Bastian Solutions BRBAC 1 HP Manual

Installation and Maintenance Manual

Model: BRBAC 1 HP

Effective December 2019

Rev.A1

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 2

Contributions

ROLE

NAME

TITLE

Author

Rajarshi Choudhuri

Design and Cost Engineer

Checker

Ben Baker

Senior Design Engineer

Approver

Chris Perry

Engineering Manager

Revision History

DATE

REVISION

REVISION DESCRIPTION

AUTHOR

12/05/2019

A1

Initial document creation

Rajarshi Choudhuri

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 3

Term and Acronym Definitions

TERM/ACRONYM

DEFINITION

AC

Alternating current

BF

Between frame; this refers to the distance between conveyor bed side frames.

BHCS

Button head cap screw

BOM

Bill of Materials

BRBAC

Belt Over Roller Bed Alternating Current; Format of AC conveyor used for

cartons, cases, or totes transport optimized for long runs. Low friction option for

conveying cartons, cases, or totes of various shapes, sizes, and weights using

rollers to support the belt.

BRBACI

Belt Over Roller Bed Alternating Current Incline; Inclined BRBAC.

BSBAC

Belt Over Slider Bed Alternating Current; Format of AC conveyor used for carton,

case, or tote transport optimized for long runs. Low friction option for conveying

carton, case, or tote or various shapes, sizes, and weights using sheet steel to

support the belt.

BSBACI

Belted Slider Bed Alternating Current Incline; Inclined BSBAC

CB

Carriage bolt

CCW

Counter-clockwise

Center Drive

Drive format of AC conveyor where the drive unit is mounted at any point along

the length of the conveyor.

CW

Clockwise

Discharge

The point where cartons, cases, or totes exit a conveyor or similar unit used in a

material handling system.

FAT

Factory Acceptance Testing

Flange

A feature in sheet metal consisting of a face and bend connected to an existing

face along a straight edge.

Glide Top

An AC belt format with a low coefficient of friction designed to allow cartons,

cases, or totes to slide across the conveying surface.

Guide Rail

Mechanism used to maintain the desired position of conveyable cartons, cases,

or totes on their respective conveying surface.

HHCS

Hex head cap screw

ID

Inner diameter of a circular, cylindrical or arced body.

Idler Roller

Cylindrically-shaped material handling component that is unpowered and used

to support a belt.

Infeed

The point where cartons, cases, or totes enter a conveyor or similar unit used in

a material handling system.

Live

A zone of conveyor runs "live" when it runs whenever energized. It is for this

reason that live zones of conveyor do not have or need any photoeyes or

reflectors.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 4

TERM/ACRONYM

DEFINITION

Longitudinal Rib

A belt format with a rib texture aligned with the belt’s direction of travel.

LOTO

Lockout Tagout

Mark Number

A numeric or alphanumeric term used to uniquely identify a conveyor bed or

collection of beds (of similar model type) within a material handling system.

Match

A mark made on mating conveyor assemblies to assist in identifying orientation

and placement within a system.

Noseover

An arced conveyor used to make a smooth transition between conveying

surfaces of differing incline or decline angles.

OAW

Overall width of any given conveyor bed.

OD

Outer diameter of a circular, cylindrical, or arced body.

OSHA

Occupational Safety and Health Administration

Polytier

Heavy duty floor support with a wide stance, capable of supporting multiple

levels and types of conveyor.

Power feeder

A section of BLVDC that will always be at the infeed of an inclined AC or the

discharge section of a declined AC.

PPE

Personal protective equipment

Pulley

Mechanical device used to change the direction of the belt in a conveyor system,

to drive and/or tension the belt.

Return Idlers

Belt-routing rollers on the underside of any given AC conveyor.

Roller

Powered or unpowered cylindrically-shaped material handling component used

for mechanical power transmission, a conveying surface, and/or support for a

belted conveying surface.

Side Cover

A PVC cover used to conceal and protect electrical components and wiring from

foreign debris and moving obstacles.

Side Frame

Structural member used to support rotating components needed for conveyor

beds.

Splice Assembly

A five-component assembly-consisting of a plate (or formed plate), two bolts,

and two nuts-that is used to secure a piece of guide rail to an adjacent piece of

guide rail, or a side frame to an adjacent side frame. This is used to provide

additional structural rigidity and ensure relative position of components is

maintained.

Tail Pulley

A non-driven pulley located at the tail end of the conveyor.

Take-up Pulley

Pulley with an adjustable position used to eliminate unnecessary slack in a belt.

Take-up Screws

Adjustment screw used to adjust the position of a take-up pulley.

TOR

Top of roller; this refers to the elevation of the conveying surface with respect to

the floor on which the conveyor is sitting.

Track

To adjust the position of conveyor components in such a way that encourages

proper belt alignment on a system.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 5

Table of Contents

1Introduction ................................................................................................................... 8

2OSHA and Safety ............................................................................................................ 8

3Model: BRBAC 1 HP ........................................................................................................ 9

3.1 Drive Section.....................................................................................................................10

3.2 Tail Section .......................................................................................................................11

3.3 Bed section .......................................................................................................................12

3.4 Noseover Section ..............................................................................................................13

3.5 Power Feeder Section........................................................................................................14

4Receiving...................................................................................................................... 16

4.1 Mark Numbers..................................................................................................................16

4.2 Skid Contents....................................................................................................................17

4.3 Skid Documentation..........................................................................................................18

5Installation................................................................................................................... 19

5.1 Floor Support Location ......................................................................................................19

