BE Ag & Industrial DD400 Application guide

PURCHASE DATE MODEL NO. SERIAL NUMBER

DEALER

DIESEL TRANSFER

TANK

DD400

OPERATIONS & PARTS MANUAL

FOR MODELS:

• DD400

TABLE OF CONTENTS

3INTRODUCTION & SAFETY

7OPERATION

8TRANSPORT

9SET UP

11 MAINTENANCE

13 EXPLODED VIEW & PARTS LIST

DD400 USER MANUAL 3

Thank you for purchasing our product. Manufactured to a high standard, this product will, if used according

to these instructions, and properly maintained, give you years of trouble-free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

SPECIFICATION

Model No: DD400

Voltage: 12V

Current: 15A

Power: 180W

Tank capacity: 400l

Flow rate: 20l/min

Duty cycle: 30 mins pm / 30 mins o

Dimensions (W x D x H): 1100 x 800 x 720mm

Nett Weight: 43.16kg

SAFETY

WARNING!

This tank must ONLY be used for diesel fuel.

• Place the tank on a flat surface before filling.

• Secure the tank to strong points with ratchet straps before transporting in or on a vehicle.

• Maintain the pump in good condition (use an authorized service agent).

• Replace or repair damaged parts. Use recommended parts only. Non authorized parts may be dangerous

and will invalidate the warranty.

• Keep the pump clean for best and safest performance.

• Ensure the power supply (vehicle battery) corresponds with the requirements of the pump (12V DC).

• Disconnect from battery when not in use.

• Wear protective gloves, and protective clothing when working around fuel.

• Keep children and unauthorized persons away from the working area.

• DO NOT place the tank near any heat source.

• DO NOT start or stop the pump by connecting or disconnecting the battery clamps.

• DO NOT allow the unit to get wet.

• DO NOT operate the pump with wet hands.

• DO NOT use the pump where explosive or flammable vapours may be present.

• DO NOT tamper with the pump connections.

INTRODUCTION

Manufactured of LLDPE for the safe transportation and dispensing o f diesel fuel when supplying on site

equipment. Complies to ADR 1.1.3.1.C for exemption from requirements of ADR regulations. Supplied with

a 12V electric pump, 4mtr electric cable and clamps and a 4mtr delivery hose with automatic fuel nozzle.

Can be safely secured and transported on a pick-up truck or van, using grooves for tie-down straps and 6

handles for positioning. Supplied with lockable cover. Not suitable for petrol.

