Bavaria BPH 2652/1 User manual

BPH 2652/1

Original operating instructions

Petrol Hedge Trimmer

Art.-Nr.: 34.038.18 I.-Nr.: 11013

Anleitung_BG-PH_2652_SPK1__ 12.06.2012 8:20 Uhr Seite 1

2

Read and follow the operating instructions and safety information

before using for the first time.

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 2

3

1

2

161143

2

1

13 6

20

18

19

3

8

14

7

17 510 9

14

7

815

12

21

6

13

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 3

4

4 5

6 7

8 9

5A

45°

45°

90°

90°

9

B

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 4

5

10 11

12 13

14 15

A

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 5

6

16

12

17

3

18

4

19

5

20

12345

78910

11

6

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 6

Important!

When using the equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating instructions and

safety regulations with due care. Keep this manual in

a safe place, so that the information is available at all

times. If you give the equipment to any other person,

hand over these operating instructions and safety

regulations as well. We cannot accept any liability for

damage or accidents which arise due to a failure to

follow these instructions and the safety instructions.

1. Safety regulations

The corresponding safety information can be found

in the enclosed booklet.

CAUTION!

Read all safety regulations and instructions.

Any errors made in following the safety regulations

and instructions may result in an electric shock, fire

and/or serious injury.

Keep all safety regulations and instructions in a

safe place for future use.

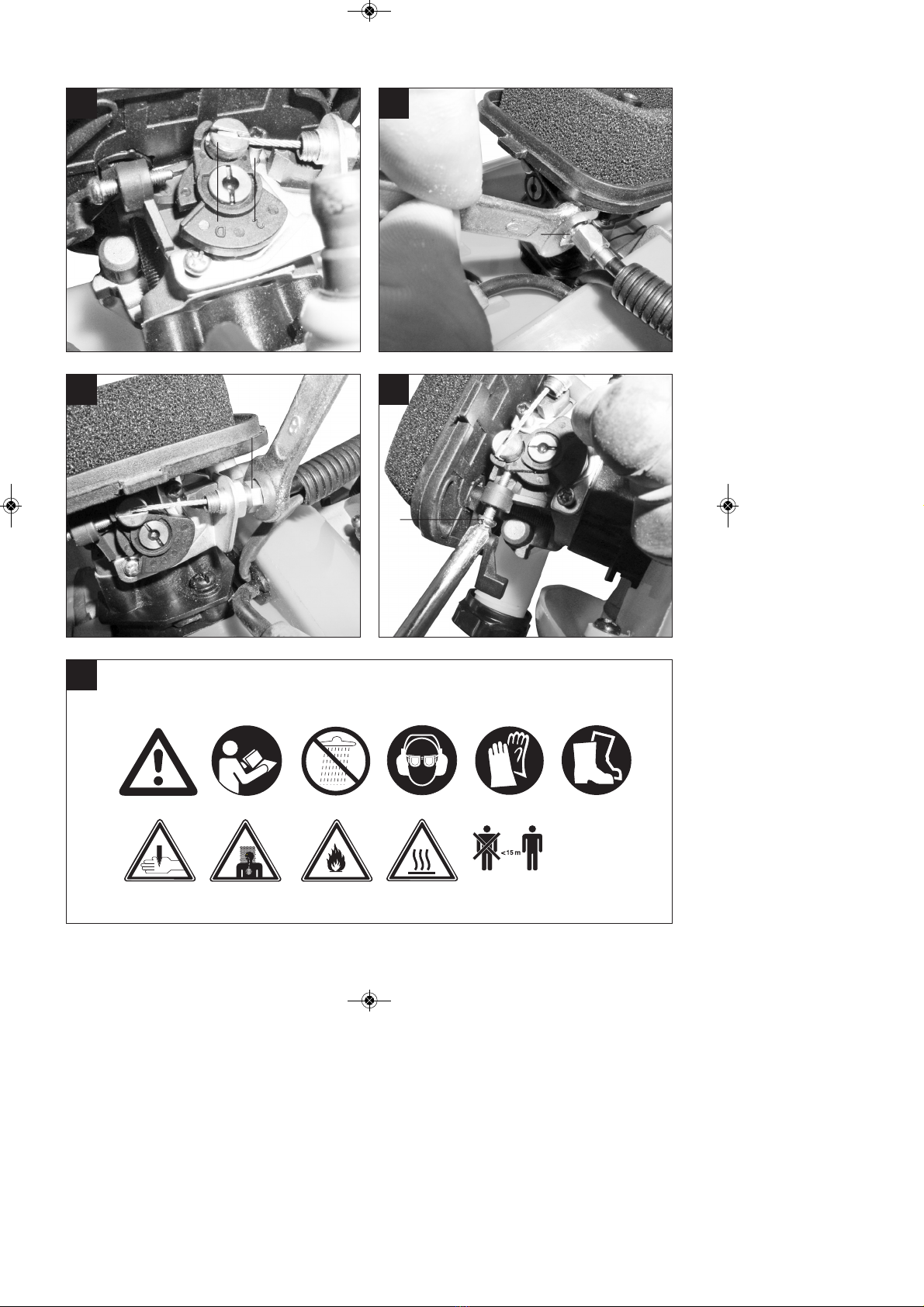

Explanation of the warning signs on the

equipment (see Fig. 20)

1. Warning!

2. Read the directions for use before operating the

equipment.

3. Do not expose the hedge trimmer to rain or wet

conditions.

4. Wear eye protection and ear plugs.

5. Wear safety gloves.

6. Wear sturdy, non-slip footwear.

7. Caution: Sharp blades! Always keep hands and

feet away from the blades.

8. Operate and start the equipment only outdoors in

well ventilated areas to reduce the danger of

injury from toxic gases.

9. Explosive material.

10. Very hot surface. Do not touch the hot exhaust

silencer, gearbox or cylinder. You may burn

yourself. These parts have become very hot

during operation and remain very hot over a long

period even after the equipment has been

switched off.

11. Maintain a distance of at least 15 m from other

persons.

