Belt Tensioning and Tracking.............................................................................................. 36

5.12.1 Screw Takeup Drives .........................................................................................................36

5.12.2 Pneumatic Takeup Drives................................................................................................... 38

5.12.3 Belt Tracking Principles ......................................................................................................39

6Maintenance and Operation................................................................................. 42

6.1 Safety During Operation ...................................................................................................... 42

6.2 Maintenance Schedule......................................................................................................... 42

6.3 Fastener Torque ................................................................................................................... 44

6.4 Belt Replacement .................................................................................................................44

6.5 Screw Takeup Drive ............................................................................................................. 45

6.5.1 Drive Motor Replacement ...................................................................................................45

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

7

6.5.2 Drive Pulley Replacement................................................................................................... 46

6.5.3 Takeup Pulley Replacement ............................................................................................... 47

6.5.4 Takeup Spring or Guide Tube Replacement ....................................................................... 47

6.5.5 Idler Roller Replacement .................................................................................................... 48

6.5.6 Bearing Replacement and Maintenance ............................................................................. 48

6.6 Pneumatic Takeup Drive...................................................................................................... 48

6.6.1 Drive Motor Replacement ...................................................................................................48

6.6.2 Drive Pulley Replacement................................................................................................... 49

6.6.3 Takeup Pulley Replacement ............................................................................................... 50

6.6.4 Takeup Chain and Sprocket Replacement and Maintenance .............................................. 51

6.6.5 Idler Roller Replacement .................................................................................................... 52

6.6.6 Bearing Replacement and Maintenance ............................................................................. 52

6.6.7 Air Cylinder Replacement ................................................................................................... 53

6.6.8 Air Regulator Replacement and Maintenance ..................................................................... 53

6.7 Tail ........................................................................................................................................54

6.7.1 Tail Pulley Replacement ..................................................................................................... 54

6.7.2 Tail Snub Replacement ......................................................................................................54

6.7.3 Bearing Replacement and Maintenance ............................................................................. 55

6.7.4 Roller Replacement ............................................................................................................55

6.7.5 Band Replacement .............................................................................................................55

6.8 Modules ................................................................................................................................55

6.8.1 Bed Roller Replacement.....................................................................................................56

6.8.2 Pressure Roller Replacement .............................................................................................56

6.8.3 Pressure Spring Replacement ............................................................................................ 56

6.8.4 Guide Bushing Replacement .............................................................................................. 56

6.9 Skew Beds............................................................................................................................ 57

6.9.1 Skew Roller and Band Replacement................................................................................... 57

6.9.2 Routing Roller Replacement ...............................................................................................57

6.10 Accessories.......................................................................................................................... 57

6.10.1 PTO ...................................................................................................................................57

6.10.2 Tracking Zones...................................................................................................................57

6.10.3 Return Roller Replacement................................................................................................. 58

7Troubleshooting and Repair................................................................................ 59

8Appendix 1: Standard Gearmotor Options......................................................... 62

9Appendix 2: General Arrangement Drawings .................................................... 64

