Bearcat CH911DH User manual

ENGLISH ESPAÑOL FRANÇAIS

BEARCATPRODUCTS.COM// 888.625.4520

OWNER’S MANUAL

ENGLISH

1.1L DIESEL KUBOTA®

P/N: 78636-00

Revision: 20220822

VIN Range: 5VJAA0411NW006958 - Current

Companion to P/N: 78640-00

Before You Begin

© 2022, Crary®Industries, All rights reserved. Produced and printed in the U.S.A.

HOW TO CONTACT Crary Bear Cat

ADDRESS PHONE E-MAIL HOURS

237 NW 12th Street

P.O. Box 849

West Fargo, ND 58078

888-625-4520

701-282-5520

Fax: 701-282-9522

sales@bearcatproducts.com

service@bearcatproducts.com

Monday - Friday

8 a.m. to 5 p.m.

Central Time

DEAR Crary®Bear Cat®CUSTOMER

Thank you for purchasing an Crary Bear Cat product. The Crary Bear Cat line is designed, tested, and manufactured to give

years of dependable performance. To keep your machine operating at peak efciency, it is necessary to adjust it correctly and

make regular inspections. The following pages will assist you in the operation and maintenance of your machine. Please read

and understand this manual before operating your machine.

If you have any questions or comments about this manual, please call us toll-free at 888-625-4520.

If you have any questions or problems with your machine, please call or write your local authorized Crary Bear Cat dealer.

This document is based on information available at the time of its publication. Crary Bear Cat is continually making

improvements and developing new equipment. In doing so, we reserve the right to make changes or add improvements to our

product without obligation for equipment previously sold.

FOR MACHINE SERVICE OR PARTS

For service assistance, contact your nearest authorized

Crary Bear Cat dealer or the factory. For parts, contact your

authorized dealer. The parts manual for your machine is

available at bearcatproducts.com/Product-Support/Find-

A-Product-Manual. Your dealer will need to know the serial

number of your machine to provide the most efcient service.

See below for information on how to identify and record the

serial number for your machine.

FOR ENGINE SERVICE OR PARTS

For engine service or parts, contact your nearest authorized

engine dealer. Crary Bear Cat does not handle any parts, repairs

or warranties for engines.

ORDERING PARTS

Only genuine Crary Bear Cat replacement parts should be used

to repair the machine. Replacement parts manufactured by

others could present safety hazards, even though they may t

on this machine. Replacement parts are available from your

Crary Bear Cat dealer.

Provide the following when ordering parts:

• The SERIAL NUMBER of your machine.

• The PART NUMBER of the part.

• The PART DESCRIPTION.

• The QUANTITY needed.

IDENTIFICATION NUMBER LOCATION

Your machine will have a vehicle identication number

(VIN). VINs are located on the left side of the trailer frame

near the hitch. They are 17-digit numbers of the format:

5VJAA001XXWXXXXXX. For the exact location of the VIN,

see the parts manual available at bearcatproducts.com/

Product-Support/Find-A-Product-Manual.

Record your identication number in the space provided and

on the warranty registration card.

VEHICLE IDENTIFICATION NUMBER

10/21

IMPORTANT WARRANTY REGISTRATION

IF YOU HAVE NOT REGISTERED YOUR CRARY BEAR CAT PRODUCT, PLEASE DO SO TODAY. TO REGISTER YOUR CRARY BEAR CAT

PRODUCT ON-LINE AT HTTPS://WWW.BEARCATPRODUCTS.COM/SUPPORT/PRODUCT-REGISTRATION/ OR CALL OUR CUSTOMER

SERVICE LINE AT (888) 625-4520 FOR ASSISTANCE IN REGISTRATION.

ENGLISH

LIMITED WARRANTY

This warranty applies to all Crary

®

Bear Cat

®

Outdoor Power Equipment manufactured by Crary Industries, Inc. and

does not include gas engine or electric powered pressure washers under the Crary Bear Cat brand. See Crary Bear

Cat Pressure Washer Limited Warranty for complete warranty details on those products.

Crary Industries, Inc. warrants to the original owner each new Crary Bear Cat product to be free from defects in

material and workmanship, under normal use and service. The warranty shall extend, from date of purchase, three

years (U.S. and Canada only [two years outside U.S. and Canada]) for Consumer use of the product, one year for

Commercial applications and six months for Rental applications. Replacement parts and accessories are warranted

for 90 days from date of installation. Batteries for Inverters and Generators are warranted for 90 days from the date

of purchase.

“Consumer” de ned as:Complete unit for personal, residential, or non-income producing use.

“Commercial” de ned as:Complete unit for commercial, institutional, property management, agricultural,horticultural

or income producing use.

“Rental” de ned as: Complete unit for rental purposes to produce income.

The product is warranted to the original owner by either a completed warranty registration on le at Crary Industries,

Inc. and/or proof of sale. Warranty coverage begins on the date of purchase. The warranty registration can be

registered on-line by visiting bearcatproducts.com/Product-Support/Product-Registration.

In the event of a failure, return the product, at your cost, along with proof of purchase to the selling Crary Bear

Cat dealer. Crary Industries, Inc. will, at its option, repair or replace any parts found to be defective in material

or workmanship. Warranty on any repairs will not extend beyond the product warranty. Repair or attempted repair

by anyone other than an authorized Crary Bear Cat dealer as well as subsequent failure or damage that may occur

as a result of that work will not be paid under this warranty. Crary Industries, Inc. does not warrant replacement

components not manufactured or sold by Crary Industries, Inc.

1. This warranty applies only to parts or components that are defective in material or workmanship.

2. This warranty does not cover normal wear items including, but not limited to: batteries, bearings, belts,

pulleys, lters, chipper blades, shredder knives.

3. This warranty does not cover normal maintenance, service, or adjustments.

4. This warranty does not cover depreciation or damage due to misuse, negligence, accident, or

improper maintenance.

5. This warranty does not cover damage due to improper setup, installation, or adjustment.

6. This warranty does not cover damage due to unauthorized modi cations of the product.

7. Engines are warranted by the respective engine manufacturer and are not covered by this warranty.

Crary Industries, Inc. is not liable for any property damage, personal injury or death resulting from the unauthorized

modi cation or alteration of an Crary Bear Cat product or from the owner’s failure to assemble, install, maintain, or

operate the product in accordance with the provisions of the Owner’s manual.

Crary Industries, Inc. is not liable for indirect, incidental, or consequential damages or injuries including but not

limited to loss of crops, loss of pro ts, rental of substitute equipment or other commercial loss. This warranty gives

you speci c legal rights. You may have other rights that may vary from area to area.

Crary Industries, Inc. makes no warranties, representations or promises, expressed, or implied as to the performance

of its products other than those set forth in this warranty. Neither the dealer nor any other person has any authority

to make any representations, warranties or promises on behalf of Crary Industries, Inc. or to modify the terms or

limitations of this warranty in any way. Crary Industries, Inc., at its discretion, may periodically offer limited, written

enhancements to this warranty.

CRARY INDUSTRIES, INC. RESERVES THE RIGHT TO CHANGE THE DESIGN AND/OR SPECIFICATIONS OF ITS

PRODUCTS AT ANY TIME WITHOUT OBLIGATION TO PREVIOUS PURCHASERS OF ITS PRODUCTS.

