Bastian Solutions RLVDC Manual

Installation and Maintenance Manual

Model: RLVDC

Effective February 2022

Rev. B

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

2

Contributions

ROLE

NAME

TITLE

Author Josh Foiles Design Engineer

Checker Ben Baker Senior Design Engineer

Approver Chris Perry Engineering Manager

Revisions

DATE

REVISION

DESCRIPTION

AUTHOR

10/21/2019

A1

Initial Document Creation

Josh Foiles

10/8/21 A2 Reformatted and Brand Update Mark Fishback

1/04/2022

Review B

MKT final draft

Mark Fishback

2/18/2022

B

Document formatting

Andrew W. Jones

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

3

Term and Acronym Definitions

TERM/ACRONYM

DEFINITION

2 Groove Roller format which uses O-Rings to transfer rotational motion from

one roller to another in DC conveyor.

BF

Between frame; this refers to the distance between conveyor bed

side frames.

Carton or Case

Term for conveyable items generally contained in cardboard boxes.

DC Direct current

DC Card A control card used to power and control the logic used when

operating a MDR in DC conveyor applications.

Discharge The point where cartons, cases, or totes exit a conveyor or similar

unit used in a material handling system.

Live

A zone of conveyor runs "live" when it runs whenever energized. It is

for this reason that live zones of conveyor do not have or need any

photoeyes or reflectors.

MDR

Motorized drive roller; DC powered conveyor roller with an internally

mounted motor which may be controlled via internal or external

commutation.

OAW Overall width of any given conveyor bed.

OD

Outer diameter of a circular, cylindrical, or arced body.

OSHA

Occupational Safety and Health Administration

Poly-V A band or roller hub format with longitudinal ribs used for power

transmission in DC conveyor applications.

PPE

Personal protective equipment

Roller

Powered or unpowered cylindrically-shaped material handling

component used for mechanical power transmission, a conveying

surface, and/or support for a belted conveying surface.

Side Cover

A PVC cover used to conceal and protect electrical components and

wiring from foreign debris and moving obstacles.

Side Frame Structural member used to support rotating components needed for

conveyor beds.

Singulation

The active separation of cartons, cases, or totes.

Wiz Nut A serrated flange nut used to cut into the surface of the component it

is tightened against.

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

4

Table of Contents

1Introduction............................................................................................................. 6

2OSHA and Safety .................................................................................................... 6

3Model: RLVDC......................................................................................................... 7

4Receiving................................................................................................................. 8

4.1 Mark Numbers ........................................................................................................................8

4.2 Skid Contents.........................................................................................................................9

4.3 Skid Documentation...............................................................................................................9

5Installation............................................................................................................. 10

6Maintenance and Operation................................................................................. 11

6.1 Safety During Operation ......................................................................................................11

6.2 Maintenance Schedule......................................................................................................... 11

6.2.1 Mechanical Service ............................................................................................................ 11

6.2.2 Electrical Service................................................................................................................ 12

6.2.3 Replacing Rollers ............................................................................................................... 13

6.2.4 Replacing Bands ................................................................................................................15

7Troubleshooting and Repair................................................................................ 17

8Standard Spare Parts ........................................................................................... 18

List of Figures

Figure 1: RLVDC General Arrangement Exploded View...........................................................................7

Figure 2: Mark Number Stickers...............................................................................................................8

Figure 3: Skid Sticker...............................................................................................................................9

Figure 4: MDR Removal-1 ..................................................................................................................... 13

Figure 5: MDR Removal-2 ..................................................................................................................... 14

Figure 6: MDR Removal-3 ..................................................................................................................... 14

Figure 7: Band Replacement .................................................................................................................16

Figure 8: RLVDC Spare Parts Exploded View........................................................................................ 18

List of Tables

Table 1: MDR Nut Torque Specifications ...............................................................................................11

Table 2: Troubleshooting Card Issues.................................................................................................... 17

Table 3: RLVDC Standard Spare Parts Table ........................................................................................ 18

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

5

Reference Documents

MANUFACTURER MANUAL

Interroll 9006 Hybrid Control for RollerDrive Manual

Interroll ZoneControl User Manual

Interroll DriveControl User Manual

Interroll EC100/110 User Manual

Interroll EC310 User Manual

Itoh Denki HBM604 User Manual

Itoh Denki IBE User Manual

Itoh Denki HB510 User Manual

Itoh Denki CBM105 User Manual

Itoh Denki Product Catalog

Bastian Solutions Side Cover and Guiderail Installation Manual

Bastian Solutions Support Installation Manual

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

6

1 Introduction

Thank you for choosing Bastian Solutions conveyor. The following manual serves as a guide for

installation, part replacement, and general maintenance for your material handling equipment. It is

important to read the manual and follow any instructions as it provides important safety information for

personnel and will maximize the longevity of the conveyor.