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

8

List of Figures

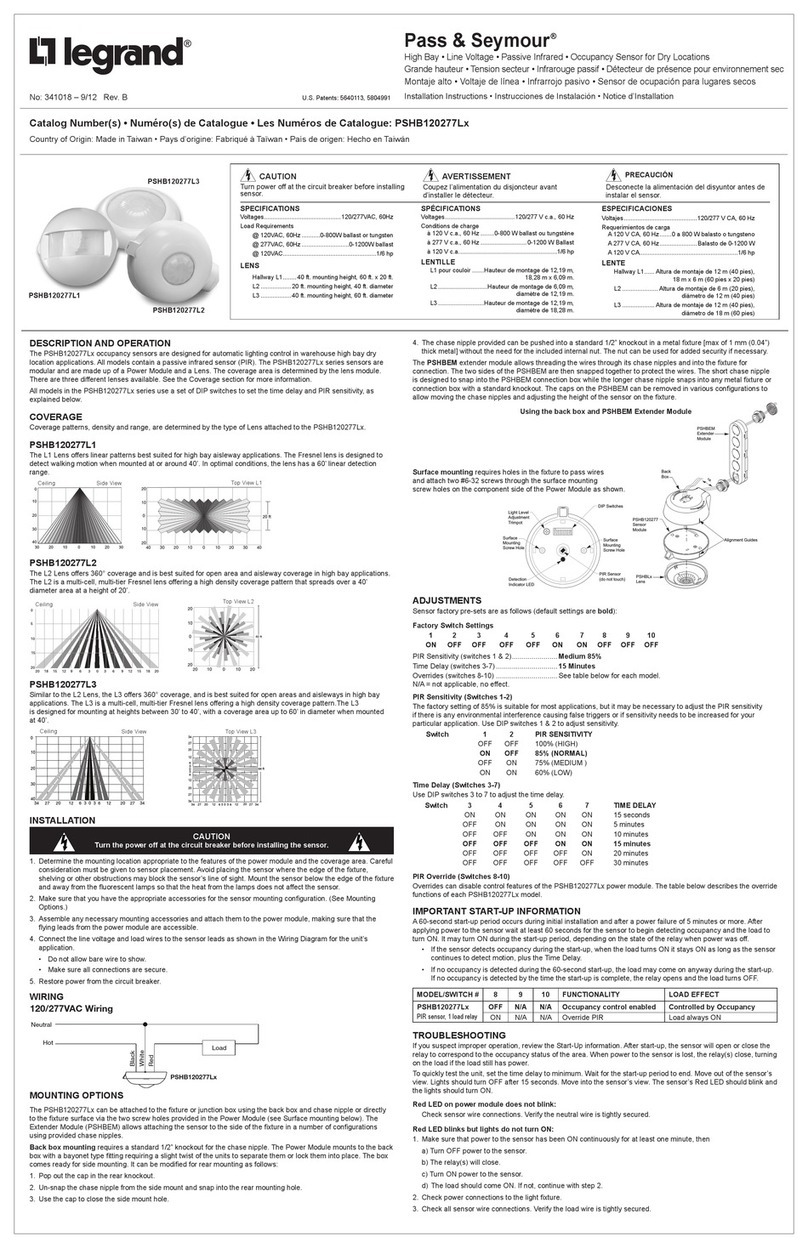

Figure 1: RLVAC Overview.................................................................................................................... 11

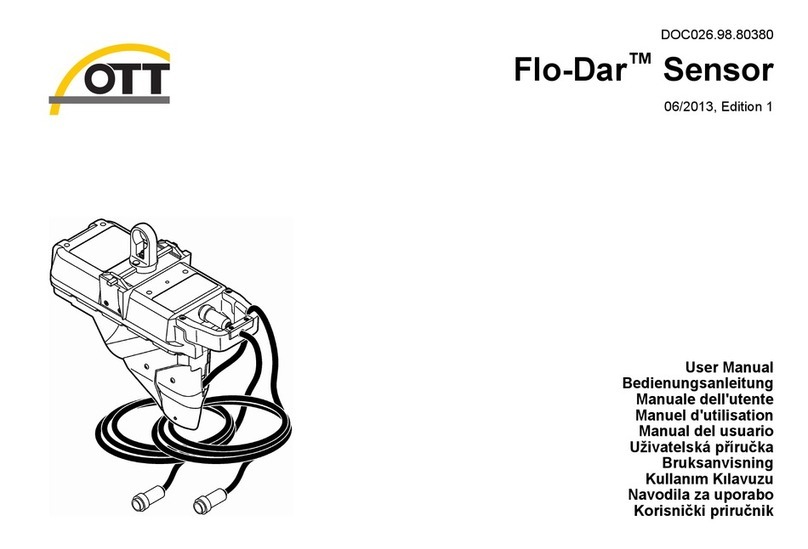

Figure 2: Screw Takeup Drive Overview ................................................................................................12