20210624

TABLE OF CONTENTS

1 SAFETY .................................................................. 1

1.1 SAFETY ALERT SYMBOL........................................ 1

1.2 FIRE HAZARD INFORMATION................................ 1

1.3 BEFORE OPERATING.............................................. 1

1.4 OPERATION SAFETY............................................... 2

1.5 FEED ROLLER SAFETY .......................................... 2

1.6 BATTERY SAFETY.................................................... 3

1.7 MAINTENANCE/STORAGE SAFETY...................... 3

1.8 TOWING SAFETY ..................................................... 3

1.9 SAFETY DECALS ..................................................... 4

1.10 SAFETY DECAL LOCATIONS ............................... 5

2 ASSEMBLY............................................................. 6

2.1 ATTACH TRAILER WHEELS.................................... 6

2.2 ATTACH HITCH ASSEMBLY .................................... 6

2.3 INSTALL REAR STABILIZER ................................... 6

2.4 ATTACH CHUTE AND SUPPORT............................ 7

2.5 ATTACH DIGITAL DISPLAY CONTROLLER

MOUNT ASSEMBLY........................................................ 8

2.6 ATTACH EXTENSION TRAY .................................... 8

2.7 ATTACH DISCHARGE TUBE ................................... 9

2.8 ADD OIL TO ENGINE.............................................. 10

2.9 CHECK/ADD HYDRAULIC FLUID ......................... 10

2.10 ADD COOLANT ..................................................... 10

2.11 INSTALL BATTERY ............................................... 10

2.12 FILL THE FUEL TANK........................................... 10

3 FEATURES & CONTROLS ................................. 11

4 OPERATION......................................................... 13

4.1 STARTING ENGINE................................................ 13

4.2 OPERATING THE CHIPPER.................................. 13

4.3 CHIPPER OPERATION GUIDELINES .................. 15

4.4 SLOWING AND STOPPING THE CHIPPER

ROTOR AND ENGINE .................................................. 16

4.5 FEED ROLLER SPEED CONTROL....................... 16

4.6 CHIPPER FEED CONTROLLER ........................... 16

4.7 USING THE DIGITAL DISPLAY CONTROLLER... 17

4.8 TOWING................................................................... 19

5 SERVICE & MAINTENANCE.............................. 20

5.1 MAINTENANCE SCHEDULE ................................. 20

5.2 ROTOR LOCK ......................................................... 21

5.3 OPEN/CLOSE ACCESS COVER ........................... 21

5.4 CHIPPER BLADES MAINTENANCE..................... 21

5.5 REMOVING THE BLADES ..................................... 22

5.6 SHARPENING THE BLADES................................. 22

5.7 INSTALLING THE BLADES.................................... 22

5.8 SETTING CHIPPER BLADE CLEARANCE .......... 23

5.9 TRAILER MAINTENANCE TIPS ............................ 23

5.10 CLEARING A PLUGGED ROTOR........................ 23

5.11 DRIVE BELTS ........................................................ 24

5.12 ROTOR BEARINGS .............................................. 24

5.13 HYDRAULIC FEED MAINTENANCE................... 25

5.14 CHANGE HYDRAULIC FLUID FILTER ............... 26

5.15 CHANGE OIL ......................................................... 26

5.16 CHECK COOLANT LEVEL ................................... 26

5.17 LUBRICATION....................................................... 27

6 TROUBLESHOOTING......................................... 28

6.1 FLASH CODES FOR THE DIGITAL DISPLAY

CONTROLLER .............................................................. 28

6.2 TROUBLESHOOTING GUIDE ............................... 29

7 SPECIFICATIONS ............................................... 31

7.1 BOLT TORQUE........................................................ 32

7.2 TEMPERATURE OPERATING WINDOW ............. 33

8 OPTIONS.............................................................. 34

19 INCH CHIPPER

ENGLISH

Section

1 SAFETY

Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury.

DANGER

1.1 SAFETY ALERT SYMBOL

Indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

WARNING

Indicates a potentially hazardous situation that, if not

avoided, may result in minor or moderate injury.

CAUTION

The Owner/Operator’s manual uses this symbol to alert

you of potential hazards. Whenever you see this symbol,

read and obey the safety message that follows it. Failure

to obey the safety message could result in personal injury,

death or property damage.

1. Read and understand this owner’s manual. Be

completely familiar with the controls and the proper

use of this equipment.

2. Familiarize yourself with all of the safety and

operating decals on this equipment and on any of its

attachments or accessories.

3. Keep safety decals clean and legible. Replace

missing or illegible safety decals.

4. Obtain and wear safety glasses

and use hearing protection at all

times when operating this machine.

5. Avoid wearing loose tted clothing.

Never operate this machine while wearing clothing

with drawstrings that could wrap around or get caught

in the machine.

6. Do not operate this machine if you are under the

inuence of alcohol, medications, or substances that

can aect your vision, balance or judgement. Do not

operate if tired or ill. You must be in good health to

operate this machine safely.

Federal, state, and local laws may

prohibit the operation of an internal

combustion engine using hydrocarbon

fuels on any forest covered, brush

covered or grass covered land or on

land covered with grain, hay or other

ammable agricultural crops, without

an engine spark arrestor in continuous eective working

order.

1.2 FIRE HAZARD INFORMATION

The engine on your power equipment, like most outdoor

power equipment, is an internal combustion engine that

burns gasoline or diesel fuel (hydrocarbons). If operating

your power equipment in aected areas, it must be

equipped with a spark arrestor in continuous eective

working order. The spark arrestor must be attached to the

engine exhaust system in such a manner that ames or

heat from the system will not ignite ammable material.

Failure of the owner/operator of the equipment to comply

with federal, state, and local laws may subject him or her

to nes and/or other penalties. Contact your local re

marshal or forest service for specic information about

which regulations apply in your area.

Contact local re authorities for laws or regulations

regarding re prevention requirements.

1.3 BEFORE OPERATING

29 INCH CHIPPER

SAFETY

1. Always stand clear of discharge area when operating

this machine. Keep face and body away from feed

and discharge openings.

2. Keep hands and feet out of feed and discharge

openings while machine is operating to avoid serious

personal injury. Stop and allow

machine to come to a complete

stop before clearing obstructions.

3. Set up your work site so you are

not endangering trac and the

public. Take great care to provide

adequate warnings.

4. Do not climb on machine when operating. Keep

proper balance and footing at all times.

5. Check cutting chamber to verify it is empty before

starting the machine.

1.4 OPERATION SAFETY

7. Do not operate this equipment in

the vicinity of bystanders. Keep

the area of operation clear of all

persons, particularly small children.

It is recommended that bystanders

keep at least 50 feet (15 meters)

away from the area of operation.

8. Do not allow children to operate this equipment.

9. Use only in daylight or good articial light.

10. Do not run this equipment in an enclosed area. Engine

exhaust contains carbon monoxide gas, a deadly

poison that is odorless, colorless and tasteless.

Do not operate this equipment in or near buildings,

windows or air conditioners.

11. Always use an approved fuel container. Do not

remove gas cap or add fuel when engine is running.

