BEAMEX MCS200 User manual

USER MANUAL -BEAMEX®MCS200 CALIBRATION WORKSTATION,

ASSEMBLY INSTRUCTIONS

Dear user,

We have made every effort to ensure the accuracy of the contents of this man-

ual. Should any errors be detected, we would greatly appreciate to receive sug-

gestions to improve the quality of the contents of this manual.

For more detailed technical data about Beamex®MCS200 Calibration Work-

station, please contact the manufacturer.

8888000 / MCS200uEng / Version 1

© Beamex 2015

BEAMEX OY AB

Ristisuonraitti 10

FIN-68600 Pietarsaari

FINLAND

Tel +358 - 10 –5505000

Fax +358 - 10 –5505404

E-mail: [email protected]m

service@beamex.com

Internet: http://www.beamex.com

User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions - Contents i

CONTENTS

Part 1, Introduction

General 2

About This Manual..................................................................3

Where Am I?....................................................................3

Typographical Conventions .............................................4

Unpacking and Inspection ......................................................4

Part 2, Standard Workstations

General 6

Assembly Instructions 7

Standard Workstation, Part list ...............................................7

How to Assemble MCS200 Standard Workstation..................9

Corner Unit...........................................................................14

How to Assemble the Corner Unit..................................14

Connecting Several Workstations Together..........................17

Connecting the Workstation to the Electrical Network...........17

Connecting the Workstation to the Pressure Supply.............18

Module Rack's Internal Connections..............................19

Use of the Workstation 21

General ................................................................................21

Part 3, Special Workstations

General 24

Electrical Trolley 25

Heavy-duty Workstation 26

General................................................................................ 26

Appendix

Safety 30

Symbols Used...................................................................... 30

Environmental Specifications............................................... 30

Standard, Desktop, Heavy Duty & Low

Workstations................................................................. 30

Safety Precautions and Warnings........................................ 31

General Warnings......................................................... 32

General Warnings Concerning Pressure

Measurement................................................................ 33

Warnings Concerning High Pressure ............................ 34

Disposal of Waste Electrical and Electronic Equipment 35

Beamex and WEEE............................................................. 35

Service 36

General................................................................................ 36

Uninstalling/installing Modules to/from MCS200................... 36

General......................................................................... 36

Instructions.................................................................... 37

Statements 38

Disclaimer............................................................................ 38

CE........................................................................................ 38

Intellectual Property Rights .................................................. 39

Copyright....................................................................... 39

Trademarks................................................................... 39

Index 41

ii User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions - Contents

User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions - Feedback iii

FEEDBACK

We want to improve our products and services constantly. Therefore we’d like

to know Your opinion of the product You use. Please spend a moment of Your

valuable time in filling this form. All respondents will receive a surprise gift in

return.

Certain questions can be answered immediately after receiving the product.

Others require some use of the product before You are able to answer them.

The best way to fill the form is to answer the items as it applies, and send the

form to us when all items are answered. There are however no definite re-

strictions; fill in the form when you feel like it (all items need not be answered).

Then send it to Beamex using one of the possibilities listed to the right.

Mail: Beamex Oy Ab

Quality Feedback

Ristisuonraitti 10

FIN-68600 Pietarsaari

FINLAND

Fax: +358 - 10 - 5505404

Only the next page needs to be

faxed to us.

Internet: http://www.beamex.com

A similar form is available as a web page

E-mail: [email protected]

Refer to the numbered items on the next

page in Your e-mail message.

iv User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions - Feedback

1. Name of the product you give feedback of:

_____________

2. Serial number and software version number

_____________ / _____________ (if applicable)

3. Any comments when receiving the product. Did the package con-

tain all required items and was it as expected?

____________________________________________

____________________________________________

____________________________________________

4. For how long have you been using the product?

_____________

5. How helpful was the manual in using the product?

(Tick a box in the percentage scale below)

6. How well did the product suit your needs?

7. How satisfied are you with the product?

8. Did anything in the product exceed your expectations? In that

case, what was it?

____________________________________________

____________________________________________

____________________________________________

9. Did anything in the product disappoint you? In that case, please

specify.

____________________________________________

____________________________________________

____________________________________________

10. Any ideas You want to propose to Beamex so that we can im-

prove our products, operations and/or services.

____________________________________________

____________________________________________

____________________________________________

Please fill in these fields in order to receive your surprise gift.

Title & Name: ______________________________________

Address: ______________________________________

_________________________________________________

_________________________________________________

Please contact me concerning the Feedback I have given.