Figure 3: Pneumatic Takeup Drive Overview ......................................................................................... 13

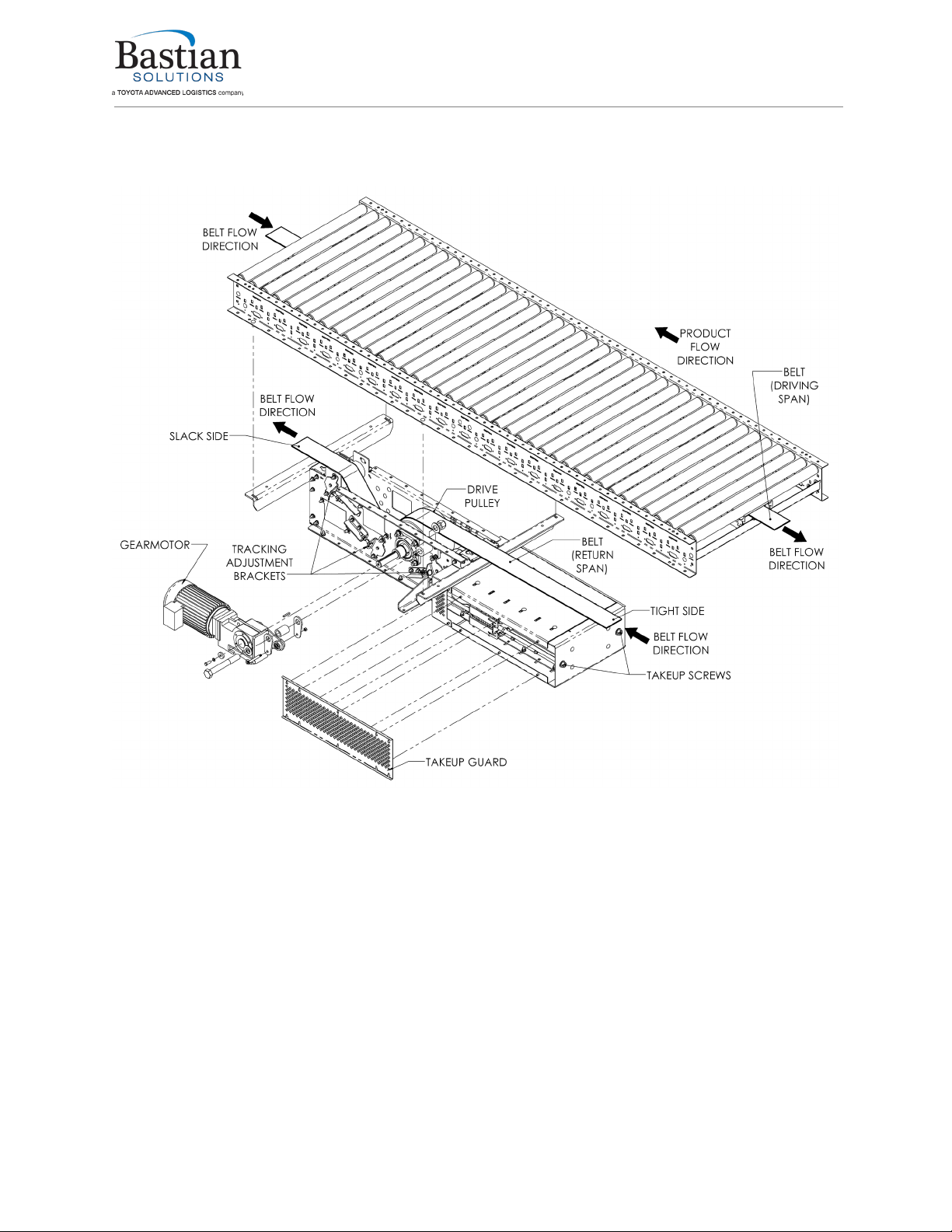

Figure 4: RLVAC Intermediate Bed Exploded View ................................................................................ 14

