BAYKON BX 6 User manual

BAYKON

B

X 6

WEIGHING TERMINAL

OPERATION MANUAL

03/2008

1

Contents:

SECTION

CONTENTS PAGE

1. Features 2

2. Installation and Commissioning 3

3. Front Panel and Key Functions 5

3.1 Display 5

3.2 Key Pad 6

3.3 Key Lock 6

4. Serial Interface 7

5. Application Software 7

6. Alibi Memory 8

7. Programming and Calibration 9

8. Options 19

8.1 Serial Interface 19

8.2 Ethernet 20

9 Housing 21

App 1 Status Bytes in Continuous Data Output 22

App 2 Host Mode Data Structure 23

App 3 Modbus RTU Data Structure 26

App 4 Trouble Shooting 27

App 5 Parameter’s Default Table 28

App 6 Calibration Table (Max / d) 29

App 7 BX 6 Model Identification 30

PRECAUTIONS

DO NOT LET THE UNAUTHORIZED PEOPLE INTERFERE THE INDICATOR.

FOR SAFETY OPERATION BX 6 SHOULD BE SUPPLIED WITH GROUNDED

VOLTAGE NETWORK.

CHECK THE POWER VOLTAGE AND GROUND CONNECTIONS BEFORE

ENERGISING BX 6.

DON’T ENERGISE BX 6 BEFORE MAKING LOAD CELL CONNECTION.

DON’T PLUG IN OR OUT THE CABLES AND/OR CONNECTORS WHILE

INDICATOR IS ENERGISED.

DO NOT OPEN THE ENCLOSURE WHILE BX 6 CONNECTED POWER

SUPPLY.

2

1.Features

BX 6 is a high tech weighing terminal designed for various industrial weighing applications.

It’s available to load custom based application software to BX 6 besides standard

application software. Standard application software is for labeling and for truck scale

applications.

The terminal had been designed according to OIML R76 recommendations and 90/384AT

directive and EN45501 standard.

1.1. Basic Features

•Weighing in single range or multi (dual) range.

•Standard application software for truck scale and labeling applications etc.

•Custom based application software ability.

•Taring with key.

•Auto zero tracking and zeroing with key.

•Power on zero availability

•High resolution display mode.

•Powerful adaptive digital filter for fast and stable reading.

•Key lock option to prevent unauthorized people’s interfering the indicator.

•Alibi memory that can store up to

149.764

( option ) weighing results.

•Standard RS 232C output and optional RS232C serial port, RS 485, 20 mA ASCII,

MODBUS and Ethernet output.

•

Optional HOST connection ability.

1.2. Technical Features

•

Input sensitivity : 0,4 µV/inc.(approved),

0,1 µV/inc (non approved)

•

Type approval

Single range : 10.000 d

Multi range : 2 x 6.000 d

•

Resolution

Display resolution : Up to 1 / 60.000 pieces

Internal resolution : Up to 1 / 8.000.000 pieces

•

Load cell excitation voltage : 5 volt DC

•

Quantity of the load cell : 6 units of 350ohm or 20 units 1200ohm

( minimum 58 ohm , maximum 1200 ohm )

•

Power supply : 230 V / 50 Hz AC

•

Power consumption : 35 VA

•

Operating temperature : Between -10°C and +40°C , up to 85% humidity,

Non condensing.

3

2. Installation and Commissioning

PRECAUTION: Please read this manual carefully before energizing the indicator and

perform the commissioning operation according the procedure given here. Use trained

personnel for cleaning, commissioning, checking and service of the indicator. The

interference of untrained personnel may cause some unwanted damages or injures.

2.1 Mechanical Installation

First of all please determine the place where your indicator can operate safely. The place

where you will use/install your indicator should be clean, not getting direct sun light if

possible, with a temperature between -10ºC and +40ºC, humidity 85% non condensing at

most and the cables should be installed safely to avoid mechanical damages.

Take care to the housing dimensions for designing your operator table. If any, you can put

the monitor on BX 6.

2.2 Electrical Installation

BX 6 operates with 230 VAC 50 Hz and supplied with power cable.