I want to receive more information on Beamex products.

Size (tick one)

XS S M L XL XXL

Things discussed in this part:

About this manual.

Unpacking MCS200.

Part 1

INTRODUCTION

2 User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions –Part 1, Introduction

GENERAL

Thank you for buying Beamex MCS200 Calibration Workstation

The MCS200 System is a Modular Calibration Workstation for calibration and

maintenance of process instruments, like transmitters, converters, temperature

probes, recorders, indicators, etc. The system is designed for instru-

ment/electrical workshops and laboratories.

MCS200 consists of a Bench System. The modular construction of the system

allows the user to customize the MCS200 System to practically any measure-

ment and calibration application.

The modules in the MCS200 System can be grouped into four main types:

1. Host modules (Calibrator modules):

MC6 Workstation Calibration Host Module.

2. Supporting modules, divided into:

P’s, i.e. Pressure Measurement Modules,

PS’s, i.e. Manual Pressure Supply Modules,

PO’s, i.e. Manual Pressure Output Modules and

RTS24P Temperature/Resistance Simulator module

3. Power Supply modules (e.g. SU1, for MCS200 Bench System)

4. POC6 Automatic Pressure Controller module

MCS200 Supporting Modules, MC6 Workstation calibration host module, POC6

Automatic Pressure Controller, Power supplies, Measuring instruments and

other modules are covered in separate manuals.

Attention!

Before taking MCS200 into use, please read the warnings

available in Appendix.

Note.

In addition to modules, MCS200 Workstation may include aux-

iliary components such as:

With MC6 Workstation

- An isolated USB Hub including its power supply.

- A non-isolated USB Hub.

With pressure related modules (PS's, PO's and POC6's).

- One or more pressure reducing valves.

General - About This Manual 3

ABOUT THIS MANUAL

MCS200 User Manual is divided into several parts as follows:

Part 1, Introduction discusses general matters.

Part 2, Standard Workstations describes how to assemble Standard

Workstations and Corner Units.

Part 3, Special Workstations presents other types of workstations

available in MCS200 System.

Part A, Appendix discusses safety, warnings

and installing/uninstalling modules.

Note.

This manual includes a description of all the MCS200 Calibra-

tion Systems available, not only the system at hand.

WHERE AM I?

The header of each spread in MCS200 User Manual informs you of where you

are: The even page shows the part you are in and the odd page shows the

main topic you are currently viewing.

Example of even page header:

2 User Manual –… –Part 1, Introduction

Example of odd page header:

General - About This Manual 3

4 User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions –Part 1, Introduction

TYPOGRAPHICAL CONVENTIONS

The following typographical conventions apply to MCS200 User Manual:

Bold text is used in following situations:

References to User Manual topics and parts and

Keywords, i.e. terms shown in the related to MCS200 or its modules.

Notes are shown in Narrow text with a border above and to the

left of the note text. Notes typically inform you of something

useful concerning the current topic.

Warnings are shown in Narrow and Bold. They also have a

shaded background and are surrounded by a border line.

Whenever you see a warning, read it carefully and take it

seriously. By not observing warnings, you may - at worst -

damage the calibrator and/or even risk your life.

UNPACKING AND INSPECTION

At the factory each new MCS200 passes a careful inspection. It should be free

of scrapes and scratches and in proper operation condition upon receipt. The

receiver should, however, inspect the unit for any damage that may have oc-

curred during transit. If there are signs of obvious mechanical damage, package

contents are incomplete, or MCS200 does not operate according to specifica-

tions, contact the purchasing sales office as soon as possible.

All the modules purchased with the MCS200 System are installed in the module

rack or in the base unit at the factory. Installation of additional modules that are

purchased later on is described in Part A, Appendix.

If you have to return a module or another part of the MCS200 System to the

factory for any reason, include a detailed description of the reason for the re-

turn. Read also chapter Service in Part A, Appendix.

Standard accessories:

Accredited calibration certificate,

this User Manual,

Warranty Card,

a CD-ROM with product information, USB

Drivers etc. and

depending on the included modules:

pressure hoses, test leads and/or clips.

Things discussed in this part:

How to assemble the Standard Workstation.

How to assemble the Corner Unit.

Internal connections inside the Module Rack.

Taking the workstation into use.