The information contained in this manual applies only to the products described. Uses, activities, or

processes related to installing or maintaining the equipment that are not explicitly described in this

manual are considered out of scope. Please contact Bastian Solutions for any questions or support that is

not clearly addressed in this document. Bastian Solutions is not responsible for misuse of the equipment

described in this manual or misuse of information in this manual. If you have any questions, contact

Bastian Solutions Customer Service at ConveyorSupport@bastiansolutiomns.com.

2 OSHA and Safety

Bastian Solutions is not responsible for ensuring that conveyors used in a system abide by OSHA

standards. Safety is of primary importance to our company, but as a product distributor we ask that

system integrators and end users conform with all applicable OSHA standards. We encourage that all

warnings in this manual are followed to avoid unnecessary risk.

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

7

3 Model: RLVDC

The Roller Live DC (RLVDC) Conveyor is designed with brushless 24V DC motor rollers. These rollers

are referred to as motor driven rollers (MDRs). RLVDC is used in applications where general transport is

all that is required. The rollers are “live” meaning they run continuously. The RLVDC is optimal for light to

medium products and works great with a variety of product sizes and types.

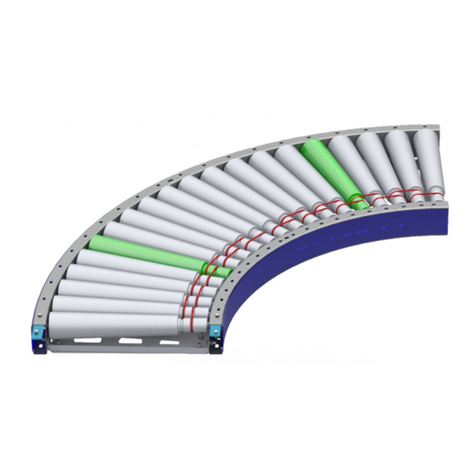

The model shown in Figure 1 serves as a reference to become familiar with the components and

terminology used in this manual. These terms will be used throughout the manual and are common

among many of the other Bastian Solutions’ conveyor product lines.

Figure 1: RLVDC General Arrangement Exploded View

The model in Figure 1 shows a 5’ RLVDC bed section. The RLVDC has 3” roller centers and has (2) 30”

zones. Each zone is made up of (9) rollers and (1) MDR. The rollers and MDRs each have two grooves

that allow them to be banded together with O-rings. Each zone has an MDR that needs to be connected

to a control card. The model shown in Figure 1 contains a dual zone card. These can be used to control

two zones. While this is a standard configuration, another very common configuration is one zone per

card.

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

8

4 Receiving

Upon delivery of any Bastian Solutions conveyor, please review and check the following:

•The quantity of items received against the Bill of Lading.

•Complete a visual inspection of equipment to determine any damage that may have occurred

during shipping. If damage is present, document with pictures.

•Review Mark Number information and layout locations. More information can be found in

subsection 4.1

If there are any missing or damaged components contact your Bastian Solutions’ conveyor representative

with as much detail as possible. If you are unsure of your Bastian Solutions’ conveyor representative,

please contact Bastian Solutions Customer Service at ConveyorSupport@bastiansolutiomns.com.