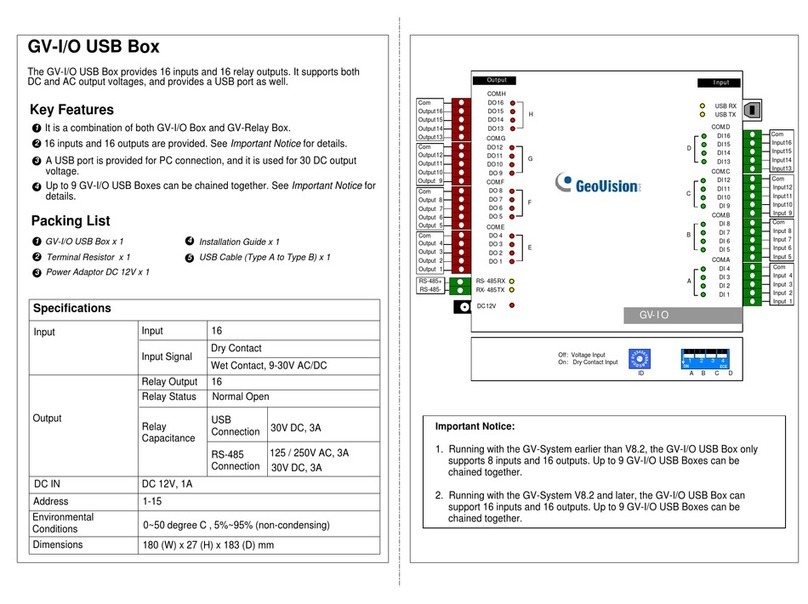

There are two jumpers on BX 6’s weighing board for calibration and for On/Off switch. To

change the position of these jumpers, open the housing and perform needed changes

and/or control them before energizing the indicator.

Ground BX 6 indicator with a cable which has at least 6 mm

2

cross section by using

the grounding connector at the backside. The quality of this grounding will provide

weighing accuracy with the safety of your indicator. If the energy condition of your plant is

not good, prepare a special power line and grounding. If you have to service the indicator,

turn the power of and wait at least 30 seconds before interfering.

J2 Calibration

( short circuit for

calibration )

J8 On/Off Switch

(always short circuit)

Figure

1

.

BX 6

weighing

board

4

2.3 Load Cell Connection

The load cell wiring should be made carefully before energizing to avoid BX 6 from

damages. The input resistance of the load cells that you will connect should be more than

58 Ω. The sense pins of BX 6 should be connected. The sense and excitation pins with the

same polarity should be short circuited at the connector side in 4 line load cell wiring.

Pin No

(DB9 Female) 6 wired Load

Cell Cable

Connection

4 wired Load

Cell Cable

Connection

1+ Excitation + Excitation

2+ Sense + Excitation

3 Shield Shield

4 - Sense - Excitation

5 - Excitation - Excitation

7 + Signal + Signal

8 - Signal - Signal

Connector body Shield Shield

Parallel Port

The standard printer output of BX 6 is standard PC compatible parallel port which is 25 pin

D-sub female. You can use standard parallel port printer cables for printer connection.

RS232C Serial Interface ( COM1 )

The serial port COM1 may be used for serial printer, host, and second scale etc.

connections of the PC board. The pin configuration of COM1 is;

Pin No

(DB9 Male) Definition

2 RXD

3 TXD

5 GND

Connector body Shield

Monitor and Keyboard Connectors

The standard monitor (D-sub, 15 pin, female ) and PS2 compatible keyboard connectors

may be used for connecting monitor and/or keyboard to BX 6.

Commissioning

After making the required installations and load cell connection of BX 6, turn the power on

and make calibration. After checking the performance of your weighing instrument you can

begin to use the indicator. If there are peripheral connections like monitor, keyboard,

parallel port, parallel I/O etc. , first you should turn the power off; make the required

connections, perform the required safety checks and energize the indicator. The parallel

port, monitor and keyboard connectors are standard PC compatible. Then set the related

parameters if there is any and check if the peripheral devices and application software are

operating properly. For commissioning of application software, please look the software

manual given you together with instrument.

