V20240125 •Page 2 of 9Model: FST

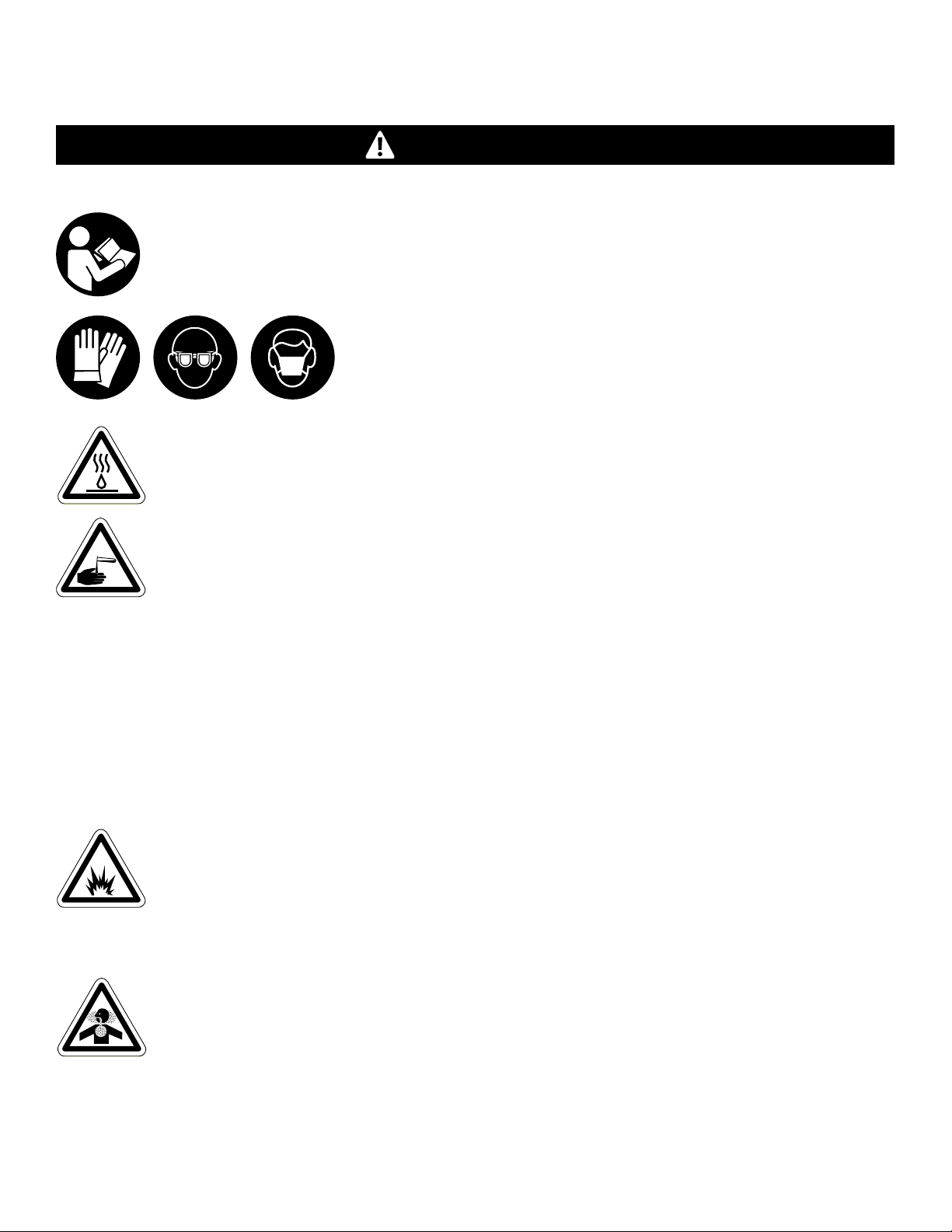

PEOPLE OR OBJECTS CAN BE HURT OR DAMAGED IF THIS UNIT IS NOT USED CORRECTLY!

Failure to read all the instructions before operating the unit may result in personal injury or death from

the improper use or the chemical solution. Anyone handling, operating or using the unit must read and

understand the instructions in the manual. The buyer assumes all responsibility for safety and proper

use in accordance with the instructions.

Using or servicing the unit without appropriate personal protective

equipment (PPE) may result in serious injury such as burns, rashes, eye,

throat or lung damage and death. Always wear PPE as indicated in the

Safety Data Sheet (SDS) when using or servicing the unit. Protect eyes, skin,

and lungs against drifting spray.

Chemical solutions may pose a health risk and death if they contact the skin or eyes, are inhaled

or swallowed. Always read and follow all chemical safety precautions and handling instructions

provided by the chemical manufacturer and the SDS associated with the chemical solution before

using the unit.

Pressure within the equipment may cause an unexpected release of the chemical solution and

cause serious injury such as burns, rashes, eye damage, throat or lung damage and death.

Always depressurize and clean the unit after each use. Release any remaining air pressure by opening

the discharge ball valve. Never leave the unit unattended while pressurized.

Using the unit with fluid temperatures above 100°F (37.8°C) may result in scalding, burns, serious injury

or death. DO NOT use a solution with a temperature above 100°F (37.8°C).

Operating the unit when damaged or leaking may result in exposure to chemical solutions, serious

injury or death. Never use the unit if it is damaged or leaking.

Never open ball valves with chemical in the tank, unless the ball valves are connected to an

appropriate location for chemical discharge. Never point the discharge valves at yourself, another

person, or any object you do not want covered in chemical. Never operate unit without the lid on.

Do not use the unit if an overflow hose is not installed. If chemical flows from the overflow port, shut

down the unit immediately and correct the problem before proceeding.

Using incoming air pressure exceeding 80 psi (5.5 bar) may result in pressure buildup, explosion,

serious injury or death. DO NOT exceed 80 psi (5.5 bar) incoming air pressure when operating

the unit.

Use of hydrocarbons and flammable products may result in explosions, fire and serious injury or death.

Never use hydrocarbons or flammable products with the unit.

Mixing an alkaline with an acid may result in a chemical reaction. Overheating of the mixture may

cause it to splatter caustic compounds or release hazardous fumes, gas and vapors. Always flush

the unit with fresh water thoroughly when switching from an alkaline to an acid or an acid to

an alkaline.

WARNING

Safety