5.2 Uniform Levelling and Straightness of Conveyor Section.....................................................20

5.3 Installing the AC Belt .........................................................................................................20

5.4 Tensioning and Tracking the AC belt ..................................................................................23

5.5 Installing and Adjusting Noseover section angle.................................................................25

5.6 Installing Underside Covers ...............................................................................................26

6Maintenance and Operation......................................................................................... 28

6.1 Safety During Operation....................................................................................................28

6.2 Mechanical Maintenance Schedule....................................................................................28

6.3 Electrical Maintenance Schedule........................................................................................29

6.4 Tail Pulley Replacement ....................................................................................................29

6.5 Drive Pulley Replacement..................................................................................................31

6.6 Take-up Pulley Replacement..............................................................................................36

6.7 Snub Roller Replacement...................................................................................................39

6.8 Idler Roller Replacement ...................................................................................................39

6.9 Bearing Replacement and Maintenance.............................................................................40

6.10 AC Motor Replacement .....................................................................................................40

6.11 AC Belt Replacement.........................................................................................................41

7Troubleshooting and Repair.......................................................................................... 42

8Spare Parts................................................................................................................... 43

Appendix 1 Spare Parts - General Arrangements ............................................................ 43

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 6

List of Figures

Figure 1: BRBAC 1HP configuration - exploded view....................................................................................9

Figure 2: BRBAC Incline 1HP configuration - exploded view ......................................................................10

Figure 3: BRBAC 1HP drive section - exploded view...................................................................................11

Figure 4: BRBAC 1HP tail section - exploded view......................................................................................12

Figure 5: BRBAC bed section - exploded view ............................................................................................13

Figure 6: BRBAC noseover section - exploded view....................................................................................14

Figure 7: BRBACI conveyor example with mark number "MK1100" ..........................................................16

Figure 8: BRBAC mark stickers - section 1...................................................................................................17

Figure 9: Skid Sticker...................................................................................................................................18

Figure 10: Diagonal measurement for conveyor section............................................................................20

Figure 11: Belt Routing - BRBAC 1 HP configurations - section view..........................................................21

Figure 12: Belt routing - BRBAC 1 HP drive - section view..........................................................................22

Figure 13: Belt routing - BRBAC 1 HP tail - section view.............................................................................22

Figure 14: Belt routing - BRBAC 1 HP tail with noseover - section view.....................................................22

Figure 15: Belt splicing schematic...............................................................................................................23

Figure 16: BRBAC 1 HP drive take-up view .................................................................................................23

Figure 17: Belt tracking by adjusting snub rollers.......................................................................................24

Figure 18: BRBAC Noseover section - angle adjustment bracket and corresponding hardware ...............25

Figure 19: BRBAC noseover section - location of check dimension............................................................26

Figure 20: Underside cover splice plate install - exploded view.................................................................27

Figure 21: Installing the underside cover to the BRBAC bed section .........................................................27

Figure 22: BRBAC 1 HP tail pulley bracket ..................................................................................................29

Figure 23: BRBAC 1 HP tail pulley take-up hardware..................................................................................30

Figure 24: BRBAC 1 HP tail pulley - lifting tail pulley out of side frame......................................................30

Figure 25: BRBAC 1 HP drive motor connection - exploded view...............................................................32

Figure 26: BRBAC 1 HP drive - underside cover..........................................................................................33

Figure 27: BRBAC 1 HP drive pulley guard..................................................................................................33

Figure 28: BRBAC 1 HP drive pulley bearing ...............................................................................................34

Figure 29: BRBAC 1 HP drive pulley removal from drive section................................................................35

Figure 30: BRBAC 1 HP drive - underside cover..........................................................................................36

Figure 31: BRBAC 1 HP drive take-up pulley bearing - motor side .............................................................37

Figure 32: BRBAC 1 HP drive take-up pulley bearing - non-motor side......................................................37

Figure 33: BRBAC 1 HP drive - take-up pulley removal...............................................................................38

Figure 34: Snub roller bracket.....................................................................................................................39

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 7

List of Tables

Table 1: Troubleshooting guide ..................................................................................................................42

Table 2: General spare parts list for BRBAC................................................................................................43

Reference Documents

Manufacturer

Manual

Habasit Holding AG

Habasit Heavy Conveyor Belts TM120RT-B (H250000385)

Habasit Holding AG

Habasit Heavy Conveyor Belts TM120LR-B (H250000441)

Habasit Holding AG

Habasit Heavy Conveyor Belts UMS130SC-B (H250000560)

Habasit Holding AG

Habasit Product Data Sheet RGLIDE-T

Habasit Holding AG

Habasit Fabric Conveyor Belts Installation and Maintenance Guide (6040)

ABB Motors and

Mechanical Inc

Dodge Quantis RHB Installation and Maintenance Instructions (499322)

Bastian Solutions

ZiPline Conveyor - Installation and Maintenance Manual: BLVDC

Bastian Solutions

ZiPline Conveyor - Side Cover and Guiderail Installation Manual

Bastian Solutions

ZiPline Conveyor - Support Installation Manual

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 8

1Introduction

Thank you for choosing ZiPline Conveyor. The following manual will serve as a guide for installation, part

replacement, and general maintenance for your material handling equipment. It is important to read the

manual and follow any instructions as it provides important safety information for personnel and will

maximize the longevity of the conveyor.

The information contained in this manual applies only to the products described. Uses, activities, or

processes related to installing or maintaining the equipment that are not explicitly described in this

manual are considered out of scope. Please contact Bastian Solutions ZiPline Conveyor for any

questions or support that is not clearly addressed in this document. ZiPline Conveyor is not responsible

for misuse of the equipment described in this manual or misuse of information in this manual. If you

have any questions, contact ZiPline Conveyor Customer Service or Support at

ZiPlineSupport@BastianSolutions.com.

