EN-5

a holder wherever practicable) and rough material;

- connect the saw to a dust collecting device when sawing

wood. In addition the operator shall be informed of factors that

inuence exposure of dust and the precautions mentioned e.g.

type of material to be machined and the importance of local

extraction (capture or source) and proper adjustment of hoods/

bafes/chutes;

Safe operation

- select the correct saw blade for the material to be cut;

- do not use the saw to cut other materials than those

recommended by the manufacturer;

- lifting and transportation information: Information shall include

where to lift and support the mitre saw and when necessary a

warning not to use guards for this purpose;

- do not use the saw without the guards in position, in good

working order and properly maintained;

- ensure that the arm is securely xed when bevelling;

- keep the oor area around the machine level, well maintained

and free of loose materials e.g. chips and cut-offs;

- provide adequate general or localised lighting;

- the operator is adequately trained in the use, adjustment and

operation of the machine;

- use correctly sharpened saw blades. Observe the maximum

speed marked on the saw blade;

- ensure that any spacers and spindle rings used are suitable for

the purpose as stated by the manufacturer;

- when tted with laser, no exchange with different type of laser

is permitted. Repairs shall only be carried out by the laser

manufacturer or an authorised agent;

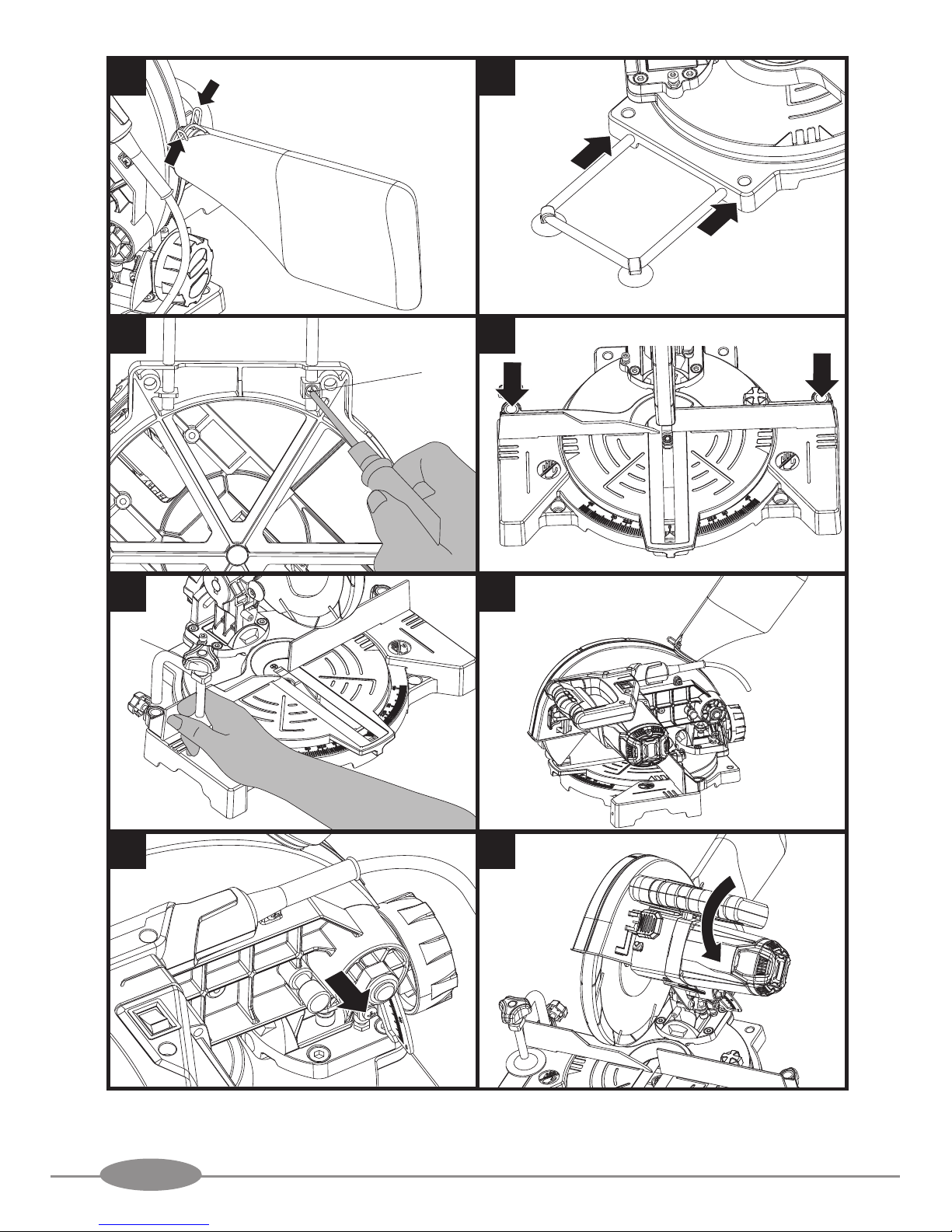

- blade replacement procedure including the method for

repositioning and a warning that this must be carried out

correctly;

- refrain from removing any cut-offs or other parts of the

workpiece from the cutting area whilst the machine is running

and the saw head is not in the rest position;

- always to clamp work pieces to the saw table

- to ensure before each cut that the machine is stable,

- if needed, to x the machine to a work bench or the like,

- if needed, to support long work pieces with appropriate

additional supports;