BECKWITH ELECTRIC M-4272 User manual

Instruction Book

Book 1 of 2

M-4272 Motor Bus

Transfer System

Digital Motor Bus

Transfer System

M-4272

• Provides Automatic and Manual transfers of motor bus systems in power

plants and industrial processing plants to ensure process continuity

• Automatically selects Fast, Delayed In-Phase, Residual Voltage, and Fixed

Time motor bus transfers, based on varying system conditions

• Applicable for one way and bi-directional Manual and Automatic transfers

• Can be expanded to accomodate multiple breaker configurations

• Multiple setpoint profiles for various application requirements

• Integrated control, supervisory functions, sequence of events, and

oscillograph recording in one device

• Extensive commissioning tools, including ringdown analysis

SYNCHRONIZING

Integrated Synchronizing System®

–2–

M-4272 Digital Motor Bus Transfer System

Standard Features

Automatic Transfer:

ThedigitalMotorBusTransfer

System (MBTS) provides the following Automatic

Transfer logic and features:

• Transferinitiated by protective relay exter-

nal to the MBTS

• Automatic Transfer after a loss of the mo-

tor bus supply voltage based on the pro-

grammableundervoltageelement.Thispro-

vides a selectable backup feature if a

manual or protective relay transfer is not

initiated.

• FastTransfer with adjustablephase angle

limit

• Delayed In-Phase Transfer at the first

phase coincidence if Fast Transfer is not

possible

• ResidualVoltageTransferatanadjustable

low residual voltage limit if Fast Transfer

and Delayed In-Phase Transfer are not

possible

• Fixed Time Transfer after an adjustable

time delay

• ProgrammableLoad Sheddingwithnotime

delay for Fast Transfer

• Programmableloadsheddingprior to

initiatingDelayed-in-PhaseTransfer,

ResidualVoltage Transfer, and Fixed

TimeTransfer

• Adjustable setpoints for delta voltage limit

and delta frequency limit

• Verifythe new source (the sourcetowhich

thebusis being transferred) is healthy and

withinacceptable upper and lowervoltage

limits

Manual Transfer

: When a Manual Transfer is initi-

ated the digital MBTS provides the follow-

ing:

• Sync check functions with adjustable

parameters

• Hot Parallel Transfer if enabled (make-

before-break)

• FastTransfer,DelayedIn-Phase Transfer,

and Residual Voltage Transfer (if the Hot

ParallelTransfer is disabled)

• ProgrammableLoad Sheddingwithnotime

delay for Fast Transfer

• Programmableload shedding priorto initi-

ating Delayed In-phase Transfer and Re-

sidualVoltage Transfer

• Verifythe new source (the sourcetowhich

thebusis being transferred) is healthy and

withinacceptable upper and lowervoltage

limits

Circuit Breaker Control:

The digital Motor Bus

TransferSystemincludes the following Circuit Breaker

Controlfeatures:

• Controlof two circuitbreakers with two indi-

vidualprogrammable breaker closing times

• Three-breakerconfiguration canbeprovided

by two M-4272 devices

• Breaker status supervision

• Breakerfailuremonitoring

• Four trip and close circuit monitoring inputs

Additional Standard Features

• Sequentialor Simultaneous Transfer Mode

• BusPhase Undervoltage (27B)

• Frequency (81) and Rate of Change of

Frequency (81R) for load shedding

• Instantaneous Phase Overload Detection

Source1 and 2(50S1) (50S2)

• BreakerFailure(50BF),Source1andSource

2

• Bus VT Fuse-Loss Detection (60FL)

• Auto Trip

• Auto Close

• Four dry output contacts (two trip and two

close) for Source 1 and Source 2, one lock-

out/blocking output contact, and 11 pro-

grammableoutputcontacts(10Form'a'and

oneForm 'c')

• Six Breaker Status inputs (a, b, and service

position) for the Source 1 and Source 2

breakers, twelve programmable digital in-

puts

• All functions can be enabled or disabled

• Remote/Localcontrol selection

• DeviceON/OFF Control Selection

• M-3931 Human-Machine Interface (HMI)

Module

• M-3972Status Module

• IRIG-B time synchronization

• Oscillographicrecording

• Two RS-232 ports (front and rear) and one

RS-485port (rear)

• M-3872ISScom®Communications andOs-

cillographicAnalysis Software

Optional Features

• RJ45 Ethernet Port Utilizing MODBUS over

TCP/IP

• 5 A or 1 A models available

• 60 Hz or 50 Hz models available

–3–

M-4272 Digital Motor Bus Transfer System

* NOTE: The 'new source' is defined as the source to which the bus is being transferred.

The M-4272 Digital Motor Bus Transfer System provides Automatic and Manual Transfers. The Fast Transfer,

DelayedIn-Phase Transfer, and Residual VoltageTransfer methods are activated atthesame time, if enabled.If

the conditions for the Fast Transfer are not met, then the Delayed In-Phase Transfer or the Residual Voltage

Transfer will be attempted. The Fixed Time Transfer is also provided if during a transfer operation, it is not

possible to monitor the motor bus voltage (due to Bus VT fuse loss, for example). The Delayed In-Phase

Transfer, Residual Voltage Transfer, and Fixed Time Transfer methods can be selectively disabled. The

Automaticor Manual Transfer operation canbe blocked by control/status inputor remote serial communications.

See Figure 2 for Typical Application of Motor Bus Transfer Systems.

Automatic Transfer

AutomaticTransfercanbeinitiated by an external protection trip signal (86P)oranexternalundervoltagefunction

(27)using control/status inputto the MotorBus Transfer System(MBTS) device ortriggered by a sudden loss of

motor bus supply voltage using the internal bus undervoltage relay (27B Function). Automatic Transfer allows

transferoperationin both directions: from Source 1toSource2, and vice-versa. The Automatic Transferprovides

Fast Transfer, Delayed In-Phase Transfer, Residual Voltage Transfer and Fixed Time Transfer. The Automatic

Transfer is blocked when any lockout/blocking condition occurs. The MBTS will not respond to any transfer

command and will not send the trip command while in the lockout/blocking condition.

Manual Transfer

Manualtransfer can be initiated byusing the local Human-MachineInterface(HMI), from a control/statusinput or

through remote serial communications. The Manual Transfer allows transfer operation in either direction: from

Source 1 to Source 2, and vice versa. Manual Transfer provides Hot Parallel Transfer or a combination of Fast

Transfer, Delayed In-Phase Transfer and Residual Voltage Transfer. The Manual Transfer is blocked when any

lockout/blockingcondition occurs. TheMBTS will not respondto any transfer command and will notsend the trip

command while in the lockout/blocking condition.

Transfer Modes

There are two transfer modes, Sequential and Simultaneous, in the open transition transfer operation.

Sequential Transfer Mode

Oncea transfer isinitiated, and if theSequential Mode isselected, the old source breaker is trippedwithin 10 ms

andclosureofthe new source* breaker is attemptedonlyuponconfirmation by the breaker status contact thatthe

old source breaker has opened. Within 4 ms of receipt of this confirmation, all three methods, Fast, Delayed In-

PhaseandResidualVoltage Transfer are enabled to supervise closure ofthenewsource*breaker, and the Fixed

Time Transfer is enabled 30 cycles later. The new source* breaker is then closed by the Fast Transfer Method if

the phase angle between the motor bus and the new source* is within the delta phase angle limit immediately

after the old source breaker opens.

If the phase angle between the motor bus and the new source* is not within the delta phase angle limit, the old

source breaker is still tripped. When the four methods of transfer are enabled, the new source* breaker then

closeseither as a resultof a subsequent movementinto the delta phaseangle limit within theFastTransfer Time

Window, a movement through a predicted zero phase coincidence within the Delayed In-Phase Transfer Time

Window, or by a drop in the motor bus voltage below the Residual Voltage Transfer limit, or after the fixed time

delay of the Fixed Time Transfer. Transfer is completed and the new source* breaker is closed by any of the

above methods whose criteria is first satisfied.

Refer to Figure 3 for Timing Sequence of Transfer Logic in Sequential Transfer Mode.

Simultaneous Transfer Mode

Alternatively, once a transfer is initiated, and if the Simultaneous Mode is selected, within 10 ms of transfer

initiate, all three methods of transfer, Fast, Delayed In-Phase and Residual Voltage Transfer are immediately

enabled to supervise closure of the new source* breaker without waiting for the breaker status contact

confirmation that the old source breaker has opened. At the same instant, the commands for the old source

breaker and the new source* breaker to trip and close are sent simultaneously if and only if the phase angle

between the motor bus and the new source* is within the delta phase angle limit for the Fast Transfer Method

immediately upon transfer initiation. However only the Fixed Time Transfer is enabled 30 cycles after the old

sourcebreaker has opened.