Figure 5: Mark Number Stickers.............................................................................................................15

Figure 6: Skid Sticker.............................................................................................................................16

Figure 7: Floor Support and Splice Plate Installation .............................................................................. 18

Figure 8: Pressure Assembly Installation Detail...................................................................................... 19

Figure 9: Skew Transition Pressure Assembly Detail ............................................................................. 19

Figure 10: Tail Belt Routing ...................................................................................................................21

Figure 11: Belt Lacing............................................................................................................................ 21

Figure 12: Screw Takeup Drive Overview .............................................................................................. 22

Figure 13: Screw Takeup Drive Belt Routing.......................................................................................... 22

Figure 14: Pneumatic Takeup Drive Overview........................................................................................ 23

Figure 15: Pneumatic Takeup Drive Belt Routing ................................................................................... 24

Figure 16: Skewed Bed Belt Routing......................................................................................................24

Figure 17: Belt Splice Alignment ............................................................................................................ 27

Figure 18: Completed Belt Splice........................................................................................................... 28

Figure 19: Return Roller Module Installation Detail................................................................................. 30

Figure 20: Pressure Roller Locations for 2”RC Pressure Modules .......................................................... 32

Figure 21: Pressure Roller Locations for 3”RC Pressure Modules .......................................................... 33

Figure 22: RLVAC Intermediate Bed Tracking Roller Details .................................................................. 34

Figure 24: Screw Takeup Drive Belt Routing..........................................................................................37

Figure 25: Tension Indicators.................................................................................................................38

Figure 25: Belt Tracking by Adjusting Snub Rollers ................................................................................ 41

Figure 26: Chain Pitch Measurement ..................................................................................................... 51

Figure 27: General Arrangement, RLVAC Bed Section, Sheet 1 of 2...................................................... 65

Figure 28: General Arrangement, RLVAC Bed Section, Sheet 2 of 2...................................................... 65

Figure 29: General Arrangement, RLVAC Tail, Sheet 1 of 1................................................................... 65

Figure 30: General Arrangement, Belt Under Roller AC, Pneumatic Takeup Drive, Sheet 1 of 1............. 65

Figure 31: General Arrangement, Belt Under Roller AC, Screw Takeup Drive, Sheet 1 of 1.................... 65

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

9

List of Tables

Table 1: Reference Documents ...............................................................................................................9

Table 2: Belt Hot Splicing Tools .............................................................................................................25

Table 3: Belt Hot Pressing Parameters .................................................................................................. 27

Table 4: Return Roller Positions for Intermediate Beds .......................................................................... 31

Table 5: Pneumatic Takeup Pressure Settings....................................................................................... 39

Table 6: Recommended Preventative Maintenance Schedule................................................................ 43

Table 7: Fastener Standard Torque Values............................................................................................ 44

Table 8: Troubleshooting Guide ............................................................................................................. 59

Table 9: Standard Gearmotors with 1.250in Output................................................................................ 62

Table 10: Standard Gearmotors with 1.500in Output.............................................................................. 63

Table 11: RLVAC General Arrangement BOM ....................................................................................... 64

Reference Documents

Table 1: Reference Documents

MANUFACTURER

MANUAL

Bastian Solutions

Conveyor Director AC User Manual

Bastian Solutions

Side Cover and Guiderail Installation Manual

Bastian Solutions

Support Installation Manual

Bastian Solutions

RLCAC Installation and Maintenance Manual

Bastian Solutions

RLSAC Installation and Maintenance Manual

Habasit Holding

AG Habasit Fabric Conveyor Belts Installation and Maintenance Guide (6040)