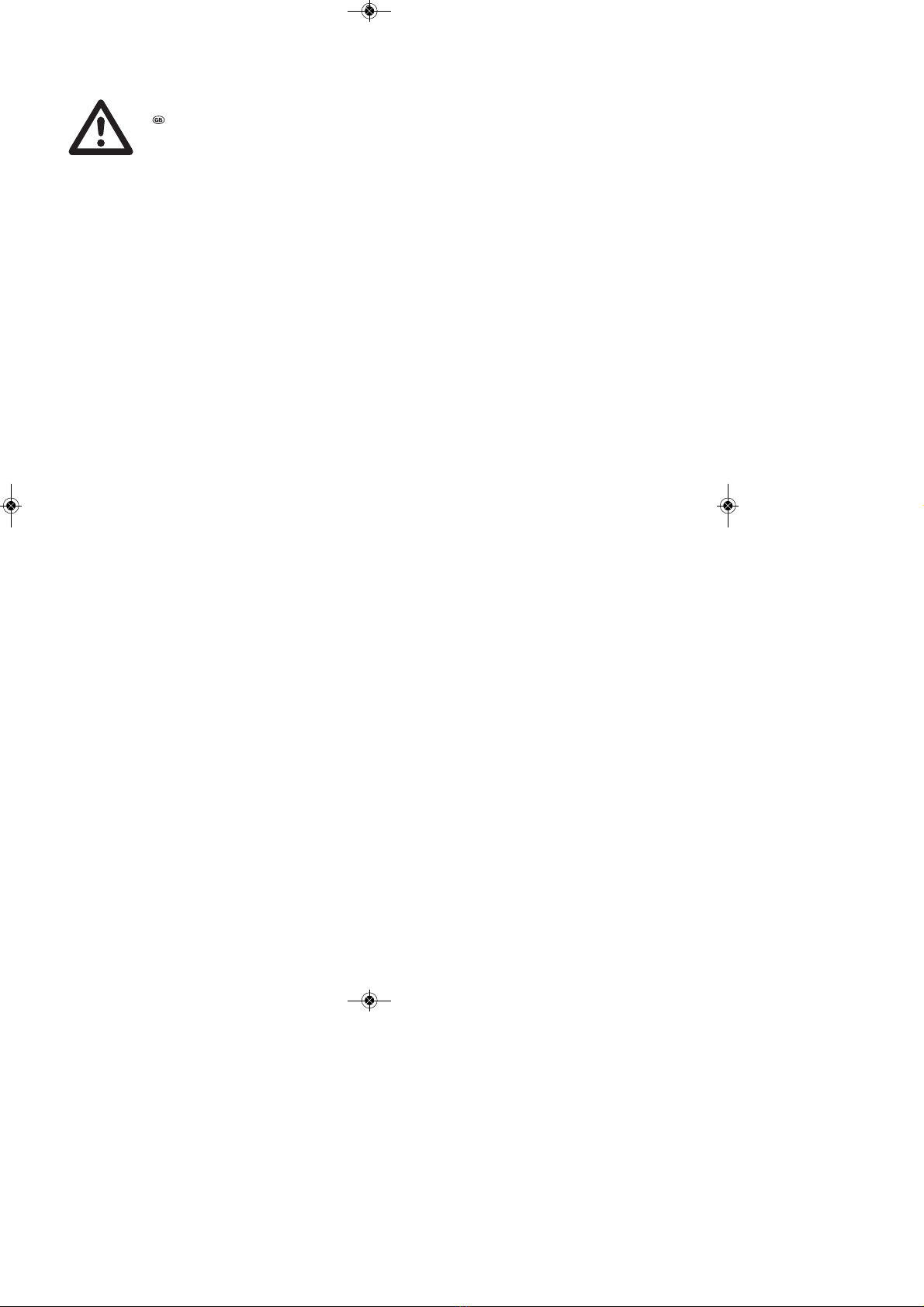

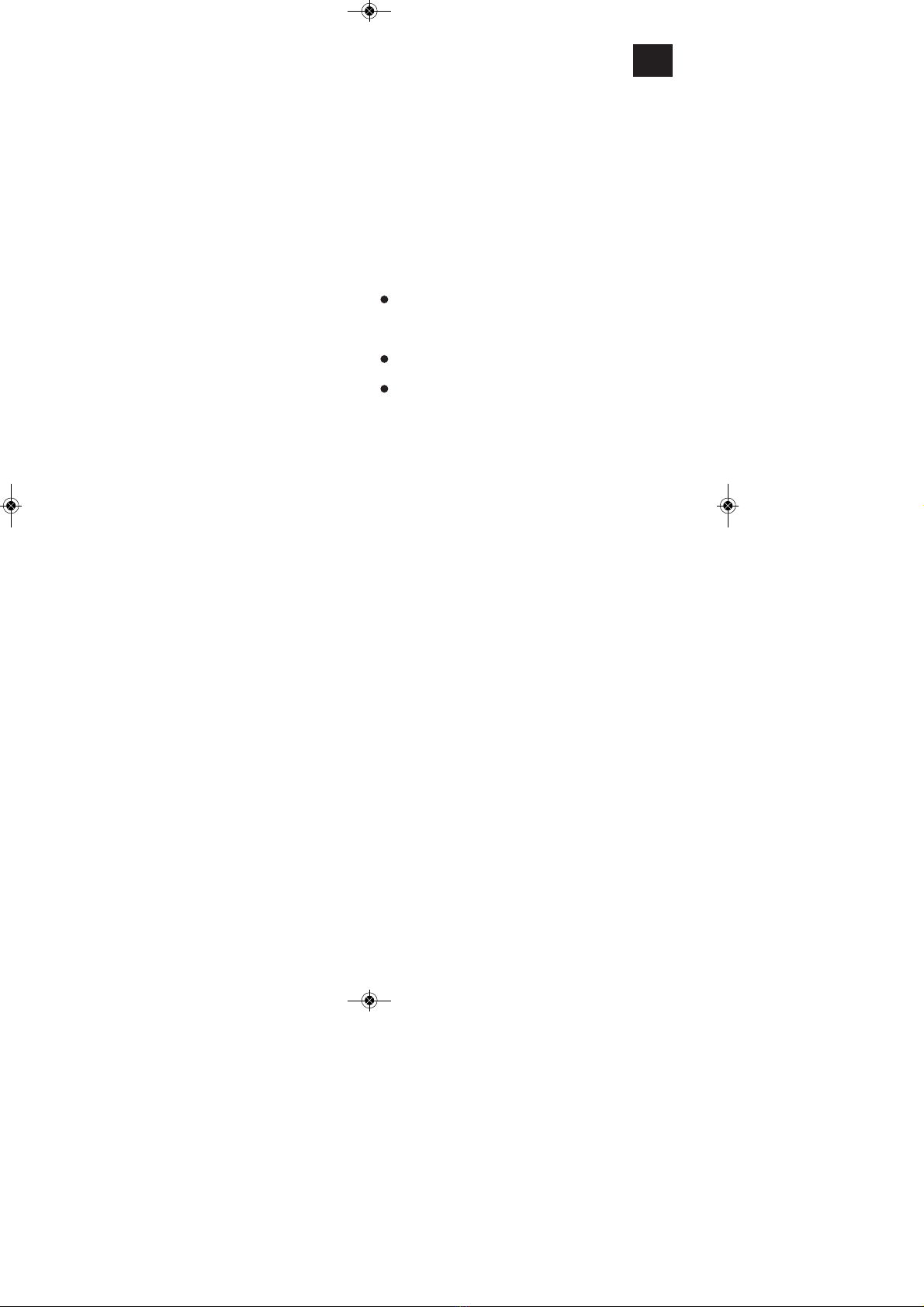

2. Layout and items supplied (Fig. 1-2)

1. Cutting blade

2. Cutting blade safety cover

3. Safety plate

4. Front handle

5. Choke lever

6. ON/OFF switch

7. Locking knob for throttle lever

8. Locking knob for rotary handle

9. Fuel pump (primer)

10. Air filter cover

11. Starter handle

12. Rear handle

13. Throttle lever “release”

14. Throttle lever

15. Silencer cover

16. Tank for fuel mixture

17. Spark plug boot

18. Spark plug wrench

19. 8 mm / 10 mm open-ended spanner

20. Combined oil/petrol cylinder

21. Cutter rail cover

3. Proper use

Important. This hedge trimmer is suitable for cutting

hedges, bushes and shrubs.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

equipment is used in commercial, trade or industrial

businesses or for equivalent purposes.

GB

7

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 13

4. Technical data

Engine type:

2-stroke engine, air-cooled, chrome cylinder

Engine output (max.): 0.75 kW / 1.0 hp

mcc62:tnemecalpsiD

Idle speed of engine: 2960 min-1

nim0088deepsenigne.xaM -1

Weight (with empty tank): 5.5 kg

mc56:htgnelliarrettuC

mc25:htgnelgnittuC

mm82:gnicapshtooT

mm91).xam(yticapacgnittuC

l5.0:yticapacknaT

A7RMPBKGN:gulpkrapS

Max. cutting speed 2300 ± 100 cuts/min

Vibration (front handle) ahv 13.33 m/s2

s/m5,1ytniatrecnuK 2

Vibration (rear handle) ahv 7.69 m/s2

s/m5,1ytniatrecnuK 2

Sound pressure level LpA 97 dB

Bd3ytniatrecnuK

Sound power level LWA 107 dB

Bd3ytniatrecnuK

Sound and vibration were measured in accordance

with DIN EN 10517.