Add fuel to a cool engine only.

12. Do not ll fuel tank indoors. Keep open ames, sparks,

smoking materials and other sources of combustion

away from fuel.

13. Do not operate machine without shields in place.

Failure to do so may cause serious injury or death.

14. Keep all guards, deectors, and shields in good

working condition.

15. Before inspecting or servicing any part of this machine,

shut o the machine and make sure all moving parts

have come to a complete stop. Disconnect the battery

and remove the ignition key where applicable.

16. Check that all screws, nuts, bolts, and other fasteners

are secured, tightened and in proper working condition

before starting the machine.

17. Do not transport or move machine while it is operating

or running.

6. The rotor will continue to rotate after being disengaged.

Shut o the machine and make sure all moving parts

have come to a complete stop before inspecting or

servicing any part of the machine. Disconnect the

battery and remove the ignition key if applicable.

7. Do not insert branches with a diameter larger than

the max chipper capacity into machine or machine

damage may occur.

8. When feeding material into machine, do not allow

metal, rocks, bottles, cans or any other foreign

material to be fed into the machine.

9. Ensure debris does not blow into trac, parked cars,

or pedestrians.

10. Keep the machine clear of debris and other

accumulations.

11. Do not allow processed material to build up in the

discharge area. This may prevent proper discharge

and can result in kickback of material through the

feed opening.

12. If the machine becomes clogged, the cutting

mechanism strikes any foreign object, or the machine

starts vibrating or making an unusual noise, shut o

machine immediately and make sure all moving parts

have come to a complete stop. Disconnect the battery

and remove the ignition key if applicable. After the

machine stops: A) Inspect for damage, B) Replace

or repair any damaged parts, and C) Check for and

tighten any loose parts.

13. On electric start models, disconnect cables from

battery before doing any inspection or service.

Remove key.

14. Check blade bolts for proper torque after every 8 hours

of operation. Check blades and rotate or resharpen

daily or as required to keep blades sharp. Failure

to do so may cause poor performance, damage or

personal injury and will void the machine warranty.

1.5 FEED ROLLER SAFETY

1. The feed roller can cause serious injury or death.

Keep hands, feet and clothing away from the feed

roller and chipper rotor blades.

2. Never climb onto the feed chute

when the unit is operating or

running.

3. Do not overreach. Keep proper

balance and footing at all times.

4. Never allow anyone to sit on the

feed chute.

5. When feeding material into the

feed roller wear eye, face and

hearing protection.

WRONG

WRONG

39 INCH CHIPPER

ENGLISH

SAFETY

1.6 BATTERY SAFETY

Improper use and care of the battery on electric start

models can result in serious personal injury or property

damage. Always observe the following safety precautions.

●Poison/Danger – Causes Severe Burns. The

battery contains sulfuric acid. Avoid contact with skin,

eyes or clothing. Keep out of reach of children.

●ANTIDOTE – External Contact: Flush immediately

with water.

●ANTIDOTE – Internal: Drink a large amount of water

or milk. Follow with milk of magnesia, beaten egg or

vegetable oil. Call a physician immediately.

●ANTIDOTE – Eye Contact: Flush with water for 15

minutes. Get prompt medical attention.

1. The battery produces explosive gases. Keep sparks,

ame or cigarettes away. Ventilate area when

charging battery. Always wear safety goggles when

working near battery.

2. The battery contains toxic materials. Do not damage

battery case. If case is broken or damaged, avoid

contact with battery contents.

3. Neutralize acid spills with a baking soda and water

solution. Properly dispose of a damaged or worn-

out battery. Check with local authorities for proper

disposal methods.

4. Do not short circuit battery. Severe fumes and re can

result.

5. Before working with electrical wires or components,

disconnect battery ground (negative) cable rst.

Disconnect positive cable second. Reverse this order

when reconnecting battery cables.

1. Before inspecting, servicing, storing, or changing

an accessory, shut o the machine and make sure

all moving parts have come to a complete stop.

Disconnect the battery and remove the ignition key

where applicable.

2. Replace any missing or unreadable safety decals.

Refer to the safety decal section for part numbers.

3. Allow machine to cool before storing in an enclosure.

4. Store the machine out of reach of children and where

fuel vapors will not reach an open ame or spark.

5. Never store this machine with fuel in the fuel tank

inside a building where fumes may be ignited by

an open ame or spark. Ignition sources can be hot

water and space heaters, furnaces, clothes dryers,

stoves, electric motors, etc.

6. Drain the fuel and dispose of it in a safe manner for

storage periods of three months or more.

DANGER / POISON

FLUSH EYES

IMMEDIATELY

WITH WATER

GET

MEDICAL

HELP

FAST

KEEP OUT OF THE REACH OF CHILDREN. DO NOT TIP. KEEP VENT CAPS TIGHT AND LEVEL.

SULFURIC

ACID CAN

CAUSE

BLINDNESS OR

SEVERE BURNS

NO

• SPARKS

• FLAMES

• SMOKING

SHIELD EYES

EXPLOSIVE

GASES CAN

CAUSE BLINDNESS

OR INJURY

1. Position and lock the discharge tube to face the

opposite direction of the towing vehicle prior to towing.

2. Connect hitch safety chains. Tighten trailer hitch

bolts. Do not attempt to tow the trailer if the vehicle is

not equipped with a 2" (50 mm) ball.

3. Do not exceed the maximum towing speed indicated

on tire sidewall. Inate tires to manufacturer’s

specications as stated on the tire sidewall.

4. Optimum towing performance can be achieved by

maintaining a horizontal trailer hitch.

5. Check wheel lug bolts periodically to ensure they are

tight and secure.

6. Make sure the jack stand and the rear stabilizer

(where applicable) on the trailer are in the UP position

during towing. Place the jack stand on a level surface

and secure it in the DOWN position before using.

7. Never allow passengers to ride on the machine.

8. If applicable, shut o fuel supply when towing.

9. Towing laws may vary in dierent countries/regions/

states. It is recommended that you contact your local

motor vehicle department for any special regulations

that pertain to towing and know the laws of any

country/region/state you travel through.

6. Stand to side of feed chute when feeding material

and release material quickly.

7. When inspecting or servicing the feed roller, secure

the feed roller in the raised position using the lock pin,

if applicable.

1.7 MAINTENANCE/STORAGE SAFETY

1.8 TOWING SAFETY

49 INCH CHIPPER

SAFETY

1.9 SAFETY DECALS

Keep hands and feet out of inlet and discharge

openings while machine is operating to avoid serious

personal injury. Stop and allow machine to come to a

complete stop before clearing obstructions.

Read and understand this owner/operators

manual. Be completely familiar with the

controls and the proper use of this equipment

Obtain and wear safety glasses and use

hearing protection at all times when operating

this machine.

Before inspecting or servicing any part of this

machine, shut o power source, remove the

key, disconnect spark plug wire from spark

plug and make sure all moving parts have

come to a complete stop.

Do not operate this equipment in the

vicinity of bystanders. Do not allow

children to operate this equipment.

Always stand clear of discharge

area when operating this machine.

Keep face and body away from discharge areas.

Do not operate machine without shields in place.

Failure to do so may cause serious injury or

death.