If the phase angle between the motor bus and the new source* is not within the delta phase angle limit, the old

source breaker is still tripped. When the four methods of transfer are enabled, the new source* breaker then

–4–

M-4272 Digital Motor Bus Transfer System

closeseither as a resultof a subsequent movementinto the delta phaseangle limit within theFastTransfer Time

Window, a movement through a predicted zero phase coincidence within the Delayed In-Phase Transfer Time

Window, or by a drop in the motor bus voltage below the Residual Voltage Transfer limit, or after the fixed time

delay of the Fixed Time Transfer. Transfer is completed and the new source* breaker is closed by any of the

above methods whose criteria is first satisfied.

Refer to Figure 4 for Timing Sequence of Transfer Logic in Simultaneous Transfer Mode.

Bus VT Fuse-Loss Detection (60FL)

A Bus VT Fuse-Loss condition is detected by comparing either the three-phase voltage of the motor bus to the

three-phase voltage of the connected source (VT's in three-phase connection) or single phase voltage of the

motor bus to a single phase voltages of the connected source (VT's in single phase connection): phase a to

phase a, phase b to phase b, and phase c to phase c.

Auto Trip

If an external operation closes the second breaker while leaving the first one closed, and if the Auto Trip feature

is enabled, there is a breaker trip option: the MBTS will trip the breaker that was originally closed or the breaker

that has just been closed within an adjustable time delay (0 to 50 Cycles in increments of 0.5 Cycle) after the

second breaker is closed. This Auto Trip operates to transfer in either direction. The purpose is to allow external

parallel transfer but prohibits inadvertent parallel operation. It must be noted that the external operation that

closed the second breaker must be supervised by means external to the motor bust transfer system.

Auto Close

If an external operation opens the second breaker while leaving the first one open, and if the Auto Close feature

is selected, the MBTS will close the breaker that was originally opened. The originally opened breaker will be

closed using the Fast Transfer, Delayed In Phase Transfer, Residual Voltage Transfer or Fixed Time Transfer

method depending upon the bus voltage decayed condition. This Auto Close operates to transfer in either

direction. The purpose is to permit a transfer when the normally-closed breaker is accidentally/inadvertently

trippedresulting in two open breakers.Thisoperation is very similartothe regular transfer process exceptit does

not send out the trip command, since the second breaker is already opened.

Lockout/Blocking

A transfer is blocked when any lockout/blocking condition described below is active:

• Voltage Blocking – If prior to a transfer, the new source* voltage exceeds the Upper or Lower voltage

limits, all transfers are blocked as long as the voltage remains outside these limits.

• External Blocking – When this control input contact is closed, all transfers are blocked.

• Incomplete Transfer Lockout – Blocks any transfer initiated by a protective relay initiate or an

automaticinitiatedtransfer or manual transfer ifthelast transfer has not beencompletedwithin the time

delay.A time delay canbe set from 50to 3000 Cycles. TheMBTS remains in thelockout condition until

manuallyreset.

• Bus VT Fuse Loss Blocking – Transfer is blocked if the Bus VT fuse loss is detected and the customer

has selected to block transfers when this occurs.

• “Both Breakers Same State” Blocking – If both breaker status contacts are in the open state, due to an

externaloperation that opens the secondbreaker while leaving the firstone open, and if theAuto Close

feature is not selected, no transfer sequence is initiated. Furthermore, any subsequent initiation of a

transfer sequence while the breakers are in this state is inhibited. Also, if both breaker status contacts

are closed due to an external operation that closes the second breaker while leaving the first one

closed, and if the auto trip feature is disabled, no transfer sequence is initiated.

• Transfer in Process Blocking – Once a transfer is in process, any other transfer initiate inputs will be

ignored until the original transfer is complete.

• Blocking After Transfer – After a transfer has been completed, any additional transfers are blocked for

0 to 8160 cycles, as selected by the user.

• Trip/Close Circuit Open Blocking – Transfer is blocked if the Trip or Close Circuit Open is detected.

• 52a and 52b Position Disagreement Blocking – Transfer is blocked when the 52a and 52b status input

positions disagree (applicable when both 52a and 52b status inputs are used).

* NOTE: The 'new source' is defined as the source to which the bus is being transferred.

–5–

M-4272 Digital Motor Bus Transfer System

†Select the greater of these accuracy values. Accuracy applies to sinusoidal voltage with constant amplitude and

frequency.

TRANSFER SETTINGS

Setpoint

Ranges Increment Accuracy†

Automatic Transfer

Fast Transfer

Delta Phase Angle Limit* 0.0 to 90.0 Degrees 0.1 Degree 0.5 Degree

Delta Voltage Limit 0 to 60 V 1 V 0.5 V or 2%

Delta Frequency Limit 0.02 to 2.00 Hz 0.01 Hz 0.01 Hz or 5%

Time Window** 1 to 10 Cycles 0.5 Cycle 1 Cycle

Closing Command

Time Delay*** 0 to 10 Cycles 0.5 Cycle 1 Cycle

* Accuracy defined at a constant frequency with a delta frequency of zero (0).

** This timer is used to limit the time window during which a Fast Transfer may be initiated.

*** This time delay is only used for Fast Transfer in Simultaneous. The trip and close commands are normally

issued at the same time. This time delay allows the flexibility to delay the closing command to accomplish the

break-before-make mode of operation (open transition).

Delayed In-Phase Transfer

Delta Voltage Limit 0 to 120 V 1 V 0.5 V or 2%

Delta Frequency Limit* 0.10 to 10.00 Hz 0.05 Hz 0.02 Hz (0.1Hz)***

Time Window** 10 to 600 Cycles 1 Cycle 1 Cycle or 1%

* The pickup accuracy applies to the 60 Hz model at a range of 57 to 63 Hz, and to the 50 Hz model at a

range of 47 to 53 Hz. Beyond these ranges, the accuracy is

0.1 Hz (3-phase);

0.4Hz(single phase).

** This timer is used to limit the time window during which an in-phase transfer may be initiated.

*** Value in parenthese applies to single phase unit.

For Delayed In-Phase Transfer, phase angle accuracy at first phase coincidence is 10.0 degrees with up to

10.0 Hz slip frequency.

Residual Voltage Transfer

Residual Voltage Limit 5 to 60 V 1 V 0.5 V or 2%

Load Shedding Time Delay* 2 to 100 Cycles 1 Cycle 1 Cycle or 1%

Enabling the Load Shedding option allows the user to assign an output contact to shed load.

* The load shedding command is issued when bus voltage drops below residual voltage limit. The close

command for the Residual Voltage Transfer is sent after the programmed load shedding time delay.

Fixed Time Transfer

Fixed Time Delay 30 to 1000 Cycles 1 Cycle 1 Cycle or 1%

Load Shedding Time Delay* 2 to 100 Cycles 1 Cycle 1 Cycle or 1%

This method is based on time delay only, and does not use the voltage, phase angle, frequency or current to

supervise the closing of the new source breaker. The 'new source' is defined as the source to which the bus is

being transferred.

Enabling the Load Shedding option allows the user to assign an output contact to shed load.

* The load shedding command is issued when the FixedTime delay has timed out. The Close command for the

Fixed Time Transfer is sent after the programmed load shedding time delay.

–6–

M-4272 Digital Motor Bus Transfer System

†Select the greater of these accuracy values. Accuracy applies to sinusoidal voltage with constant amplitude and

frequency.

TRANSFER SETTINGS

Setpoint

Ranges Increment Accuracy†

Manual Transfer

Fast Transfer

Delta Phase Angle Limit* 0.0 to 90.0 Degrees 0.1 Degree 0.5 Degree

Delta Voltage Limit 0 to 60 V 1 V 0.5 V or 2%

Delta Frequency Limit 0.02 to 2.00 Hz 0.01 Hz 0.01 Hz or 5%

Time Window** 1 to 10 Cycles 0.5 Cycle 1 Cycle

Closing Command

Time Delay*** 0 to 10 Cycles 0.5 Cycle 1 Cycle

* Accuracy defined at a constant frequency with a delta frequency of zero (0).

** This timer is used to limit the time window during which a Fast Transfer may be initiated.

*** This time delay is only used for Fast Transfer in Simultaneous mode. The trip and close commands are

normally issued at the same time. This time delay allows the flexibility to delay the closing command to

accomplish the break-before-make mode of operation (open transition).