4 DD400 USER MANUAL

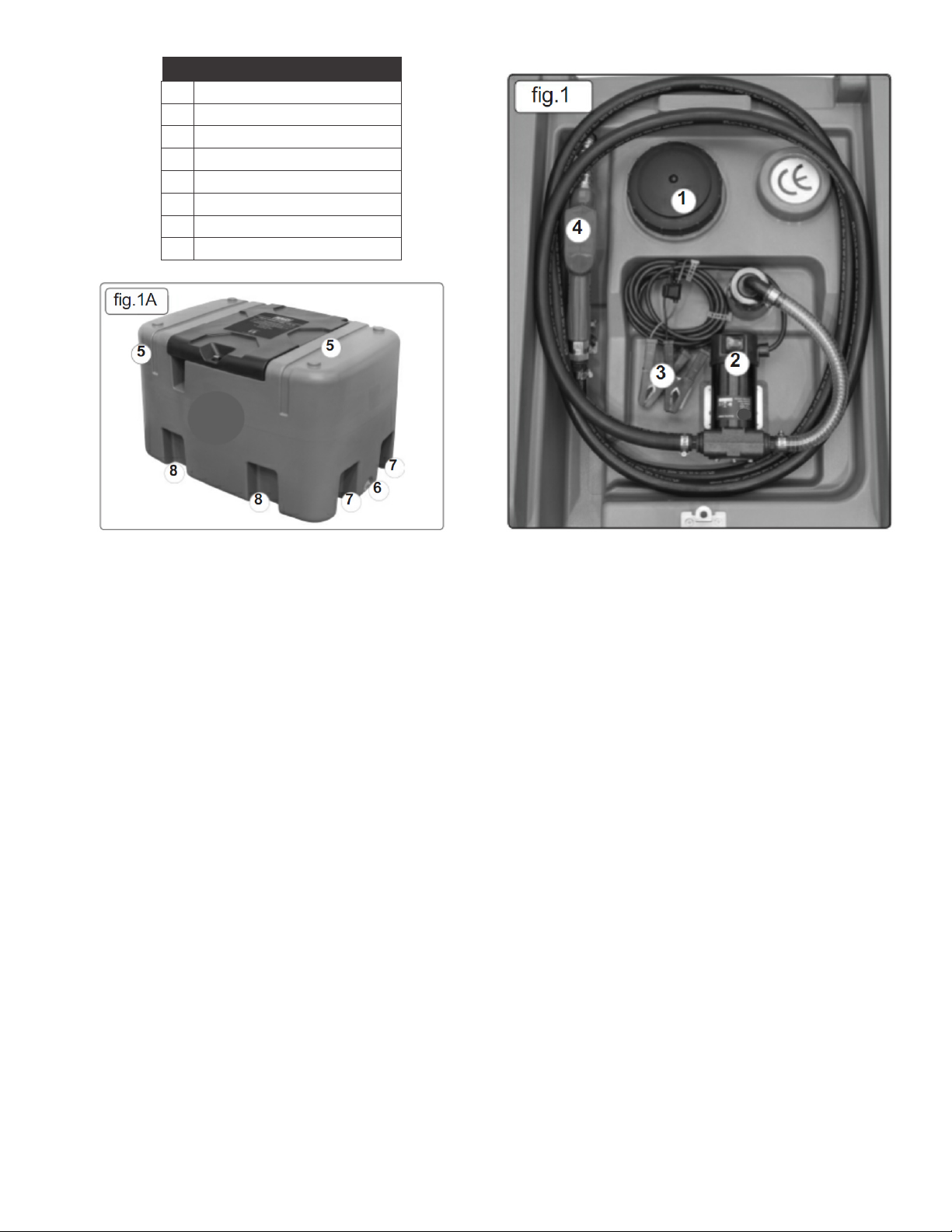

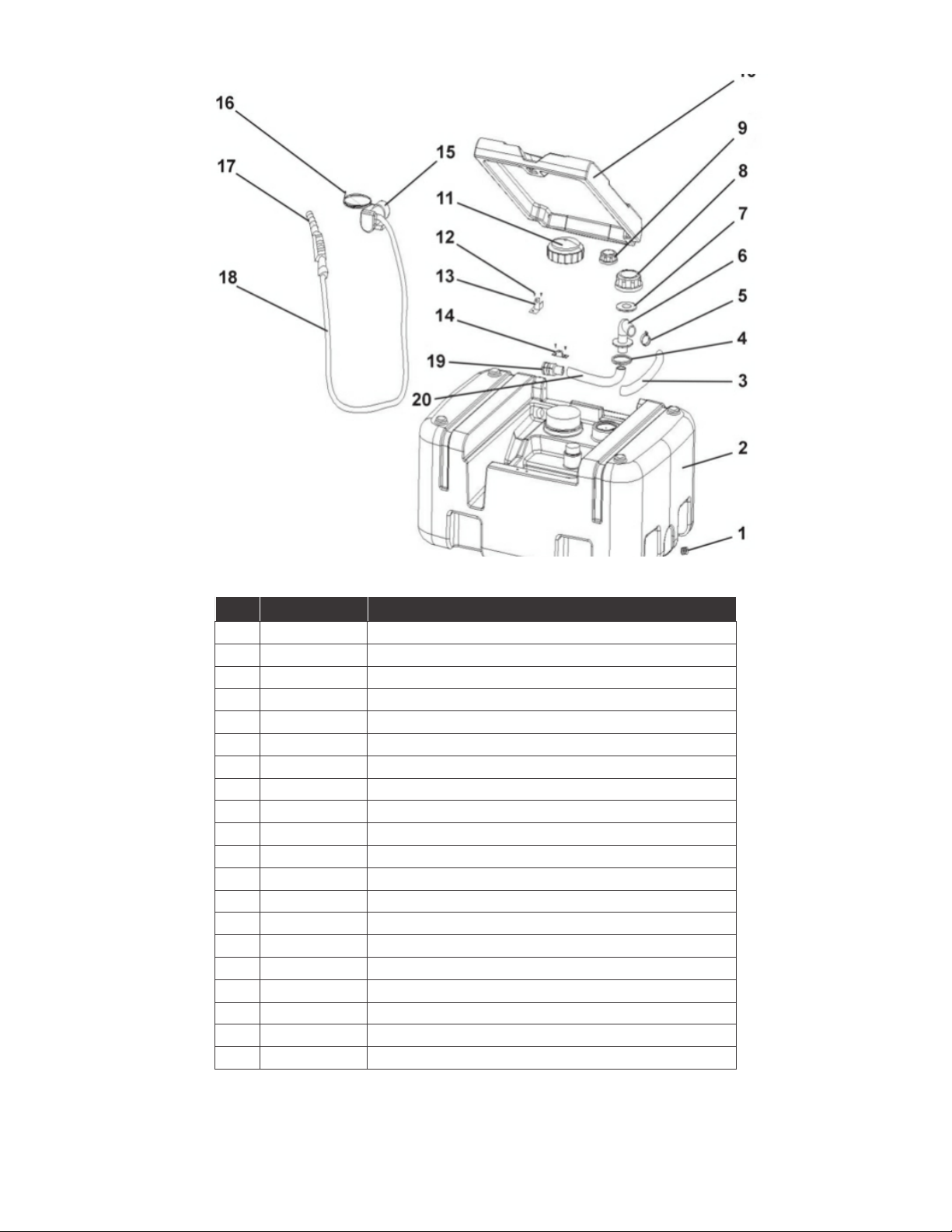

KEY (FIG 1 & FIG 1A)

1 Breather Lid

2 Pump On/O Switch

3 Battery Clips

4 Automatic Fluid Nozzle

5 Securing Strap Locations

6 Vent Plug

7 Fork Locations

8 Moulded Hand Holds

OPERATION

TRANSPORT

Move the empty tank assembly with two persons using the hand holds moulded into the base of the unit

(fig.1A.8).

Move by forklift truck using the fork locations shown in (fig.1A.7). Ensure that the filler (fig.1A.1) is closed

before moving.

Secure the tank to the carrying vehicle by ratchet straps. Locations for the straps are moulded into the tank

(fig.1A.5).

FILLING

DO NOT run the pump without fuel in the tank. To do so will damage the pump’s internal components and

will invalidate your warranty.

The tank is filled by unscrewing the filler (fig.1.1) in an anticlockwise direction. Refit the filler cap immediately

after filling.

WARNING take care not to overfill the tank.

FUEL DISPENSING

Before connecting to a battery, make sure that the pump switch (fig.5.2) is in the ‘o’ (O) position. Connect

the battery clips to the 12V battery, observing correct polarity (red clamp to +ve terminal, black clamp to -ve

terminal).

Switch the pump switch to the ‘on’ (I) position.

Unwind sucient hose and place the nozzle (fig.4) in the receiving tank and pull the trigger (fig.4). Delivery

will commence and continue until the trigger is released.

The trigger can be locked in one of three positions by engaging the latch (fig.4) to hold the trigger open. DO

NOT leave the nozzle unattended with the trigger latched open.

Slight pressure on the trigger will release the latch.

When the level in the receiving tank reaches the nozzle, delivery will stop automatically.

When delivery is complete, switch o the pump. Ensure the hose is wound into its housing on the tank and

that the nozzle is secured in its storage place.

DD400 USER MANUAL 5

DO NOT operate the pump continuously for more than 30 minutes. The duty cycle of the unit is 30 minutes,