Check blade bolts for proper torque

after every 8 hours of operation.

Check blades and rotate or resharpen

daily or as required to keep blades

sharp. Refer to owners manual for instructions. Failure to do so may

cause poor performance, damage or personal injury and will void the

machine warranty.

See Section 1.10 for decal locations. Familiarize yourself with all of the safety and operating decals on the machine

and the associated hazards. See the engine owner’s manual or contact the engine manufacturer for engine safety

instructions and decals.

PN 12174

Keep hands and feet out of inlet and

discharge openings while machine

is operating to avoid serious

personal injury. Stop and allow

machine to come to a complete

stop before clearing obstructions.

1 6

2

7

3

4

5

PN 12169

PN 12172

PN 12173

PN 12174

PN 12175

PN 12250

PN 12183

Read and understand your owners manual before operating. If owners

manual was not included or you have any questions, please call

800.247.7335 or 701.282.5520 (U.S.A.).

Do not operate this equipment in the vicinity

of bystanders. Do not allow children to

operate this equipment. Always stand clear

of discharge area when operating this

machine. Keep face and body away from

discharge areas. Rotate the discharge tube over the hitch before towing

and lock securely in place.

8

10

11

PN 14942-00

PN 32109-00

PN 32154-00

Press clutch pedal down with foot to disengage

belt while starting engine. Slowly release foot

to engage chipper belt after chipper is running.

Feed roller support must be secured in

the up position prior to servicing chipper

feed area. Feed roller can fall and cause severe bodily harm. Consult

owner’s manual for proper method of securing feed roller support. Lower

feed roller before operating chipper.

9PN 18983-00

59 INCH CHIPPER

ENGLISH

SAFETY

12 PN 32327-00 ENG. & FR.

(32339-00 ESP. & PORT.)

13 PN 32328-00 ENG. & FR.

(32340-00 ESP. & PORT.)

14 PN 32330-00 ENG. & FR.

(32342-00 ESP. & PORT.)

15 PN 32332-00 ENG. & FR.

(32341-00 ESP. & PORT.)

1.10 SAFETY DECAL LOCATIONS

The numbers below correspond to the decals in Section 1.9. Make certain that all safety and operating decals on this

machine are kept clean and in good condition. Decals that need replacement must be applied to their original locations.

*Decal located under shield

**Decal located on trailer

69 INCH CHIPPER

Section

2 ASSEMBLY

1. Remove the chipper from its shipping crate. Place the unit on a level surface before attempting to assemble.

2. Raise the trailer several inches from the ground with a hoist or jack. Support the chipper securely.

3. Lift one wheel to a hub and align the wheel lug holes with the hub lug bolts. Thread the lug nuts onto the bolts and

tighten them to 75 ft-lbs. Follow a star pattern when tightening the lug bolts. Repeat this step for the remaining

wheel.

1. Insert the adjustable hitch assembly into the hitch

opening in the chipper trailer frame as shown in

Figure 2.1.

2. Adjust the hitch pole to desired length and secure to

frame by inserting the 1" × 6” hitch pole pin through

the appropriate hole in hitch pole and hole in frame.

3. Secure the hitch pole pin with lynch pin.

4. Attach safety chain from front of trailer frame to

bottom hole of gusset at the front of the hitch pole

with one 3/8" × 1-1/2” hex bolt, washers and nut.

Figure 2.1, Trailer Hitch Pole Assembly Installation

If any bolts or nuts are dropped in the machine, be

sure to remove them before starting the machine.

WARNING

The rear stabilizer is installed by sliding the stabilizer into

the trailer support guide on the rear of the chipper frame.

The stabilizer is secured and adjusted with the provided

snap pin.

Figure 2.2, Rear Stabilizer

2.1 ATTACH TRAILER WHEELS

2.2 ATTACH HITCH ASSEMBLY 2.3 INSTALL REAR STABILIZER

79 INCH CHIPPER

ENGLISH

ASSEMBLY

Do not operate this unit without the chipper chute

correctly installed. Rotating cutting blades can cause

serious personal injury.

WARNING

1. Use a support or hoist to hold the chipper chute in place on the hydraulic feed.

2. Attach the chute support (1) to the rear end of the trailer using one 3/8" × 1-1/4” bolt (2) and nylock nut (3). Torque

to 35 ft-lbs. Refer to Figure 2.3 for proper positioning of the weldment. Attach the other end of the chute support (1)

to the chute (4) using existing hardware.

3. Attach the chipper chute (4) to the hydraulic feed using eight 3/8" × 1-1/4” carriage bolts (5) and nylock nuts (6).

Use three bolts on each side and two on the bottom. Install clamp (7) for wire harness as shown in Figure 2.3. If

feed roller is obstructing the top bolt holes, it may be necessary to use the hydraulic jack to raise the feed roller in

order to insert the top bolts. Before inserting the top side bolts to mount the chute, it is important to raise the feed

roller high enough to engage the locking mechanism. See Section 5.10 for instructions on how to use the hydraulic

jack to lift and secure the feed roller.

4. Connect the wire harness coming from the feed chute (4) to the connector that is located underneath the feed

chute (4).

In tropical regions, areas of high humidity or rainfall

amounts, dielectric grease may be added to wire

harness connectors to provide corrosion resistance.

NOTE

2.4 ATTACH CHUTE AND SUPPORT

Figure 2.3, Attaching the Chute Support

1

3

2

4

5

67

89 INCH CHIPPER

ASSEMBLY

1. Tilt the extension tray (1) up, so the bottom of the tray is facing outward. Slide the extension tray between the

extension hinge and chipper chute lips (2).

2. Tilt the extension tray down until the tray rests on the extension hinge, and the extension tray lips contact the back

of the chipper chute lips.

3. Insert four 3/8" × 1" carriage bolts (3) and one 3/8" × 1-1/2" carriage bolt (4) (included in owner’s kit) through the

extension tray and hinge. Secure the bolts with nylock nuts (5) from the bottom (Figure 2.5).

4. Install knee bar sensor mount (7) on the exterior of the extension tray using two 5/16" × 3/4" bolts (6) and one nylock

nut (5) as shown in Figure 2.6.