2OSHA and Safety

ZiPline Conveyor is not responsible for ensuring that conveyors used in a system abide by OSHA

standards. Safety is of primary importance to our company, but as a product distributor we ask that

system integrators and end users conform with all applicable OSHA standards. We encourage that all

warnings in this manual are followed to avoid unnecessary risk.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 9

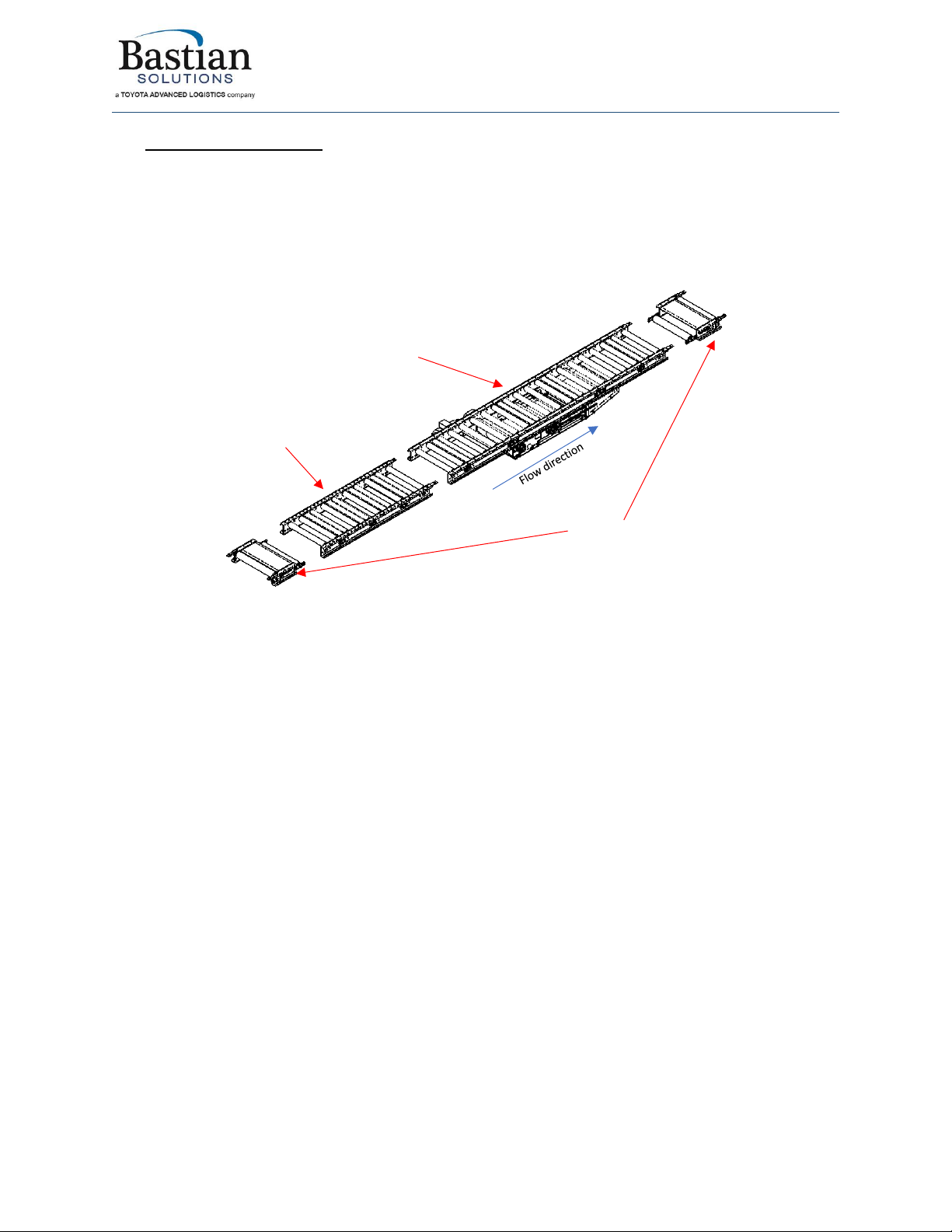

3Model: BRBAC 1 HP

The Belted Roller Bed AC (BRBAC) conveyor is designed to convey product across long distances without

product accumulation. The ZiPline Conveyor BRBAC 1 HP is available in two configurations: straight and

incline/decline. ZiPline Conveyor uses Baldor-Dodge gearmotors to the drive the BRBAC conveyor. Figure