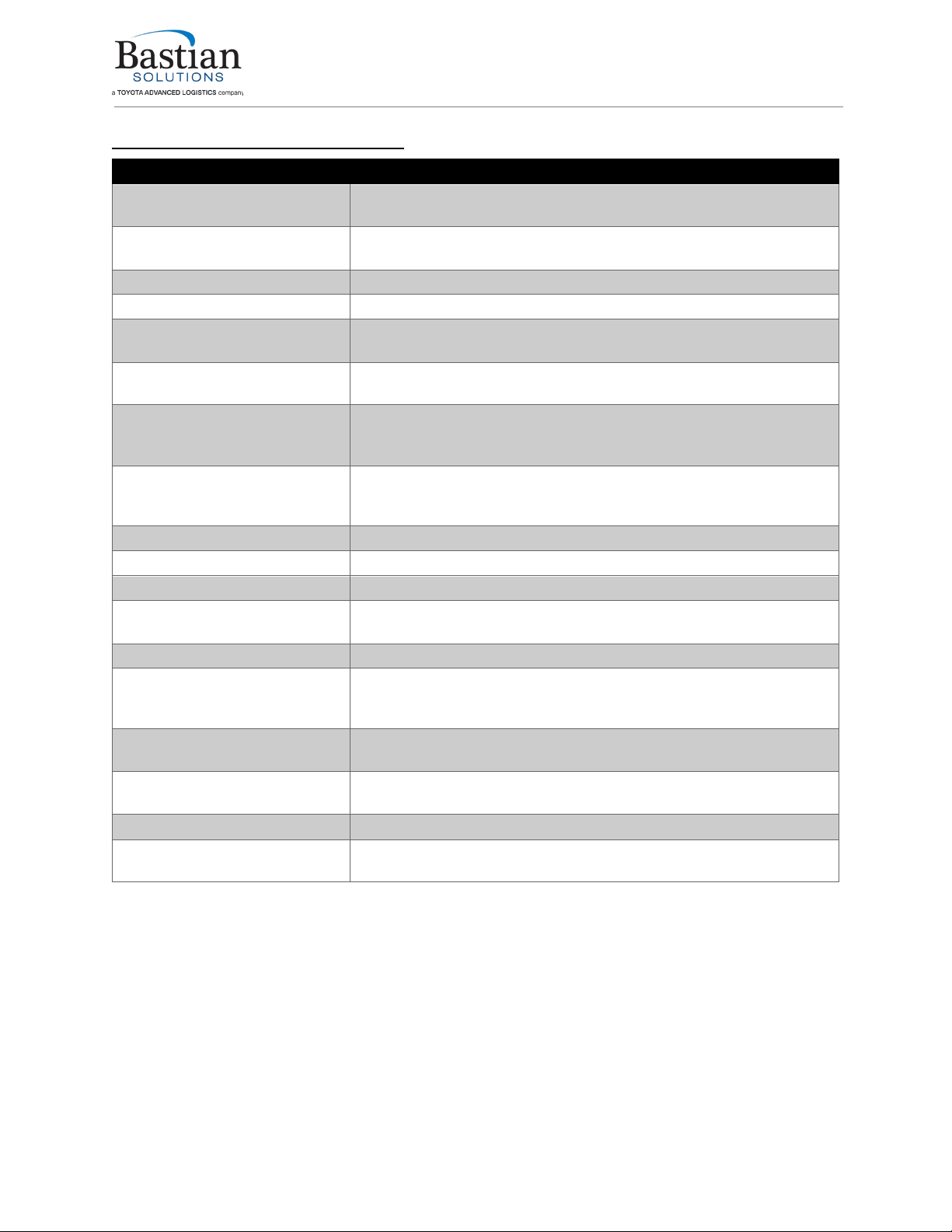

4.1 Mark Numbers

A mark number is a specific number given to a piece of equipment. A mark number is usually made up of

a single product line (RZPDC, RLVDC, BZPDC, etc.) but can contain many bed section lengths. They can

range from two inches to hundreds of feet. The mark number is used to help identify where the piece of

equipment will go within the system layout.

Every bed section of conveyor will have (2) stickers. One sticker on the infeed end of the bed, and one

sticker on the discharge end of the bed. Each sticker will contain the following information:

•Project Number and Name

•Model Type

•Mark Number

•Match

•Piece

•Flow

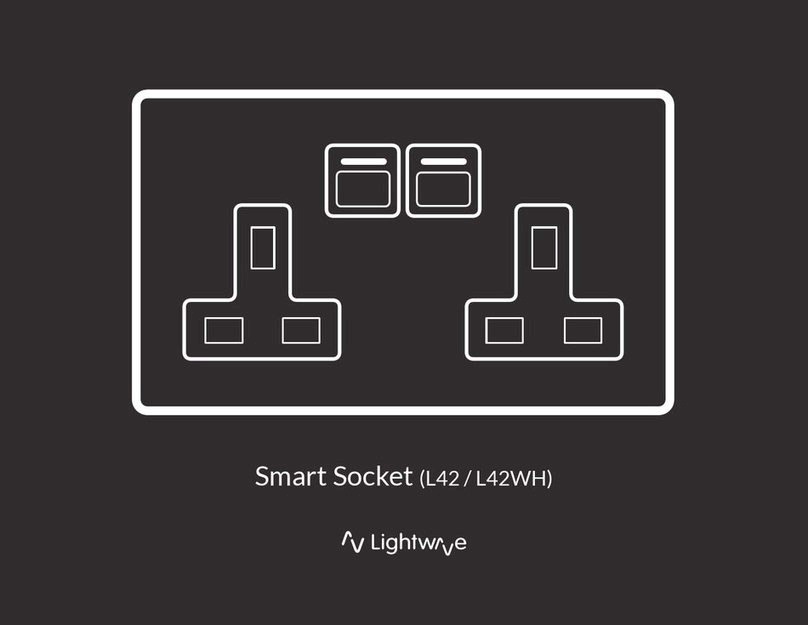

Figure 2 shows stickers that would appear on an RZPDC that has two bed sections.