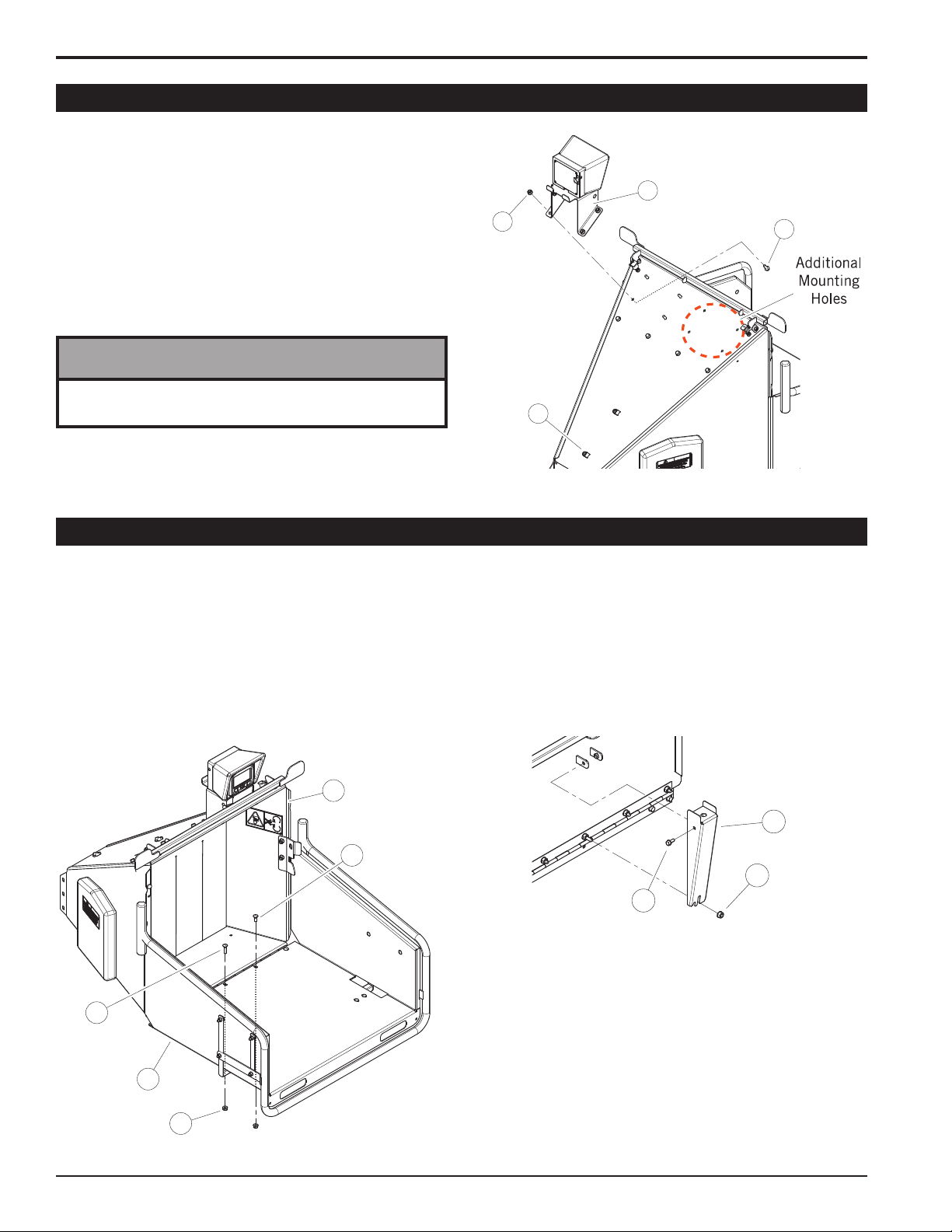

2.5 ATTACH DIGITAL DISPLAY CONTROLLER MOUNT ASSEMBLY

1. Remove the bolts (1) and nuts (2) attaching the digital

display controller mount assembly (3) to the inside of

the chute.

2. Attach mount assembly to the outside of the chute as

shown.

3. Route harness using the zip ties and two holders (4)

shown in Figure 2.4. Leave excess harness at the

controller to allow rotation of the enclosure from side

to side.

Figure 2.4, Digital Display Controller Enclosure

1

2

3

4

The controller mount assembly can be attached to the

chute in either set of mounting holes.

NOTE

Figure 2.5, Attaching the Extension Tray

1

2

3

4

5

2.6 ATTACH EXTENSION TRAY

5

7

6

Figure 2.6, Knee Bar Sensor Mount

99 INCH CHIPPER

ENGLISH

ASSEMBLY

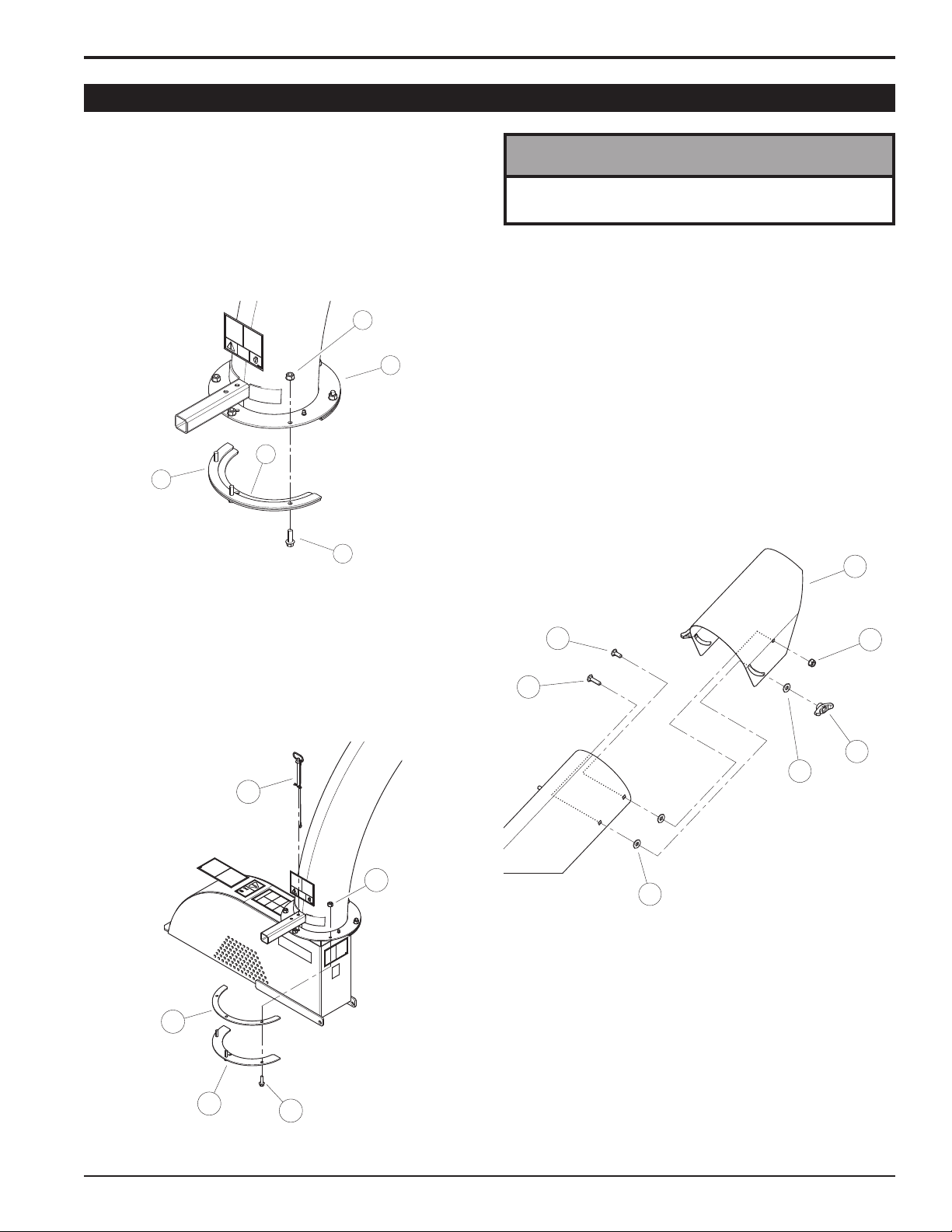

1. Attach one clamping ring (1) and one spacer ring (2)

to discharge tube base (3) using three 3/8" × 1-1/4"

bolts (4) and nylock nuts (5). Tighten leaving 1/16"

gap to assist in mounting to ange. See Figure 2.7.