ABB Motors and

Mechanical Inc Dodge Quantis RHB Installation and Maintenance Instructions (499322)

ABB Motors and

Mechanical Inc

Instruction Manual for DODGE® Setscrew, Eccentric Collar, D-Lok, H-E Series,

E-Z Kleen, Ultra Kleen and Food Safe Mounted Ball Bearings (MN3016)

ProCal

Innovations, LLC

(PCI)

INSTALLATION INSTRUCTIONS: XT®, QD®, HE & TAPERLOCK® BUSHINGS

(31905)

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

10

1 Introduction

Thank you for choosing Bastian Solutions Conveyor. The following manual serves as a guide for

installation, part replacement, and general maintenance for your material handling equipment. It is

important to read the manual and follow any instructions as it provides important safety information for

personnel and will maximize the longevity of the conveyor.

The information contained in this manual applies only to the products described. Uses, activities, or

processes related to installing or maintaining the equipment that are not explicitly described in this

manual are considered out of scope. Please contact Bastian Solutions Conveyor for any questions or

support that is not clearly addressed in this document. Bastian Solutions Conveyor is not responsible for

misuse of the equipment described in this manual or misuse of information in this manual. If you have any

questions, contact Bastian Solutions Conveyor Customer Service or Support at

ConveyorSupport@BastianSolutions.com.

2 OSHA and Safety

Bastian Solutions Conveyor is not responsible for ensuring that conveyors used in a system abide by

OSHA standards. Safety is of primary importance to our company, but as a product distributor we ask that

system integrators and end users conform with all applicable OSHA standards. We encourage that all

warnings in this manual are followed to avoid unnecessary risk.

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

11

3 Model: RLVAC

3.1 Overview

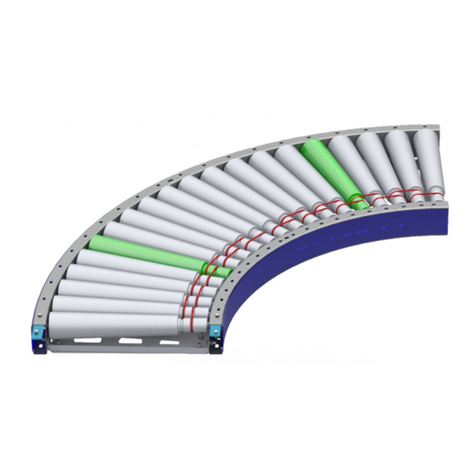

The Roller Live AC (RLVAC) conveyor is designed for longer runs of transport conveyor in applications

which require rollers instead of belted transport. RLVAC uses a continuous belt under the conveying

rollers driven by an AC gearmotor, which is engaged with the various conveying zones by means of

adjustable spring tension.

Figure 1: RLVAC Overview

3.2 Belt

The main conveying belt is 99mm wide and is available with two different joining options.

The laced belt is quick to install and quick to repair, and does not require special tools or expertise with

the lacing factory installed. It is well suited for any conveyors within its load capacity (light to medium

product loads, or heavy loads on shorter conveyors).

The hot-spliced belt requires special tools and skills to create splices, and cannot be installed or replaced

as rapidly due to the minimum time for the splices to heat and cool. However, it is a more durable option

that is necessary for very heavy loads (working strength of the hot splice is about 2.7 times the working

strength of the lacing) and is maintenance-free for the life of the belt. The hot-spliced belt is also quieter

because there is no metal lacing contacting the conveying rollers.

3.3 Drive Section

Two different drive designs are available for RLVAC conveyors. The screw (fixed) takeup drive is the least

expensive option and is available for conveyor lengths up to 100 ft and total product loads up to 1050 lbs

with a laced belt or 3200 lbs with a hot-spliced belt. Because the screw takeup drive is manually

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

12

tensioned, it requires periodic tension adjustment as the belt elongates. See Table 6: Recommended

Preventative Maintenance Schedule in section 6.2 for the required belt retensioning frequency.