Figure 2: Mark Number Stickers

The match field on the stickers is used to indicate if two bed sections are to be spliced to one another. As

shown in Figure 2, the stickers where the two beds splice together both contain “Match: 1”. The piece

field defines the bed section number within the mark. The flow refers to the direction of product flow along

the conveyor system.

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

9

4.2 Skid Contents

Skids will contain varying combinations of conveyor sections, support structures, accessories, and

pertinent hardware. For protection of product integrity during shipping, accessories and supports may be

delivered on separate but labeled skids.

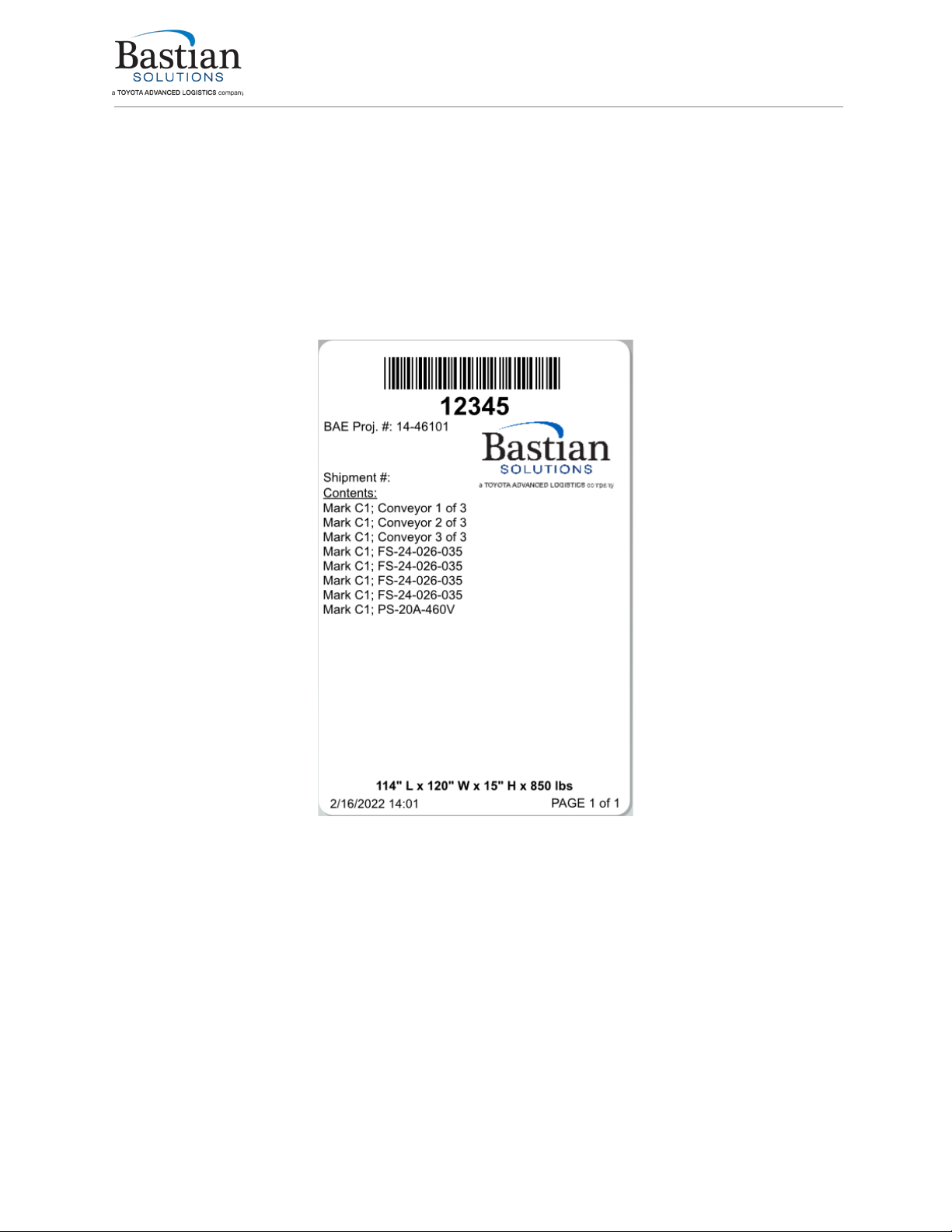

4.3 Skid Documentation

All shipments will contain a Bill of Lading for the delivery company, a skid label, and a skid manifest. Skid

labels have the contents of each shipped item located on the skid. Figure 3 shows a sample of a skid

label. These stickers are placed on the surface of each skid.