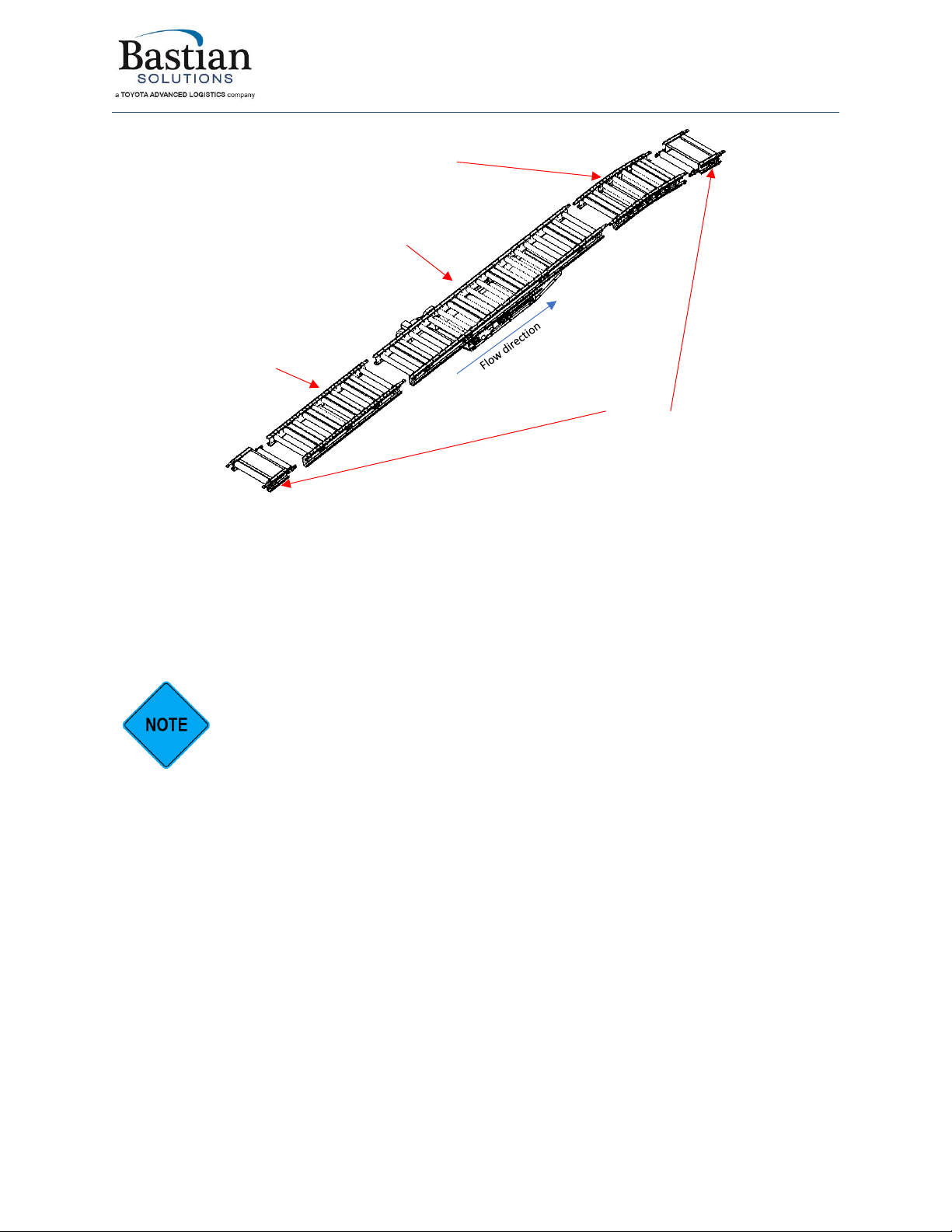

1 illustrates an exploded view of the different sections that constitute a 1HP BRBAC configuration and

some common terms used to describe these sections.

Figure 1: BRBAC 1HP configuration - exploded view

There are five main parts that make up a BRBAC conveyor line: the drive section, the tail section, the

bed sections, the noseover section and the power feeder section. Figure 1 illustrate the drive, tail and

bed sections only. The noseover and power feeder sections are added when there is an elevation

change between the infeed and discharge end of the BRBAC conveyor section. Figure 2 illustrates an

exploded view of the different sections that constitute a 1HP BRBAC inline configuration and some

common terms used to describe these sections.