The pneumatic takeup drive offers a low-maintenance automatic tension adjustment and a longer belt

takeup distance for conveyor lengths up to 200 ft, or heavily-loaded conveyors. Since the pneumatic

takeup automatically adjusts belt tension based on the conveyor load, it can handle heavier total product

loads, up to 1900 lbs with a laced belt or 4100 lbs with a hot-spliced belt.

Figure 2: Screw Takeup Drive Overview

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

13

Figure 3: Pneumatic Takeup Drive Overview

3.4 Tails

The RLVAC tail section is a 36” conveyor section that contains the tail pulley and a snub roller. The tail

sections are always placed as the first and last bed sections in an AC mark number. Rollers in the tail

section are banded together to transmit power from the live zone in the section to the rollers above the tail

pulley.

Optional power takeoff (PTO) timing pulleys may also be installed on a tail section to drive an additional

conveyor section from the belt of the RLVAC conveyor.

3.5 Intermediate Beds

Intermediate beds contain one or more live roller zones and modules. An intermediate bed consists of

conveying rollers on the top, with pressure rollers mounted in modules below. The belt will be routed

between the conveying rollers and the pressure rollers during installation. See Figure 4: RLVAC

Intermediate Bed Exploded View for details.

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

14

Figure 4: RLVAC Intermediate Bed Exploded View

3.6 Skew Beds

Skew beds are a specific type of intermediate bed with a deeper sideframe. Instead of driving the

conveying rollers directly, the belt drives intermediate idler rollers which are each banded up to several

skewed conveying rollers. The start and end of the skew section contain short sections of straight banded

conveyor which is banded to the bed section before or after the skewed section, to allow for the routing

pulleys that redirect the belt. This arrangement prevents tracking and belt wear issues that would be

caused if the belt ran directly on the skewed conveying rollers.

Other than the difference in roller spacing caused by the extra layer of rollers, the modules in a skew bed

function the same way as in any other intermediate live bed.

Skew beds are always oriented to skew the product away from the band side.

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

15

4 Receiving

Upon delivery of any Bastian Solutions conveyor, please review and check the following:

•The quantity of items received against the Bill of Lading.

•Complete a visual inspection of equipment to determine any damage that may have occurred

during shipping. If damage is present, document with pictures.

•Review Mark Number information and layout locations. More information can be found in

subsection 4.1.

If there are any missing or damaged components contact your Bastian Solutions Conveyor representative

with as much detail as possible. If you are unsure of your Bastian Solutions Conveyor representative,

please contact Customer Service at ConveyorSupport@BastianSolutions.com.

4.1 Mark Numbers

A mark number is a specific number given to a piece of equipment. A mark number is usually made up of

a single product line (RZPDC, RLVDC, BZPDC, etc.) but can contain many bed section lengths. They can

range from two inches to hundreds of feet. The mark number is used to help identify where the piece of

equipment will go within the system layout.

Every bed section of conveyor will have (2) stickers. One sticker on the infeed end of the bed, and one

sticker on the discharge end of the bed. Each sticker will contain the following information:

•BSC Project Number and Name

•Model Type

•Mark Number

•Match

•Piece

•Flow

Figure 5 shows stickers that would appear on an RZPDC that has two bed sections.

The match field on the stickers is used to indicate if two bed sections are to be spliced to one another. As

shown in Figure 5, the stickers where the two beds splice together both contain “Match: 1”. The piece

field defines the bed section number within the mark. The flow refers to the direction of product flow along

the conveyor system.

4.2 Skid Contents

Skids will contain varying combinations of conveyor sections, support structures, accessories, and

pertinent hardware. For protection of product integrity during shipping, accessories and supports may be

delivered on separate but labeled skids.