Figure 3: Skid Sticker

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

10

5 Installation

The installation supervisor should have elevation and layout prints with detailed information regarding the

placement of conveyor sections and support structures. This information is not the responsibility of

Bastian Solutions to provide unless otherwise specified.

1. Clear the workspace around the portion of the layout selected for installation.

2. Measure out from a constrained origin to start placement of supports. It is recommended that

snap chalk lines are used, or other methods of keeping a consistent line.

3. Use elevation layouts to determine the conveyor’s top of conveying surface.

4. Place the support type that the layout designates. Each support type has a corresponding mark

sticker.

5. Check the flow direction on the mark stickers to ensure that conveyors are mounted properly.

6. Place the conveyor onto the support structure and fasten it securely using the 3/8”-16 carriage

bolts and wiz nuts provided. The recommended torque specification is 26ft-lbs.

7. Attach any guiderail or miscellaneous accessories. For information on guiderail installation,

please reference the “Bastian Solutions Conveyor Side Cover and Guiderail Installation Manual”

8. Check that the height of the infeed and discharge ends are correct per the system layout.

9. Lag the supports to the floor (or other permanent fixture).

Refer to the “Bastian Solutions Conveyor Support Installation Manual” for

more information on installing conveyor.

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

11

6 Maintenance and Operation

The longevity and proper functionality of Bastian Solutions conveyor is based upon standard operating

practices and general maintenance of equipment. Setting up a regular maintenance schedule will help to

ensure that products comply with the equipment’s warranty. Lockout/Tagout procedures should be

implemented before performing any maintenance.

6.1 Safety During Operation

The list below explains a series of recommended precautions that should be taken when personnel are

near the equipment. This list is not intended to be the only precautions taken, but it serves as a guide of

important steps to follow.

•Only fully trained employees should operate or perform maintenance on the conveyors. Proper

training should include the detailed description of fail-safes, stopping devices, or other emergency

regulations put in place.

•WARNING stickers should be replaced if worn or damaged.

•All personnel in the area should be alerted prior to starting any conveyor at all times. This process

may vary depending on the conditions and layout of the site, but it should use audible and visual

cues and all personnel should be made aware of the protocol.

•Operators should inspect the conveyor for damage, foreign objects, and verify all personnel is

clear of the equipment prior to engaging drive.

•Ensure that all areas are clear of objects prior to loading and unloading.

•No personnel should ever ride, climb, step, sit on, or otherwise put body weight on the conveyor.

Doing so puts both personnel and equipment at risk.

•Maintenance should be performed at regular intervals to assure the safety of operators and the

longest life of components. Should a component break during operation or prior to operation, then

lockout/tagout instructions should be performed immediately to prevent exposure to hazards.

6.2 Maintenance Schedule

To prolong the life of the material handling equipment and reduce the risk of potential safety

hazards, it is vital that a preventative maintenance program be set in place and followed. The

following instructions will help identify key areas requiring maintenance.

6.2.1 Mechanical Service

•An auditory inspection of the equipment should be performed to identify any unusual noise that

may indicate that there is a problem with the equipment.

•Check all nuts and bolts to ensure bolts remain tight. MDR nuts should be torqued using a torque

wrench to each MDR’s torque specs. Please reference Table 1 for a list of common MDRs and

their torque requirements.

•O-rings/bands should be inspected for excessive wear, stretching or slip and replaced as

necessary.

•The recommended interval for maintenance is at least once every 6 months.

Table 1: MDR Nut Torque Specifications

MDR

MDR NUT TORQUE SPECS

Interroll EC100/110

30 ft-lbs

Interroll EC310

50 ft-lbs

Itoh Denki PM486FE/FP

23 ft-lbs

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

12

6.2.2 Electrical Service

•All Bastian Solutions’ conveyor DC products operate at either 24V or 48V, nominally.

•If adjustment of control card settings is required, refer to the respective technical manual listed in

Reference Documents, or contact Bastian Solutions Customer Service at

ConveyorSupport@bastiansolutiomns.com.

