through the 2-13 pins of MT1389, and after amplifying treatment of built-in amplifier of MT 1389,

the signals are treated in two parts within MT1389:

After being processed by the internal digital servo signal circuit of MT1389, part of the signal

forms into corresponding servo control signal, and output focus (FOSO), tracking (TRSO), main

shaft (DMSO) and feed (FMSO) servo control signal from the P42, P41, P37 and P38 of MT1389

and send them to the driver circuit BA5954 to amplify the drive. After drive amplification, the

signals will drive the focus coil, tracking coil, main shaft motor and feed motor. The focus and

tracking servoswill be used to adjust the object lens and enable laser beam to identify signal from

compact disc correctly; the feed servo will be used to drive the laser head to move longitudinally,

and scan the compact disc; the main shaft servo is used to control the main shaft motor to read the

signals in constant linear speed and drive the disc to rotate.

After being processed by the internal VGA voltage-controlled amplifier of MT1389 in

amplification and balance frequency compensation; another part of the signals is converted into

digital signal by the internal A/D converter. When the deck readsthe CD/VCD signals, these

signals will be EFM demodulated in MT1389, and after accomplishing CIRC error regulation in

internal MT1389, output to the next grade to carry out audio and video decoding; when the deck

readsthe DVD signals, these signals will be ESM demodulated in MT1389, and after

accomplishing RSPC error regulation in internal MT1389, output to the next grade to carry out

audio and video decoding.