5

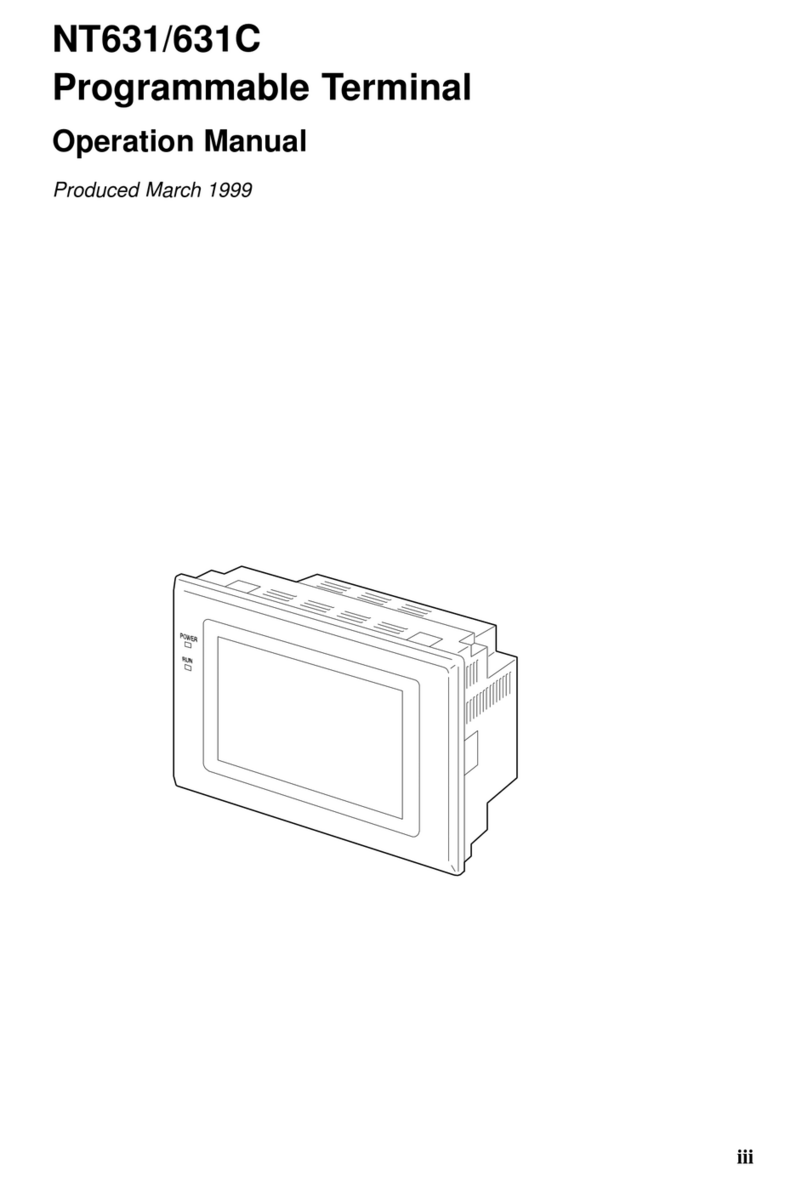

3. Front Panel and Key Functions

Figure 2. Front panel view of BX 6

3.1 Display

The weight display of BX 6 is seven segment LED. Under the weight display 6 LEDs take

place related to weighing. At the right side of the display there are three LED’s for

indicating the net, gross and the unit.

The meanings of the indication LEDs about basic symbols of weighing that take place

under the display are:

:

With multi range scales these LEDs indicate the range that scale operates

at the moment. For single range scales only first range LED lits.

:

Means BX 6 displays information different from the weight.

:

Means the weight value on the display is stable.

:

Means the weight is in real zero range.

:

Means the key lock is in function.

6

3.2 Key Pad

The keys and the key functions of BX 6 are:

Zeroing: In Gross mode, if the scale doesn’t show zero while there is no load

on the platform, you can zero the scale by pressing this key.

Taring: Pressing this key tares the scale and get into the Net mode.

Print: The function of print key is depend on the application software.

High Resolution: By pressing this key the weight value can be viewed with

higher resolution in a short period.

Info: This key is being used to view total information. To return to the weight

display, press F key or Info key.

To clear the weight total, you need to press zeroing key while the total value

is seen on the display and [All C ] will appear on the display. You can

confirm deletion by pressing <Enter> key or cancel by pressing <F> key.

Function : This key used in combination with other keys of BX 6 as

described in this manual.

3.3 Key Lock

BX 6 has ability to lock the keys to avoid unauthorized person’s interfere.

You can activate or deactivate this function by pressing “ F “ and “Key Lock” keys

sequentially. The LED with key sign which takes place at the bottom of the info LEDs at

the left side of the display indicates the keys are locked.

7

4. Serial Interface

There are two type of serial output in BX 6. The first is from PC board ( COM1 ) and the

data output of this interface is depend on the application software located on the PC

board. The second type optional data output is from weighing board and is for interfacing

with the weighing board directly.

The baud rate of optional serial data output can be selected as 1200, 2400, 4800, 9600,

19200, 38400 or 57600. Data length and parity can be 8 bit no parity, 7 bit even parity, 7

bit odd parity . The serial data interface has 1 start bit and 1stop bit.

The optional serial ports of BX 6 are suitable for bi-directional communication. If, you

transmit ASCII codes of P, Z, T or C letters to the serial port of BX 6; the indicator will act

like the related keys are pressed.

Only continuous output can be programmed for more than one interface.

4.1 Continuous Mode :

The format of the data output of optional serial output in continuous mode had been given

below.

Status

Indicated

Tare

STX

STA

STB

STC

D5 D4 D3 D2 D1 D0 D5 D4 D3 D2 D1 D0 CR CHK

You can find the structure of status bytes in Appendix 1.