Figure 5: Mark Number Stickers

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

16

4.3 Skid Documentation

All shipments will contain a Bill of Lading for the delivery company, a skid label, and a skid manifest. Skid

labels have the contents of each shipped item located on the skid. Figure 6 shows a sample of a skid

label. These stickers are placed on the surface of each skid.

RLVAC conveyor may arrive in multiple skids for the same mark number. The number of skids shipped is

dependent on the OAW and OAL of the mark number.

Upon receiving the skid on site, please inspect for any visual damage of the equipment. If there are any

damages, please contact your BSC representative with images and details of the skid.

Figure 6: Skid Sticker

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

17

5 Installation

5.1 Layout

The installation supervisor on site should have the elevation and layout prints with detailed information

regarding the placement of conveyor sections and support structures. This information is not the

responsibility of Bastian Solutions Conveyor to provide unless otherwise specified.

1. Clear the workspace around the portion of the layout selected for installation.

2. Ensure that the conveyor and accessory skids containing the correct RLVAC mark number are

unpacked and all components are accounted for.

3. Measure out from the constrained origin to start placement of supports. It is recommended that

snap chalk lines are used, or other methods of keeping a consistent line.

A straight and level installation is crucial to proper belt tracking. The extra time spent

creating an accurate layout will more than pay for itself in time saved during belt

tracking and troubleshooting.

4. Use the elevation layouts to determine the top of conveyor surface and the incline/decline angle

of a mark section.

5. Place the support type that the layout designates.

6. Check the approximate height of each support and adjust if necessary. Final heights will be set

after the supports and conveyor are installed.

5.2 Setting the Conveyor

1. Check the flow direction on the mark stickers to ensure that conveyor is installed in the correct

order and that each section is facing the correct direction.

2. Starting from one end, place the conveyor onto the support structure and fasten with 3/8”-16

carriage bolts and serrated flange nuts.

3. Install a splice plate underneath each top flange at the bed break with 5/16”-18 hex bolts and

serrated flange nuts. Use the splice plate to align the mating sideframes vertically and

horizontally. See Figure 7: Floor Support and Splice Plate Installation.

4. At each section break, install a pressure assembly. See section 5.3 for details.

5. Before moving on to the next section, torque the 5/16” splice plate fasteners to 17 ft-lb and the

3/8” floor support fasteners to 31 ft-lb.

Do not lift the drive section of the conveyor using the lifting lug on the AC motor and

gearbox. This will cause damage to the gearbox and drive pulley.

6. Check that the upstream and downstream heights of the conveyor section agree with the system

layout instructions and that the conveyor is leveled side-to-side.

7. Check that all floor supports are aligned with the chalk line or other layout mark to ensure that the

conveyor is straight.

8. Secure the supports to the floor (or other permanent fixture).

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

18

Figure 7: Floor Support and Splice Plate Installation

Refer to the “Bastian Solutions Conveyor Support Installation Manual” for more

information on installing conveyor.

5.3 Pressure Assembly Installation

1. RLVAC conveyor modules are pushed against the belt by pressure assemblies in between each

module. The pressure assemblies between modules in the same bed section are pre-installed,

but pressure assemblies between bed sections must be installed as the bed sections are set.

2. See Figure 8: Pressure Assembly Installation Detail for a section view showing a pressure

assembly between bed sections. Also see Detail A of Figure 28: General Arrangement, RLVAC

Bed Section, Sheet 2 of 2 in Appendix 2: General Arrangement Drawings for additional details.

3. Remove either the upstream or downstream conveying roller (1) immediately next to the bed

break. Drop in an upper pressure plate (76) and a 3”L carriage bolt (77). The upper pressure

plate sits in notches in the two bed spacers.

4. Push a spring pressure plate assembly (80) up through the holes in the bed spacers. The rubber

springs will press over the two protruding pins on the two modules. Ensure that the carriage bolt

passes through the hole in the pressure plate assembly.