II. Processing Procedure of Control Signal

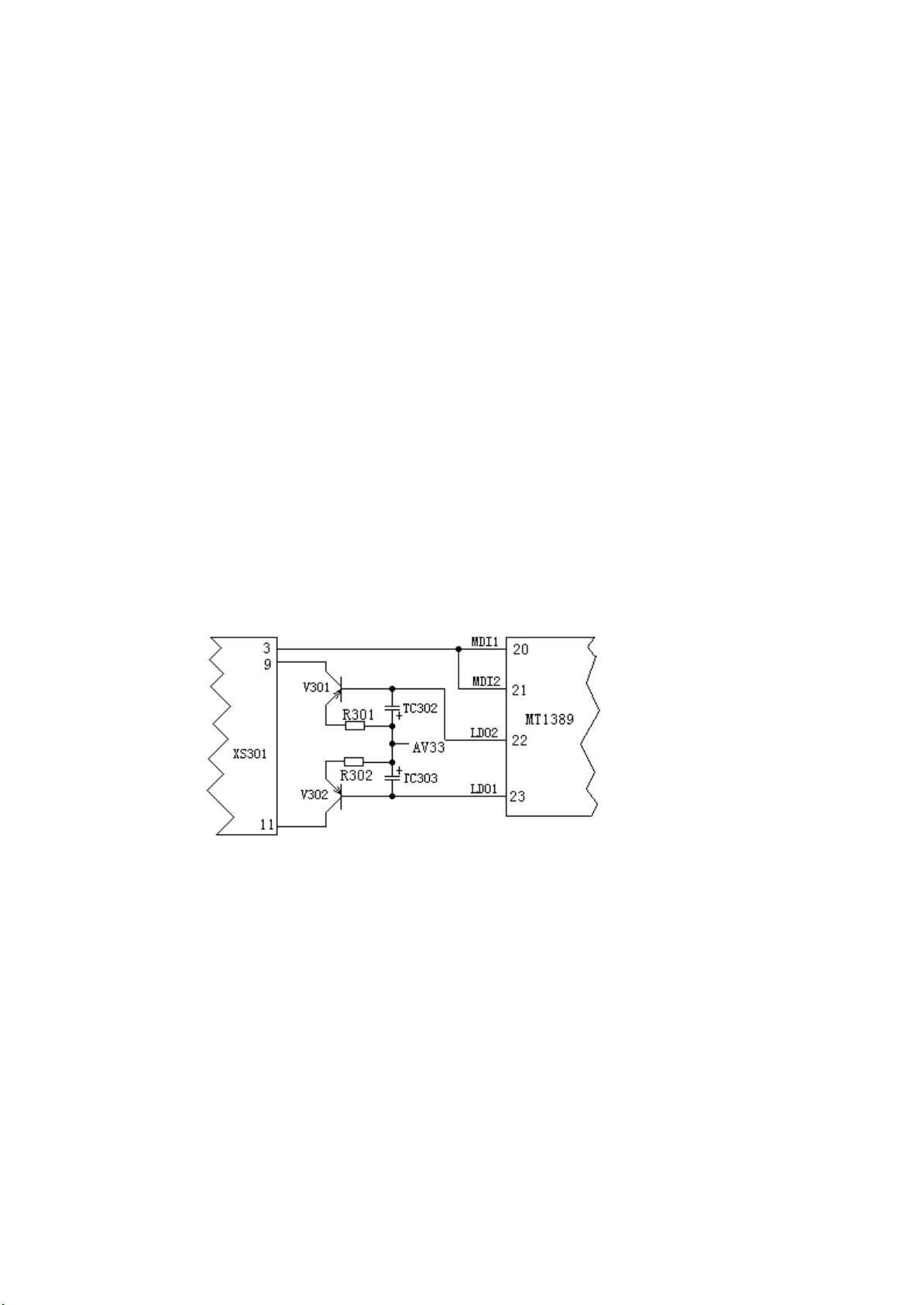

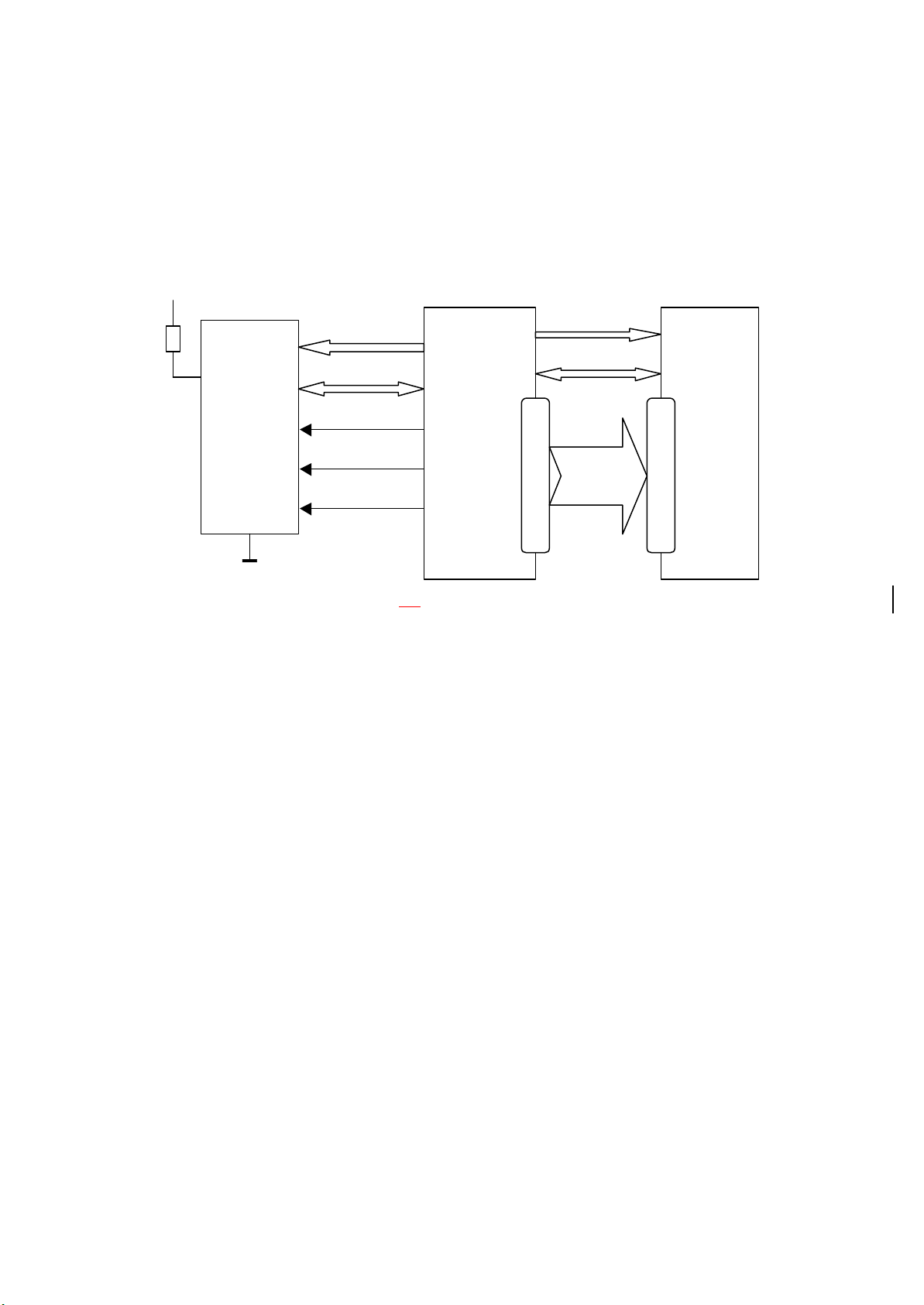

1. Automatic control of laser power, with the circuit shown as the Figure II:

Figure II

MT1389 is integrated with APC (automatic light power control) circuit. Its Pin 20 is the pin for

inputting VCD laser power rate detection signal, the Pin 21 is the pin for inputting DVD laser

power rate detection signal, and the Pin 23 is the pin for outputting VCD laser power rate drive

control. When the Pin 23 finds that the laser output power rate is too strong, the output voltage on