Bed Section

Tail Section

1HP –motor

side left -

Drive Section

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 10

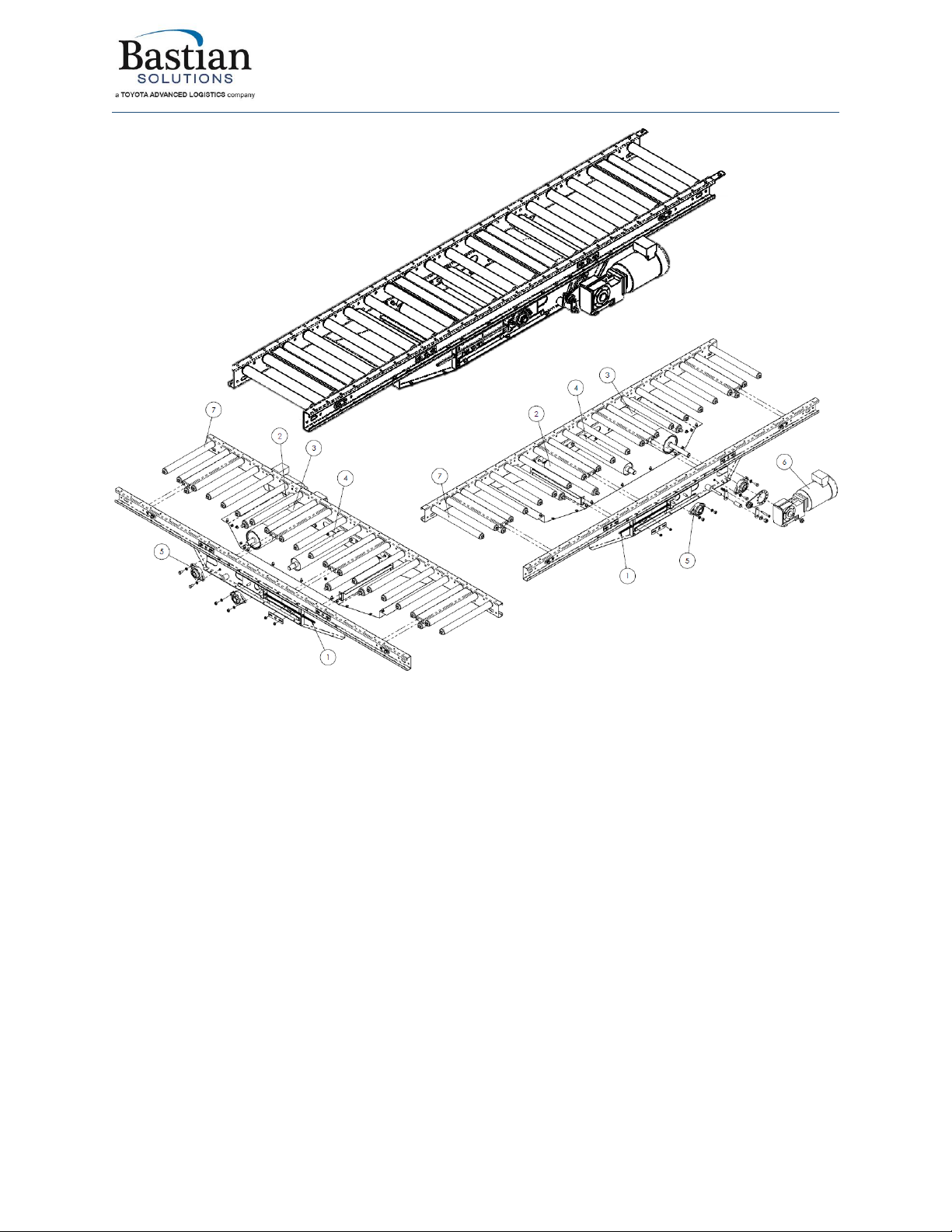

Figure 2: BRBAC Incline 1HP configuration - exploded view

3.1 Drive Section

The BRBAC drive section is a 10’ conveyor section that contains the motor, take-up subassembly for the

belt tension and the drive pulley. The BRBAC drive sections are offered in 18”, 24”, 30”, and 36” OAW.

The sub-configurations are based on the motor mount side, i.e left-side and right-side sub-

configurations. The motor mount side is determined by facing downstream of the conveyor.

The left-hand and right-hand sub-configuration of the drive sections are not the same

conveyor assembly but are reversible on site with additional spare parts. In case this

switch needs to be made, please contact your ZiPline Conveyor representative.

The drive sections are not designed to run backwards. This makes belt tracking very sensitive and

inconsistent on the BRBAC section. ZiPline Conveyor recommends making the sub-configuration change

with additional spare parts on site. Please contact your ZiPline Conveyor representative for assistance

and information to make the sub-configuration change.

Figure 3 illustrates the BRBAC 1 HP (motor left side) drive section exploded view with a list of spare

parts. Appendix 1 has the general arrangements for the BRBAC 1 HP drive section labelled as GA-

BRBAC-MW-120-0002.

Noseover Section

1HP –motor

side left -

Drive Section

Bed Section

Tail Section

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 11

The BRBAC drive section is designed to be positioned towards the center or biased towards the

downstream of the conveyor section. In extreme cases, the BRBAC 1 HP drive section can be placed

adjacent to two tail sections.

3.2 Tail Section

The BRBAC tail section is a 12” conveyor section that contains the tail pulley and tail pulley take-up

subassembly. The tail sections are always placed as the first and last bed section in a BRBAC section. The

BRBAC tail sections are offered in 18”, 24”, 30” and 36” OAW. Figure 4 illustrates the BRBAC 1HP tail

section exploded view with a list of spare parts. Appendix 1 has the general arrangements for the BRBAC

1HP tail section labelled as GA-BRBAC-MW-12-0001.

Figure 3: BRBAC 1HP drive section - exploded view

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 12

The BRBAC tail sections does not come standard with underside covers. The underside

covers for the BRBAC tail sections need to be ordered separately as an accessory.

3.3 Bed section

The BRBAC bed section are idler bed sections in the BRBAC conveyor. The BRBAC bed section is offered

in 18”, 24”, 30” and 36” OAW and range between 12” to 120” OAL in 6” increments. The BRBAC bed

sections are identical for all offered BRBAC configurations. Figure 5 illustrates the BRBAC bed section

exploded view with a list of spare parts. Appendix 1 has the general arrangements for the BRBAC bed

section labelled as GA-BRBAC-MW-120-0001.

Figure 4: BRBAC 1HP tail section - exploded view

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 13

Figure 5: BRBAC bed section - exploded view

The BRBAC bed sections does not come standard with underside covers. The

underside covers for the BRBAC bed sections need to be ordered separately as an

accessory.