after which the motor must be left to cool down for a further 30 minutes.

DO NOT run the unit for more than 2-3 minutes with the delivery nozzle closed.

MAINTENANCE

The pump contains no user-serviceable parts.

Repairs should only be undertaken by competent persons.

Check the integrity of all the hose connections periodically. If any leakage is evident, strip the joint and wind

PTFE tape around the male thread.

Check all electrical connections and cables for wear and damage. Rectify any faults found.

Keep clean, especially the dispenser nozzle.

Clean with a damp, soapy cloth.

DO NOT use abrasive or solvent cleaners.

4. OPERATION

4.1. TRANSPORT

4.1.1. Move the empty tank assembly with two persons using the hand holds moulded into the base of the unit (fig.1A.8).

4.1.2. Move by forklift truck using the fork locations shown in (fig.1A.7). Ensure that the filler (fig.1A.1) is closed before moving.

4.1.3. Secure the tank to the carrying vehicle by ratchet straps. Locations for the straps are moulded into the tank (fig.1A.5).

4.2. FILLING

4.2.1. DO NOT run the pump without fuel in the tank. To do so will damage the pump’s internal components and will invalidate your warranty.

4.2.2. The tank is filled by unscrewing the filler (fig.1.1) in an anticlockwise direction. Refit the filler cap immediately after filling.

WARNING take care not to overfill the tank.

4.3. FUEL DISPENSING

4.3.1. Before connecting to a battery, make sure that the pump switch (fig.5.2) is in the ‘off’ (O) position. Connect the battery clips to the

12V battery, observing correct polarity (red clamp to +ve terminal, black clamp to -ve terminal)

4.3.2. Switch the pump switch to the ‘on’ (I) position.

4.3.3. Unwind sufficient hose and place the nozzle (fig.4) in the receiving tank and pull the trigger (fig.4). Delivery will commence and

continue until the trigger is released.

4.3.4. The trigger can be locked in one of three positions by engaging the latch (fig.4) to hold the trigger open. DO NOT leave the nozzle

unattended with the trigger latched open.

