Datum/Date

2004-10-22

Utgåva/Issue

1

Service Manual

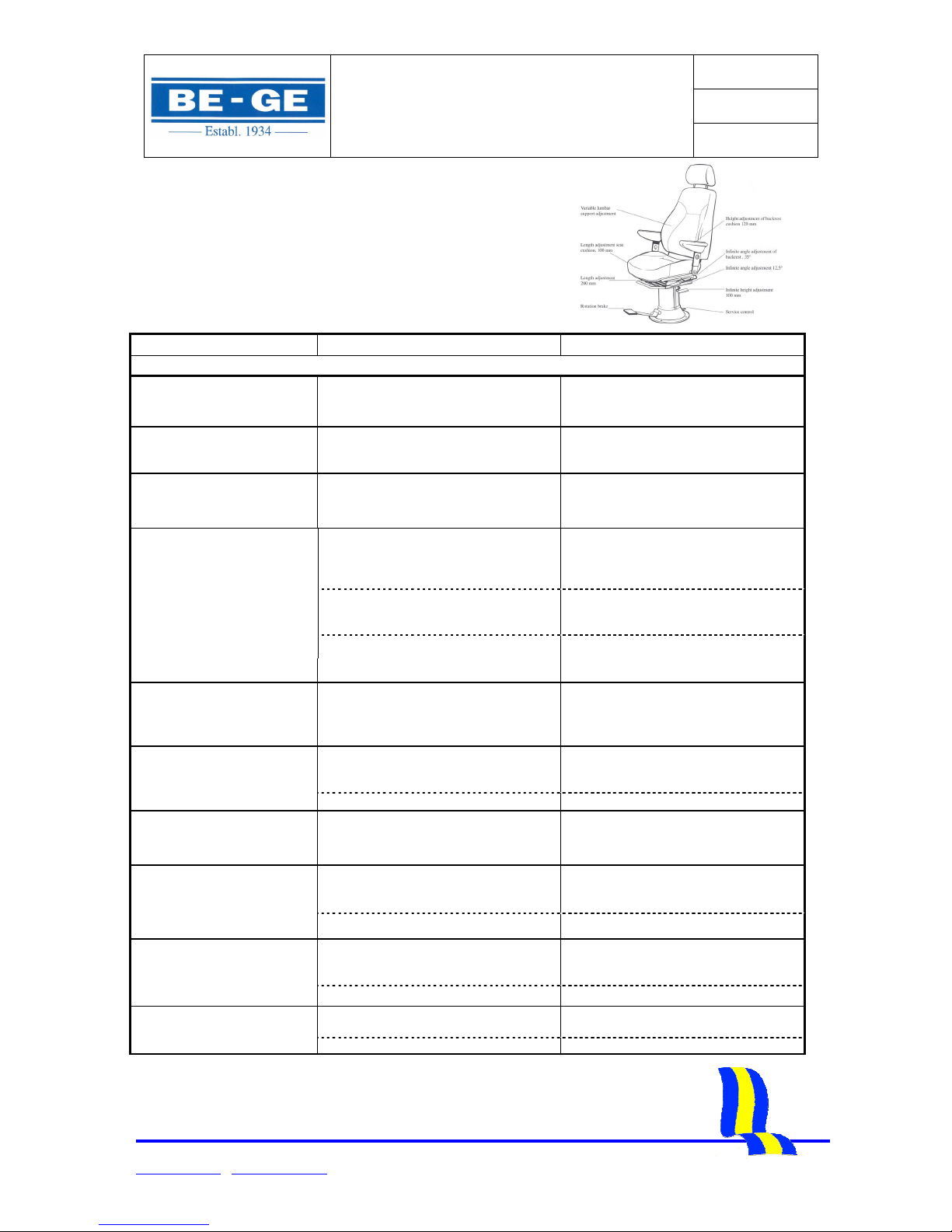

Be-Ge 8652

Recommended Maintenance

Sida/Page

5(14)

Be-Ge Industri AB

Box 912 S-572 29 Oskarshamn. Tel. +46(0)491-761800. Fax +46(0)491-81900.

Inspection Service Instruction Illustration

5.

Check the seatback adjuster

and the seatback high

adjustment function.

Appliances:

Slotted chisel

Box wrench 17 mm

Riveting Punch 7 mm

Striking tool

Grease solvent cleaner

(

CRC™ Bräkleen, or equivalent)

Grease

(Recommended grease is of type

Kernite, Skidoo, or equivalent)

If the seatback does not keep position

and does not keep the positioned

angle, then the seatbacks angle

adjustment gasspring needs to be

changed.

Remove the seat cushion (1).

See service appendix 3

Loosen the gassprings front locking

(2).

Strike out the tension peg at the rear

attachment (3) on the frame back

section alternatively unscrew the

gascylinders body from the rear

attachments of the fork attachement

Change the gasspring.

If the seatback does not keep position

and does not keep the positioned

height then dirt/grease or similar

might have got in the locking surface

for the height adjustment locking

eccentric.

This calls for cleaning of the frames

tube profile, back frames inner tube

profile and eccentric locking parts.

Recommended cleaning is CRC™

Bräkleen or equivalent.

An annual maintenance and re-

lubricating of the seatback and seat

cushion slide surfaces is to be done.

NB. Make sure of that no grease is

added onto the back adjustment

locking. Recommended grease is

Kernite, Skidoo, or equivalent.

2

22

2

3

33

3

1

11

1

NB.

No grease