5. Before starting the machine

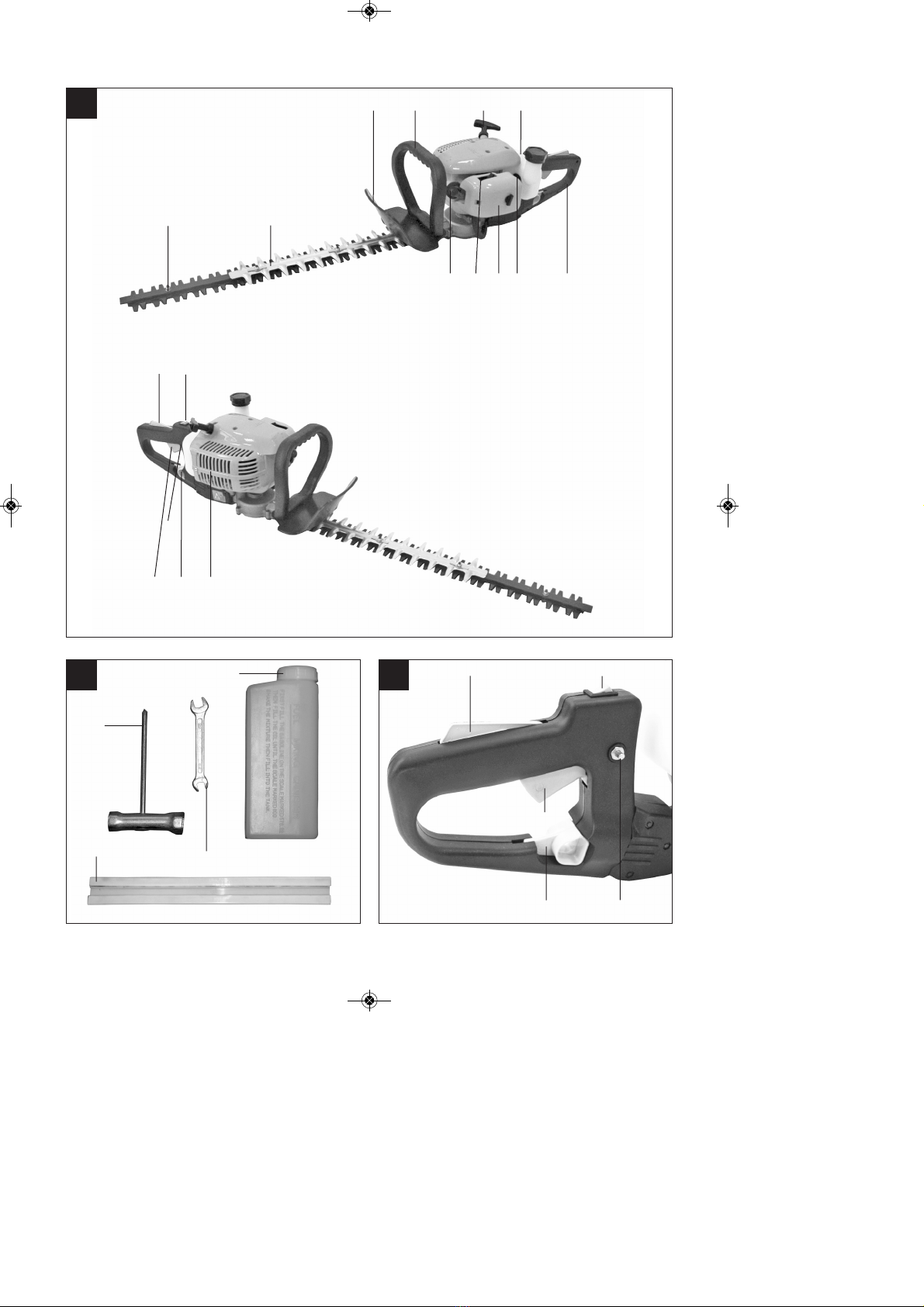

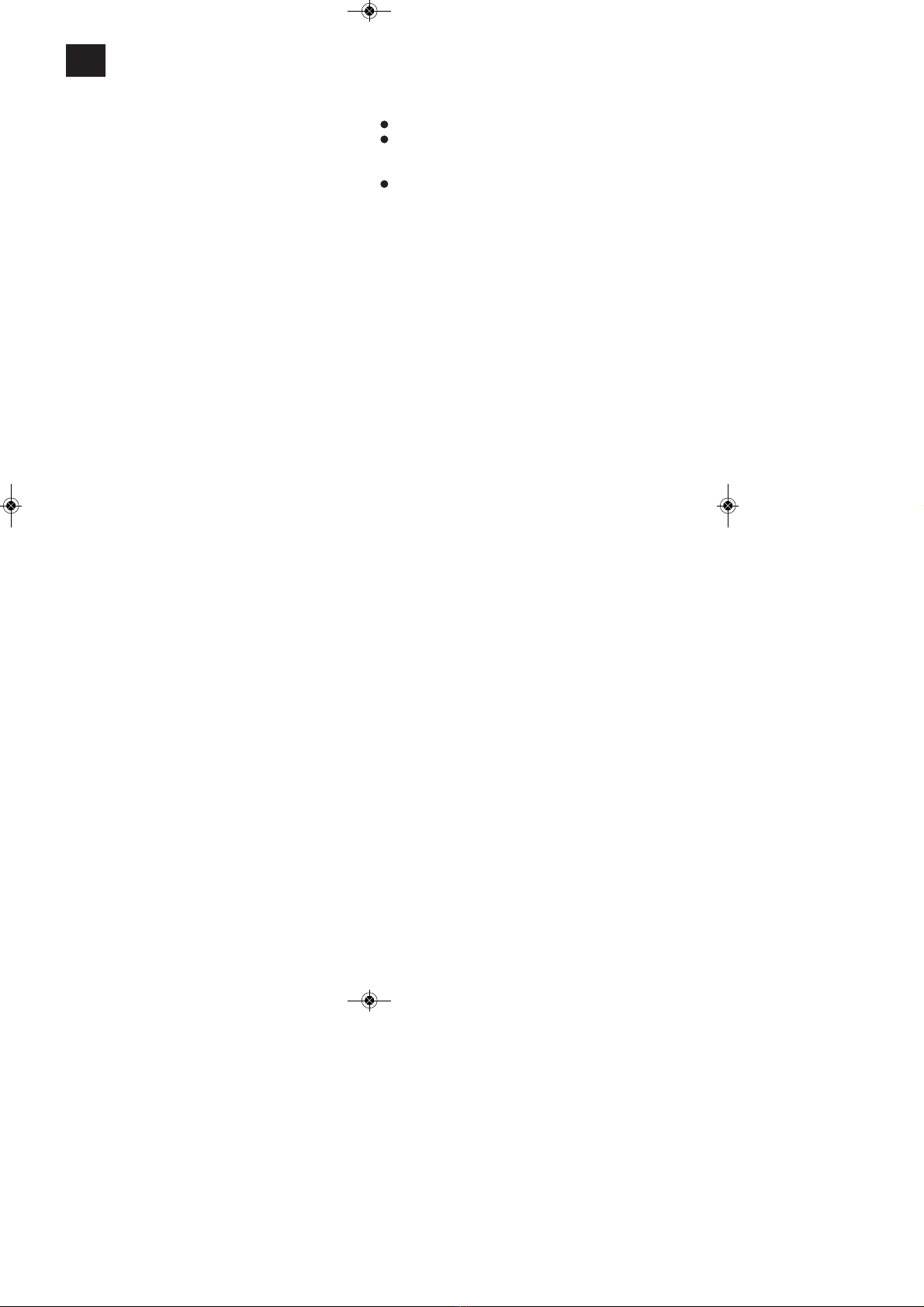

5.1 Installation

The hedge trimmer is supplied fully assembled. No

assembly work is required.

To make it easier to control, the machine is fitted with

a rotary handle that can be adjusted as required into

positions at angles of -90°/-45°/0°/+45°/+90°. To do

this, pull the lever (Fig. 5/Item B) backwards, turn the

rotary handle into the required position and then

allow the lever to lock at the front again. The various

adjustable positions facilitate working above head

height or in other places with different access.

Please note: The rotary handle may only be

adjusted when the engine is switched off.

5.2 Fuel and oil

Recommended fuels

Use only a mixture of normal unleaded petrol and

special 2-stroke engine oil. Mix the fuel mixture as

indicated on the fuel mixing table.

Please note: Do not use a fuel mixture which has

been kept for longer than 90 days.

Please note: Do not use 2-stroke oil with a

recommended mixing ration of 100:1. If inadequate

lubrication causes engine damage, the

manufacturer’s engine warranty will be voided.

Please note: Only use containers designed and

approved for the purpose to transport and store fuel.

Pour the correct quantities of petrol and 2-stroke oil

into the mixing bottle (see scale printed on the

bottle). Then shake the bottle well.

5.3 Fuel mixture table

Mixing procedure: 40 parts petrol to 1 part oil

6. Operation

Please note that the statutory regulations governing

noise abatement may differ from town to town.