2. Slide the tube onto the mounting ange on the

chipper frame. The discharge clamp (1) should slide

underneath the lip of the ange. Tighten the bolts to

secure it.

3. Install the second half of the spacer (2) and clamp

ring (1) on the discharge tube with 3/8" × 1-1/4" bolts

(4) and nylock nuts (5).

4. Attach lanyard with discharge pin (6) as shown in

Figure 2.8. Loop on lanyard installed below nut

located under discharge handle.

Figure 2.9, Attach Discharge Deector

7

11

9

12

8

10

13

Figure 2.8, Attach Discharge Tube

1

2

4

5

6

Keep nuts as tight as possible while allowing the

discharge tube to freely turn.

NOTE

Figure 2.7, Attach Clamp Ring and Spacer

1

2

3

4

5

5. Lubricate the tube by applying grease to the grease

zerk at the base of the tube. Rotate the tube and

apply grease until the tube rotates freely.

6. Rotate the tube 360 degrees and lock it in place with

the lock pin to make sure it is mounted correctly.

7. Attach the discharge deector (7) to the discharge

tube. Connect the deector with two 3/8" × 1-1/2"

carriage bolts (8) through the lower hole in the

discharge tube. Run these bolts through the inside

of the tube, 1/2" washer (12), deector, 3/8" washer

(13), and then knob (9).

8. Finish bolting the deector to the tube with two 3/8"

× 1" carriage bolts (10) through the end hole in the

discharge tube and secure with washers and nylock

nuts (11).

2.7 ATTACH DISCHARGE TUBE

10 9 INCH CHIPPER

ASSEMBLY

To avoid sparks and a possible explosion or re due

to a short circuit, do not touch the positive (+) battery

terminal and any surrounding metal with tools, jewelry

or other metal objects. When installing battery cables,

connect the positive (+) cable rst and the negative (-)

cable last.

WARNING

Gasoline and diesel fuels are highly

ammable and their vapors are

explosive. To prevent personal injury or

property damage:

Store fuel only in approved containers,

in well ventilated, unoccupied buildings,

away from sparks or ames. A container

with a capacity of 2 gallons or less with

a pouring spout is recommended. Do

not ll the fuel tank while the engine is hot or running,

since spilled fuel could ignite if it comes in contact

with hot parts or sparks from ignition. Do not start the

engine near spilled fuel. Never use fuel as a cleaning

agent.

DO NOT MIX OIL WITH FUEL.

WARNING

Use only those types of fuels that are recommended in

your engine owner’s manual.

To add fuel:

1. Stop engine and wait for all parts to stop moving.

Remove key from key switch. Allow the engine and

muer to cool for at least three minutes.

2. Clean area around fuel ll cap and remove cap.

3. Using a clean funnel, ll fuel tank to 1/2" below bottom

of ller neck to provide space for any fuel expansion.

Install fuel ll cap securely and wipe up any spilled

gasoline.

Hydraulic uid drives the feed roller. The machine was

shipped with uid, as it was tested at the factory. However,

check the uid levels before initial operation and add if

necessary.

The hydraulic pump requires premium hydraulic uids

containing high quality rust, oxidation, and foam inhibitors.

These include premium turbine oils, API CD engine oils

per SAE J183, M2C33F or G automatic transmission

uids meeting Allison C-3 or Caterpillar TO-2, and certain

specialty agricultural tractor uids.

You will need to purchase a battery. Choose a battery

that meets or exceeds the engine manufacturer’s

specications. Consult your engine owner’s manual or

authorized dealer for specication details.

Check the level of coolant before you start the diesel

engine. While operating, make sure the uid is between

the full and the low marks. Add if necessary. Refer to the

engine owner’s manual for further coolant information.

For additional information, please see the chart under

Temperature Operating Window (Section 7).

IMPORTANT

2.9 CHECK/ADD HYDRAULIC FLUID

2.10 ADD COOLANT

2.11 INSTALL BATTERY

2.12 FILL THE FUEL TANK

Check the oil level and, if needed, ll the engine crankcase

with the type and amount of oil specied in the engine

owner’s manual.

2.8 ADD OIL TO ENGINE To install the battery:

1. Open the battery box (11-1/8" × 7-3/4" × 10-1/8") and

insert battery into the battery box.

2. Attach the positive (red) battery cable from the engine

to the positive (+) battery terminal.

3. Attach the negative (black) battery cable from the

engine to the negative (-) battery terminal.

4. Secure the cover on the battery box with the strap.

119 INCH CHIPPER

ENGLISH

Section

3 FEATURES & CONTROLS

Understanding how your machine works will help you achieve the best results when using your chipper. The following

descriptions dene the features and controls of your machine.

REFER TO ENGINE OWNER’S MANUAL FOR FURTHER ENGINE OPERATING INSTRUCTIONS.

3.1 MACHINE

12 9 INCH CHIPPER

FEATURES & CONTROLS

1. CHUTE EXTENSION TRAY

The feed chute has an extension tray that folds down.

Raise the extension tray to an upright position and

secure with latch before towing the machine.

2. DIGITAL DISPLAY CONTROLLER

Used to control the chipper. See Sections 4 and 6 for

more information.

3. DISCHARGE CAP

Directs the discharge of material vertically. Adjust the

discharge cap by turning the knobs located on the

side. Turn knob counterclockwise to loosen discharge

cap. Adjust to desired position. Turn knob clockwise

to secure discharge cap.

4. DISCHARGE TUBE

Directs the discharge of chipped material horizontally.

The discharge tube can be rotated 360° horizontally

by removing the pin and rotating the discharge

tube until the discharge faces the desired position.

Replace the pin in one of the holes on the base of the

discharge.

5. ROTOR ACCESS COVER

Tilts up to expose rotor.

6. ROTOR LOCK

Use the rotor lock to hold the rotor in place when

doing any maintenance work. See Section 5.2.

7. FEED CHUTE

Materials to be chipped are fed into the feed chute,

through the feed roller, to the chipper blades.

8. TOP SAFETY BAR

In the event of an emergency, push the top safety bar

and feed roller will reverse.

9. FEED ROLLER LIFT JACK

Used to lift the feed roller. The feed roller can be

raised to inspect and service the machine and to

clear a plugged rotor. Secure the feed roller in the

raised position using the provided snap pin.

10. FEED ROLLER SPEED CONTROL

Controls the speed of the feed roller. Allows the

operator to have better control over the material

being fed into the chipper. Turning the knob clockwise

will decrease the speed of the feed roller. Turning the

knob counterclockwise will increase the speed of the

feed roller.

11. HITCH JACK

Always have in UP position and clear from ground

when towing. When in use, place in DOWN position

on a level surface. Turn handle to raise or lower wheel.

12. MANUAL CONTAINER

Conveniently holds your manuals.

13. REAR STABILIZER

Prevents the chipper from tipping when disconnected

from tow vehicle. Always have in UP position and

clear from ground when transporting the chipper.