•If there is a need to replace a DC control card, perform the following:

oDe-energize associated power supply and remove respective side cover (if applicable)

oAdjust settings of replacement control card to match those of the existing control card.

oRemove the existing control card from the side frame for ease of cable disconnection:

If the existing control card has a mounting plate, remove wiz nut securing control

card mounting plate to side frame.

If the existing control card is secured to the conveyor side frame with anything

other than a mounting plate, install new securing material on the new control card

and re-use the securing material on the side frame.

oOne at a time, remove all cables and connectors and plug them into the same respective

connection port on the new control card.

oIf the control card in question has a mounting plate, remove the mounting plate secured

to the existing control card, and install it on the new control card (if the new control card

does not already have a mounting plate installed on it).

oInstall the new control card on the conveyor side frame

oRe-energize associated power supply, check the lane for proper system functionality, and

reinstall respective side cover (if applicable).

Never “hot swap” control cards (i.e. disconnect and reconnect power

connector on control cards without de-energizing respective power supply).

When doing this, there is an increased risk of damaging the new control

card.

There is always a possibility that control card errors are being caused by

faulty communication cables (RJ45, CAT5, or CAT6), or problems with

adjacent cards connected via the communication cables.

•If cards or card fuses are blowing:

oEnsure there are no shorts in system power wiring

oEnsure all conveyor side frames are electrically bonded and provided a direct connection

to earth ground

oEnsure control card DIP switch settings match those needed for zone MDR (if applicable)

oIf associated conveyor zone has powered brake roller, ensure it is electrically connected

oIf problems persist, refer to the respective technical manual listed in the Reference

Documents section of this document.

•If experiencing any other electrical problems with Bastian Solutions DC conveyor, contact Bastian

Solutions Customer Service at ConveyorSupport@bastiansolutiomns.com.

When performing electrical work on Bastian Solutions conveyor, ensure

adherence to all applicable OSHA standards.

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

13

6.2.3 Replacing Rollers

If polyvee bands or 2” roller spacing is being used, it will often be easier to

remove a roller/band by disassembling the zone roller-by-roller until reaching

the roller/ band that is being replaced. The directions in this segment refer to

replacement of rollers within a 3” roller center conveyor.

For motor driven rollers (MDRs):

1. Follow the lockout/tagout procedure in place to ensure safety.

2. Remove the side cover from the intended work area.

3. Loosen the MDR nut located on the cable side of the roller.

4. Pull the MDR bracket away from the frame. Refer to Figure 4

Figure 4: MDR Removal-1

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

14

5. Apply pressure on the end of the hex shaft opposite the cable using a small diameter punch or

similar tool until the shaft clears the frame. Be careful NOT to apply a side load to the hex shaft.

Refer to Figure 5.

Figure 5: MDR Removal-2

6. Provide upward force on the roller body until the hex is sitting above the side frame. Refer to

Figure 6. (A putty knife or other flat surface tool is recommended to be placed between the hex

shaft and the inside of the frame. This will help protect the paint on the side frame.)

Figure 6: MDR Removal-3

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

15

7. Pull the threaded shaft out of the side frame.

8. Pull the MDR away from the bands until the MDR is completely free of the side frames and

bands.

9. Slide the new MDR cable through the MDR washer and guide it through the hex hole.

10. Place the MDR bracket back onto the threaded shaft.

11. Guide the MDR back through the existing bands.

12. Use a putty knife or other flat surface tool to guide the hex shaft into the hex hole.

13. Fasten the MDR nut using a torque wrench to the appropriate value given in Table 1.

14. Plug the MDR into the card.

15. Replace the side cover.

For standard rollers:

1. Follow the lockout/tagout procedure in place to ensure safety.

2. Remove the side cover from the intended work area.

3. Apply pressure on the end of the hex shaft opposite the wiring using a small diameter punch or

similar tool until the shaft clears the frame. Be careful NOT to apply a side load to the hex shaft.

Refer to Figure 5.

4. Provide upward force on the roller body until the hex is sitting above the side frame. Refer to

Figure 6. (A putty knife or other flat surface tool is recommended to be placed between the hex

shaft and the inside of the frame. This will help protect the paint on the side frame.)

5. Remove the hex shaft from the opposite hex hole

6. Pull the roller away from the bands until the roller is completely free of the side frames and bands.

7. Slide the new roller through the bands.

8. Once the new roller is through both bands, guide the hex shaft into the hex hole.

9. After the hex shaft is in the hex hole, the opposite side shaft can be inserted into the appropriate

hex hole. Use the roller’s length as leverage to aid in this step.