4.2 Host Interface

Two type of host connection can be made : The first is the host connection from PC board

which is for data transfer from application software via RS232C serial port ( COM1 ) or

Ethernet output. The second host connection can be made via serial interface option of

the weighing board. This connection can be used for host interfacing of the weighing

board ( Look appendix 2).

5. Application Software

BX 6 has standard application software for weighbridges and for labeling etc. Additionally,

the custom based application software may be loaded to BX 6.

For the information of the application software, please look the software manual given you

together with the instrument.

8

6. Alibi Memory

The alibi memory of BX 6 shall be installed and activated for legal metrologic usage,

because of the free programmable application software ability of BX 6. The alibi records

can be displayed or printed.

To reach a definite record you have to enter to parameter 802. After reaching the desired

record, the recorded data can be view from display. If it is needed you can print this record

together with following 9 records by pressing print key. If you press print key in parameter

803, the whole recorded data will be sent via serial port. Printing can be finished via F key.

The empty fields will be printed as ------ and the corrupted records will be printed as

xxxxx. For the records of which weighing results can not be given, the message [ no rec ]

will be seen on display.

If the alibi memory is activated, the alibi record number is also found on the print out data.

After installing the alibi board or changing weighing board changed Error 41 or 42 will seen

on the display after power on for activating alibi memory. If the calibration jumper is short

circuited, you can activate the alibi board by pressing enter key after power on. Otherwise,

the alibi errors will be disappeared by pressing enter key, but you could not get any data

output from BX 6 (Error 43 will be seen after pressing print key).

By parameter 804, you can print the information data about alibi card. These data are;

SN : Alibi card pin code,

SA : The start alibi record number with this indicator,

LA : The alibi record number of the next weighing with this indicator,

CN : Calibration counter number,

CS : Check sum status,

AS : Alibi memory record capacity.

The alibi connector must be used for printing out the alibi records. This connector (This D-

sub, 9 pin and female) is located in the housing. The pin configuration of this alibi data

interface connector is;

Pin No

(DB9 Male) Definition

3 TXD

5 GND

The baud rate of alibi memory serial data output is 9600. The other serial data

specifications are; 1 start bit, 8 bits data length, 1stop bit and no parity bit.

9

7. Programming and Calibration

In this section you will find the programming and calibration procedure of indicator

according to your application. The signs those take place on the lower right corner of the

keys indicate the function of the keys in programming menu. The basic meanings of these

keys are given in the table below.

Exit without

saving Advancing

next

parameter

Get back to

previous

parameter

Select the digit

will be

changed

Changing

parameter

value or

increasing the

blanking digit

Enter

7.1 Entering the Programming and Calibration Menu

Press F and Info keys sequentially to enter the Programming and Calibration Menu. First

[FunC ] and then [PASSWr ] prompts will be seen on the display sequentially. Here you

can enter to the parameters block by using the service password (Zero and Info) or the

operator password (Tare) and confirm with Enter. The calibration jumper (See Section 2.2)

should be short circuit to change the metrological related parameters .

Programming and Calibration menu consist of main blocks which are shown as [X-- ]

and sub-blocks. By using ↑and ↓keys you can reach previous or next main blocks.

After reaching the desired main block, you can get in by pressing Enter key. As you enter

the block you will reach the first sub-block in that main block. The sub-block address will

be seen on the display as [X0- ]. You can also search between the sub-blocks by using

↑and ↓keys and reach the first parameter of the sub-block seen on the display by

pressing Enter key. The number of the parameter comes on display as [XY0 ]. Again you

can search between parameters by ↑and ↓keys. For entering numerical value in the

parameters, press the tare key to select the digit and press the zero key the change the

value.

7.2 Exiting the Programming and Calibration Menu

If you press F key on which parameter you are, you will get out of the active sub-block and

reach the next sub-block. If you press F key again, you will get out of the active block and

reach the next main block. If you press F key once again, the [SAvE ] message appears

on the display. Here you can press Enter key to save the changes into the memory, or you

can press Tare key to store the changes until the power goes off, or you can press F key

to abort changes. [Waıt] message will be seen on the display for a little while, and

automatically get back to weighing mode.

Especially for legal metrological usage, please don’t forget to turn the power off and

remove the calibration jumper to start operation.

10

Changeable with any

password

Changeable with service

password

Changeable with service

password and calibration

jumper

80 _

RECORDS

800

CAL. COUNT.

801

ALIBI

802

ALIBI REC

803

ALIBI PRT

8_ _

M.LOGIC REC.

804

ALIBI INFO

30 _

CALĐB.

300

GRAVITY

301

CAL.

3_ _

CALIBRATION

31 _

CAL. ADJ

311

SPAN CAL.

312

SPAN ADJ CAL

.

310

ZERO CAL.