Delayed In-Phase Transfer

Delta Voltage Limit 0 to 120 V 1 V 0.5 V or 2%

Delta Frequency Limit* 0.10 to 10.00 Hz 0.05 Hz 0.02 Hz (0.1Hz)***

Time Window** 10 to 600 Cycles 1 Cycle 1 Cycle or 1%

* The pickup accuracy applies to the 60 Hz model at a range of 57 to 63 Hz, and to the 50 Hz model at a

range of 47 to 53 Hz. Beyond these ranges, the accuracy is

0.1 Hz (3-phase);

0.4Hz (single phase).

** This timer is used to limit the time window during which an in-phase transfer may be initiated.

*** Value in parenthese applies to single phase unit.

For Delayed In-Phase Transfer, phase angle accuracy at first phase coincidence is 10.0 degrees with up to

10.0 Hz slip frequency.

Residual Voltage Transfer

Residual Voltage Limit 5 to 60 V 1 V 0.5 V or 2%

Load Shedding Time Delay* 2 to 100 Cycles 1 Cycle 1 Cycle or 1%

* The load shedding command is issued when bus voltage drops below residual voltage limit. The close

command for the Residual Voltage Transfer is sent after the programmed load shedding time delay.

Enabling load shedding option allows the user to assign an output contact to shed load.

–7–

M-4272 Digital Motor Bus Transfer System

†Select the greater of these accuracy values. Accuracy applies to sinusoidal voltage with constant amplitude and

frequency.

TRANSFER SETTINGS

Setpoint

Ranges Increment Accuracy†

Manual Transfer (cont.)

Hot Parallel Transfer

Delta Phase Angle Limit* 0.0 to 90.0 Degrees 0.1 Degree 0.5 Degree

Delta Voltage Limit 0 to 60 V 1 V 0.5 V or 2%

Delta Frequency Limit 0.02 to 0.50 Hz 0.01 Hz 0.01 Hz or 5%

Time Window 1.0 to 50.0 Cycles 0.5 Cycle 1 Cycle

Tripping Command

Time Delay** 0.0 to 30.0 Cycles 0.5 Cycle 1 Cycle

* Accuracy defined at a constant frequency with a delta frequency of zero (0).

** This time delay is only used in the Manual Transfer to implement a Hot Parallel Transfer (make-before-

break).

Auto Trip

Trip Originally Closed Enable/Disable ____ ____

Breaker

Trip Breaker Enable/Disable ____ ____

Just Closed

Tripping Command

Time Delay 0.0 to 50.0 Cycles 0.5 Cycle 1 Cycle

–8–

M-4272 Digital Motor Bus Transfer System

†Select the greater of these accuracy values. Accuracy applies to sinusoidal voltage with constant amplitude and

frequency.

TRANSFER SETTINGS

Setpoint

Ranges Increment Accuracy†

Common Function SettingsCommon Function Settings

Common Function SettingsCommon Function Settings

Common Function Settings

Upper Voltage Limit 5 to 180 V 1 V 0.5 V or 2%

New Source

Lower Voltage Limit 5 to 180 V 1 V 0.5 V or 2%

New Source

Breaker Closing Time #1

(Source 1 Breaker)(1) 0.0 to 12.0 Cycles 0.1 Cycle 0.3 Cycle

Breaker Closing Time #2

(Source 2 Breaker)(1) 0.0 to 12.0 Cycles 0.1 Cycle 0.3 Cycle

Breaker Closing Time

Deviation #1 (2) 0.0 to 6.0 Cycles 0.1 Cycle 0.3 Cycle

Breaker Closing Time

Deviation #2 (2) 0.0 to 6.0 Cycles 0.1 Cycle 0.3 Cycle

52a and 52b Position Disagreement

Pickup Time Delay(3) 0 to 30 Cycles 1 Cycle 1 Cycle

(Source 1 Breaker)

Dropout Time Delay(3) 0 to 30 Cycles 1 Cycle 1 Cycle

(Source 1 Breaker)

Pickup Time Delay(3) 0 to 30 Cycles 1 Cycle 1 Cycle

(Source 2 Breaker)

Dropout Time Delay(3) 0 to 30 Cycles 1 Cycle 1 Cycle

(Source 2 Breaker)

Incomplete Transfer

Lockout Time(4) 50 to 3000 Cycles 1 Cycle 1 Cycle or 1%

Local Manual Transfer

Initiate Time Delay(5) 0 to 8160 Cycles 1 Cycle 1 Cycle or 1%

Remote Manual Transfer

Initiate Time Delay(7) 0 to 8160 Cycles 1 Cycle 1 Cycle or 1%

Blocking After

Transfer Time(6) 0 to 8160 Cycles 1 Cycle 1 Cycle or 1%

Trip Command

Pulse Length 15 to 30 Cycles 1 Cycle 1 Cycle

Close Command

Pulse Length 15 to 30 Cycles 1 Cycle 1 Cycle

(1)

This is the time it takes the breaker to close from the issue of a close command to when the breaker status

contact closes. The selectable adaptive breaker closing time is also provided.

(2)

An alarm is activated if the actual Breaker Closing Time exceeds the programmed closing time by

this

value.

(3)

The Time Delays are only applicable when both 52a and 52b Status Inputs of the S1 and S2 breakers are

used. The Pickup Time Delay is used to block transfer when the 52a and 52b Status Input positions

disagree.

(4)

This timer is used for situations where the transfer was not completed. Response to a breaker failure is

considered a complete transfer, and resets this timer.

(5)

This time delay is only applicable when the manual transfer is initiated from the local front panel via the HMI

or Com1 port.

(6)

This timer is used to block any additional transfer after a transfer has been completed.

(7)

This time delay is only applicable when manual transfer is initiated from the Control/Status input, Com2

Port, Com3 Port or Ethernet Port.

–9–

M-4272 Digital Motor Bus Transfer System

†Select the greater of these accuracy values. Accuracy applies to sinusoidal voltage with constant amplitude and

frequency. Values in parentheses apply to 1 A CT secondary rating.

50

BF1

50

BF2

27B

FUNCTIONS

Setpoint

Ranges Increment Accuracy†

27B Bus Phase Undervoltage

Pickup #1, #2, #3, #4 5 to 120 V 1 V 0.5 V or 2%

Inhibit Setting** 5 to 120 V 1 V 0.5 V or 2%

Time Delay 1 to 8160 Cycles 1 Cycle -1 to +3 Cycles or 0.5%*

* The pickup and time delay accuracies apply to 60 HZ models at a range of 57 to 63 Hz, and to 50 Hz models at

a range of 47 to 53 Hz. Beyond these ranges, the time delay accuracy is 6 Cycles or 0.75% for the bus frequency

down to 25 Hz. The time delay accuracy is

OO

OO

O

20 Cycles or 1% for the bus frequency at a range of 5 to 25 Hz.

** The Voltage Inhibit setting can be enabled or disabled.

27B #1 is the Bus Phase Undervoltage initiate function that is used for Automatic Transfer from S1 to S2 direction.

27B #2 is the Bus Phase Undervoltage initiate function that is used for Automatic Transfer from S2 to S1 direction.

27B #3 can be used for load shedding.

27B #4 can be used for alarm or trip function.

The 27B functions are applicable only when the bus phase voltage input is applied.

50S1 Instantaneous Phase Overload Detection (Source 1)

Pickup #1, #2 1.0 to 100.0 A 0.1 A 0.1 A or 3%

(0.2 to 20.0 A)* (0.02 A or 3%)

Time Delay 1 to 8160 Cycles 1 Cycle 2 Cycles or 1%

* Values in parentheses apply to 1A secondary rating. Since this is only a single phase element, the 50S1

Function can only be used for overload detection and not used for overcurrent protection.

50S2 Instantaneous Phase Overload Detection (Source 2)

Pickup #1, #2 1.0 to 100.0 A 0.1 A 0.1 A or 3%

(0.2 to 20.0 A)* (0.02 A or 3%)

Time Delay 1 to 8160 Cycles 1 Cycle 2 Cycles or 1%

* Values in parentheses apply to 1A secondary rating. Since this is only a single phase element, the 50S2

Function can only be used for overload detection and not used for overcurrent protection.

50BF-1 Breaker Failure (Source 1)

Pickup Current 0.10 to 10.00 A 0.01 A 0.1 A or 2%

(0.02 to 2.00 A)* (0.02 A or 2%)

Time Delay 1 to 30 Cycles 1 Cycle 1 Cycle

50BF-1 can be initiated from designated M-4272 output contacts or programmable inputs.