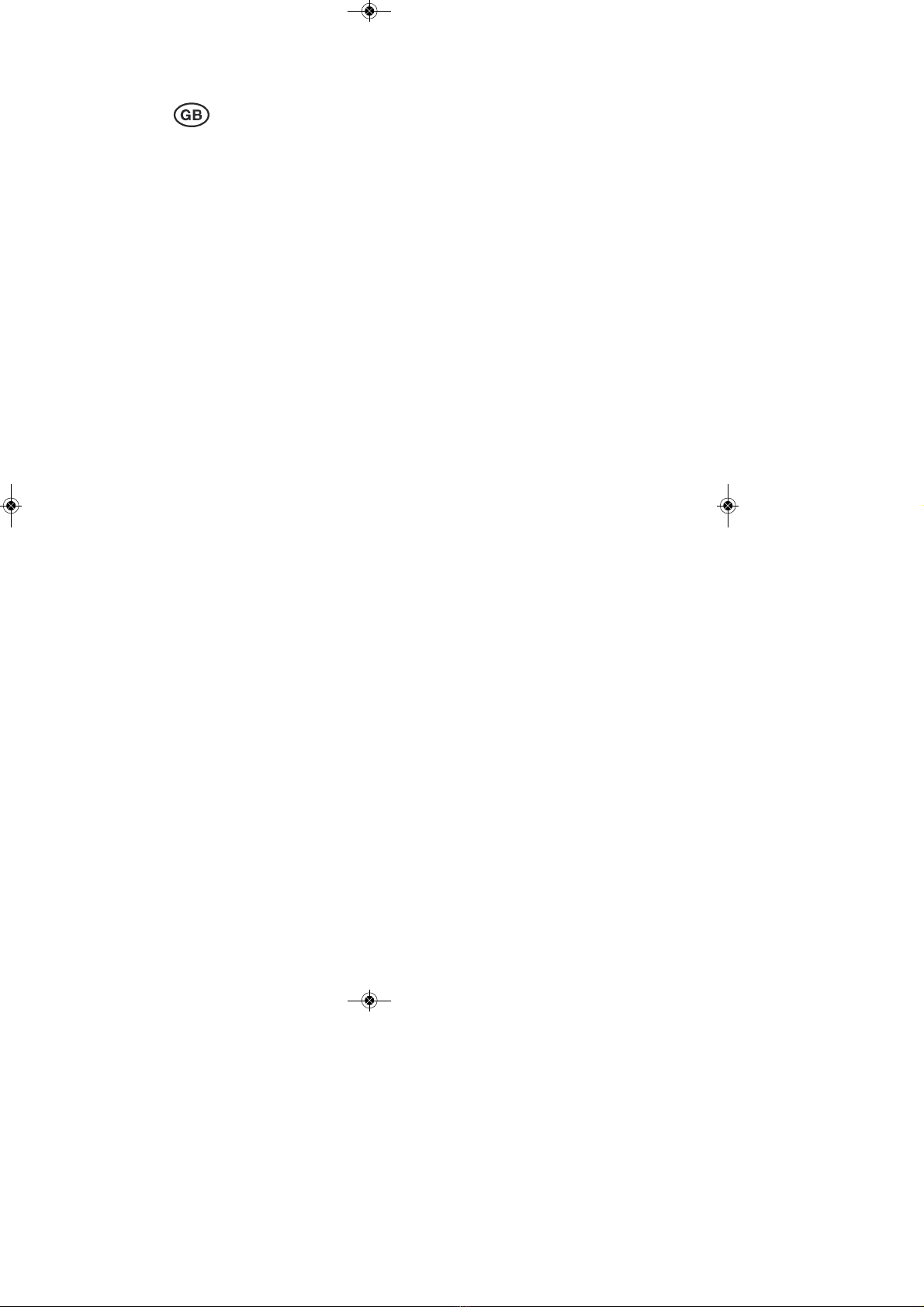

6.1 Starting the engine from cold (Fig. 3-5)

Fill the tank with the required amount of oil/petrol

mix.

1. Set the machine down on a hard, level surface.

2. Set the choke lever (Fig. 4/Item 5) to “ ”.

3. Press the fuel pump (primer) (Fig. 4/Item 9) 10

times.

4. Move the ON/OFF switch (Fig. 3/Item 6) to “I”

5. Secure the throttle lever. To do this, press the

throttle lever lock (Fig. 3/Item 13) and then press

the throttle lever (Fig. 3/Item 14) and lock the

throttle lever by pressing the locking knob (Fig.

3/Item 7) at the same time.

6. Hold the machine by the front handle in your

right hand and pull the starter cable (Fig. 5/Item

A) up to the first resistance point (approx. 10

cm). Then tug sharply on the starter cable 4

times. The machine should start.

Please note: Never allow the starter cable to

snap back. This may damage the machine.

7. If the engine has started, set the choke lever

immediately to “ ” and allow the machine to

GB

8

Petrol 2-stroke oil

1 liters 25 ml

5 liters 125 ml

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 14

warm up for approx. 10 seconds.

Then release the throttle lever by simply

actuating it (the engine then returns to running in

idle mode).

8. If the engine does not start up, repeat steps 6-7

above.

Please note: If the engine does not start up even

after several attempts, read the section “Engine

Troubleshooting”.

Please note: Always pull the starter cable out in a

straight line. If it is pulled out at an angle, then friction

will occur on the eyelet. As a result of this friction, the

cable will become frayed and will wear away faster.

6.2 Starting the engine when warm (if the

machine has not been switched off for more than

15 – 20 minutes)

1. Set the machine down on a hard, level surface.

2. Switch the ON/OFF switch to “I”.

3. Secure the throttle lever (in the same way as

described in “Starting the engine when cold”).

4. Hold the machine by the front handle in your

right hand and pull the starter cable up to the first

resistance point (approx. 10 cm). Then tug

sharply on the starter cable. The machine should

start after 1-2 tugs. If the machine does not start

after 6 pulls, repeat steps 1 – 7 of the procedure

for starting the engine from cold.

6.3 Switching off the engine

Emergency Stop procedure:

If it becomes necessary to stop the machine

immediately, set the ON/OFF switch to “Stop” or “0”

Normal procedure:

Let go of the throttle lever and wait until the engine

has changed to idling speed. Then set the ON/OFF

switch to “Stop” or “0”.

6.4 Practical tips

Never allow the machine to run at low speed for

starting or for cutting.

Cutting for dense growth: The most effective

method is to use wide, sweeping movements,

guiding the cutting edge of the blade straight through

the branches. A slight incline of the blade downwards

towards the movement will produce best cutting

results.

It is recommended to tie a guide line of string or the

like along the hedge so that you cut the hedge to a

level height. The branches above it will be cut off.

(Fig. 6)

Cutting the side of a hedge: Cut the sides of the

hedge with curve-shaped movements from the

bottom up. (Fig. 7)

Please note: As a result of its design, if you work

with the machine on its side for a lengthy period and

the tank not completely filled, the motor may stall.

7. Cleaning, maintenance, storage and

ordering of spare parts

7.1 Cleaning

Keep all safety devices, air vents and the motor

housing free of dirt and dust as far as possible.