When disconnected from tow vehicle, place in DOWN

position on a level surface.

14. KNEE BAR

In the event of an emergency, push the bar in and

forward feed will stop. Hold the knee bar reset button

on controller to resume operation.

15. SAFETY CHAINS

Safety chains are used, during towing, to prevent

the chipper from completely separating from the tow

vehicle in the event the chipper detaches from the

tow vehicle. Cross the safety chains under the hitch

and connect to tow vehicle.

16. COUPLER

2" coupler. Always use safety chains when towing.

17. HYDRAULIC FLUID TANK

Check level of hydraulic uid before each use.

18. FUEL TANK

Fuel level indicator is located on top.

19. DRIVE BELT SHIELD

Never remove shields when in use.

20. ENGINE THROTTLE

Turn counterclockwise to increase throttle. Turn

clockwise to decrease throttle.

21. BATTERY BOX

Use group 24 600 CCA min.

22. BELT ENGAGEMENT PEDAL

During engine start-up, the engagement foot pedal

must be depressed. With the engine at 1/4 throttle,

carefully engage the rotor by slowly releasing the

engagement foot pedal, allowing the rotor to speed

up gradually. Engaging the rotor too quickly with the

engine at full or half throttle will bog down the engine

and will shorten the life of the belt. See Sections 4.2

and 4.4.

23. CONTROL PANEL

Contains engine controller with hour meter and on/

o key.

139 INCH CHIPPER

ENGLISH

FEATURES & CONTROLS

Mode Icons

Appears when the engine is at rest and the unit is in stop mode with no alarms active.

Appears when the engine is at rest and the unit is in auto mode with no alarms active.

Appears when the engine is at rest and the unit is waiting for a manual start with no alarms active.

Appears when a timer is active, for example cranking time, with no alarms active.

Appears when the engine is running, and all timers have expired with no alarms active. The animation speed

is reduced when running in idle mode.

Appears when the unit is in the front panel editor.

Warning Alarm Icons:

Warnings are non-critical alarm conditions and serve to draw the operator's attention to an undesirable condition.

Warning alarms are self-resetting when the fault condition is removed.

Warning Alarm Icons

Fail to Stop

Note: Fail to Stop could indicate a faulty oil pressure sensor. If the engine is at rest,

check oil sensor wiring and conguration.

The controller has detected a condition that indicates the engine is running when it has

been instructed to stop.

Charge Failure The auxiliary charge alternator voltage is low as measured from the W/L terminal.

3.2 ENGINE CONTROLLER A - STOP BUTTON

Pressing the button will shut down the engine or stop

auto-start.

B - AUTO BUTTON

Typical function is not used for this application. Pressing

the button will shut down the engine or stop auto-start.

C - START BUTTON

Pressing the button will begin the auto-start process.

D - MENU NAVIGATION BUTTON

Pressing the button will toggle between Engine RPM's,

Battery Voltage, and Engine Hours shown in the display.

E - MODE ICON

Icons indicating the engine state or the engine controller

operating mode are shown in the display.

F - FAULT LED

The indicator ashes when an Electrical Trip or Shutdown

Fault occurs.

14 9 INCH CHIPPER

FEATURES & CONTROLS

Shutdown Alarm Icons:

Shutdown alarms are latching and immediately stop the engine. The alarm condition must be rectied before a resetting.

The alarm must be accepted and cleared, and the fault removed to reset the module. If the alarm condition remains, it

is not possible to reset the unit (The exception to this is the Low Oil Pressure alarm, as the oil pressure is low with the

engine at rest).

Shutdown Alarm Icons

Fail to Start The engine has failed to start after the congured number of start attempts.

Low Oil Pressure The controller detects the engine oil pressure is low after the Safety On Timer expired.

High Coolant

Temperature

The controller detects the engine collant temperature is high after the Safety On Timer

expired.

Over Speed The engine speed has risen above the over speed alarm setting.

Charge Failure The auxiliary charge alternator voltage is low as measured from the W/L terminal.

Emergency Stop The emergency stop button has been depressed. This failsafe (normally closed to

emergency stop) input and immediately stops the set when the signal is removed.

Magnetic Pick-

Up Failure Pulses are no longer being detected from the magnetic pickup probe.

159 INCH CHIPPER

ENGLISH

Section

4 OPERATION

As with any other piece of outdoor equipment, getting the

feel for how your machine operates and getting to know

the best techniques for particular jobs are important to

overall good performance.

CHIPPING OPERATION

The chipping operation takes place in the middle of the

machine, where hardened steel chipper blades are

mounted on a rotating rotor assembly. Material fed into

the chipper chute is sliced into small chips and propelled

out through a discharge tube.

4.1 STARTING THE ENGINE

BEFORE ATTEMPTING TO START THIS MACHINE,

MAKE SURE THE BELT IS DISENGAGED AND THE

HANDLE IS IN THE “START” POSITION.

NEVER ATTEMPT TO START MACHINE WITH THE

DRIVE BELT ENGAGED.

1. Please refer to engine owner’s manual for priming

procedure for rst time starting, or if the unit has been

sitting for prolonged period.

2. Check levels of fuel, oil, and hydraulic uid and ll if

necessary.

3. Place chipper engagement handle in the START

position.

Before operating your machine, be sure you read

and understand all safety, controls and operating

instructions in this owner’s manual and on your

machine. Failure to follow these instructions can result

in serious injury or property damage.

WARNING

Move machine to a clear, level area outdoors before

starting. Do not operate in the vicinity of bystanders.

Make sure cutting chamber is empty before starting.

WARNING

4. Open the throttle slightly by turning throttle knob (A)

counterclockwise a 1/4 turn.

5. Turn key to the right or “On” position.

6. Press the start button on the engine controller. Engine

will begin autostart immediately and alarm will sound.

After 5-10 seconds of warming, the starter on the

engine will engage. The length of cranking will vary

depending on conditions. To interrupt the start-up

process, press the stop button.

4.2 OPERATING THE CHIPPER

To begin operating the chipper, follow the steps below:

1. AFTER engine is warmed for 2-3 minutes and is ready

for use, move the throttle control to approximately

25% of full throttle.

2. Engage the belt by slowly lowering the belt

engagement handle.

DO NOT engage the belt with engine running at

high RPM.

Engaging belt while engine is running at high

RPM will result in signicant belt squealing and

damage.

Engaging belt while engine is running at high

RPM can also damage vital drive components of

the chipper.

3. If the chipper engine stalls while engaging the

belt, move engagement handle back to the START

position, restart engine, SLIGHTLY increase throttle

and attempt engagement again.

4. Once the belt is engaged, continue to SLOWLY turn

the throttle knob counterclockwise to increase throttle

to 100% or full throttle. ALWAYS run the chipper at

100% or full throttle when chipping material.

16 9 INCH CHIPPER

OPERATION

5. If the chipper jams, the feed roller will reverse

momentarily to remove the branch. Once the branch

is removed, rotate it before reinserting into the

chute. Alternately insert and retract the limb or insert

continuously at a rate that will not kill the engine.

6. Sharpen the chipping blades periodically. Check

the sharpness of the blades every 5-15 hours. Refer to

the Service and Maintenance section for sharpening

instructions.