* Value in parentheses apply to 1A Secondary Rating

50BF-2 Breaker Failure (Source 2)

Pickup Current 0.10 to 10.00 A 0.01 A 0.1 A or 2%

(0.02 to 2.00 A)* (0.02 A or 2%)

Time Delay 1 to 30 Cycles 1 Cycle 1 Cycle

50BF-2 can be initiated from designated M-4272 output contacts or programmable inputs.

* Value in parentheses apply to 1A Secondary Rating

50

S1

50

S2

–10–

M-4272 Digital Motor Bus Transfer System

FUNCTIONS (Cont.)

Setpoint

Ranges Increment Accuracy†

Source 1 Breaker Failure (Using breaker status)

Time Delay 0 to 30 Cycles 1 Cycle 1 Cycle

The breaker failure time delay is used to monitor breaker failure when using the breaker status inputs only.

The breaker is considered failed when the breaker status has not changed state within this programmable

time delay after a trip command is issued. A separate time delay is provided for breaker failure function

(50BF) whencurrent is present.

Source 2 Breaker Failure (Using breaker status)

Time Delay 0 to 30 Cycles 1 Cycle 1 Cycle

The breaker failure time delay is used to monitor breaker failure when using the breaker status inputs only.

The breaker is considered failed when the breaker status has not changed state within this programmable

time delay after a trip command is issued. A separate time delay is provided for breaker failure function

(50BF) when current is present.

81 Frequency (bus voltage)

Pickup #1, #2 50.00 to 67.00 Hz 0.01 Hz 0.02 Hz (1.0 Hz)**

40.00 to 57.00 Hz*

Time Delay #1, #2 5 to 65,500 Cycles 1 Cycle 3 Cycles or 1%

The pickup accuracy applies to 60 Hz models at a range of 57 to 63 Hz, and to 50 Hz models at a range of 47

to 53 Hz. Beyond these ranges, the accuracy is

0.1 Hz (3-phase);

0.4Hz(single phase).

The 81 #1 Function can be used to initiate Load Shedding. The 81 Function is automatically disabled when the

bus phase voltage input is less than 5 to 15 V (Positive Sequence) based on the frequency, or less than 5 V

(Single Phase).

* This range applies to 50 Hz nominal frequency model.

** Value in parenthese applies to single phase bus voltage frequency.

81R Rate of Change of Frequency (bus voltage)

Pickup #1, #2 0.10 to 20.00 Hz/Sec. 0.01 Hz/Sec. 0.05 Hz/Sec. or 5%

Time Delay #1, #2 3 to 8160 Cycles 1 Cycle +20 Cycles

Negative Sequence

Voltage Inhibit 0 to 99% 1% 0.5%

Increasing ROCOF Enable/Disable

The 81R #1 Function can be used to initiate Load Shedding. 81R function can only be used when the bus

voltage input is three-phase, and for load shedding.

81

81R

†Select the greater of these accuracy values. Accuracy applies to sinusoidal voltage with constant amplitude and

frequency.

–11–

M-4272 Digital Motor Bus Transfer System

TCM

CCM

ISSL

†Select the greater of these accuracy values. Accuracy applies to sinusoidal voltage with constant amplitude and

frequency.

FUNCTIONS (Cont.)

Setpoint

Ranges Increment Accuracy†

Bus VT Fuse-Loss Detection

Delta Pickup* 5 to 25 V 1 V .05 V or 2%

Time Delay** 1 to 8160 Cycles 1 Cycle 3 Cycles or 1%****

Blocking Drop Out

Time Delay*** 1 to 300 Cycles 1 Cycle 3 Cycles or 1%****

* Mismatched voltage of the motor bus in respect to the connected source.

** This time delay is for the programmable alarm output.

*** This is the time it takes to drop out (reset) the block transfer after no Bus VT fuse-loss is detected.

**** The pickup and time delay accuracies apply to 60 HZ models at a range of 57 to 63 Hz, and to 50 Hz

models at a range of 47 to 53 Hz. Beyond these ranges, the time delay accuracy is 6 Cycles or 0.75% for the

bus frequency down to 25 Hz. The time delay accuracy is

O

20 Cycles or 1% for the bus frequency at a range

of 5 to 25 Hz.

If the bus VT fuse-loss is detected, the user must either select block transfer or initiate the Fixed Time

Transfer.

Bus VT fuse-loss output is intiated from internally generated logic.

Trip and Close Circuit Monitor

TripCircuit Monitor

TCM-1 Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

TCM-1 Dropout Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

TCM-2 Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

TCM-2 Dropout Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

CloseCircuit Monitor

CCM-1 Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

CCM-1 Dropout Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

CCM-2 Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

CCM-2 Dropout Time Delay 1 to 8160 Cycles 1 Cycle 1 Cycle or 1%

The CCM/TCM inputs are provided for monitoring the continuity of the Source 1 and Source 2 trip and close

circuits. The inputs can be used for nominal trip/close coil voltages of 24 V dc – 250 V dc. Trip and closing

circuit monitoring are performed in the active breaker status only (trip circuit supervision when breaker is

closed and close circuit supervision when breaker is open.) Both the DC supply and continuity for each of the

circuits are monitored.

ISSLogic®

ISSLogic uses control/status input status, system status, function status, output contact close

signals to develop 6 programmable logic schemes.

Time Delay #1-#6 0 to 65500 Cycles 1 Cycle 1 Cycle or 1%

Dropout/Reset Time Delay

#1-#6 0 to 65500 Cycles 1 Cycle 1 Cycle or 1%

60FL

–12–

M-4272 Digital Motor Bus Transfer System

Multiple Setpoint Profiles (Groups)

The system supports four setpoint profiles. This feature allows multiple setpoint profiles to be defined for the

type of transfer initiated (Automatic , Manual or Hot Parallel) and the direction of the next transfer.

Metering

The Digital Motor Bus Transfer System provides metering of voltage and current of the Source 1 and Source 2,

and Voltage and Frequency of the Motor Bus.

Meteringaccuracies are:

Voltage: 0.5V or 0.5%,whichever is greater (from 57 to 63 Hz for 60 Hz models; from 47 to 53 Hz

for 50 Hz models)

1.0 V or 0.75%, whichever is greater (below 57 Hz or beyond 63 Hz for 60 Hz models;

below 47 Hz or beyond 53 Hz for 50 Hz models)

Current: 5 A rating, 0.1 A or 3%, whichever is greater

1 A rating, 0.02 A or 3%, whichever is greater

Frequency: 0.02 Hz (from 57 to 63 Hz for 60 Hz models; from 47 to 53 Hz for 50 Hz models)

0.1Hz(below57 Hz or beyond 63 Hz for60Hzmodels; below 47 Hz or beyond 53Hzfor50

Hz models)

Phase Angle: 0.5 degree or 0.5%,whichever is greater

Oscillographic Recorder

The oscillographic recorder provides comprehensive data recording of all monitored waveforms, and status

inputs storing up to 248 cycles of data. The total record length is user-configurable from 1 to 16 partitions. The

numberof samples per cycleused to store thedata is user selectable.The number of samplesper cycle that can

be selected is 16 or 32 (50 or 60 Hz). The number of samples selected effects the length of the data that can be

savedand its resolution. The lowerthe number of samples, thelongerthe record length thatcanbe stored (but at

alowerresolution).

The oscillographic recorder is triggered by a designated control/status input (usually a protective relay initiate

input), an automatically initiated signal, a trip output, a manual transfer signal or from serial communications.

When untriggered, the recorder continuously stores waveform data, thereby keeping the most recent data in

memory.When triggered, the recorderstores pre-trigger data, then continuesto store data inmemory for a user-

defined,post-trigger delay period.Therecordsmay be analyzedusingBeckwithElectricISScom®Communications

and Oscillographic Analysis Software, and are also available in COMTRADE file format.

Transfer Event Log

A transfer event log is considered complete when one of following occurs:

1. When the breaker from the old source opens and the breaker to the new source* closes.

2. Whenabreaker failure occurs.

3. When the incomplete transfer timer times out.

Dependingontransfer type, up to fourtransferswill be stored. When 16eventsare stored, any subsequent event

willcause the oldest event to be lost.Each Transfer Event Logparameter is timestamped with the dateand time

in 1 ms increments.

The trigger and complete events are used to define the time frame during which the transfer event log is storing

information. A reset feature is provided to clear this log through the serial communications. The Transfer Event

Log is available for viewing utilizing the M-3872 ISScom Communications Software.