10. Use a putty knife or other flat surface tool to guide the hex shaft into the opposite hex hole.

11. Replace the side cover.

6.2.4 Replacing Bands

1. Follow the lockout/tagout procedure in place to ensure safety

2. Remove the side cover from the intended work area.

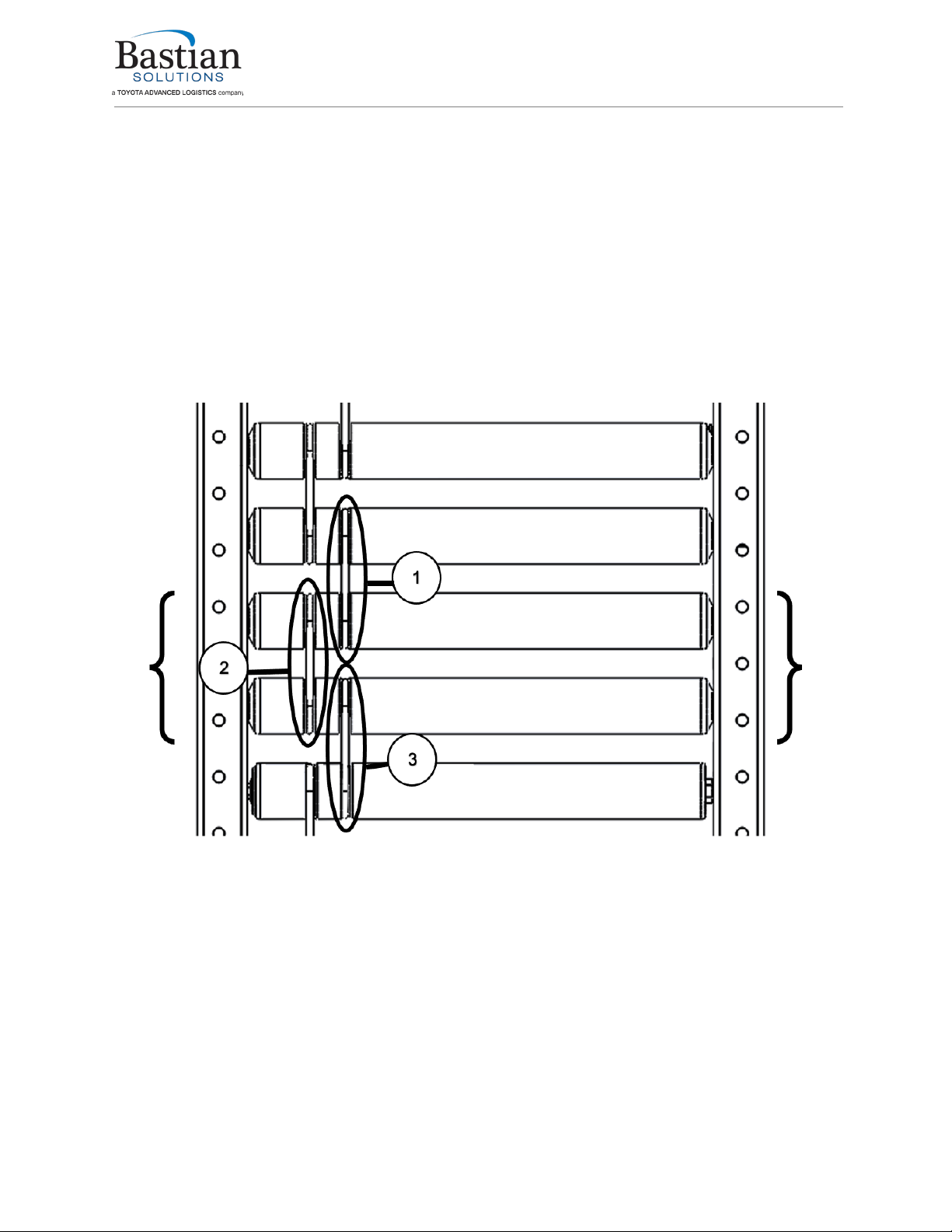

3. If the band being replaced is on the outside groove/hub of the roller as shown in circle 2 of Figure

7 the two rollers within the brackets will need to be removed. Follow the roller removal steps in

the roller replacement procedure.

4. After the rollers have been removed, slide one of the rollers that was removed through the band

in circle 1 of Figure 7.

5. After the roller is within circle 1, slide the new band onto the same roller on the groove side of the

roller. (Left side in Figure 7)

6. Use the new band to help guide the hex shaft into the hex hole.

This method is effective but requires a large amount of tension in the bands.