Wipe the equipment with a clean cloth or blow it

with compressed air at low pressure.

We recommend that you clean the device

immediately each time you have finished using it.

Clean the equipment regularly with a moist cloth

and some soft soap. Do not use cleaning agents

or solvents; these could attack the plastic parts of

the equipment. Ensure that no water can seep

into the device.

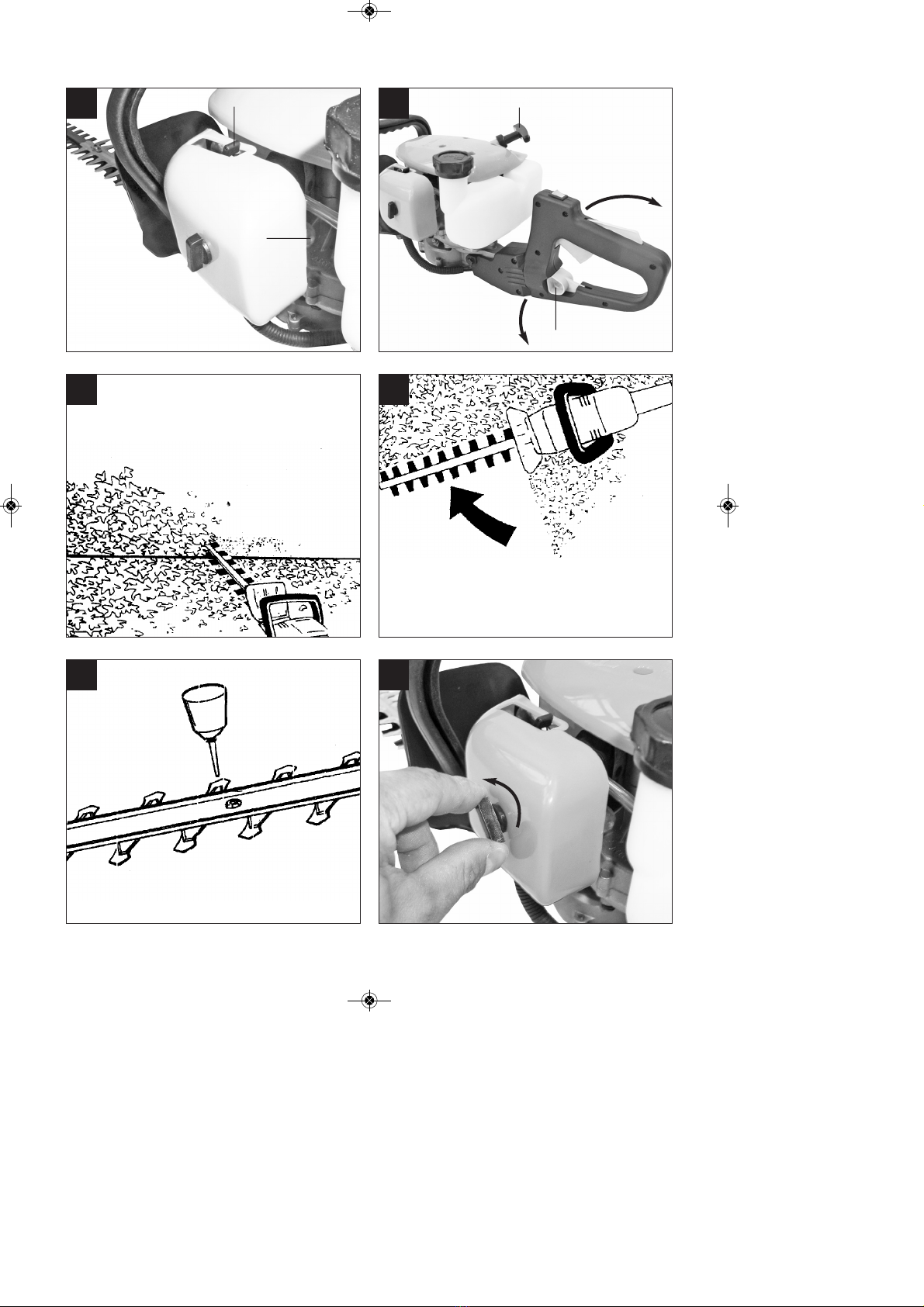

7.2 Maintenance

Always switch off the head trimmer and remove the

spark plug boot before carrying out any maintenance

work.

1. The cutter blades are high quality, made of

tempered steel and in normal use there is no

need to sharpen the blades. If you accidentally

strike a wire, stone, glass or other hard object,

this may cause a notch in the blade. There is no

need to remove the notch as long as it does not

adversely affect the movement of the cutting

edges. If it does adversely affect this movement,

switch off the machine and use a fine file or a

fine grinding stone to remove the notch. Ensure

that the blade’ s cutting edge is always well oiled

(see Fig. 8).

2. If you drop the hedge trimmer, check whether it

has suffered any damage. If it is damaged

contact an authorized customer service outlet or

call 1300 922 271.

3. Only clean the machine after it has been

switched off. Use only mild soap and a damp

cloth to clean it. Never allow fluid to get into the

machine. Do not use caustic cleaning products.