Sequence of Events Recording

In addition to the Transfer Event Log the Digital Motor Bus Transfer System provides Sequence of Events

Recording. The Sequence of Events Recording stores every change in the input status, trip commands, close

commands, any signal to initiate a transfer, type of transfer, change in any breaker status, and status reset.

*NOTE: The 'new source' is defined as the source to which the bus is being transferred.

–13–

M-4272 Digital Motor Bus Transfer System

Each of these Running Events are time stamped with the date and time in 1 ms increments. The Running Event

Logstores the last 512 events,whena new event occurs theoldestevent is removed. A resetfeatureis provided

toclear this log throughthe serial communications.The events and theassociated data are availablefor viewing

utilizing the M-3872 ISScom®Communications Software.

Calculations

Current and Voltage Values:TheDigital Motor Bus Transfer System uses discrete Fourier Transform (DFT)and

RMScalculation algorithm onsampled voltage and current signals to extract fundamental amplitude, phaseand

frequencyfor the M-4272.

Power Input Options

Nominal 110/120/230/240 V ac, 50/60 Hz, or nominal 110/125/220/250 V dc. Operates properly from 85 V ac to

265 V ac and from 80 V dc to 312.5 V dc. Withstands 315 V dc or 300 V ac for 1 second. Burden 20 VA at 120

V ac/125 V dc.

Nominal24/48 V dc,Operates properly from 18 V dc to56 V dc.Withstands 65 V dc for 1 second. Burden46 VA

at 24 V dc and 30 VA at 48 V dc.

This unit includes two power supplies which are not redundant.

Sensing Inputs

Nine Voltage Inputs – Rated for a nominal voltage of 50 V ac to 140 V ac (user configurable) at 60 Hz or 50 Hz.

Will withstand 240 V continuous voltage and 360 V for 10 seconds. Voltage transformer burden is less than 0.2

VA at 120 V. Source voltage may be phase-to ground or phase-to-phase connected. For proper operation of

M-4272 MBTS, the connections for the Source 1, Source 2 and Bus voltages must match each other. The unit

may have up to three voltage inputs for each of the Source 1, Source 2, and Bus Voltages. Typical connection

diagramsare illustrated inFigures 10 through15.

OneSource 1 CurrentInput – Rated for acurrent (IR) of5.0 A or 1.0A (optional) at 60 Hz or 50Hz. Will withstand

4IRcontinuouscurrent and 100 IRfor 1 second. Current transformerburdenisless than 0.5 VA at 5A(5Aoption),

or 0.3 VA at 1 A (1 A option).

OneSource 2 CurrentInput – Rated for acurrent (IR) of5.0 A or 1.0A (optional) at 60 Hz or 50Hz. Will withstand

4IRcontinuouscurrent and 100 IRfor 1 second. Current transformerburdenisless than 0.5 VA at 5A(5Aoption),

or 0.3 VA at 1 A (1 A option).

Control/Status Inputs

To provide proper operation and breaker status LED indication on the front panel, the INPUT1 through INPUT 6

statusinputs must be connectedto the 52a,

52b,52a/b and 52SP (serviceposition) breaker status contacts. The

control/statusinputs, INPUT7 throughINPUT18, can beprogrammed to initiatethe transfer orblock the transfer

operation, trigger the oscillographic recorder, or to operate one or more outputs. The control/status inputs are

designed to be connected to dry contacts and are internally wetted with a 24 V dc power supply.The four Aux

Inputs must be connected to the trip and close circuit monitoring.

Output Contacts

OutputcontactsOUTPUT1throughOUTPUT4areavailabletoTripandClosetheSource1andSource2breakersand

areclosedforadefinedpulselength(pulselengthcanbeprogrammedfrom15to30Cycles).Thepowersupplyalarm

outputcontact (form'b')andtheself-test alarmoutputcontact(form'c'),andoneoutputcontactforlockoutorblocking

status(form 'c').Theseoutputs arepre-defined.

Theeleven programmable output contacts (tenform ‘a’ and one form‘c’),the Lockout/Block alarm outputcontact

(form'c'), the powersupply alarm outputcontact (form 'b') and the self-test alarmoutput contact (form‘c’), are all

rated as per ANSI/IEEE C37.90-1989 for tripping. (Make 30 A for 0.2 seconds, carry 8 A, break 6 A @ 120 V ac,

break 0.5A @ 48 V dc; 0.3A @ 125 V dc; 0.2A @ 250 V dc with L/R = 40 mSec.)

Any of the MBTS functions can be individually programmed to activate any one or more of the programmable

output contacts (Outputs 5 to 16). Any output contact can also be selected as pulsed or latched. ISSLogic can

also be used to activate an output contact.

*NOTE: The 'new source' is defined as the source to which the bus is being transferred.

–14–

M-4272 Digital Motor Bus Transfer System

*NOTE: The 'new source' is defined as the source to which the bus is being transferred.

Breaker Closing Time and Breaker Failure Monitoring

The Breaker Closing Time Monitoring feature measures the breaker closing time each time a transfer occurs. If

this time varies by more than a selectable breaker closing time deviation of the programmed time, an alarm is

activated.The breaker closing timeismeasured from the timethe close command issentuntil the breaker status

indicates that the breaker is closed.

The selectable Adaptive Breaker Closing Time is provided. If it is enabled, a new setpoint of the breaker closing

time will be automatically updated to an average value of 8 breaker closing time's measurements; however the

setpoints of the breaker closing time are not permitted to write and change unless this feature is disabled.

The breaker status inputs are also monitored for breaker failure. The breaker is considered failed when the

breaker status has not changed state within a programmable time after a trip command is issued. When

SimultaneousTransfermodeis selected and a breaker failureoccursonthebreaker that should have tripped, the

breaker that was just closed will be tripped. This prevents the new source* from being continuously connected

with the failed breaker, which could have a fault.

In addition to using the breaker status in determining when a breaker has failed, the current through the breaker

can also be used to determine if the breaker has operated. The loss of current after a trip can be selected to

provideamorepositiveindicationofbreakeroperation.Aninstantaneousovercurrentbreakerfailureelementwith

a time delay (50BF) is provided to minimize breaker failure coordination margins.

Power up Self-Test and Continuous On-Line Testing

The system performs self test verifications when power is first applied to the unit. These include verifying the

operationof the multiplexer,programmable gain amplifier, analog to digital converter, DSP chip, Hostprocessor

and all RAM chips. After the initial self test is complete and the system is operating normally, continuous self

check verification continues to check for correct operation of the system. The continuous self check verification

tests are performed in the background and do not effect the response time of the unit to emergency conditions.

In addition to the background tests, there are tests that can be performed in the diagnostic mode during periodic

off line system testing. These additional tests can exercise the relay outputs, check front panel LED operation,

verify input status operation, check pushbutton operation and communication operation.

Target/Status Indicators and Controls

The SYS OK LEDreveals propercyclingofthe microcomputer; it can beprogrammedtoflash or to be illuminated

continuously. The SOURCE 1 BRKR CLOSED and SOURCE 2 BRKR CLOSED red LEDs illuminate when the

breakeris closed (when the 52a contact isclosed). The SOURCE 1 BRKR OPEN and SOURCE 2 BRKR OPEN

green LEDs illuminate when the breaker is open (when the 52a contact is open). The 52 contact input can be

configuredfor either “a”,“b” or "a/b" inputs.The corresponding BRKR status LEDwill illuminate whenany of the

conditions, events or unit functions activate.

Pressing and releasing the STATUS RESET pushbutton resets the STATUS LEDs if the conditions causing the

operation have been removed. Pressing and holding the STATUS RESET pushbutton will allow conditions,

eventsor functions thatare picked up tobe displayed. The PS1 andPS2 LEDs will remain illuminated as long as

poweris applied to the unitandthe power supply is operatingproperly. TIME SYNC LED illuminates when avalid

IRIG-B signal is applied and time synchronization has been established. The TRIP SOURCE 1, CLOSE

SOURCE 1, TRIP SOURCE 2 and CLOSE SOURCE 2 status indicators are latched due to the pulsed nature of

these commands. To provide information about which outputs were operated during the last transfer the

appropriate TRIP SOURCE 1, CLOSE SOURCE 1, TRIP SOURCE 2 or CLOSE SOURCE 2 LEDsin the Status

module are latched until reset or the next transfer.