Because of this tension fingers can be pinched if not done carefully.

7. Once the groove side hex shaft (Left side in Figure 7) is within the hex hole, insert the opposite

side hex shaft into the appropriate hex hole. Use the roller’s length as leverage to aid in this step.

As called out in the roller replacement procedure, use a putty knife or other flat surface tool to

protect the paint on the side frame.

8. After the first roller has successfully been re-installed, install the second roller.

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

16

9. Slide the roller through the old band in circle 3 of Figure 7. Then slide the roller through the new

band. (This step can be difficult as the bands are tight.)

10. Once the roller has both bands around it, guide the hex shaft into the hex hole.

11. Once the groove side hex shaft (Left side in Figure 7) is within the hex hole, insert the opposite

side hex shaft into the appropriate hex hole. Use the roller’s length as leverage to aid in this step.

As called out in the roller replacement procedure, use a putty knife or other flat surface tool to

protect the paint on the side frame.

12. If the band being replaced is on the inside groove/hub of the roller as shown in the blue circle of

Figure 7, then remove the hex shafts opposite the groove/hub.

13. Roll the band being replaced down the length of the two rollers.

14. Roll the new band up the length of the two rollers.

15. Re-insert the hex shafts into the appropriate hex holes.

16. Replace side covers.

Figure 7: Band Replacement

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

17

7 Troubleshooting and Repair

Many issues that may arise with Bastian Solutions conveyor can be corrected with minimal field repairs.

Bastian Solutions encourages using the following troubleshooting techniques before contacting a Bastian

Solutions representative as these are the same techniques used by our field service engineers. To assist

in data collection, Bastian Solutions asks that any issues that arise be recorded in a log, with the mark

number, a description of the issue, and the steps taken to resolve the issue. Table 2 gives direction for

retroreflective photoeyes. If a diffuse photoeye is being used, verify that the sensor is set to Light Mode(L)

(Arrow pointed at L on photoeye).

Table 2: Troubleshooting Card Issues

ERROR

CAUSE

ACTION

Conveyor flow direction,

speed, or acceleration is

incorrect

Incorrect DIP switch settings

Check card manufacturer’s

literature to verify proper switch

configuration.

Zone not operating

No power supply Check that the power supply is

on and wired to the card

Fuse is blown Check LED lights and replace

the fuse if confirmed short

Incorrect DIP switch setting

Check card manufacturer’s

literature to verify proper switch

configuration

System reverses or jogs

without prompting

Fuse is blown

Check the fuses of all cards in

the immediate system

Incorrect DIP switch setting

Check card manufacturer’s

literature to verify proper switch

configuration

Communication cable incorrectly

connected or faults

Check com cables and replace if

faulty.

System turns off when several

zones are in use at the same

time

Power supply insufficient

Check the number of zones per

power supply

Check that the power supply

and AC voltage source are

working properly and installed

correctly

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

18

8 Standard Spare Parts

Figure 8: RLVDC Spare Parts Exploded View

Table 3: RLVDC Standard Spare Parts Table

REF. NO. DESCRIPTION COMMON CONFIGURATIONS

1ROLLERS

2 GROOVE

POLYVEE

2BANDS

O-RING- 2IN ROLLER SPACING

O-RING – 3IN ROLLER SPACING

POLYVEE- 2IN ROLLER SPACING

POLYVEE- 3IN ROLLER SPACING

3MOTOR DRIVEN ROLLERS (MDRS)

2 GROOVE/POLYVEE – INTERROLL EC100

2 GROOVE/POLYVEE – INTERROLL EC110

2 GROOVE/POLYVEE – INTERROLL EC310

2 GROOVE/POLYVEE – ITOH PM486FE

2 GROOVE/POLYVEE – ITOH PM486FP

Installation and Maintenance Manual: RLVDC

Published February 2022

Rev. B

19

Bastian Solutions Conveyor Installation and Maintenance Manual

Model: Bastian Solutions RLVDC Conveyor

© 2022 Bastian Solutions, LLC

All rights reserved. This document contains information considered proprietary to Bastian Solutions. It

may not be duplicated, used, or disclosed without written permission from Bastian Solutions. It may not

be used in whole or in part for any purpose other than its intended purpose as an operation, installation,

and maintenance manual for the product or products described herein. Bastian Solutions reserves the

right to revise the contents of this document as necessary.

Bastian Solutions, LLC

1821 Bastian Court

Westfield, IN 46074

Customer Support: ConveyorSupport@bastiansolutiomns.com

This manual suits for next models

1

Table of contents

Other Bastian Solutions Accessories manuals