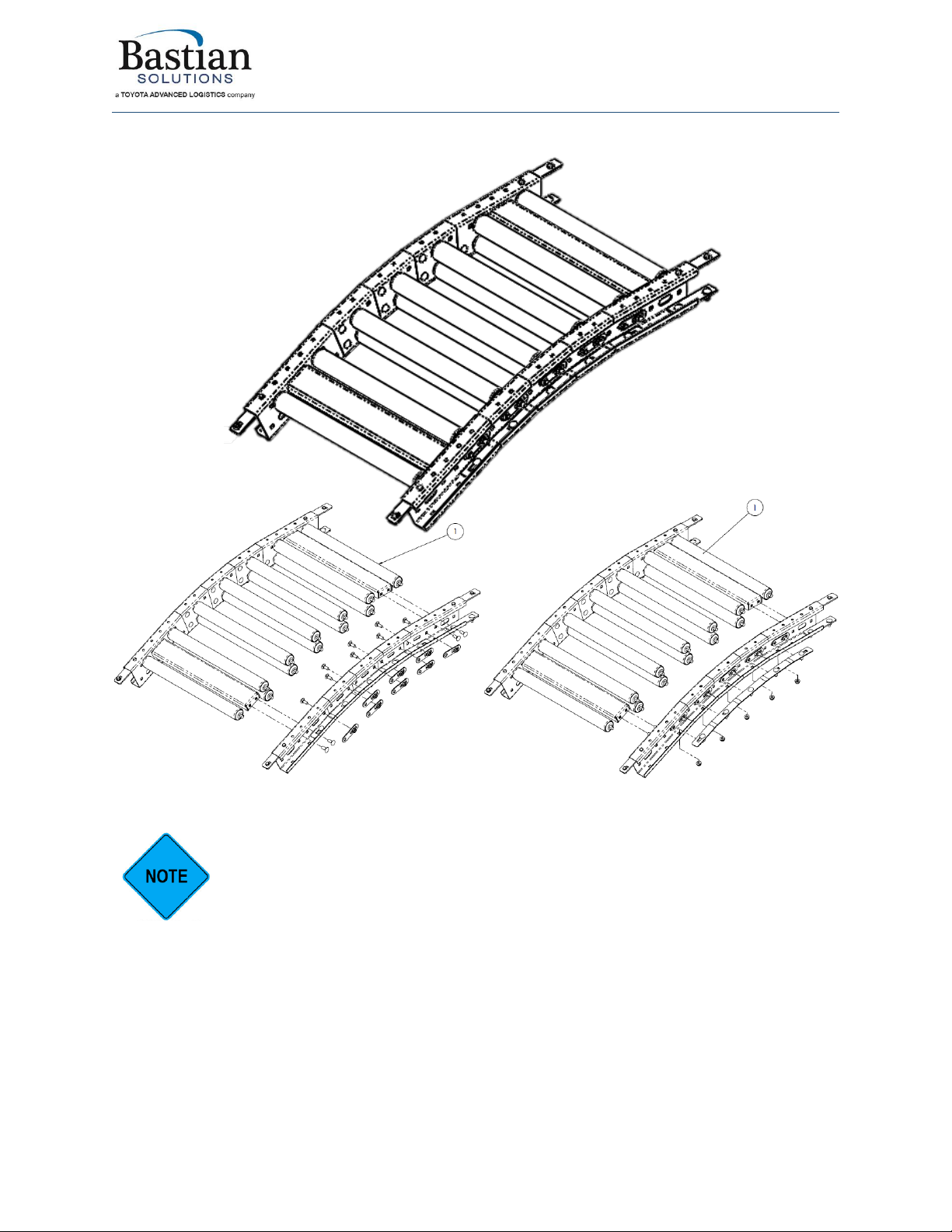

3.4 Noseover Section

The BRBAC noseover section is a 42” conveyor section that is vertically sectioned to allow for angular

adjustment between 0 to 25 degrees. The angular adjustment can be made by adjusting the hardware in

the bottom of the channel in the side frame on both sides. The BRBAC noseover section is offered in

18”, 24”, 30” and 36” OAW. The BRBAC noseover section is identical for all BRBAC configurations.

The BRBAC noseover section is a recommended conveyor section for a BRBAC

incline/decline conveyor. An incline/decline BRBAC conveyor without a noseover

section can result in damage to the package conveyed due to rough transitions

between incline/decline and straight sections.

Figure 6 illustrates the BRBAC noseover section exploded view with a list of spare parts. Appendix 1 has

the general arrangements for the BRBAC noseover section labelled as GA-BRBAC-MW-42-0001.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 14

Figure 6: BRBAC noseover section - exploded view

The BRBAC noseover section does not come standard with underside covers. The

underside covers for the BRBAC noseover section need to be ordered separately as an

accessory.

3.5 Power Feeder Section

The BRBAC power feeder section is a BLVDC conveyor section that is on the upstream section of a

BRBAC incline conveyor, or on the downstream section of a BRBAC decline conveyor. The BRBAC power

feeder section is offered in 18”, 24”, 30” and 36” OAW. The OAL of the power feeder section is

dependent on the system design.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 15

The BRBAC power feeder section is not on the same mark number as the BRBAC

conveyor on shipment.

The BRBAC power feeder section is a recommended conveyor section for a BRBAC

incline/decline conveyor. An incline/decline BRBAC conveyor without a power feeder

section can result in damages to the package conveyed due to rough transitions

between straight and inline/decline sections.

For more information on the BRBAC power feeder section, please refer to Bastian Solutions ZiPline

Conveyor Installation & Maintenance Manual: BLVDC.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 16

4Receiving

Upon delivery of any ZiPline Conveyor, please review and check the following:

•The quantity of items received against the Bill of Lading.

•A visual inspection of equipment should be completed to determine any damage that may have

occurred during shipping. If damage is present, document with pictures.

•Review Mark Number information and layout locations. More information can be found in

subsection 4.1 (Mark Numbers).

If there are any missing or damaged components, please contact your ZiPline Conveyor representative

with as much detail as possible. If you are unsure of your ZiPline Conveyor representative, please

4.1 Mark Numbers

A mark number is a specific number given to a piece of equipment. A mark number is usually made up of

a single product line (RZPDC, RLVDC, BZPDC, etc.) but can contain many bed section lengths. They can

range from two inches to hundreds of feet. The mark number is used to help identify where the piece of

equipment will go within the system layout. The mark number for a BRBAC is segmented to its

constituent sections from upstream to downstream. For example, let’s consider a BRBAC section of

mark number “MK1100” illustrated in Figure 7.