Part 2

STANDARD WORKSTATIONS

6 User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions –Part 2, Standard Workstations

GENERAL

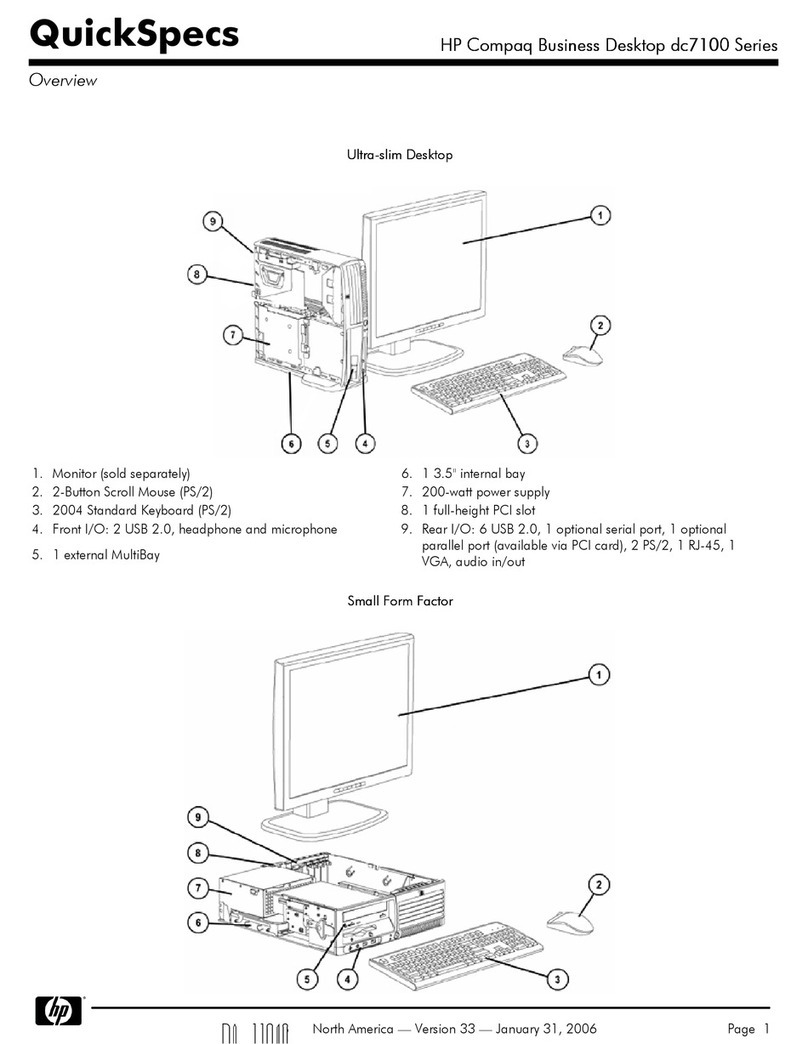

In the Standard Workstation a Module Rack is located above the table top.

The available widths of the workstations are as follows:

Width of table(* Width of corresponding Module Rack(*

1.8 m / 5' 10¼ " 1.880 m / 6' 2"

1.5 m / 4' 11" 1.575 m / 5' 2"

*)All foot/inch values are approximate.

The Module Rack includes a power supply module and additional modules ac-

cording to your own needs.

Note.

The table top may also be of a semiconducting material where ESD requirements apply. The

assembly instructions presented further on apply to both "normal" table tops as well as a sem-

iconducting table tops. Table frames and accessories are ESD painted as standard.

Each workstation consists of

a table frame,

a table top and

a module rack.

Assembly Instructions - Standard Workstation, Part list 7

ASSEMBLY INSTRUCTIONS

We recommend that you read all assembly instructions before assembling any

of the MCS200 tables. This especially if you have several tables delivered. The

basic information is below, but the following chapters are useful when assem-

bling several tables connected to each other:

How to Assemble the Corner Unit on page 14 and

Connecting Several Workstations Together on page 17.

STANDARD WORKSTATION,PART LIST

Part name and, if more than one: amount

CODE

(if applicable)

Notes.

Most codes end with a dash and two numbers. In the list on the

left (and all part lists further on), the end part of the code is

marked "-XX", eg. "-49". The first part of the code indicates the

part. The end part of the code is irrelevant.

The list on the left contains the essential items for assembling

the workstation. There are some additional items like nuts,

bolts and plastic covers for the holes in legs etc. which are not

mentioned, but can surely be assembled without special in-

structions.

The optional item PC Rack is not mentioned in the list above,

but is mentioned in the assembly instructions further on be-

cause it is of use to know at which point, and how, the PC

Rack should be installed.