2_ _

SETUP PRMT

20 _

SETUP

200

M.LOGIC

201

DISPLAY

202

PWR ON ZERO

203

ZERO

204

AUTO.ZERO

205

TARE

206

M.DETEC

21 _

WEIGHING

210

W. TYPE

211

CAP1 / d1

212

CAP2 / d2

9_ _

CTRL PRMT

90 _

TESTS

900

KEY PAD

901

S.PORT 1

904

mV

91

_

BX S/N

91

0

BX

91

1

OPT 1

91

2

OPT

2

91

3

OPT 3

976

COEFF.7

97 _

CAL. COEFF.

970

COEFF.

1

971

COEFF.2

972

COEFF.3

973

COEFF.4

974

COEFF.5

975

COEFF.6

979

SAVE COEFF.

978

COEFF.9

977

COEFF.8

990

ALL PRMT.

99 _

PRMT. PRT

991

DEFAULT

0_ _

INTERFACE

04 _

PRINTER

045

MIN. PRT

046

PRT CTRL

01 _

INT 1

010

D.FORMAT

011

BAUD

012

HANDSHAKE

013

ADR

0

14

PARITY

02

_

INT 2

020

D.FORMAT

021

BAUD

022

HANDSHAKE

023

ADR

024

S. MODE

025

PARITY

1_ _

CONFIG

120

9

SLOWEST

120

5

12 _

FĐLTER

120

F.ADJ

120

0

NO FILTER

120

1

FASTEST

120

2

120

3

120

4

11 _

START UP

114

BUZZER

11

7.3 Programming

[0--] Interface Block

You can reach the parameters about optional serial interface of BX 6 indicator in this

section.

[01-] Interface-1

This sub-block includes the parameters about the 1

st

optional serial interface of BX 6.

[010 X ] Data Format

0 : No data transfer.

1 : Continuous data output.

2 : NA

3 : Host mode. This mode is being used for programming or using the indicator

with computer.

[011 X] Baud Rate

0 : 1200 Baud 1 : 2400 Baud 2 : 4800 Baud

3 : 9600 Baud 4 : 19200 Baud 5 : 38400 Baud

6 : 57600 Baud

[012 X] Handshake

0 : No Handshake 1 : Xon/Xoff 2 : Hardware.

Warning: If you choose hardware as handshake, the serial interface-2 can not be

used as RS232C.

[013 XX] Address

You can define a device address between 1 and 99 by this parameter. If you enter

0, indicator will operate without an address.

[014 X] Data length and parity

0 : 8 bit, no parity 1 : 7 bit, odd parity 2 : 7 bit, even parity

[02-] Interface-2

This sub-block includes the parameters about the 2

nd

optional serial interface of BX 6.

[020 X ] Data Format

0 : No data transfer.

1 : Continuous data output.

2 : NA

3 : Host mode. This mode is being used for programming or using the indicator

with computer.

4 : Modbus RTU

Note: The parameter 025 must be selected as 0 for Modbus RTU output.

12

[021 X] Baud Rate

0 : 1200 Baud 1 : 2400 Baud 2 : 4800 Baud

3 : 9600 Baud 4 : 19200 Baud 5 : 38400 Baud

6 : 57600 Baud

[022 X] Handshake

0 : No Handshake 1 : Xon/Xoff

[023 XX] Address

You can define a device address between 1 and 99 by this parameter. If you enter

0, indicator will operate without an address.

[024 X] Serial Mode

0 : Serial Interface-2 operates as RS232C ( par. 012 ≠2 ) .

1 : Serial Interface-2 operates as RS485 .

2 : Serial Interface-2 operates as 20 mA CL ASCII.

[025 X] Data length and parity

0 : 8 bit, no parity 1 : 7 bit, odd parity 2 : 7 bit, even parity

[04-] Weight Data transfer

The serial interface between weighing board and PC104 board is standard single line

format, 9600 baudrate. You can adjust only following features.

[045 ] Minimum Print

[ XXXXXX] If the weight is less than the value entered here, the data will not be

printed.

[046 X] Print Method

This parameter selection must be convenient to the application software in PC

board.

0 : Printing via key or application software.

1 : Auto print.

2 : Print interlock

Explanation: If this parameter selected as auto print, the data will automatically be

printed when the data exceeds minimum print value and become stable. The weight

value should decrease under minimum print value to reprint.

If this parameter selected as print interlock, after printing the weight must be

changed to reprint.

13

[1--] Configuration Block

In this block the parameters take place which are being used to set BX 6 according to your

application.

[11-] Start Up

[114 X] Buzzer

0 : No Buzzer.

1 :The Buzzer will active when a key pressed, in case of error messages or when

the alarm is active.

[12-] Filter

In this block the proper filter values according to the operating conditions can be entered.