7. Limbs fed in to the chipper chute must be 9"

(22.9 cm) in diameter or less. Trim side branches

that cannot be bent enough to feed into the chipper

chute. Hold small diameter branches together in a

bundle and feed in simultaneously.

8. Alternate green or fresh cut material with dry

material to lubricate the chipping blades for

longer life and better performance. Chipping dead,

dry material will create heat and dull the chipping

blades quicker.

9. ALWAYS feed brush from the side of the chipper

chute, rather than from the front. Step aside to avoid

being hit by the brush moving into the chipper.

10. ALWAYS place limb, butt end rst, into the

chipper chute until it contacts the chipper blades.

The actual feed rate of the limb into the chipper will

depend on the type of material fed and sharpness of

the cutting blades.

11. NEVER use the belt engagement to clear a

plugged rotor. This may cause belt damage. Refer

to the instructions for clearing a plugged rotor in the

Service and Maintenance section.

12. NEVER attempt to clear a plugged rotor or discharge

with the engine running. ALWAYS shut engine OFF

before servicing any part of this machine.

13. NEVER attempt to chip pieces of metal, rock, bottles,

cans or other foreign objects.

●Never lean over the chipper chute to push objects

into the cutting device. Use a push stick or brush

paddle.

●Never use shovels or forks to feed brush. They

can cause extensive damage if they contact the

blades. In addition, metal pieces can be ejected

from the chipper chute and cause serious injury

or death.

●Never feed brush into the chute with your feet.

●Never use hands or feet to clear materials that

build up in the chute.

CAUTION

Turn Throttle Lock Clockwise to Lock Throttle at 100%.

5. Turn Throttle Lock (A) clockwise to prevent losing

RPM while operating the machine.

4.3 CHIPPER OPERATION GUIDELINES

The machine chips a variety of materials into a more

readily decomposed or handled condition. The following

guidelines will help you get started.

1. Gradually increase engine speed until full throttle

is achieved. When the controller light is steady green

the engine speed is high enough to begin to chip.

2. ALWAYS run engine at full operating speed before

starting to chip material.

3. Engage the hydraulic feed by pushing the forward

button from the Chipping Screen (see Section 4.7 for

more details on utilizing the Digital Display Controller).

4. If the chipper rotor slows, the feed roller will stop

automatically to process backed up material. Feed

material more evenly.

Read and follow all safety instructions in this manual.

Failure to operate the machine in accordance with

the safety instructions MAY RESULT IN PERSONAL

INJURY!

WARNING

●Obtain and wear safety glasses at all times when

operating the machine.

● Do not wear loose tting clothing.

●The operator should always wear heavy boots,

gloves, pants and a long-sleeved shirt.

●Use common sense and practice safety to protect

yourself from branches, sharp objects, and other

harmful objects.

CAUTION

Table of contents

Other Bearcat Chipper manuals

Popular Chipper manuals by other brands

Great Circle

Great Circle GUO054 instruction manual

Craftsman

Craftsman 247.79585 owner's manual

Echo

Echo CH8540 Specification sheet

Farmi Forest

Farmi Forest VALBY CH140 L Operation, maintenance and spare parts

W-W Grinder

W-W Grinder renegade 250 owner's manual

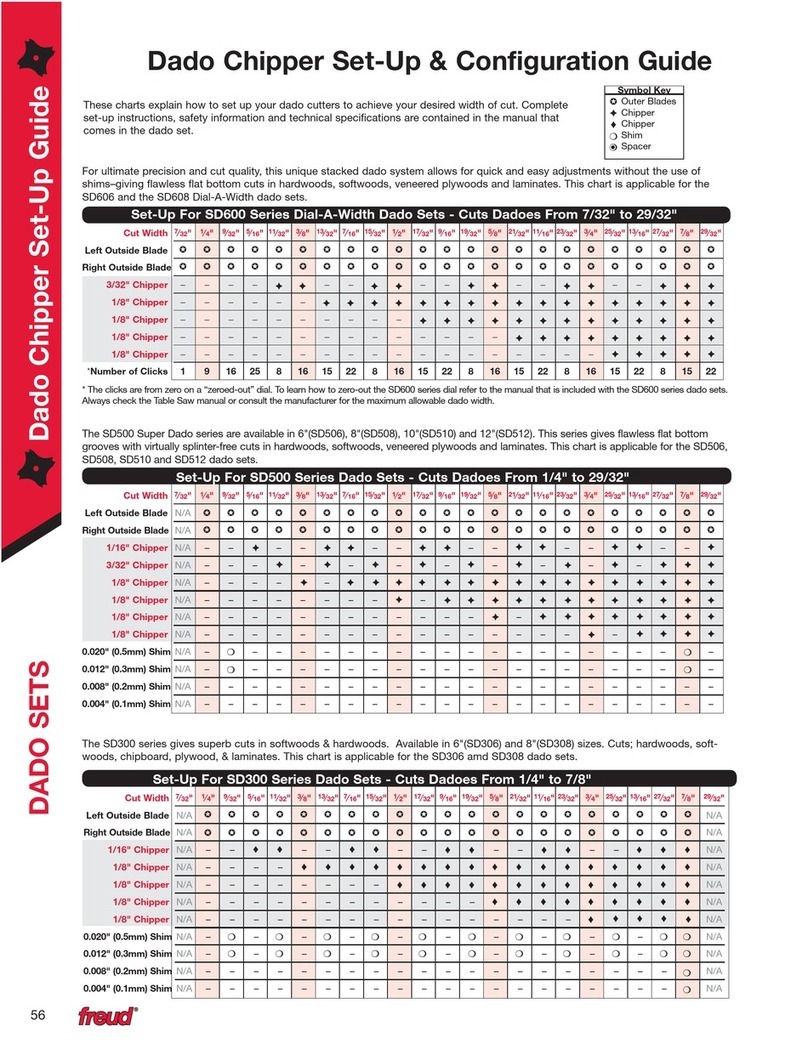

Freud

Freud SD200 Series Setup and configuration guide

Timberwolf

Timberwolf TW 230HB (Diesel) instruction manual

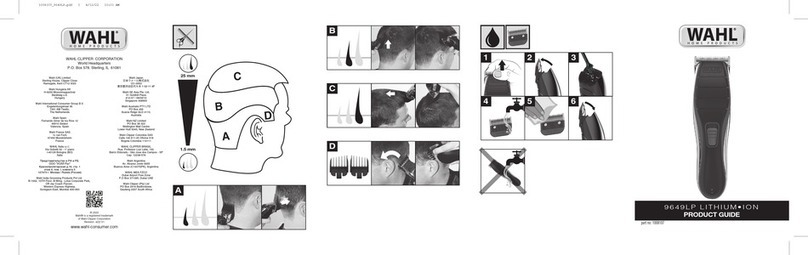

Wahl

Wahl 9649LP Product guide

Craftsman

Craftsman 79964 owner's manual

Wallenstein

Wallenstein BXMT32G Setup instructions

Garland

Garland 250 E instruction manual

Farmi Forest Corporation

Farmi Forest Corporation 100F OPERATION, MAINTENANCE AND SPARE PARTS MANUAL