Figure 7: BRBACI conveyor example with mark number "MK1100"

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 17

MK1100 has the following BRBAC sections, organized from upstream to downstream:

•SECTION 1 - BRBAC tail section, 12” OAL, 24” OAW

•SECTION 2 - BRBAC noseover section, 42” OAL, 24” OAW

•SECTION 3 - BRBAC bed section, 120” OAL, 24” OAW

•SECTION 4 - BRBAC bed section, 60” OAL, 24” OAW

•SECTION 5 - BRBAC drive section, 1HP motor side left, 120” OAL, 24” OAL

•SECTION 6 - BRBAC tail section, 12” OAL, 24” OAW

The BRBAC power feeder section is the last section in the list above but will be part of

a different mark number. In this example, the mark number for the BRBAC power

feeder is “MK1100-PF”.

Each BRBAC section will have (2) stickers on the side frame. One sticker on the upstream side of the

conveyor frame, and the other sticker on the downstream side of the conveyor frame. Each sticker

contains the following information.

•ZiPline Project Number and Name

•Model Type

•Mark Number

•Match

•Piece

•Flow direction

Figure 8 illustrates the mark stickers on the side of the section 1 of MK1100 from the example above.

Figure 8: BRBAC mark stickers - section 1

4.2 Skid Contents

Skids will contain varying combinations of conveyor sections, support structures, accessories, and

pertinent hardware. For protection of product integrity during shipping accessories and supports may be

delivered on separate labeled skids. BRBAC accessories include the following:

•Floor supports/Polytier/Ceiling hangers (with mounting hardware)

•AC belt

•Underside bed covers (with mounting hardware)

•Guide rail (with mounting hardware)

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 18

4.3 Skid Documentation

All shipments will contain a Bill of Lading for the delivery company, a skid label, and a skid manifest. Skid

labels have the contents of each shipped item located on the skid. Figure 9 shows a sample of a skid

label. These stickers are placed on the surface of each skid.

Figure 9: Skid Sticker

BRBAC conveyor may arrive in multiple skids for the same mark number. The number of skids shipped is

dependent on the OAW and OAL of the mark number. The accessories for the BRBAC conveyor will ship

on separate skids.

Upon receiving the skid on site, please inspect for any visual damage of the equipment. If there are any

damages, please contact your ZiPline Conveyor representative with images and details of the skid.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 19

5Installation

The installation supervisor on site should have the elevation and layout prints with detailed information

regarding the placement of conveyor sections and support structures. This information is not the

responsibility of ZiPline Conveyor to provide unless otherwise specified.

1. Clear the workspace around the portion of the layout selected for installation.

2. Ensure that the conveyor and accessory skids containing the correct BRBAC mark number are

unpacked and all components are accounted for.

3. Measure out from the constrained origin to start placement of supports. It is recommended that

snap chalk lines are used, or other methods of keeping a consistent line.

4. Use the elevation layouts to determine the conveyor top of conveyor surface and the

incline/decline angle of a mark section.

5. Place the support type that the layout designates. Each support type has a corresponding mark

sticker.

6. Check the flow direction on the mark stickers to ensure that conveyor is mounted properly.

7. Place the conveyor onto the support structure and fasten 3/8” -16 carriage bolts and serrated

flange nuts. Torque the serrated flange nuts to 31 ft-lb.

8. Refer to Section 5.5 to install and adjust the angle of the noseover section.

Do not lift the drive section of the conveyor using the lifting lug on the AC motor and

gearbox. This will cause damage to the gearbox and drive pulley. Use any mounting

point at the corners of the drive section.

9. Check for straightness and level of the conveyor sections. See instructions in section 5.2.

10. Route the supplied AC belt through the assembled conveyor. See instructions in section 5.3.

11. Attach any applicable accessories and connecting hardware to the mounted conveyor section.

12. Check that the upstream and downstream heights of the conveyor section agree with the

system layout instructions.

13. Secure the supports to the floor (or other permanent fixture).

ZiPline Conveyor does not provide hardware for attaching floor supports to the floor

or other permanent surface.

The floor supports of the installed BRBAC conveyor section must be permanently

secured prior to operation. Failure to do so can cause damage to the equipment and

injure personnel in the area. Please take necessary precautions during install.

5.1 Floor Support Location

When locating the floor support locations on site, ZiPline Conveyor recommends reviewing the

guidelines outlined in Bastian Solutions ZiPline Conveyor - Support Installation Manual.

There are two floor supports between the power feeder and the tail section. If you have a floor support

missing, contact your ZiPline conveyor representative.

Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019 Rev.A1 20

5.2 Uniform Levelling and Straightness of Conveyor Section

The straightness of the BRBAC sections is critical to the performance of the conveyor. Please ensure that

the conveyor bed sections are checked for uniform level and straightness. To check for uniform levelling,

use a large level guide to confirm that all conveyor sections are appropriately levelled. To ensure that

the conveyor sections are straight and square, measure the diagonals of each conveyor section. Figure