One of the most important features of BX series is viewing filter characteristic on the

display and with the help of this option, you can select the most suitable filter without

exiting the programming mode.

[120 X ] Filter

The filter value can be selected from 0 to 9 ( The minimum value of the filter at least

7 in normal weighing applications). As you enter this parameter and press Enter key

while [120 X] seen on the display, the weight variation can be seen on the display.

The value of the filter can be changed by using ↑and ↓keys and the weight

variation for every value can be seen on the display. After finishing the filter

selection you can go to next step by pressing the F key.

[2--] Scale Block

[20-] Set Up

The parameters about weighing operation are being entered here.

[200 X] Approved

0 = No 1 = Yes

[201 X] Increased Indication

0 = by pressing key 1 = Always increased indication

[202 X] Power on Zero

According to the selection below, during power on, if the weight is in the percentage

of the capacity, the scale will automatically be zeroed. If the weight is not in zeroing

range, the display will show [E E E ] message until pressing enter key.

0 = disable 1 = ± 2% 2 = ± 10%

[203 X] Zeroing Range

0 = disable 1 = ± 2% 2 = ± 20%

14

[204 X] Auto Zero Tracking

AZT automatically readjusts the scale to zero for compensating selected small

deviation per second around center of zero.

0 = disable 1 = ± 0,5e 2 = ± 1e 3 = ± 3e

[205 X] Tare

0 = Tare disabled 1 = Pushbutton Tare

[206 X] Motion Detector

This parameter defines the sensitivity level which will determine what is considered

as stable.

0 = ± 0,3e 1= ± 0,5e 2= ± 1e 3= ± 2e 4 = No motion detector

[21-]Scale Build

The capacity and the resolution of the scale will be defined here.

[210 X] Scale Type

The capacity and resolution parameters will vary according to the selection here.

0 = Single Range 1 = Dual Range

You will reach the next parameter by pressing the Enter key. But please note that

the following parameters will vary according to this selection.

If single range had been selected ;

[212 ] Capacity

Press Tare key to enter this parameter.

[CAP ]

[ XXXXXX ]

The capacity of the first weighing range ( Select from Appendix 6 ) will be entered

here via Tare and Zero keys and confirmed with Enter key.

[d ]

[ XXXXXX ]

Display resolution will be selected by Zero key and confirmed with Enter key.

If dual range had been selected ;

[211 ] Range 1

Press Tare key to enter this parameter.

[CAP1 ]

[ XXXXXX ]

The capacity of the first weighing range ( Select from Appendix 6 ) will be entered

here via Tare and Zero keys and confirmed with Enter key.

[d1 ]

[ XXXXXX ]

Display resolution of the first weighing range will be selected by Zero key and

confirmed with Enter key .

15

[212 ] Range 2

Press Tare key to enter this parameter.

[CAP2 ]

[ XXXXXX ]

The capacity of the first weighing range ( Select from Appendix 6 ) will be entered

here via Tare and Zero keys and confirmed with Enter key.

[d2 ]

[ XXXXXX ]

Display resolution of the second weighing range will be selected by Zero key and

confirmed with Enter key .

[3--] Calibration Block

The calibration of the scale will be performed here.

[30-] Calibration

[300 ] Gravity

This parameter should be used in the scale that will be verified in two stages by

gravity adjustment (in legal metrologic applications). This parameter should not be

touched in other applications.

If you enter a value in this parameter before calibration (as six decimal digits.

Enter 798564 for 9.798564), this value will be assumed as the reference gravity

acceleration where the first stage of the calibration performed. After calibration this

parameter will be zeroed. If value of this parameter is zero, which means no gravity

adjustment had been performed after calibration.

In the second stage of verification, the gravity acceleration of the place that the

weighing instrument will be used should be entered (as six decimal digits. Enter

800065 for 9. 800065) and exit programming by saving the changes without

entering the calibration (par 301).

[301 ] Calibration

Begin the calibration by pressing Enter key. Unload the scale when the displays

shows [ZEro.CA] message and press Enter key. The display will show [WAıt ]

message during zero calibration. In this while the pan must be empty and the scale

must be stable. Approximately 10 seconds later display will show [LoAd ] and then

[ XXXXXX ] . The value shown on the display is the weight that should be used for

span calibration. If the value of the test weights that will be used is different from the

value shown on the display, define the new value via Tare and Zero keys, place

the test weights on the scale and press Enter key. Just like zero calibration [WAıt ]

message will shown on the display 10 seconds while span calibration is being

performed. Then indicator will prompt you to save the calibration by [SAvE ]

message. You can save the calibration by pressing Enter key. Pressing F key will

not save the calibration.

16

[31-] Adjustment

In this sub-block you can only perform zero adjustment or span adjustment without full

calibration operation.