GB

9

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 15

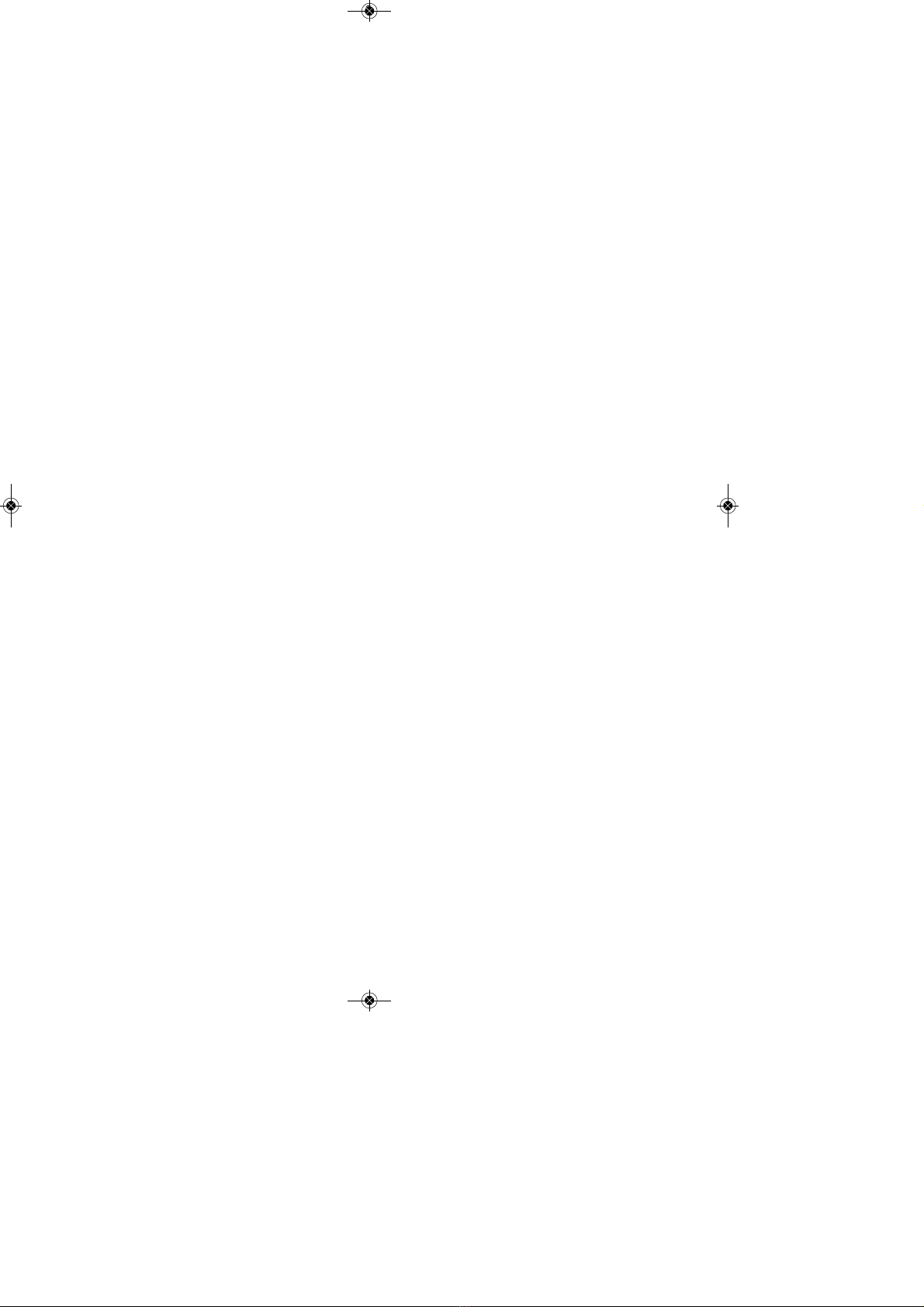

7.2.1 Maintenance of the air filter (Fig. 9-11)

Soiled air filters reduce the engine output by supply

too little air to the carburetor.

Regular checks are therefore essential. The air filter

should be checked after every 25 hours of use and

cleaned if necessary. If the air contains a lot of dust,

the air filter should be checked more frequently.

1. Remove the air filter cover (Fig. 9-10)

2. Remove the filter element (Fig. 11)

3. Clean the filter element by tapping it or blowing

it.

4. Assemble in reverse order.

Please note: Never clean the air filter with petrol or

inflammable solvents. Clean the air filter with

compressed air or by tapping it.

7.2.2 Maintenance of the spark plug (Fig. 12-14)

Spark plug gap = 0.025 inch (0.635 mm). Tighten the

spark plug with a torque of 12-15 Nm.

Check the spark plug for dirt and grime after 10

hours of operation and if necessary clean it with a

copper wire brush. Thereafter service the spark plug

after every 50 hours of operation.

1. Pull off the spark plug boot (Fig. 13) by twisting.

2. Remove the spark plug (Fig. 14) with the

supplied spark plug wrench.

3. Assemble in reverse order.

7.2.3 Maintenance of the gearbox (Fig. 15)

The gearbox must be lubricated every year before

the start of the season at the lubrication nipple (Fig.

15/Item A). Place a conventional grease gun on the

nipple and press approx. 3 strokes of conventional

machine grease into the gearbox. If you use the

trimmer frequently, grease the gearbox more often.

7.2.4 Carburetor settings

Important. Settings on the carburetor may only be

made by authorized customer service personnel.

The air filter cover must be removed before any work

on the carburetor, as shown in Figures 9 – 10.

Setting the throttle cable:

If the maximum speed of the machine falls over time

and you have ruled our all the other causes listed in

section 9 Troubleshooting, it may be necessary to

adjust the throttle cable.

First of all check whether the carburetor opens fully

when the throttle handle is pressed fully. This is the

case if the carburetor slide (Fig. 16/Item 1) rests

against the stop (Fig. 16/Item 2) when the throttle is

fully open. Figure 16 shows the correct setting. If the

carburetor slide does not touch the stop, it must be

adjusted.

The following work is required to adjust the throttle

cable:

Undo the lock nut (Fig. 17/Item 3) a few turns.

Undo the adjusting screw (Fig. 18/Item 4) until

the carburetor slide rests against the stop when

the throttle is fully open, as shown in Figure 16.

Retighten the lock nut.

Setting the idling speed:

Important. Set the idling speed when the machine is

warm.

If the engine stalls when the throttle is not pressed

and you have ruled out all the other causes listed in

section 9 Troubleshooting, the idling speed must be

adjusted. To do this turn the idling speed screw (Fig.

19/Item 5) clockwise until the machine runs smoothly

at idling speed.

If the idling speed is so fast that the cutting blades do

not reach a standstill, the idling speed must be

reduced by turning the idling speed screw (Fig.

19/Item 5) counterclockwise until the cutting blades

stop.

7.3 Storage

Please note: If you fail to follow these instructions

correctly, deposits may form on the interior of the

carburetor which may result in the engine being more

difficult to start or the machine suffering permanent

damage.

1. Carry out all the maintenance work.

2. Drain the fuel out of the tank (use a conventional

plastic petrol pump from a DIY store for this

purpose).

3. When the fuel has been drained, start the

engine.

4. Allow the engine to run at idling speed until it

stops. This will clean the remainder of the fuel

out of the carburetor.

5. Leave the machine to cool (approx. 5 minutes).

6. Remove the spark plug (see point 7.2.2).

7. Place a teaspoon full of 2-stroke engine oil into

the combustion chamber. Pull the starter cable

several times carefully to wet the internal

components with the oil. Fit the spark plug again.