4.3.5. Slight pressure on the trigger will release the latch.

4.3.6. When the level in the receiving tank reaches the nozzle, delivery will stop automatically.

4.3.7. When delivery is complete, switch off the pump. Ensure the hose is wound into its housing on the tank and that the nozzle is

secured in its storage place.

4.3.8. DO NOT operate the pump continuously for more than 30 minutes. The duty cycle of the unit is 30 minutes, after which the motor must

be left to cool down for a further 30 minutes.

4.3.9. DO NOT run the unit for more than 2-3 minutes with the delivery nozzle closed.

5. MAINTENANCE

5.1.

5.2.

5.3.

5.4.

-

x

The pump contains no user-servicable parts.

Repairs should only be undertaken by competent

persons.

Check the integrity of all the hose connections

periodically. If any leakage is evident, strip the

joint and wind PTFE tape around the male thread.

Check all electrical connections and cables for wear

and damage. Rectify any faults found.

Keep clean, especially the dispenser nozzle.

Clean with a damp, soapy cloth.

DO NOT use abrasive or solvent cleaners.

fig.3

fig.41

55

fig.5

87

87

2

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling center and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 24 months from purchase date, proof of which is required for any claim.

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories

and packaging should be sorted, taken to a recycling center and disposed of in a manner

which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers

and dispose of the product and fluids according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to

alter data, specifications and component parts without prior notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 24 months from purchase date, proof of which is required for any

claim.

6 DD400 USER MANUAL

Item

Part No.

Description

Item

Part No.

Description

1

DD400.01

Vent Plug

2

DD400.02

Tank 400L

11 DD400.11 Breathing Cap

12 MSP610.S

Machine screw pan Head Phillips M6 x 10mm

3

DD400.03

3/4" Connection Hose

13

DD400.13 Nozzle Holder

4

DD400.04 Lower Seal for Suction Elbow 14 DD400.14

Tank Lid Lock Holder

5

DD400.05 Hose Clip

15

DD400.15 Electric Pump 12V

6

DD400.06 Suction Elbow 16 DD400.16

Bracket for Electric Pump

7

DD400.07

Upper Seal for Suction Elbow

17 DD400.17

Automatic fluid Nozzle

8

DD400.08

Suction Cap

18

DD400.18 Delivery Hose 4 mt

9

DD400.09 Level Gauge 19 DD400.19 Filter

10

DD400.10

Tank Lid

20 DD400.20 Hose

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product. Spare parts must be fitted by a competent person

WARRANTY: Guarantee is 24 months from purchase date, proof of which will be required for any claim.

Parts List:

Portable Diesel Tank 12V

Model No: DD400

REF PART NUM DESCRIPTION

1 DD400.01 Vent Plug

2 DD400.02 Tank 400L

3 DD400.03 3/4" Connection Hose

4 DD400.04 Lower Seal for Suction Elbow

5 DD400.05 Hose Clip

6 DD400.06 Suction Elbow

7 DD400.07 Upper Seal for Suction Elbow

8 DD400.08 Suction Cap

9 DD400.09 Level Gauge

10 DD400.10 Tank Lid

11 DD400.11 Breathing Cap

12 MSP610.S Machine screw pan Head Phillips M6 x 10mm

13 DD400.13 Nozzle Holder

14 DD400.14 Tank Lid Lock Holder

15 DD400.15 Electric Pump 12V

16 DD400.16 Bracket for Electric Pump

17 DD400.17 Automatic fluid Nozzle

18 DD400.18 Delivery Hose 4 mt

19 DD400.19 Filter

20 DD400.20 Hose

EXPLODED VIEW & PARTS LIST

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data,

specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product. Spare parts must be fitted by a competent

person

WARRANTY: Guarantee is 24 months from purchase date, proof of which will be required for any claim.

DD400 USER MANUAL 7

8 DD400 USER MANUAL

PHONE: 604-850-7770

FAX: 604-850-7774

TOLL FREE PHONE: 1-877-588-3311

TOLL FREE FAX: 1-800-665-7334

BRABEREQ.COM

WGSALES@BRABEREQ.COM

Table of contents

Popular Tank Equipment manuals by other brands

Liqua

Liqua H-Flex Steam Liner instruction manual

Field Tuff

Field Tuff FTF-10GOR owner's manual

Global Water Solutions

Global Water Solutions PressureWave Installation and operation manual

Grundfos

Grundfos El.stirrer f.60l tank Installation and operating instructions

ENCON

ENCON SAF-T-TUB 01052539 Installation, operation and maintenance manual

Amtrol

Amtrol THERM-X-TROL ST-5C Series Installation & operation instructions