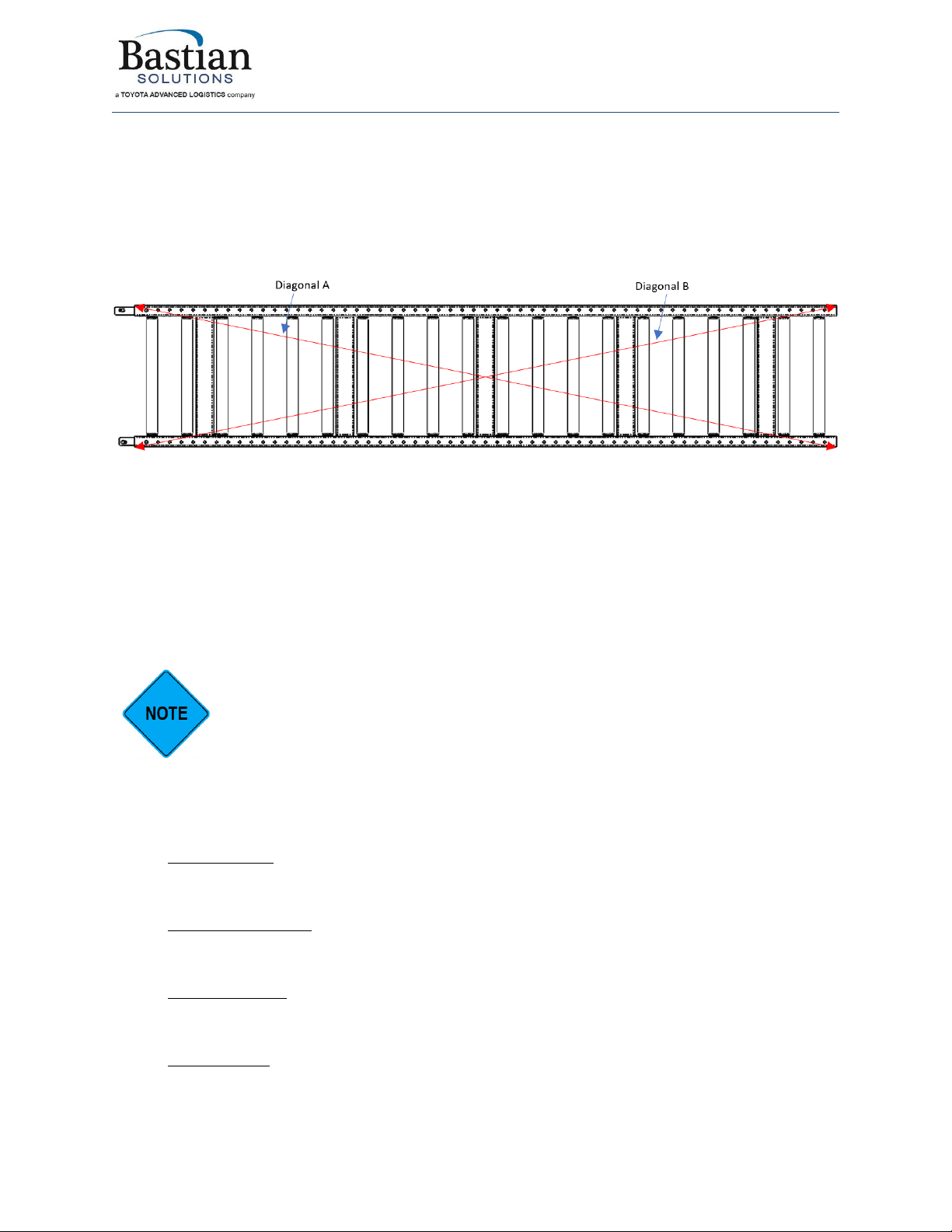

10 illustrates the diagonal measurement for the conveyor sections.

Figure 10: Diagonal measurement for conveyor section

•If the dimension of diagonal A and diagonal B of the bed section are within 1/16” of each other,

then the bed is sufficiently square.

•If the two diagonals of the bed section are different by more than 1/16”, adjust the splice plate

and floor support mounting hardware.

•If this adjustment is not sufficient, attach turnbuckles under the conveyor section and adjust for

square accordingly. Turnbuckles are typically installed to the bottom mounting holes of the

sideframe of a BRBAC section.

ZiPline Conveyor does not supply turnbuckle kits for additional section straightness

adjustments.

5.3 Installing the AC Belt

ZiPline Conveyor BRBAC comes available with four standard belt types. The belt and additional

documentation are as follows:

1. Rough Top Belt –The Rough top belt is a “trackmate”general purpose nonwoven PVC heavy

conveyor belt with a rough top (one side only). The product data sheet is called Habasit Heavy

Conveyor Belts TM120RT-B (Code: H250000385).

2. Longitudinal Rib Belt –The Longitudinal Rib Belt is a “trackmate”general purpose nonwoven

PVC heavy conveyor belt with a longitudinal groove structure. The product data sheet is called

Habasit Heavy Conveyor Belts TM120LR-B (Code: H250000441).

3. Brushed Top Belt –The brushed top is a rubber saturated “ulti-mate”nonwoven heavy conveyor

belt with an impregnated fleece on one side. The product sheet is called Habasit Heavy

Conveyor Belts UMS130SC-B (Code: H250000560).

4. Glide Top Belt –The glide top belt is a rubber conveyor and processing belt with a low friction

surface. The product sheet is called Habasit Product Data Sheet RGLIDE-T.

Table of contents

Other Bastian Solutions Accessories manuals

Popular Accessories manuals by other brands

ELEKTROBOCK

ELEKTROBOCK TS10 manual

Johnson Controls

Johnson Controls NS Series installation instructions

Cognex

Cognex In-Sight 2000 Training manual

ML

ML Knightsbridge SKR003A Installation & maintenance manual

PRÜFTECHNIK

PRÜFTECHNIK Fluke DBS 30 operating instructions

Novital

Novital Covatutto 108 User instruction