[310 ] Zero Adjustment

This parameter is only being used for refreshing the zero level of the scale to

prevent wrong weighing from zero drifts. Begin the zero adjustment by pressing

Enter key. Unload the scale when the displays shows [ZEro.CA] message and

press Enter key again. The display will show [WAıt ] message during zero

adjustment. In this while the scale must be unloaded and stable. Approximately 10

seconds later display will prompt you to save the calibration by [SAvE ] message.

You can confirm the saving zero adjustment by pressing Enter or cancel it by

pressing F key.

[311 ] Span Adjustment

This parameter lets you to perform span adjustment. By pressing Enter key

[ XXXXXX ] appears on the display. The value shown on the display is the weight

that should be used for span calibration. If the value of the test weights that will be

used is different from the value shown on the display, define the new value via Tare

and Zero keys, place the test weights on the scale and press Enter key. Just like

zero calibration [WAıt ] message will shown on the display 10 seconds while span

calibration is being performed. Then indicator will prompt you to save the calibration

by [SAvE ] message. You can confirm the saving calibration by pressing Enter key

or cancel it by pressing F key.

[312 ] Span Adjustment Under Load

This parameter is being used to perform span adjustment of a scale without lifting

the load on it. This operation especially used for span adjustment for filled tanks.

You can make span adjustment without removing the load in the tank.

As you press enter key [P.ZEro ] message appears on the display. This means the

scale will determine the present load as temporary zero. After getting ready for this

level, which means temporary zero adjustment Enter key should be pressed. The

display will show [WAıt ] message during temporary zero adjustment. After this

step,

The display will show [LoAd ] a little while and then [ XXXXXX ] . The value shown

on the display is the weight that should be used for span calibration. If the value of

the test weights that will be used is different from the value shown on the display,

define the new value via Tare and Zero keys, place the test weights on the scale

and press Enter. Just like zero calibration [WAıt ] message will shown on the

display 10 seconds while span calibration is being performed. Then indicator will

prompt you to save the calibration by [SAvE ] message. You can confirm the

saving calibration by pressing Enter or cancel it by pressing F key

17

[8--] Metrological Data Block

The parameters about Metrologic Registry are being entered in this section.

[80-] Metrologic Records

In this block, change the parameters with ↑key and use enter key according to parameter

descriptions.

[800] Counter

This counter increases by 1 automatically after entering the programming mode

with calibration jumper and service password. This counter can not be changed

manually.

[801] Alibi Memory

This parameter shall be selected as 1 for legal metrologic usage of the instrument.

0 = Not used 1 = In use

[802] Finding Any Record From Alibi Memory

You can call a record by entering record no via Tare and Zero keys in the alibi

memory. If Print key is pressed while an Alibi record is on the display, this record

will be printed with the 9 records previous it.

[803] Print All Alibi Memory Records

The data in the Alibi memory can be printed by pressing Print key. You can stop

printing with F key.

[804] Alibi Info

You can get some fundamental information about Alibi board and records by

pressing Print key.

[9--] Diagnostics

The operations about checking and testing BX 6 can be made here.

[90-] Tests

[900 ] Key Pad

Press Enter key. [900 --] message appears on the display. In this step every keys

ASCII code will be shown on the display as you press the related key. By this way

you can test if all the keys are functional or not. Pressing ↑key will take you to the

next parameter.

[904 ] mV Indication

As you press Enter key the output voltage of the load cell will be shown on the

display. This uncalibrated value is only for test / service purposes.

18

[91-] Serial Numbers

[910] BX Serial No

The serial number of BX 6 will be shown on the display as you press Enter key.

[911] Option 1 Serial No

The serial number of BX option 1 will be shown on the display as you press Enter

key.

[912] Option 2 Serial No

The serial number of BX option 2 will be shown on the display as you press Enter

key.

[913] Option 3 Serial No

The serial number of BX option 3 will be shown on the display as you press Enter

key.

[97-] Calibration Coefficients

The parameters take places in this section are the calibration parameters of BX 6. These

values can be used when a problem occurs about the calibration of BX 6 if they had been

noted before. You can refresh the calibration by entering correct values.

[99-] Printing Parameter Values

[990] Print All Parameters

By pressing Print key the whole parameters can be printed from Alibi memory

connector located in the terminal.

[991] Loading Default Parameters

Press Enter key. [ Ld dEf ] message appears on the display. Press Tare key for

loading default values or press F key to go 9- sub block.

19

8. Options

8.1 Serial Interface

2 additional serial interfaces ( for weighing board interfacing ) can be added to BX 6 in

addition to standard COM1. One of the outputs of optional serial interface card is RS232,

and the other one can be selected as RS232, RS485 or 20 mA ASCII CL. 012 parameter

should not be selected as 2 ( hardware handshake ), for programming the second

optional data output as RS232C. Up to 32 instruments can be connected with RS485

output.