8. Clean the exterior housing of the machine.

9. Store the machine in a cold, dry place where it is

out of the reach of ignition sources and

inflammable substances.

10. Always place the cover over the cutter when

transporting or storing the equipment.

GB

10

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 16

GB

11

Fertilizers and other chemical garden products often

contain substances that accelerate the rate of

corrosion of metals. Do not store the machine on or

near fertilizers or other chemicals.

Restarting

1. Remove the spark plug.

2. Pull the starter cable several times to clean the

oil residue out of the combustion chamber.

3. Clean the spark plug contacts or fit a new spark

plug.

4. Fill the tank. See the section entitled Fuel and oil.

5. Complete steps 1-7 described under the point

entitled “Starting the engine from cold”.

7.4 Ordering replacement parts

Please quote the following data when ordering

replacement parts:

Type of machine

Article number of the machine

Identification number of the machine

Replacement part number of the part required

For our latest prices and information please call

1300 922 271.

8. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material

and can therefore be reused or can be returned to

the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 17

GB

12

Fault Possible cause Troubleshooting

The machine does not start. Correct starting procedure not

followed.

Follow the instructions for starting.

Sooted or damp spark plug Clean the spark plug or replace it

with a new one.

Incorrect carburetor setting Contact an authorized customer

service outlet or call

1300 922 271.

The machine starts but does not

develop its full output.

Incorrect choke lever setting Set choke lever to

Soiled air filter Clean the air filter

Incorrect carburetor setting Contact an authorized customer

service outlet or call

1300 922 271.

The engine does not run smoothly Incorrect electrode gap on the

spark plug

Clean the spark plug and adjust

the electrode gap or fit a new spark

plug.

Incorrect carburetor setting Contact an authorized customer

service outlet or call

1300 922 271.

Engine smokes excessively Incorrect fuel mix Use the correct fuel mix (see fuel

mixing table)

Incorrect carburetor setting Contact an authorized customer

service outlet or call

1300 922 271.

9. Troubleshooting

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 18

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 19

EINHELL AUSTRALIA PTY LTD

6/166 Wellington Street

Collingwood VIC 3066

Australia

Phone: 1300 922 271

Dear

Customer,

All of our products undergo strict quality checks. In the unlikely event that your device develops a fault, please

contact our service department at the address shown on this guarantee certificate. Of course, if you would

prefer to call us then we are also happy to offer our assistance under the service number printed below.

Please note the following terms under which claims under the Einhell Express Guarantee can be made:

1. The benefits conferred by the Einhell Express Guarantee are in addition to all rights and remedies which

you may be entitled to under the Australian Consumer Law, and any other statutory rights you may have

under other applicable laws. This Einhell Express Guarantee does not exclude, restrict or modify any

We do not charge you for the Einhell Express Guarantee.

2. Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods

fail to be of acceptable quality and the failure does not amount to a major failure.

3. The Einhell Express Guarantee only covers problems caused by material or manufacturing defects, and

our liability under the Einhell Express Guarantee is limited, at our discretion, to the rectification of these

defects or replacement of the product. Please note that the product has not been designed for use in

commercial, trade or industrial applications. Consequently, the Einhell Express Guarantee will not apply

if the product is used in commercial, trade or industrial applications or for other equivalent activities.

4. The following are also excluded from the Einhell Express Guarantee: compensation for transport

damage, damage caused by failure to comply with the installation/assembly instructions or damage

caused by unprofessional installation, failure to comply with the operating instructions (e.g. connection to

the wrong mains voltage or current type), misuse or inappropriate use (such as overloading of the

product or use of non-approved tools or accessories), failure to comply with the maintenance and safety

regulations, ingress of foreign bodies into the product (e.g. sand, stones or dust), effects of force or

external influences (e.g. damage caused by the product being dropped) and normal wear resulting from

proper operation of the product. The Einhell Express Guarantee will also not apply if any attempt is made

5. The Einhell Express Guarantee is valid for a period of 2 years starting from the purchase date of the

product. Claims made under the Einhell Express Guarantee should be submitted before the end of this

guarantee period and within two weeks of the defect being noticed. No claims under the Einhell Express

Guarantee will be accepted if submitted after the end of this guarantee period. The original guarantee

period remains applicable to the device even if repairs are carried out or parts are replaced. In such

cases, the work performed or parts fitted will not result in an extension of the guarantee period for the

Einhell Express Guarantee, and the Einhell Express Guarantee will not apply for the work performed or

6. To make a claim under the Einhell Express Guarantee, please send the relevant product postage-free to

the address shown below and enclose either the original or a copy of your sales receipt or another dated

proof of purchase. It would help us if you could describe the nature of the problem in as much detail as

possible. If the defect is covered by the Einhell Express Guarantee, your product will be repaired

immediately and returned to you, or we will send you a new device (at our election).

Any costs incurred by you in making a claim under this Einhell Express Guarantee, unless specified

otherwise in this guarantee certificate, must be borne by you.

Of course, we are also happy to offer a chargeable repair service for any defects which are not covered by the

scope of the Einhell Express Guarantee or for products which are no longer covered by the Einhell Express

Guarantee. To take advantage of this service, please send the product to our service address.

such rights or remedies.

to tamper with the product.

parts fitted. This also applies when an on-site service is used.

The guarantee provided in this Guarantee Certificate is given by Einhell Australia Pty Limited

ACN 134 632 858 of 6/166 Wellington Street, Collingwood, Victoria (Telephone number 1300 922 271)

GUARANTEE

CERTIFICATE

(Einhell Express Guarantee).

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 20

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 21

Anleitung_BG-PH_2652_SPK1__ 12.06.12 08:20 Seite 22

EH 06/2013 (01)

Other manuals for BPH 2652/1

1

This manual suits for next models

1

Table of contents

Other Bavaria Trimmer manuals

Popular Trimmer manuals by other brands

Black & Decker

Black & Decker GT249 instruction manual

Tanaka

Tanaka TBC-225 Illustrated parts manual

Wahl

Wahl MINI ARCO General safety instructions Intended use

Craftsman

Craftsman WEEDWACKER 358.745320 instruction manual

Bosch

Bosch ART 24 Original instructions

Gemsy

Gemsy GEM 8900D Series OPERATION INSTRUCTION/PARTS BOOK