Legs, 2 pcs(*

Vertical part:

890402-XX

Horizontal part:

890401-XX

Lower horizontal support

1800 mm table:

854864-XX

1500 mm table:

854863-XX

Upper horizontal support

1800 mm table:

890417-XX

1500 mm table:

890416-XX

Table top supports, 2 pcs

890405-XX

8 User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions –Part 2, Standard Workstations

C-profiles, 2 pcs

1800 mm table:

890410-XX

1500 mm table:

890409-XX

Module Rack supports, 2 pairs

820164-XX

Module Rack

(None)

Table top

Std 1800 mm:

TT18875TL

ESD 1800 mm:

TT18875TL-ESD

Std 1500 mm:

TT15775TL

ESD 1500 mm:

TT15775TL-ESD

Perforated plate

1800 mm table:

861531-XX

1500 mm table:

861526-XX

*) A pair of legs as mentioned in the beginning of the part list is delivered with

the fist table or with all standalone tables. If the order includes Extension

Tables (including a Corner Unit), the Extension Tables and Corner Units in-

clude an extension leg, one each.

Assembly Instructions - How to Assemble MCS200 Standard Workstation 9

HOW TO ASSEMBLE MCS200 STANDARD WORKSTATION

If your delivery includes a Corner Unit, it is recommended to assemble it first.

Then place the Corner Unit where you want it to be located and build the

Standard/Extension Workstation(s) around it.

How to Assemble the Corner Unit is on page 14.

Fix the horizontal part of the leg from below using

M8x30 screws and washers (diameter 16 mm). The

position is correct when there is one hole visible be-

hind the leg.

Fix the lower horizontal sup-

port to the legs using M8x30

screws, washers (diameter 16

mm) and M8 nuts. Place the

support to the height showed

in the pictures. When placing

the support, turn the leg a

little to ease up the place-

ment.

Do not tighten yet!

10 User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions –Part 2, Standard Workstations

Fix the table top supports to

the legs using M8x30 screws,

washers (diameter 16 mm)

and M8 nuts. Place the sup-

ports to the height shown in

the pictures.

Do not tighten yet!

Note.

The height of the table top can be

adjusted between according to

your needs.

Max. loading capacity of the pair of table top sup-

ports is 120 kg (440 lbs).

Fix the 1st C-profile using

M8x30 screws and washers

(diameter 20 mm). Place the

C-profile at the back if there is

no PC rack included in the

delivery. Place the C-profile in

the middle if there is a PC

rack included. Do not fix the

2nd C-profile yet.

Assembly Instructions - How to Assemble MCS200 Standard Workstation 11

Place the panel supports to

the height shown in the pic-

ture.

Place the rubber insulation

parts to the three holes under

the Module Rack. Place the

Module Rack above the panel

supports. Fix the Module

Rack using M6x30 screws

and washers.

Important!

The frame of the table must

always be isolated from the

module rack!

12 User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions –Part 2, Standard Workstations

Fix the 2nd C-profile using

M8x30 screws and washers

(diameter 20 mm)

If your MCS200 does not include the optional PC rack, skip to next page.

Fix the PC rack to the C-

profiles using M6x20 screws,

washers and threaded nuts.

Place the threaded nuts in-

side the C-profiles and tighten

the screws.

Assembly Instructions - How to Assemble MCS200 Standard Workstation 13

Fix the table top using 5x20 wood screws. Two at the front, two at each table

top support and three at the back.

Fix the perforated plate on its place. Place the leg covers on top of the legs us-

ing M6x12 bolts and washers. Press the plastic covers to the holes in the legs.

Tighten the screws and you're done.

General information about TowerLine workstations

The workstation can be balanced by turning the adjustment feet under

the workstation.

The workstation can be equipped with practical accessories such as

shelves, lighting, display holders etc. The accessories can be placed to

different height at the workstation.

The legs include built-in channels that can be used to hide cables.

The Module Rack panel is safety earthed.

14 User Manual - Beamex®MCS200 Calibration Workstation, Assembly Instructions –Part 2, Standard Workstations

CORNER UNIT

The Corner Unit differs from a Standard/Extension Workstation only by its spe-

cial look. A Standard Workstation and an Extension Workstation in a 90 degree

angle may be combined with the help of the Corner Unit.

HOW TO ASSEMBLE THE CORNER UNIT

If you have both Standard/Extension Workstations and Corner Units, assemble

the Corner Unit first where convenient. Then place it where you want it to be

located and assemble the Standard/Extension Workstation(s) around the Cor-

ner Unit.

Table of contents