5. Install a washer (78) and nylock nut (79). Hand tighten only at this stage. Overtightening will

make the belt difficult to install.

6. If the conveyor contains one or more skewed beds, the transitions to those skewed beds get a

special one-sided lower pressure plate (83). The remainder of the pressure assembly is installed

the same as on non-skewed beds. See Figure 9: Skew Transition Pressure Assembly Detail. For

additional context, this detail is “Detail B” in Figure 16: Skewed Bed Belt Routing, in section 5.5.3.

7. Replace the removed conveying roller.

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

19

Figure 8: Pressure Assembly Installation Detail

Figure 9: Skew Transition Pressure Assembly Detail

5.4 Leveling and Straightening

1. Starting at one end, use a laser level or other accurate method to check the sideframe height at

each bed break on both sides of the conveyor, and adjust the supports as needed. All bed breaks

should be in the same plane and level side-to-side, +/- 1/16”.

Installation and Maintenance Manual: RLVAC

Published February 2022

Rev. B

20

2. Run a string line along the centerline of the conveyor, down its entire length, approximately 2”

above the rollers. Tension the string until it is freely suspended (not touching any rollers).

3. Measure the distance between the string and the edge of the sideframe at each bed break. The

distance should be the same at every bed break, +/- 1/8”. Adjust by loosening the support

anchoring bolts and sliding the entire floor support sideways if needed. The floor support

anchoring holes are slotted to allow some side-to-side adjustment. Re-secure the support once it

is in position.

5.5 Installing the Belt

1. Remove a few idler rollers near each tail, and approximately every 50 feet along the length of the

conveyor, as needed to pull the belt through. See section 6.7.4 for details.

2. Mount the roll of belting on a sturdy pole or axle, secured between the tines of a forklift or similar,

where the belting can be easily unrolled. Position the belt behind the tail of the conveyor nearest

the drive.

The belt should be installed with the shiny traction layer facing up towards the

conveying rollers and the textured or fabric side down towards the pressure rollers. For

belts with traction material on one side only, this orientation is important for correct

functionality. For belts with traction material on both sides, keeping the shiny layer

towards the conveying rollers will reduce noise.

3. Tape a thin piece of metal or stiff cardboard to the end of the belt to keep the end straight and

help guide it through the conveyor. Make sure the final thickness is less than 1/4”.

If the belt is prepared for a hot splice joint, it will have a small scrap of belting taped to

the end to protect the finger joint. Leave that piece of belting in place.

4. Once the belt reaches the other end of the conveyor, route it through the tail and pull the belt

through, leaving the return span hanging below the conveyor.

a. See Figure 10: Tail Belt Routing for belt routing through the tail.

b. Ensure that the return span of the belt is routed above any items (floor support cross

braces, conduits, etc.) that might cross underneath the conveyor.

5. If the conveyor has skewed beds, see section 5.5.3 for belt routing through skewed beds.

6. Once the end of the belt reaches the drive, pull additional belt through until the roll is empty.

Position the end of the belt on the top of the conveyor in a convenient place to join the belt ends.

7. Route the belt through the drive. See sections 5.5.1 or 5.5.2 for belt routing, depending on

whether the conveyor uses a screw takeup or pneumatic takeup drive.

8. Route the belt through the second tail and bring the two belt ends together.

9. Remove tape from the belt.

10. See section 5.5.3 if the belt uses a hot spliced joint.

Table of contents

Other Bastian Solutions Accessories manuals

Popular Accessories manuals by other brands

Panasonic

Panasonic KX-HNA101C installation guide

Zwave

Zwave Minoston MP21ZS manual

Honeywell

Honeywell V4043 installation instructions

ORION TELESCOPES & BINOCULARS

ORION TELESCOPES & BINOCULARS SSSSI-III instruction manual

Hunter

Hunter Wireless Rain-Clik Product information

Dometic GROUP

Dometic GROUP WAECO CoolFreeze CF11 operating manual