–15–

M-4272 Digital Motor Bus Transfer System

Communication

Communication ports include rear RS-232 and RS-485 ports, a front RS-232 port, a rear IRIG-B port, and an

Ethernet port (optional). The communications protocol implements serial, byte-oriented, asynchronous

communication, providing the following functions when used with the Windows™-compatible M-3872 ISScom®

Communicationsand Oscillographic Analysis Software. MODBUS protocol is supported, providing:

• Interrogationand modification ofsetpoints and configuration

• Time-stamped status information for the 4 most recent Transfer Event logs

• Time-stamped status information for the 512 most recent events in the Sequence of Events log

• Real-time metering of all measured quantities, control status inputs, and outputs

• Downloadingof recorded oscillographic dataand Sequence of Eventsrecorder data

• Initiate manual transfer and Sequence of Events recorder

TheM-3872 ISScom Communicationsand Oscillographic AnalysisSoftware enables theplotting and printingof

M-4272 waveform data downloaded from the unit to any IBM-PC compatible computer. The ISScom

Communications and Oscillograph Analysis Software can also be used to analyze the operation of the system,

determine timing of the trip and close commands, breaker times and to evaluate “bus ringdown” test data. The

evaluationof“busringdown”dataeliminatestherequirementforseparaterecordingequipmentduringcommissioning.

IRIG-B

The M-4272 accepts either modulated or demodulated IRIG-B time clock synchronization signals. The IRIG-B

time synchronization information is used to correct the local calendar/clock and provide greater system wide

synchronization for status and oscillograph time tagging.

HMI Module

LocalaccesstotheM-4272 is provided through the M-3931 Human-Machine Interface(HMI)Module,allowingfor

easy-to-use, menu-driven access to all functions using a 6-pushbutton keyboard and a 2-line by 24 character

alphanumericdisplay. The M-3931module includes the following features:

• User-definable access codes providing three levels of security

• Real-time metering of all measured quantities, control status inputs, and outputs

• InitiateManual Transfer

• Remote/Localcontrol

• Device On/Off control

Status Module

An M-3972 Status Module provides 24 status and 8 output LEDs. Appropriate status LEDs illuminate when the

corresponding M-4272 conditions, event or function activates. The status indicators can be reset with the

STATUS RESET pushbutton if the activated conditions have been removed. The OUTPUT LEDs indicate the

status of the programmable output contacts. There are an additional 4 status LEDs, 8 output LEDs and 12 input

LEDs located on the front panel.

ISSLogic®

This feature can be programmed utilizing the M-3872 ISScom Communications Software. ISScom takes the

control/status input status, system status and function status, and by employing (OR, AND, NOR and NAND)

booleanlogic and timers, can activatean output, change activesettingprofiles, initiate transfer, orblock transfer.

There are six ISSLogic Functions per setting profile, depending on the number of different MBTS settings

defined,the scheme mayprovide up to24 different logic schemes. The ISSLogic Function Diagram is illustrated

in Figure 1.

*NOTE: The 'new source' is defined as the source to which the bus is being transferred.

–16–

M-4272 Digital Motor Bus Transfer System

ISSLogic Functions

Blocking Inputs

Selectable And/Or

Programmable

Inputs and AUX

Input

Block Via

Communication

Point

Initiating Inputs

Initiating Function

Selectable And/Or

Selectable And/Or/Nor/Nand

Selectable And/Or

Programmable

Inputs and AUX

Input

Programmable

function(s)

(Incl. ISSLogic

and System

Status)

Initiating Outputs

Selectable And/Or

Outputs

Initiate Via

Communication

Point

Programmed

Time Delay

Programmed

Outputs 5-16

Log in

Sequence of

Events

0-65,500 cycles

(1091sec at

60Hz)

Log Pickup in

Sequence of

Events

ISSLogic # N

Activated

This section of ISSLogic initiates

the Function Operation

This section of ISSLogic is used

to Block the Function Operation

This section of ISSLogic

used to activate the desired Output

Initiate

Transfer

Programmed

Profile

Settings

Groups 1-4

Block

Transfer

Selectable And/Or

Figure 1 ISSLogic®Function Diagram

–17–

M-4272 Digital Motor Bus Transfer System

Tests and Standards

M-4272 Digital Motor Bus Transfer System complies with the following type tests and standards:

Voltage Withstand

Dielectric Withstand

IEC60255-5 3,500 V dc for 1 minute applied to each independent circuit to earth

3,500 V dc for 1 minute applied between each independent circuit

1,500 V dc for 1 minute applied to IRIG-B circuit to earth

1,500 V dc for 1 minute applied between IRIG-B to each independent circuit

1,500 V dc for 1 minute applied between RS-485 to each independent circuit

Impulse Voltage

IEC60255-5 5,000 V pk, +/- polarity applied to each independent circuit to earth

5,000 V pk, +/- polarity applied between each independent circuit

1.2 by 50 μs, 500 ohms impedance, three surges at 1 every 5 seconds

IEC60255-5 > 100 Megaohms

Electrical Environment

Electrostatic Discharge Test

EN60255-22-2 Class 4 (8 kV)—point contact discharge

EN60255-22-2 Class4(15kV)–air discharge

Fast Transient Disturbance Test

EN60255-22-4 Class A (4 kV, 2.5 kHz)

Surge Withstand Capability

ANSI/IEEE 2,500 V pk-pk oscillatory applied to each independent circuit to earth

C37.90.1- 2,500V pk-pk oscillatory applied between each independent circuit

1989 5,000 V pk Fast Transient applied to each independent circuit to earth

5,000 V pk Fast Transient applied between each independent circuit

ANSI/IEEE 2,500 V pk-pk oscillatory applied to each independent circuit to earth

C37.90.1- 2,500V pk-pk oscillatory applied between each independent circuit

2002 4,000 V pk Fast Transient burst applied to each independent circuit to earth

4,000 V pk Fast Transient burst applied between each independent circuit

QNOTE: The signal is applied to the digital data circuits (RS-232, RS-485, IRIG-B, Ethernet communication

portcoupling port) throughcapacitive coupling clamp.

ANSI/IEEE 80-1000 Mhz @ 35 V/m

C37.90.2

Output Contacts

ANSI/IEEE Make 30 A for 0.2 seconds, off for 15 seconds for 2,000 operations, per Section 6.7.1,

C37.90.0 Tripping OutputPerformance Requirements

–18–

M-4272 Digital Motor Bus Transfer System

Atmospheric Environment

Temperature

IEC 60068-2-1 Cold,–20° C

IEC 60068-2-2 Dry Heat, +70° C

IEC 60068-2-78 Damp Heat, +40° C @ 93% RH

Mechanical Environment

Vibration

IEC 60255-21-1 Vibration response Class 1, 0.5 g

Vibration endurance Class 1, 1.0 g

IEC 60255-21-2 Shock Response Class 1, 5.0g

Shock Withstand Class 1, 15.0g

Bump Response Class 1, 10.0g

Compliance

cULus-Listedper508 – Industrial Control Equipment

– Industrial Control Equipment Certified for Canada CAN/CSA C22.2 No. 14-M91

cULus-ListedComponent per 508A TableSA1.1 Industrial Control Panels

European Safety -EN 61010-1:2001, CAT II,Pollution Degree 2

Physical

Size: 19.00" wide x 6.96" high x 10.20" deep (48.3 cm x 17.7 cm x 25.9 cm)

Mounting: Theunit is a standard 19", semiflush, 4-unit high, rack-mount paneldesign, conforming toANSI/EIA

RS-310C and DIN 41494 Part 5 specifications. Optional mounting is available.

Approximate Weight: 20 lbs (9.1kg)

Approximate Shipping Weight: 30 lbs (13.6 kg)

Recommended Storage Parameters

Temperature:

5° C to 40° C

Humidity:

Maximum relative humidity 80% for temperatures up to 31° C, decreasing to 31° C

linearly to 50% relative humidity at 40° C.

Environment:

Storage area to be free of dust, corrosive gases, flammable materials, dew, perco-

lating water, rain and solar radiation.

See M-4272 Instruction Book, Appendix G, Layup and Storage for additional information.

Patent & Warranty

The M-4272 Digital Motor Bus Transfer System has patents pending.

The M-4272 Digital Motor Bus Transfer System is covered by a five year warranty from date of shipment.

External Connections

M-4272external connection points are illustrated in Figure 5, External Connections.

Specification subject to change without notice.

–19–

M-4272 Digital Motor Bus Transfer System

QNOTE:CurrentTransformersareusedfortheM-4272,50BFFunction,theyarenotrequiredfortransferoperation.

Figure 2 Typical Applications of Motor Bus Transfer Systems

TWO-BREAKER CONFIGURATION

THREE-BREAKER CONFIGURATION

VT-M VT-SU

VT-B

52

M

STATION BUS SYSTEM

N.C.

M

TWO-BREAKER CONFIGURATION

CT-M

N.O. 52

SU

CT-SU

UNIT AUXILIARY

TRANSFORMER STATION SERVICE

TRANSFORMER

M

M-4272

IS1 IS2

VS1 VS2

VBus

STATION BUS SYSTEM

N.C.

52

S1

VT-B1

N.C. 52

S2

VT-S2

BUS 1 BUS 2

VT-B2

52T

N.O.

BUS-TIE

VT-S1

CT-S1 CT-S2

CT-B1 CT-B2

M-4272 M-4272

MMM M

Source 1 (S1) Source 2 (S2)

IS1 IS1

VS1

VS2 VBus IS2

VS1

IS2 VBus VS2

Other manuals for M-4272

1

Table of contents

Other BECKWITH ELECTRIC Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

Murata

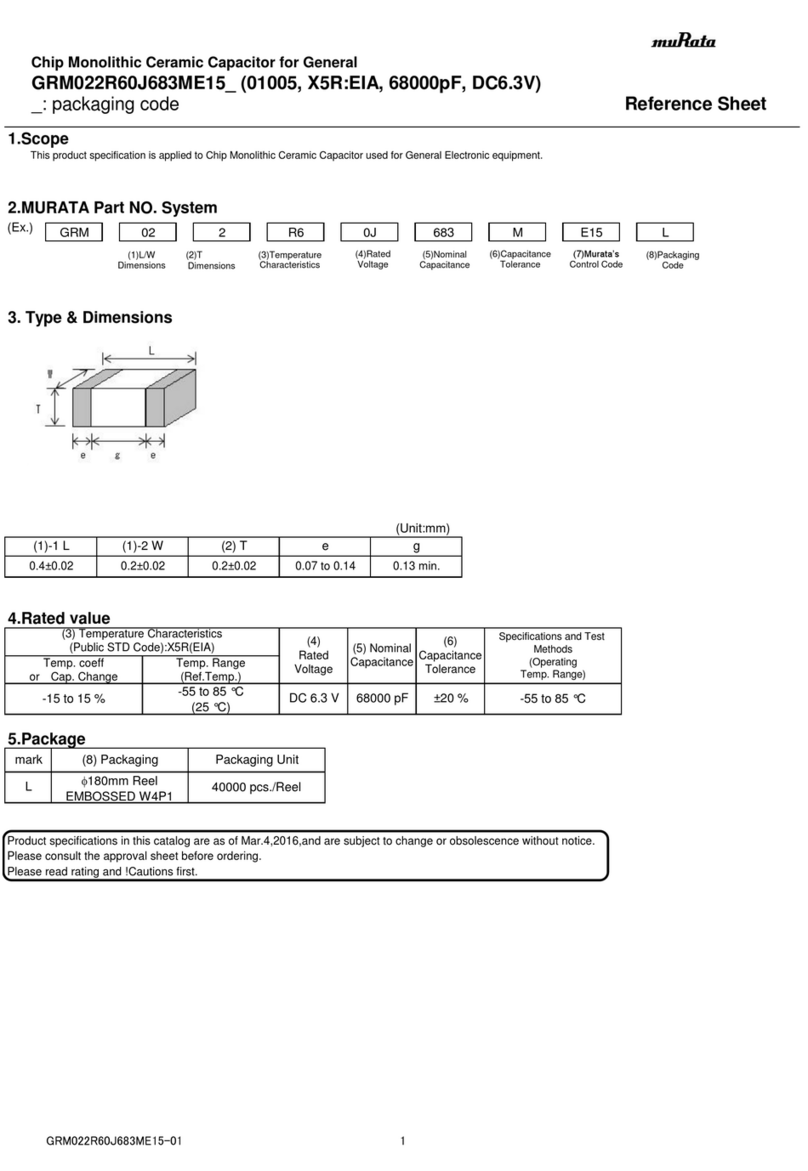

Murata GRM0225C1E5R7CA03 Series Reference sheet

ETAS

ETAS ES4435.1 user guide

Morris Products

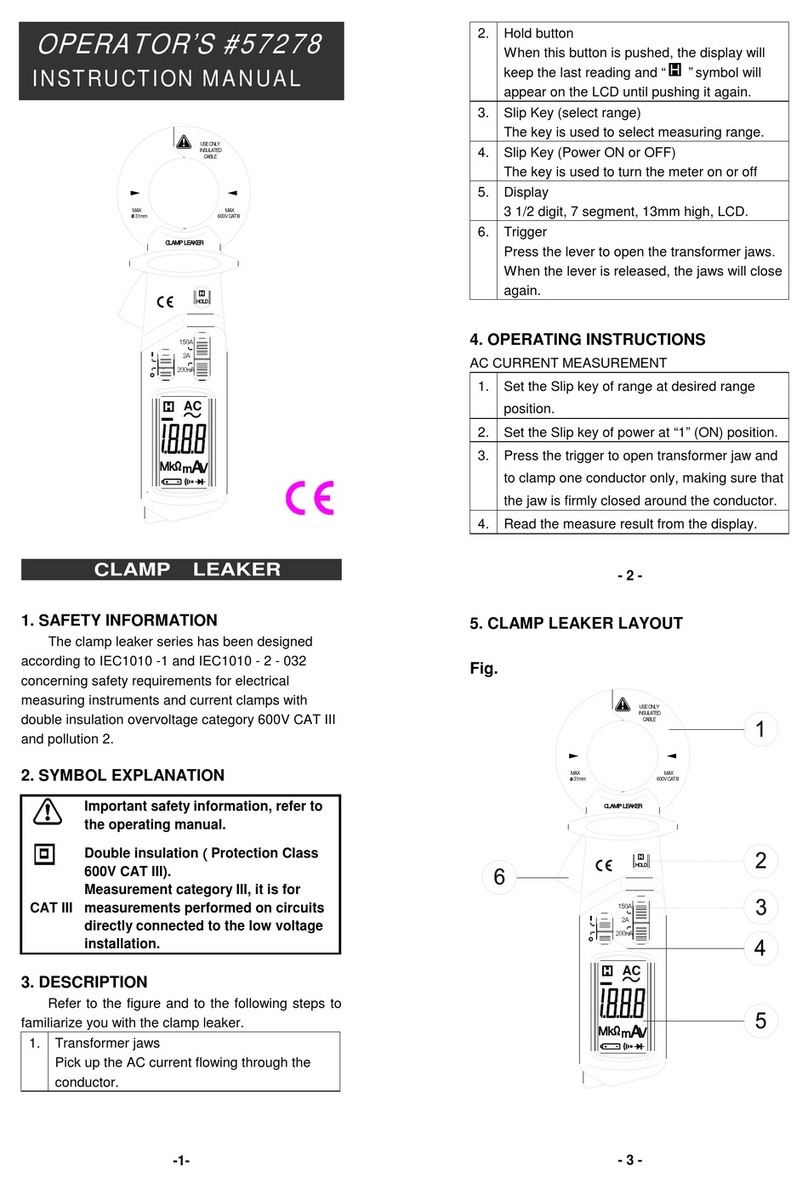

Morris Products CLAMP LEAKER Series Operator's instruction manual

Murata

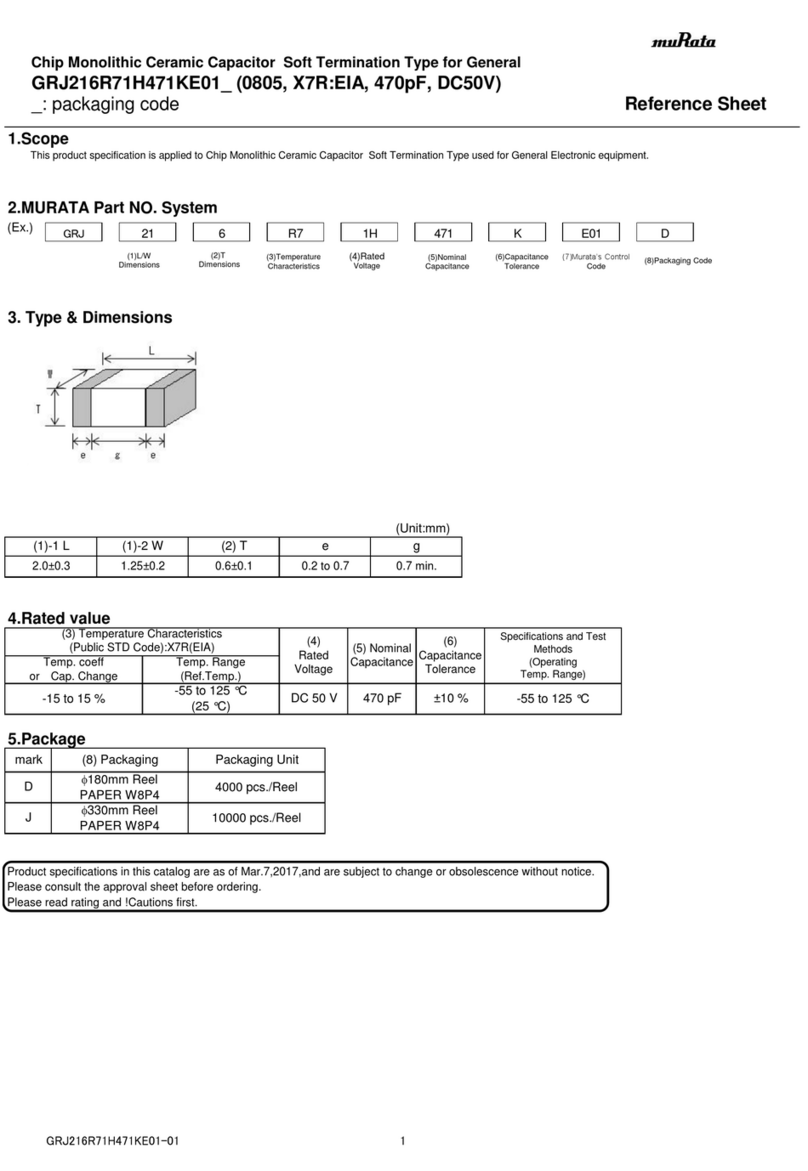

Murata GRJ216R71H471KE01 Series Reference sheet

Eaton

Eaton PT 10 instruction manual

Elenco Electronics

Elenco Electronics RS-500 instruction manual

Ravas

Ravas SAFECHECK Installation and user manual

Murata

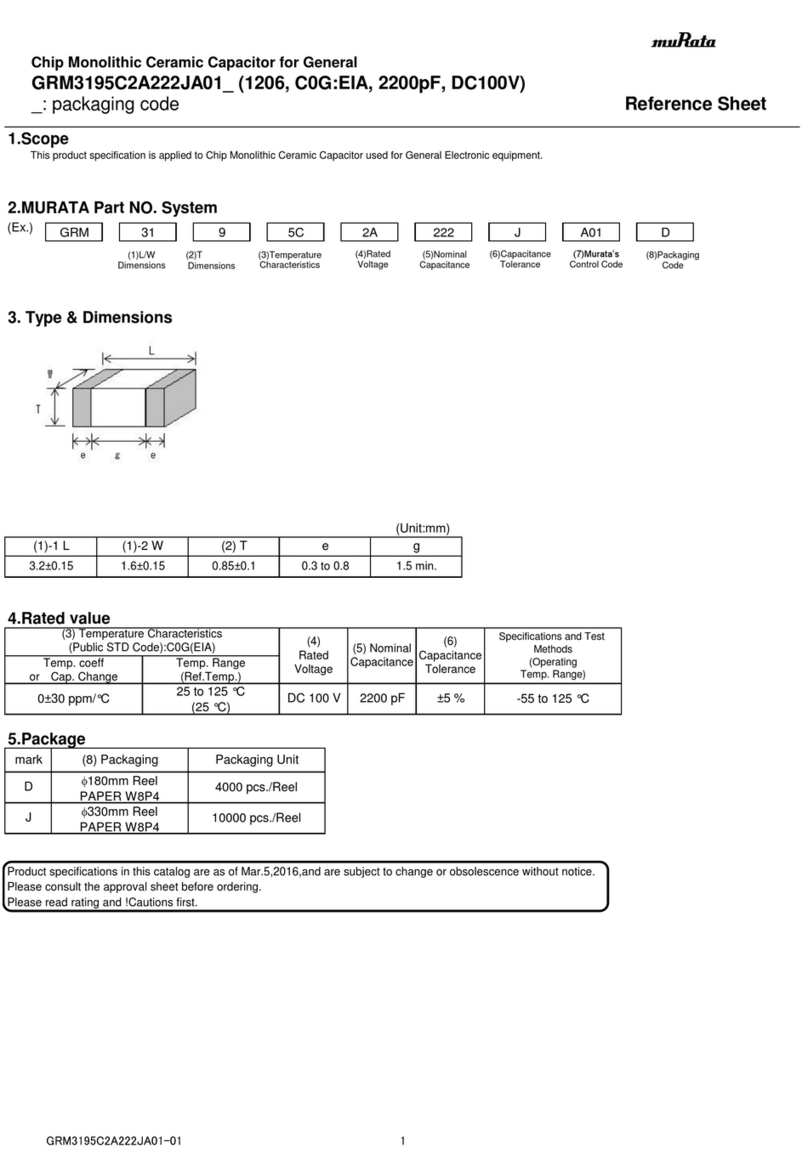

Murata GRM3195C2A222JA01 Series Reference sheet

Murata

Murata GRM022R60J683ME15 Series Reference sheet

Siemens

Siemens SINUMERIK 840D sl operating manual

Murata

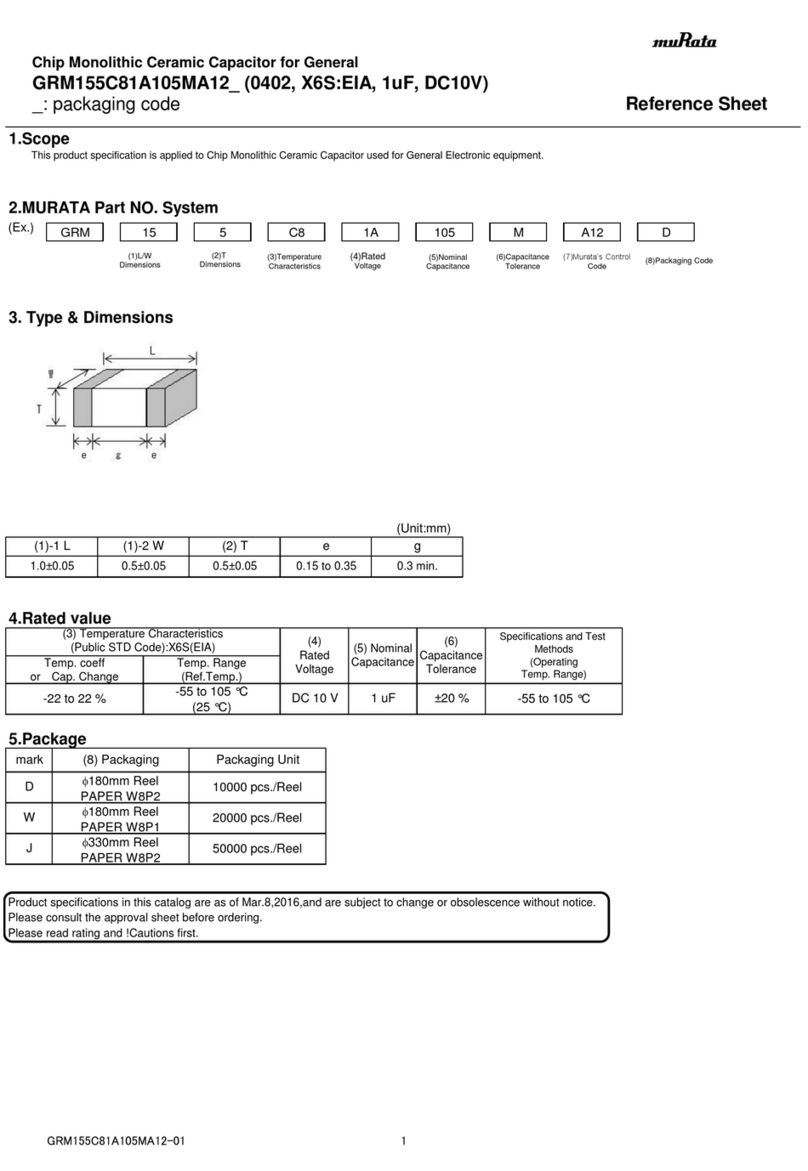

Murata GRM155C81A105MA12 Series Reference sheet

Siemens

Siemens 3VT9500-1U.00 operating instructions