The settings of interfaces is being made in Serial data 1 ( par 01- ) and Serial data 2

( par 02- ) parameter groups. The pin configuration of the optional D25 female serial

interface connector is given below.

Pin Number

(DB25 Female) 012 parameter

is 0 or 1 012 parameter

is 2

2 TxD1 ( par. 01- ) TxD1 ( par. 01- )

3 RxD1 ( par. 01- ) RxD1 ( par. 01- )

4 TxD2 ( par. 02- ) RTS1 ( par. 01- )

5 RxD2 ( par. 02- ) CTS1 ( par. 01- )

7 GND ( RS 232C ) GND ( RS 232C )

8 R- ( par. 02- ) R- ( par. 02- )

9 R+ ( par. 02- ) R+ ( par. 02- )

10 T+ ( par. 02- ) T+ ( par. 02- )

11 +V ( par. 02- ) +V ( par. 02- )

19 Termination ( RS 485 )

Termination ( RS 485 )

20 Termination ( RS 485 )

Termination ( RS 485 )

21 A ( par. 02- ) A ( par. 02- )

22 B ( par. 02- ) B ( par. 02- )

24 T- ( par. 02- ) T- ( par. 02- )

D25 body Shield Shield

The RS485 interface termination can be done by short circuited pin 19 and 20. These

short circuits terminates the line with internal termination resistor 100 Ω.

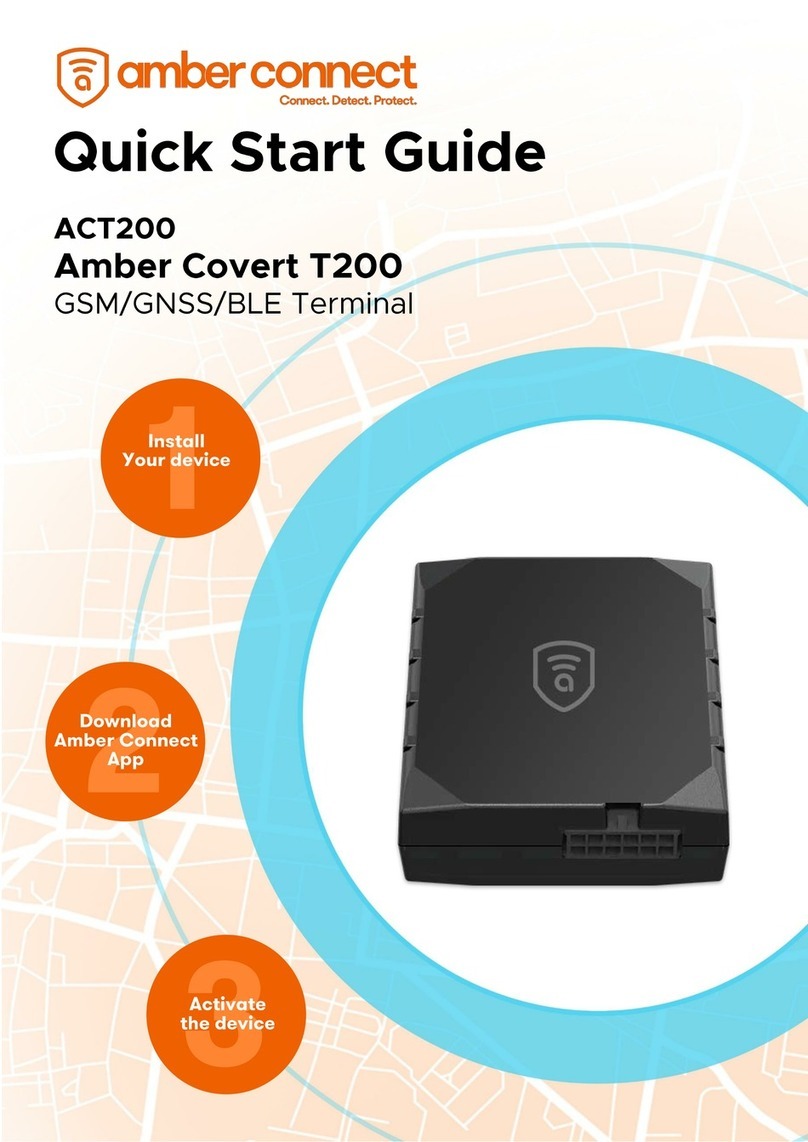

The 20mA CL ASCII transmit output is passive in standard. The connections should be

made as given in the figure below for activating this transmit output. ( Active output is not

available for the instrument ).

25

11

10

24

9

8

BX 6

Figure

3

.

20 mA

CL

ASCII interface connection

Table of contents