Pin 23 will increase after the processing of internal circuit of MT1389, and then the conduction

degree of V302 (2SB1132) and the voltage on its integration polar will decrease, which

consequently lead to the decrease of voltage supplied to the laser tube, the weakening of laser head

lighting, and thus achieve the automatic adjustment on laser output power. The Pin 22 is the pin for

outputting DVD laser power drive control, with the specific control procedure similar to that of

VCD.

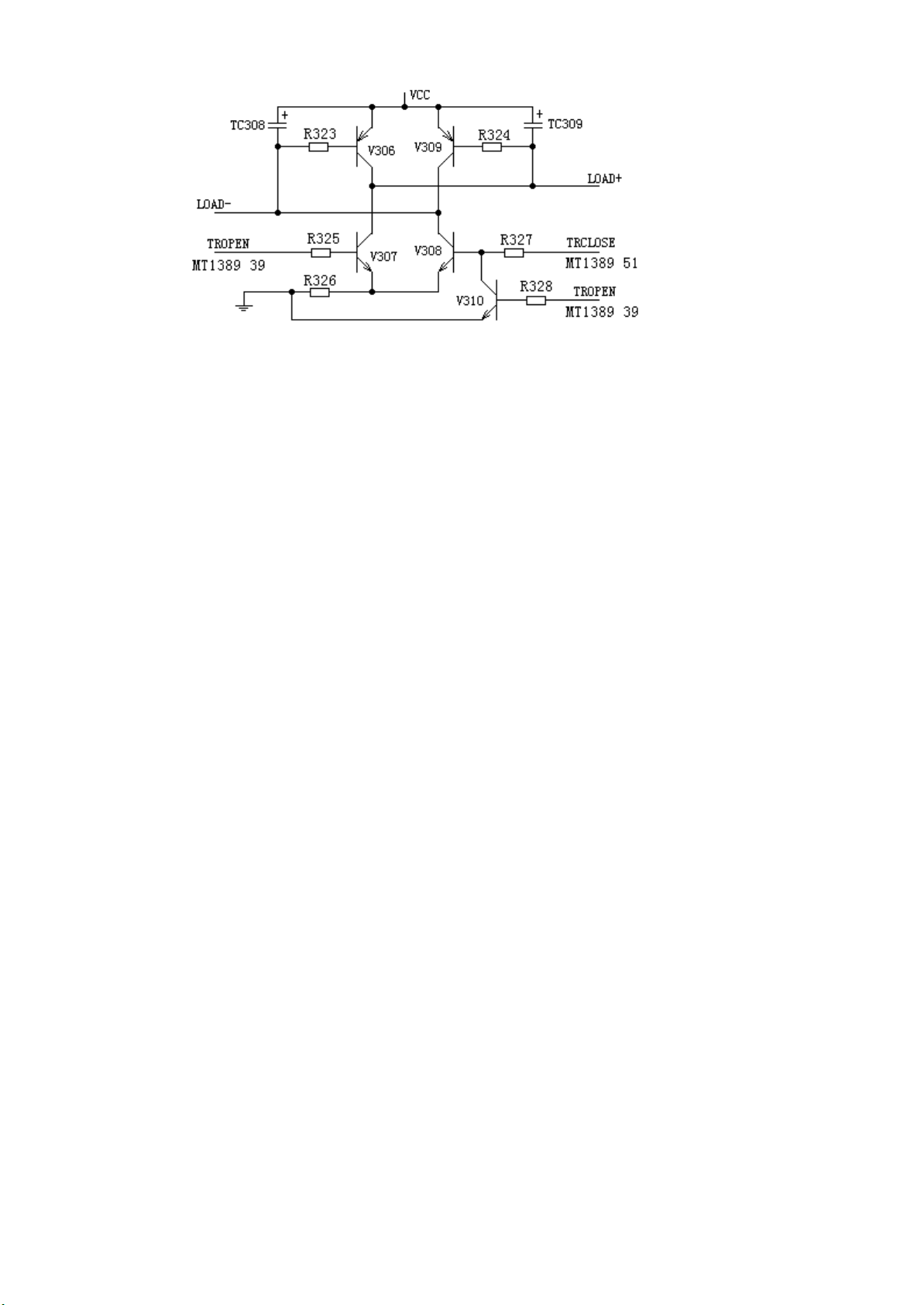

2. The tray open/close control circuit is shown as the Figure III: