BECKWITH ELECTRIC M-2601 User manual

Instruction Book

M-2601/02/03 Autodaptive®

Regulator Control

CONTROLS

Autodaptive®

Regulator Control

M-2601

• Adaptive control feature significantly reduces number of tap

changes for a given Voltage Regulation uality Factor (VR F)

• Uses proprietary sampling to measure fundamental voltage, Watts

and VArs at a rate of 240 samples per half cycle

• Enhanced data output display with SLIMcom® software

Replaces Siemens Regulators MJ-1A, MJ-2A, MJ-3, MJ-3A,

MJ-X; IJ-2, IJ-2A; SJ-4, SJ-5, SJ-6; UJ-2, UJ-4, UJ-5, UJ-5C

and some UA Series Regulator Controls

–2–

M-2601 Autodaptive Regulator Control

The M-2601 Autodaptive®Regulator Control is a unique microcontroller-based solution to regulator control

requirements. Using conventional Siemens Regulator inputs, the control accomplishes regulator control,

based on voltage. Communication and control features of the M-2601 are accomplished utilizing either

M-2802 SLIMcom®for Windows™from a PC platform, or M-2808 SLIMcom for Visor™Communications

Software.

Features

The M-2601 Autodaptive Regulator Control includes a user-defined Bandcenter and Voltage Regulation

Quality Factor (VRQF) that permits optimization of the tapchanging process. Also included are: a DRAG

HANDS RESET button, a VOLTAGE SOURCE selector switch and binding posts for Motor Power, Control

Voltage and Voltage Test. Separate fuses for motor power, control, relays and the neutral circuit are located

on the rear of the panel.

Configurable setpoints include:

Bandcenter: Adjustable from 90.0 V to 135.0 V in 0.1 V increments.

Bandwidth: 1 V, predetermined by regulator step size.

VRQF: Adjustable from 0.4 V to 2.0 V in 0.1 V increments.

CT to VT Phasing Correction: Adjustable from 0° to +330° in 30° increments.

VT User Correction Voltage: VT correction from –12 V to +12 V in 0.01 V increments.

CT User Correction Multiplier: Adjustable from 50% to 200%, in 1% increments.

Voltage Limiting: Upper Voltage Limit adjustable from 90 V to 136 V, Lower Voltage Limit adjustable from

89 V to 135 V.

Line Drop Compensation: R & X (forward and reverse) adjustable from –24 V to +24 V in 1 V increments.

Intertap Minimum Delay: Adjustable from 5 seconds to 15 seconds in 0.1 second increments.

Raise/Lower Maximum Output Hold Time: Adjustable from 1 second to 15 seconds in 0.1 second

increments.

VAr Bias Setpoints:

Largest Cap Bank

: Adjustable from 0 KVAr to 11057 KVAr.

Control Functions

Presettable Operations Counter: This software counter increments by one or two counts (user-selectable)

per close/open cam switch operation, and may be preset by the user from 0 to 999,999.

Resettable Operations Counter: A second software counter, similar to the operations counter, which may

be reset by the user.

Inputs

Control Voltage Input: Nominal 120 V ac, 60 Hz; operates properly from 80 V ac to 140 V ac. The burden

imposed on the input is 6 VA or less.

Motor Power Input: Nominal 120 V ac or 240 V ac, 60 Hz, at up to 6 A.

Line Current Input: Line drop compensation is provided by a current transformer input with a 0.2 A full scale

rating. The burden imposed on the current source is 0.03 VA or less, at 200 mA. The input will withstand 400

mA for two hours and 4 A for 1 second.

The unit will withstand twice the voltage input for one second, and four times the voltage input for one cycle.

Fuse protected for voltage above these limits.

–3–

M-2601 Autodaptive Regulator Control

Front Panel Controls

AUTO/MANUAL switch:Selects operational mode of regulator.

RAISE/OFF/LOWER switch: Provides manual tap position control.

VOLTAGE SOURCE: Allows the selection of either an internal or external voltage source.

LED Indicators

The front panel LED indicators alert the user to the following conditions:

Out-of-Band RAISE and LOWER (3 position): GREEN (Initial Timing), AMBER (switch operation in 1 to 5

minutes), RED (switch operation in 1 minute or less).

CPU OK, flashing GREEN, indicates the control is working properly.

REV PWR, RED, indicates a reverse power condition exists.

NEUTRAL LIGHT, AMBER, indicates regulator is in the neutral position.

Output Contacts

Raise Output: Capable of switching 6 A at 120 V ac to 240 V ac motor power.

Lower Output: Capable of switching 6 A at 120 V ac or 240 V ac motor power.

Voltage Measurement Accuracy

Voltage accuracy of K0.7% in accordance with ANSI/IEEE C57.15-1986 defining control accuracy of

operation.

Communications

Serial communications is available via a front panel-mounted, optically-isolated RS-232 serial data port in a

DE 9-pin configuration, with available data rate of 9600 baud.

Environmental

Temperature: Stated accuracies maintained from –40°C to +80°C.

Humidity: Stated accuracies are maintained up to 95% relative humidity (non-condensing).

Fungal Resistance: A conformal coating is used on the printed circuit board to inhibit fungal growth.

Transient Protection

High Voltage: All input and output terminals will withstand 1500 V ac to chassis or instrument ground for one

minute, for all terminals to ground with a leakage current less than 25 mA. Input and output circuits are

electrically isolated from each other, from other circuits and from ground.

Surge Withstand Capability: All input and output circuits are protected against system transients. Units

pass all requirements of ANSI/IEEE C.37.90.1-1989 defining surge withstand capability.

Radiated Electromagnetic Withstand Capability: All units are protected against electromagnetic radiated

interference from portable communications transceivers.

Electrostatic Discharge Sensitivity: Per IEC 1000–4.

Physical

Size: 15" high x 9-7/8" wide x 3-1/2" deep (38.1 cm x 25.08 cm x 8.9 cm)

Mounting: Mechanically interchangeable with existing Siemens equipment.

Approximate Weight: 4 lbs, 13 oz (2.18 kg)

Approximate Shipping Weight: 10 lbs (4.54 kg)

BECKWITH ELECTRIC CO., INC.

6190 - 118th Avenue North • Largo, Florida 33773–3724 U.S.A.

Phone (727) 544-2326 • FAX (727) 546-0121

E-MAIL [email protected]

WEB PAGE www.beckwithelectric.com

© 2000 Beckwith Electric Co.

Printed in U.S.A. 800-2601-SP-03 09/01

Accessories

M-2802 SLIMcom®for Windows™

M-2808 SLIMcom for Visor™

Metering

The following are examples of measured and calculated parameters that are available in real-time:

•PrimaryVoltage •Primary Current •Power Factor

•KWatts** •KVArs** •KVA**

•Secondary Voltage •Secondary Current •VRQF✝

•CT Phasing •Avg Taps/Day •Tap Position

•Preset Counter •Alarm Status •Voltage Profile

Historical Data Plot

•Up to seven time-stamped analog calculated or measured values

•1 digital parameter can be plotted

■NOTE: All stored data available with time stamp. Five minute averaged samples are stored 111 days.

Sampling rate adjustable from 5 to 60 minutes, with resultant change to storage period.

Voltage Outage Plot

•Voltage plots (previous 10 seconds of data) for the last 4 voltage outage events are displayed.

Tap Statistics Plot

•The Tap Statistics Plot presents a graphical representation of tap position usage history.

Other

•Prints detailed reports of all setpoints and data.

•Entry and Readout of setpoints.

**Value calculated in SLIMcom

.

All primary quantities are also calculated in SLIMcom.

✝

VRQF is the RMS deviation in the fundamental component of an AC voltage from a desired AC voltage. It is computed as the

square root of the sum of the squares of deviations in the fundamental component of the voltage from the desired value. The

sum is computed as a running recursive average of frequently taken samples of the fundamental component, obtained in at

least one full cycle of the wave. The time constant of the recursive computation is 6 hours. The recursive average takes at

least six hours to settle to a proper sum, and is generally never stopped, once started.

M-2931 Handspring™Visor™Deluxe, with SLIMcom for Visor Communications Software

Patents

The M-2601 Autodaptive®Regulator Control is covered by U.S. Patents, 5,315,527, 5,554,064, 5,541,498

and 5,530,338 with other patents pending.

Warranty

The M-2601 Autodaptive Regulator Control is covered by a two year warranty from date of shipment.

Specification subject to change without notice.

CONTROLS

Autodaptive®

Regulator Control

M-2602

• Adaptive control feature significantly reduces number of tap

changes for a given Voltage Regulation uality Factor (VR F)

• Uses proprietary sampling to measure fundamental voltage, Watts

and VArs at a rate of 240 samples per half cycle

• Enhanced data output display with SLIMcom® software

Replaces General Electric ML-32 and VR-1 Regulators, and

SM-1, SM-2, and SM-2A Regulator Controls

–2–

M-2602 Autodaptive Regulator Control

The M-2602 Autodaptive®Regulator Control is a unique microcontroller-based solution to regulator control

requirements. Using conventional GE Regulator inputs, the control accomplishes regulator control, based on

voltage. Communication and control features of the M-2602 are accomplished utilizing either M-2802

SLIMcom®for Windows™ from a PC platform, or M-2808 SLIMcom for Visor™Communications Software.

Features

The M-2602 Autodaptive Regulator Control includes a user-defined Bandcenter and Voltage Regulation

Quality Factor (VRQF) that permits optimization of the tapchanging process. Also included are: a DRAG

HANDS RESET button, a VOLTAGE SOURCE selector switch and binding posts for Motor Power, Control

Voltage and Voltage Test. Separate fuses for motor power, control, relays and the neutral circuit are located

on the rear of the panel.

Configurable setpoints include:

Bandcenter: Adjustable from 90.0 V to 135.0 V in 0.1 V increments.

Bandwidth: 1 V, predetermined by regulator step size.

VRQF: Adjustable from 0.4 V to 2.0 V in 0.1 V increments.

CT to VT Phasing Correction: Adjustable from 0° to +330° in 30° increments.

VT User Correction Voltage: VT correction from –12 V to +12 V in 0.01 V increments.

CT User Correction Multiplier: Adjustable from 50% to 200%, in 1% increments.

Voltage Limiting: Upper Voltage Limit adjustable from 90 V to 136 V, Lower Voltage Limit adjustable from

89 V to 135 V.

Line Drop Compensation: R & X (forward and reverse) adjustable from –24 V to +24 V in 1 V increments.

Intertap Minimum Delay: Adjustable from 5 seconds to 15 seconds in 0.1 second increments.

Raise/Lower Maximum Output Hold Time: Adjustable from 1 second to 15 seconds in 0.1 second

increments.

VAr Bias Setpoints:

Largest Cap Bank

: Adjustable from 0 KVAr to 11057 KVAr.

Control Functions

Presettable Operations Counter: This software counter increments by one or two counts (user-selectable)

per close/open cam switch operation, and may be preset by the user from 0 to 999,999.

Resettable Operations Counter: A second software counter, similar to the operations counter, which may

be reset by the user.

Inputs

Control Voltage Input: Nominal 120 V ac, 60 Hz; operates properly from 80 V ac to 140 V ac. The burden

imposed on the input is 6 VA or less.

Motor Power Input: Nominal 120 V ac or 240 V ac, 60 Hz, at up to 6 A.

Line Current Input: Line drop compensation is provided by a current transformer input with a 0.2 A full scale

rating. The burden imposed on the current source is 0.03 VA or less, at 200 mA. The input will withstand 400

mA for two hours and 4 A for 1 second.

The unit will withstand twice the voltage input for one second, and four times the voltage input for one cycle.

Fuse protected for voltage above these limits.

–3–

M-2602 Autodaptive Regulator Control

Front Panel Controls

AUTO/MANUAL switch:Selects operational mode of regulator.

RAISE/OFF/LOWER switch: Provides manual tap position control.

VOLTAGE SOURCE: Allows the selection of either an internal or external voltage source.

LED Indicators

The front panel LED indicators alert the user to the following conditions:

Out-of-Band RAISE and LOWER (3 position): GREEN (Initial Timing), AMBER (switch operation in 1 to 5

minutes), RED (switch operation in 1 minute or less).

CPU OK, flashing GREEN, indicates the control is working properly.

REV PWR, RED, indicates a reverse power condition exists.

NEUTRAL LIGHT, AMBER, indicates regulator is in the neutral position.

Output Contacts

Raise Output: Capable of switching 6 A at 120 V ac to 240 V ac motor power.

Lower Output: Capable of switching 6 A at 120 V ac or 240 V ac motor power.

Voltage Measurement Accuracy

Voltage accuracy of K0.7% in accordance with ANSI/IEEE C57.15-1986 defining control accuracy of

operation.

Communications

Serial communications is available via a front panel-mounted, optically-isolated RS-232 serial data port in a

DE 9-pin configuration, with available data rate of 9600 baud.

Environmental

Temperature: Stated accuracies maintained from –40°C to +80°C.

Humidity: Stated accuracies are maintained up to 95% relative humidity (non-condensing).

Fungal Resistance: A conformal coating is used on the printed circuit board to inhibit fungal growth.

Transient Protection

High Voltage: All input and output terminals will withstand 1500 V dc to chassis or instrument ground for one

minute, for all terminals to ground with a leakage current of less than 25 mA. Input and output circuits are

electrically isolated from each other, from other circuits and from ground.

Surge Withstand Capability: All input and output circuits are protected against system transients. Units

pass all requirements of ANSI/IEEE C.37.90.1-1989 defining surge withstand capability.

Radiated Electromagnetic Withstand Capability: All units are protected against electromagnetic radiated

interference from portable communications transceivers.

Electrostatic Discharge Sensitivity: Per IEC 1000–4.

Physical

Size: 15" high x 9-1/4" wide x 2-3/8" deep (38.1 cm x 23.5 cm x 5.6 cm)

Mounting: Mechanically interchangeable with existing GE equipment.

Approximate Weight: 4 lbs, 4 oz (1.93 kg)

Approximate Shipping Weight: 10 lbs (4.54 kg)

Accessories

M-2802 SLIMcom®for Windows™

M-2808 SLIMcom for Visor™

Metering

The following measured and calculated parameters are available in real-time:

•PrimaryVoltage •Primary Current •Power Factor

•KWatts** •KVArs** •KVA**

•Secondary Voltage •Secondary Current •VRQF✝

•CT Phasing •Avg Taps/Day •Tap Position

•Preset Counter •Alarm Status •Voltage Profile

Historical Data Plot

•Up to seven time-stamped analog calculated or measured values

•1 digital parameter can be plotted

■NOTE: All stored data available with time stamp. Five minute averaged samples are stored 111 days.

Sampling rate adjustable from 5 to 60 minutes, with resultant change to storage period.

Voltage Outage Plot

•Voltage plots (previous 10 seconds of data) for the last 4 voltage outage events are displayed.

Tap Statistics Plot

•The Tap Statistics Plot presents a graphical representation of tap position usage history.

Other

•Prints detailed reports of all setpoints and data.

•Entry and Readout of setpoints.

**Value calculated in SLIMcom

.

All primary quantities are also calculated in SLIMcom.

✝

VRQF is the RMS deviation in the fundamental component of an AC voltage from a desired AC voltage. It is computed as the

square root of the sum of the squares of deviations in the fundamental component of the voltage from the desired value. The

sum is computed as a running recursive average of frequently taken samples of the fundamental component, obtained in at

least one full cycle of the wave. The time constant of the recursive computation is 6 hours. The recursive average takes at

least six hours to settle to a proper sum, and is generally never stopped, once started.

M-2931 Handspring™Visor™Deluxe, with SLIMcom for Visor Communications Software

Patents

The M-2602 Autodaptive®Regulator Control is covered by U.S. Patents, 5,315,527, 5,554,064, 5,541,498

and 5,530,338 with other patents pending.

Warranty

The M-2602 Autodaptive Regulator Control is covered by a two year warranty from date of shipment.

Specification subject to change without notice.

BECKWITH ELECTRIC CO., INC.

6190 - 118th Avenue North • Largo, Florida 33773–3724 U.S.A.

Phone (727) 544-2326 • FAX (727) 546-0121

E-MAIL [email protected]

WEB PAGE www.beckwithelectric.com

© 2000 Beckwith Electric Co.

Printed in U.S.A.

800-2602-SP-01 09/01

CONTROLS

Autodaptive®

Regulator Control

M-2603

• Adaptive control feature significantly reduces number of tap

changes for a given Voltage Regulation uality Factor (VR F)

• Uses proprietary sampling to measure fundamental voltage, Watts

and VArs at a rate of 240 times per half cycle

• Enhanced data output display with SLIMcom® software

Replaces Cooper CL-2, CL-4A, CL-4B,

and CL-4C Regulator Controls

–2–

M-2603 Autodaptive Regulator Control

The M-2603 Autodaptive®Regulator Control is a unique microcontroller-based solution to regulator control

requirements. Using conventional Cooper Regulator inputs, the control accomplishes regulator control,

based on voltage. Communication and control features of the M-2603 are accomplished utilizing either

M-2802 SLIMcom®for Windows™from a PC platform, or M-2808 SLIMcom for Visor™Communications

Software.

Features

The M-2603 Autodaptive Regulator Control includes a user-defined Bandcenter and Voltage Regulation

Quality Factor (VRQF) that permits optimization of the tapchanging process. Also included are: a DRAG

HANDS RESET button, a VOLTAGE SOURCE selector switch and binding posts for Motor Power, Control

Voltage and Voltage Test. Separate fuses for motor power, control, relays and the neutral circuit are located

on the rear of the panel.

Configurable setpoints include:

Bandcenter: Adjustable from 90.0 V to 135.0 V in 0.1 V increments.

Bandwidth: 1 V, predetermined by regulator step size.

VRQF: Adjustable from 0.4 V to 2.0 V in 0.1 V increments.

CT to VT Phasing Correction: Adjustable from 0° to +330° in 30° increments.

VT User Correction Voltage: VT correction from –12 V to +12 V in 0.01 V increments.

CT User Correction Multiplier: Adjustable from 50% to 200%, in 1% increments.

Voltage Limiting: Upper Voltage Limit adjustable from 90 V to 136 V, Lower Voltage Limit adjustable from

89 V to 135 V.

Line Drop Compensation: R & X (forward and reverse) adjustable from –24 V to +24 V in 1 V increments.

Intertap Minimum Delay: Adjustable from 5 seconds to 15 seconds in 0.1 second increments.

VAr Bias Setpoints:

Largest Cap Bank

: Adjustable from 0 KVAr to 11057 KVAr.

Control Functions

Presettable Operations Counter: This software counter increments by one or two counts (user-selectable)

per close/open cam switch operation, and may be preset by the user from 0 to 999,999.

Resettable Operations Counter: A second software counter, similar to the operations counter, which may

be reset by the user.

Inputs

Control Voltage Input: Nominal 120 V ac, 60 Hz; operates properly from 80 V ac to 140 V ac. The burden

imposed on the input is 6 VA or less.

Motor Power Input: Nominal 120 V ac or 240 V ac, 60 Hz, at up to 6 A.

Line Current Input: Line drop compensation is provided by a current transformer input with a 0.2 A full scale

rating. The burden imposed on the current source is 0.03 VA or less, at 200 mA. The input will withstand 400

mA for two hours and 4 A for 1 second.

The unit will withstand twice the voltage input for one second, and four times the voltage input for one cycle.

Fuse protected for voltage above these limits.

Front Panel Controls

AUTO/MANUAL switch:Selects operational mode of regulator.

RAISE/OFF/LOWER switch: Provides manual tap position control.

VOLTAGE SOURCE: Allows the selection of either an internal or external voltage source.

–3–

M-2603 Autodaptive Regulator Control

LED Indicators

The front panel LED indicators alert the user to the following conditions:

Out-of-Band RAISE and LOWER (3 position): GREEN (Initial Timing), AMBER (switch operation in 1 to 5

minutes), RED (switch operation in 1 minute or less).

CPU OK, flashing GREEN, indicates the control is working properly.

REV PWR, RED, indicates a reverse power condition exists.

NEUTRAL LIGHT, AMBER, indicates regulator is in the neutral position.

Output Contacts

Raise Output: Capable of switching 6 A at 120 V ac to 240 V ac motor power.

Lower Output: Capable of switching 6 A at 120 V ac or 240 V ac motor power.

Voltage Measurement Accuracy

Voltage accuracy of K0.7% in accordance with ANSI/IEEE C57.15-1986 defining control accuracy of

operation.

Communications

Serial communications is available via a front panel-mounted, optically-isolated RS-232 serial data port in a

DE 9-pin configuration, with available data rate of 9600 baud.

Environmental

Temperature: Stated accuracies maintained from –40°C to +80°C.

Humidity: Stated accuracies are maintained up to 95% relative humidity (non-condensing).

Fungal Resistance: A conformal coating is used on the printed circuit board to inhibit fungal growth.

Transient Protection

High Voltage: All input and output terminals will withstand 1500 V ac to chassis or instrument ground for one

minute, for all terminals to ground with a leakage current of less than 25 mA. Input and output circuits are

electrically isolated from each other, from other circuits and from ground.

Surge Withstand Capability: All input and output circuits are protected against system transients. Units

pass all requirements of ANSI/IEEE C.37.90.1-1989 defining surge withstand capability.

Radiated Electromagnetic Withstand Capability: All units are protected against electromagnetic radiated

interference from portable communications transceivers.

Electrostatic Discharge Sensitivity: Per IEC 1000–4.

Physical

Size: 17-5/8" high x 10-1/8" wide x 2-3/8" deep (52.71 cm x 25.72 cm x 5.6 cm)

Mounting: Mechanically interchangeable with existing Cooper equipment.

Approximate Weight: 4 lbs, 13 oz (2.18 kg)

Approximate Shipping Weight: 10 lbs (4.54 kg)

Accessories

M-2802 SLIMcom®for Windows™

M-2808 SLIMcom for Visor™

Metering

The following measured and calculated parameters are available in real-time:

•PrimaryVoltage •Primary Current •Power Factor

•KWatts** •KVArs** •KVA**

•Secondary Voltage •Secondary Current •VRQF✝

•CT Phasing •Avg Taps/Day •Tap Position

•Preset Counter •Alarm Status •Voltage Profile

Historical Data Plot

•Up to seven time-stamped analog calculated or measured values

•1 digital parameter can be plotted

■NOTE: All stored data available with time stamp. Five minute averaged samples are stored 111 days.

Sampling rate adjustable from 5 to 60 minutes, with resultant change to storage period.

Voltage Outage Plot

•Voltage plots (previous 10 seconds of data) for the last 4 voltage outage events are displayed.

Tap Statistics Plot

•The Tap Statistics Plot presents a graphical representation of tap position usage history.

Other

•Prints detailed reports of all setpoints and data.

•Entry and Readout of setpoints.

**Value calculated in SLIMcom

.

All primary quantities are also calculated in SLIMcom.

✝

VRQF is the RMS deviation in the fundamental component of an AC voltage from a desired AC voltage. It is computed as the

square root of the sum of the squares of deviations in the fundamental component of the voltage from the desired value. The

sum is computed as a running recursive average of frequently taken samples of the fundamental component, obtained in at

least one full cycle of the wave. The time constant of the recursive computation is 6 hours. The recursive average takes at

least six hours to settle to a proper sum, and is generally never stopped, once started.

M-2931 Handspring™Visor™Deluxe, with SLIMcom for Visor Communications Software

Patents

The M-2603 Autodaptive®Regulator Control is covered by U.S. Patents, 5,315,527, 5,554,064, 5,541,498

and 5,530,338 with other patents pending.

Warranty

The M-2603 Autodaptive Regulator Control is covered by a two year warranty from date of shipment.

Specification subject to change without notice.

BECKWITH ELECTRIC CO., INC.

6190 - 118th Avenue North • Largo, Florida 33773–3724 U.S.A.

Phone (727) 544-2326 • FAX (727) 546-0121

E-MAIL [email protected]

WEB PAGE www.beckwithelectric.com

© 2000 Beckwith Electric Co.

Printed in U.S.A.

800-2603-SP-01 09/01

WARNING

DANGEROUS VOLTAGES, capable of causing deat or serious

injury, are present on t e external terminals and inside t e equip-

ment. Use extreme caution and follow all safety rules w en an-

dling, testing or adjusting t e equipment. However, t ese internal

voltage levels are no greater t an t e voltages applied to t e exter-

nal terminals.

DANGER! HIGH VOLTAGE

– This sign warns that the area is connected to a dangerous high voltage, and you

must never touch it.

PERSONNEL SAFETY PRECAUTIONS

The following general rules and other specific warnings throughout the manual must be followed during application,

test or repair of this equipment. Failure to do so will violate standards for safety in the design, manufacture, and intended

use of the product. Qualified personnel should be the only ones who operate and maintain this equipment. Beckwith

Electric Co., Inc. assumes no liability for the customer’s failure to comply with these requirements.

–This sign means that you should refer to the corresponding section of the operation

manual for important information before proceeding.

Always Ground the Equipment

To avoid possible shock hazard, the chassis must be connected to an electrical ground. When servicing

equipment in a test area, the Protective Earth Terminal must be attached to a separate ground securely

by use of a tool, since it is not grounded by external connectors.

Do NOT operate in an explosive environment

Do not operate this equipment in the presence of flammable or explosive gases or fumes.To do so would

risk a possible fire or explosion.

Keep away from live circuits

Operating personnel must not remove the cover or expose the printed circuit board while power is ap-

plied. In no case may components be replaced with power applied. In some instances, dangerous volt-

ages may exist even when power is disconnected.To avoid electrical shock, always disconnect power and

discharge circuits before working on the unit.

Exercise care during installation, operation, & maintenance procedures

The equipment described in this manual contains voltages high enough to cause serious injury or death.

Only qualified personnel should install, operate, test, and maintain this equipment. Be sure that all per-

sonnel safety procedures are carefully followed. Exercise due care when operating or servicing alone.

Do not modify equipment

Do not perform any unauthorized modifications on this instrument. Return of the unit to a Beckwith

Electric repair facility is preferred. If authorized modifications are to be attempted, be sure to follow

replacement procedures carefully to assure that safety features are maintained.

PRODUCT CAUTIONS

Before attempting any test, calibration, or maintenance procedure, personnel must be completely familiar

with the particular circuitry of this unit, and have an adequate understanding of field effect devices. If a

component is found to be defective, always follow replacement procedures carefully to that assure safety

features are maintained. Always replace components with those of equal or better quality as shown in the

Parts List of the Instruction Book.

Avoid static charge

This unit contains MOS circuitry, which can be damaged by improper test or rework procedures. Care

should be taken to avoid static charge on work surfaces and service personnel.

Use caution when measuring resistances

Any attempt to measure resistances between points on the printed circuit board, unless otherwise noted

in the Instruction Book, is likely to cause damage to the unit.

i

Table of Contents

Table of Contents

M-2601/02/03 Autodaptive®Regulator

Control

Instruction Book

Chapter 1 Introduction

1.0 Description .......................................................................................... 1–1

Use of LDC ......................................................................................... 1–2

1.1 Accessories ........................................................................................ 1–2

Chapter 2 Front Panel Controls

2.0 Introduction ......................................................................................... 2–1

2.1 COMM Port......................................................................................... 2–1

2.2 Status Indicators ................................................................................ 2–1

Chapter 3 Installation

3.0 Installation .......................................................................................... 3–1

3.1 Installation of the M-2601 .................................................................. 3–1

Removal of the Siemens Control ...................................................... 3–1

Installation of the M-2601 .................................................................. 3–4

3.2 Installation of the M-2602 .................................................................. 3–6

Removal of the General Electric Control .......................................... 3–7

Installation of the M-2602 .................................................................. 3–8

3.3 Installation of the M-2603 ................................................................ 3–10

Removal of the Cooper Control ....................................................... 3–11

Installation of the M-2603 ................................................................ 3–12

3.4 Transient Protection ......................................................................... 3–14

3.5 External Connections ....................................................................... 3–14

ii

M-2601/02/03 Autodaptive Regulator Control Instruction Book

Chapter 4 Applications

4.0 Introduction ......................................................................................... 4–1

VRQF .................................................................................................. 4–1

VAr Bias ............................................................................................. 4–2

4.1 Measurements & Calculations ........................................................... 4–2

Voltage Measurements ...................................................................... 4–2

Current Measurements ....................................................................... 4–2

Rails and Limits ................................................................................. 4–3

4.2 Voltage Regulation ............................................................................. 4–3

Standard Control Settings .................................................................. 4–3

Password Applicability ....................................................................... 4–3

Bandcenter .......................................................................................... 4–3

Voltage Regulation Without LDC ....................................................... 4–3

Voltage Regulation With LDC ............................................................ 4–3

4.3 Regulation Limits ................................................................................ 4–5

Upper Voltage Limit............................................................................ 4–5

Lower Voltage Limit............................................................................ 4–5

Tap Position Limits ............................................................................ 4–5

4.4 Non-Sequential/Blocking .................................................................... 4–5

4.5 Counters.............................................................................................. 4–5

Operations Counter ............................................................................ 4–5

4.6 CT/VT Phase Shift ............................................................................. 4–5

4.7 Ratio Multipliers .................................................................................. 4–6

VT User Correction Voltage ............................................................... 4–6

CT User Correction Voltage ............................................................... 4–6

Primary Voltage and Current Multipliers ........................................... 4–6

4.8 Tap Position ....................................................................................... 4–6

Tap Position by Keep Track.............................................................. 4–6

Chapter 5 Communications

5.0 Introduction ......................................................................................... 5–1

Chapter 6 Field Operation Verification

6.0 Bench Test ......................................................................................... 6–1

6.1 Post-Installation Test ......................................................................... 6–4

iii

Table of Contents

Chapter 7 SLIMcom™

7.0 Introduction ......................................................................................... 7–1

7.1 Installation and Setup ........................................................................ 7–1

Hardware Requirements ..................................................................... 7–1

Installation .......................................................................................... 7–3

System Setup..................................................................................... 7–3

7.2 Description .......................................................................................... 7–3

Primary Status.................................................................................... 7–4

Secondary Status ............................................................................... 7–4

Tap Position Clock............................................................................. 7–4

Alarm LED Indicators ......................................................................... 7–4

Biasing Display Bar............................................................................ 7–4

Timing and Misc Display Bar ............................................................ 7–4

File Menu ............................................................................................ 7–5

Load Data Submenu ........................................................................... 7–5

Setup Menu ........................................................................................ 7–7

Security Menu .................................................................................... 7–7

Change Passwords Command ........................................................... 7–8

Password Entry Command ................................................................ 7–8

Commands Menu................................................................................ 7–8

Setpoints Command ........................................................................... 7–8

Parameters.......................................................................................... 7–9

Alarms ............................................................................................... 7–10

Time .................................................................................................. 7–10

Counters............................................................................................ 7–10

VAr Control ....................................................................................... 7–10

Inhibit On/Off .................................................................................... 7–10

Voltage Bias Command ................................................................... 7–10

Selections Command ....................................................................... 7–11

Graph Selections Table ................................................................... 7–11

Metering Setpoints Selection Table ................................................ 7–12

Erase Control Submenu ................................................................... 7–12

Retrieve Data Menu ......................................................................... 7–12

History Data...................................................................................... 7–12

Outage Data ..................................................................................... 7–12

Tap Statistics ................................................................................... 7–12

Metering Data ................................................................................... 7–12

M-2501 Import .................................................................................. 7–12

Window Menu ................................................................................... 7–13

Help Menu......................................................................................... 7–13

Appendix A Communications

A.0 Null Modem Cable ..............................................................................A–1

iv

M-2601/02/03 Autodaptive Regulator Control Instruction Book

Figures Page

Chapter 1 Introduction

1-1 Functional Diagram ........................................................................... 1–2

Chapter 2 Front Panel

2-1 M-2601 Front Panel............................................................................ 2–2

Chapter 3 Installation

3-1 M-2601 Outline Dimensions ............................................................... 3–2

3-2 Siemens Control in Cabinet ............................................................... 3–3

3-3 M-2601 Autodaptive®Regulator Control in Cabinet .......................... 3–4

3-4 M-2601 External Connections ............................................................ 3–5

3-5 M-2602 Outline Dimensions ............................................................... 3–6

3-6 General Electric Control in Cabinet ................................................... 3–7

3-7 M-2602 Autodaptive Regulator Control in Cabinet ............................ 3–8

3-8 M-2602 External Connections ............................................................ 3–9

3-9 M-2603 Outline Dimensions ............................................................. 3–10

3-10 Cooper Control in Cabinet ................................................................ 3–11

3-11 M-2603 Autodaptive Regulator Control in Cabinet .......................... 3–12

3-12 M-2603 External Connections .......................................................... 3–13

Chapter 6 Test Procedure

6-1 External Connections for Test Procedure ......................................... 6–2

Chapter 7 SLIMcom™

7-1 SLIMCom Main Menu Flow................................................................ 7–2

7-2 Metering Status Screen ..................................................................... 7–3

7-3 History Data Screen ........................................................................... 7–5

7-4 Tap Statistics Screen ........................................................................ 7–6

7-5 Outage Screen.................................................................................... 7–6

7-6 Setup Communications Screen ......................................................... 7–7

7-7 Identification Dialog ............................................................................ 7–7

7-8 Change Level Access Code .............................................................. 7–8

7-9 Passwords Entry Submenu................................................................ 7–8

v

Table of Contents

Figures (

cont

)Page

Chapter 7 SLIMcom (

cont

)

7-10 Setpoints Dialog Box ......................................................................... 7–9

7-11 Tap Position Setpoints .................................................................... 7–11

7-12 Graph Selections .............................................................................. 7–11

7-13 Metering Selections.......................................................................... 7–12

7-14 Metering Data ................................................................................... 7–13

Appendix A Communications

A-1 Null Modem Cable, 9-pin to 9-pin ......................................................A–1

Tables Page

4-1 Level 1 Password Adjustable Parameters ........................................ 4–4

4-2 Approximate Ratio of Line Reactance to

Resistance (X/R) of Typical Distribution Circuits ............................. 4–4

800-2601/02/03-IB-00 11/00

© 2000 Beckwith Electric Co.

Printed in U.S.A. (11.06.00)

This manual suits for next models

2

Table of contents

Popular Microcontroller manuals by other brands

Texas Instruments

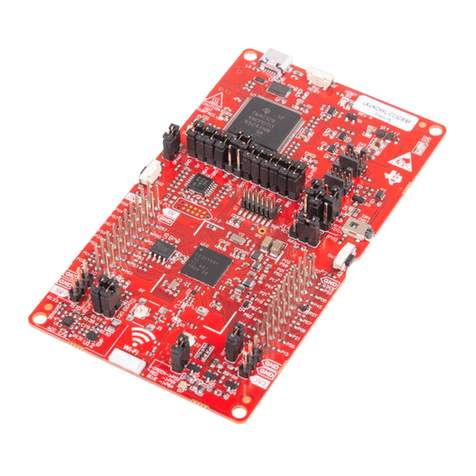

Texas Instruments CC3235 SimpleLink Series user guide

Renesas

Renesas 78K0/FB2-L user manual

NXP Semiconductors

NXP Semiconductors KE1xF Series Reference manual

Microchip Technology

Microchip Technology PD-95-10GC Series user guide

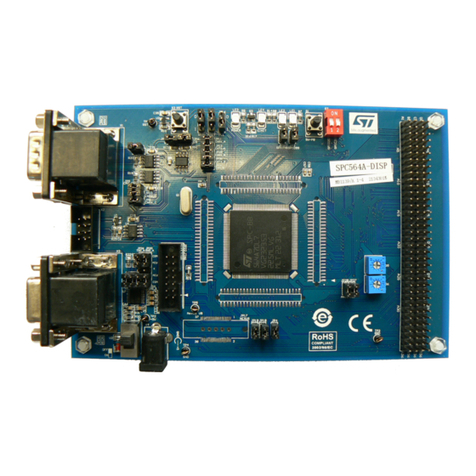

ST

ST SPC56A Series user manual

Nuvoton

Nuvoton NuMicro M0A21 Series Technical reference manual