DANGER

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet before

opening the face plate of the control box. Touching areas where high voltages are present can result in severe injury.

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from

sources of strong electrical noise such as high-

frequency welders.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltages should

be within ±10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than

the requirements for the sewing machine's electrical

consumption.

Insufficient power supply capacity may cause

problems with correct operation. In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation.

The ambient temperature should be within the range

of 5℃ to 35℃ during use.

Temperatures which are lower or higher than this may

cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation should

occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct operation.

Avoid exposure to direct sunlight during use.

Exposure to direct sunlight may cause problems with

correct operation.

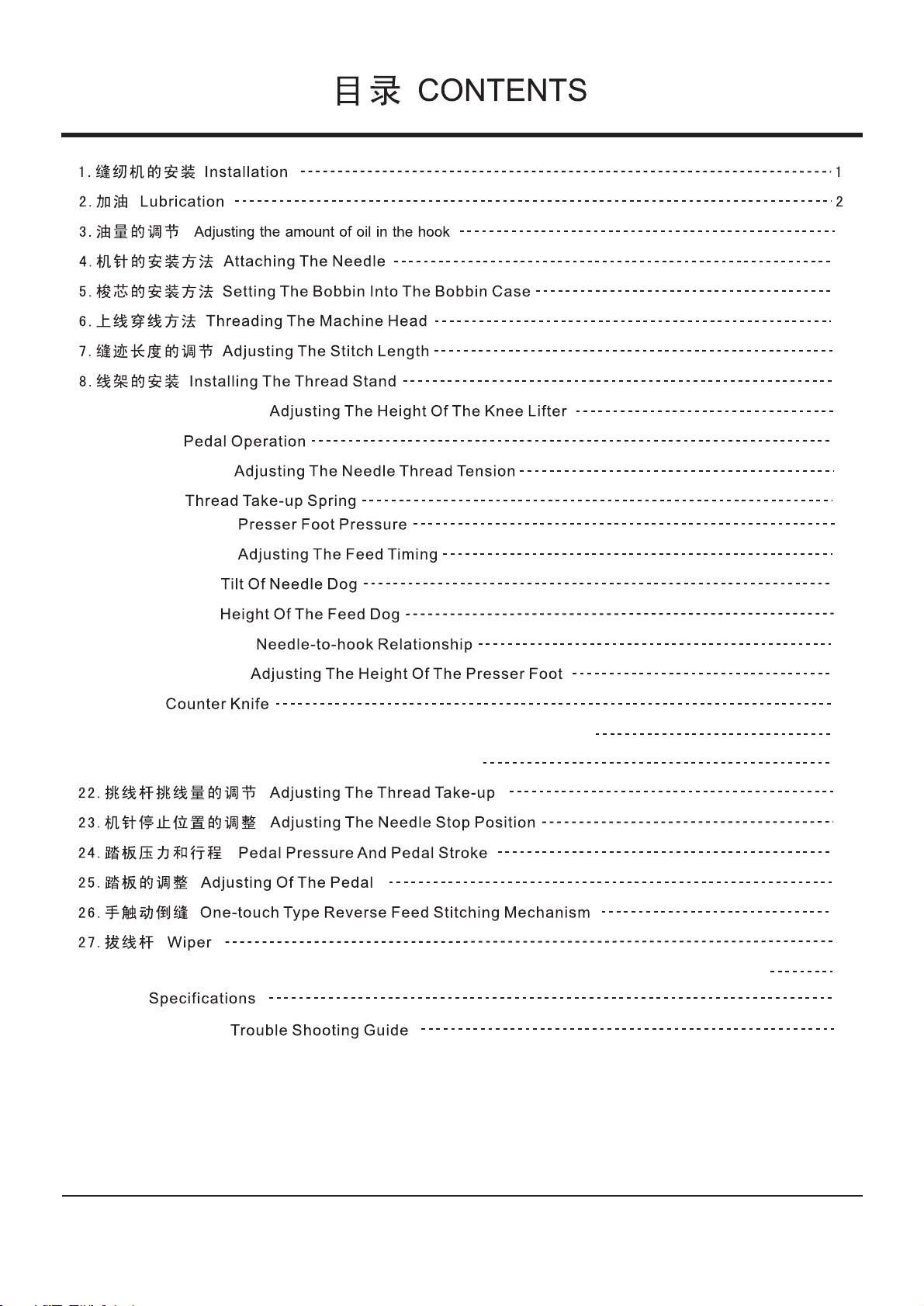

Installation

Machine installation should only be carried out

by a qualified technician.

Contact your dealer or a qualified electrician for

any electrical work that may need to be done.

The sewing machine weighs approximately 40kg.

The installation should be carried out by two or

more people.

Don't connect the power cord until installation is

complete, otherwise the machine may operate if

the foot switch is depressed by mistake, which

could result in injury.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

Install the safety covers to the machine head and

motor.

Hold the machine head with both hands when tilting

it back or returning it to its original position.

Furthermore, after tilting back the machine head,

do not push the face plate side or the pulley side

from above, as this could cause the machine head

to topple over, which may result in personal injury

or damage to the machine.

All cords should be secured at least 25mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too

firmly with staples, otherwise there is the danger

that fire or electric shocks could occur.

If using a work table which has caster, the

casters should be secured in such a way so that

they cannot move.

Be sure to wear protective goggles and gloves

when handling the lubricating oil and grease, so

that they don't get into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they can

cause vomiting and diarrhoea.

Keep the oil out of the reach children.

! !

!

!!

!

!

!

!

!

!

!

Notes On Safety

http://procapitalist.ru/sms