Assembly-Programming-Instructions_Cold-Rack_e_05-10-2018 Page 2

Contents

1 Installation and commissioning ............................................................................................4

1.1 Acceptance ...................................................................................................................4

1.2 Place of installation .......................................................................................................4

1.3 Preparation....................................................................................................................5

1.4 Mobile version...............................................................................................................5

1.5 Installation options.........................................................................................................5

1.6 Connection to the customer's integrated system............................................................5

1.7 Possible installation of the control panel for the installation variant................................6

1.8 Step-by-step instructions for installation and commissioning.........................................9

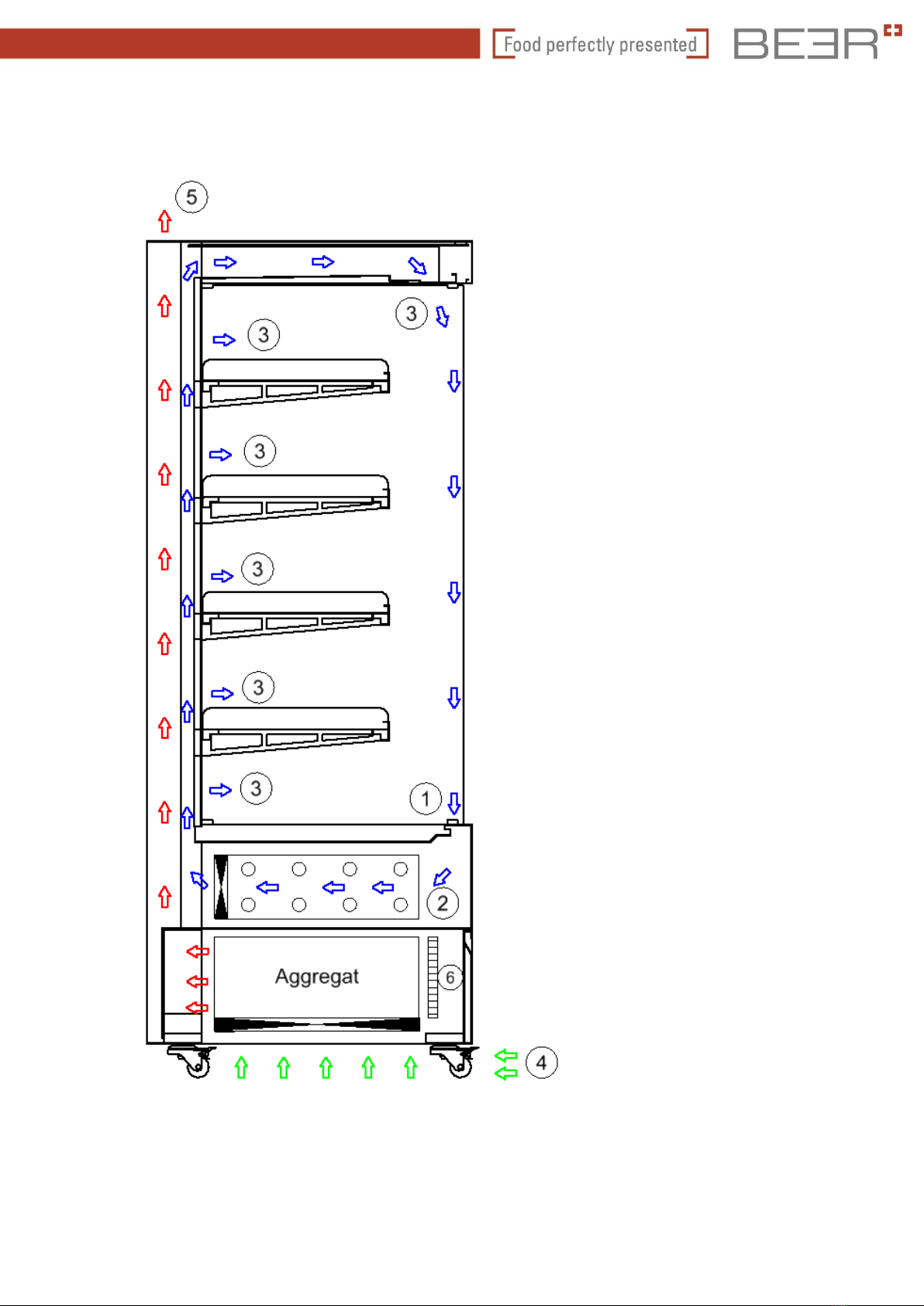

1.9 Functionality of the showcase, air ducts ......................................................................10

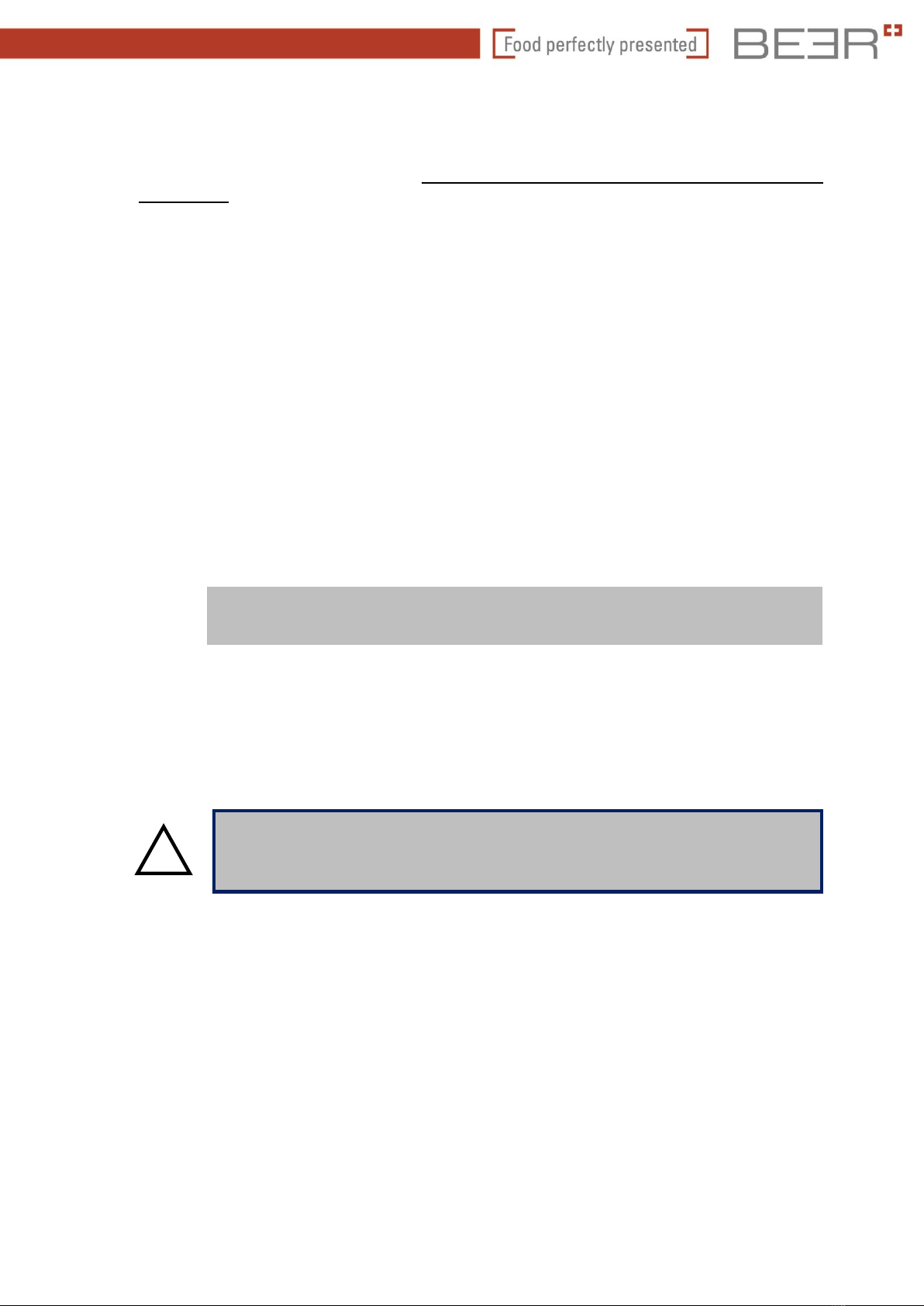

1.10 Avoiding the worst error in installation .........................................................................11

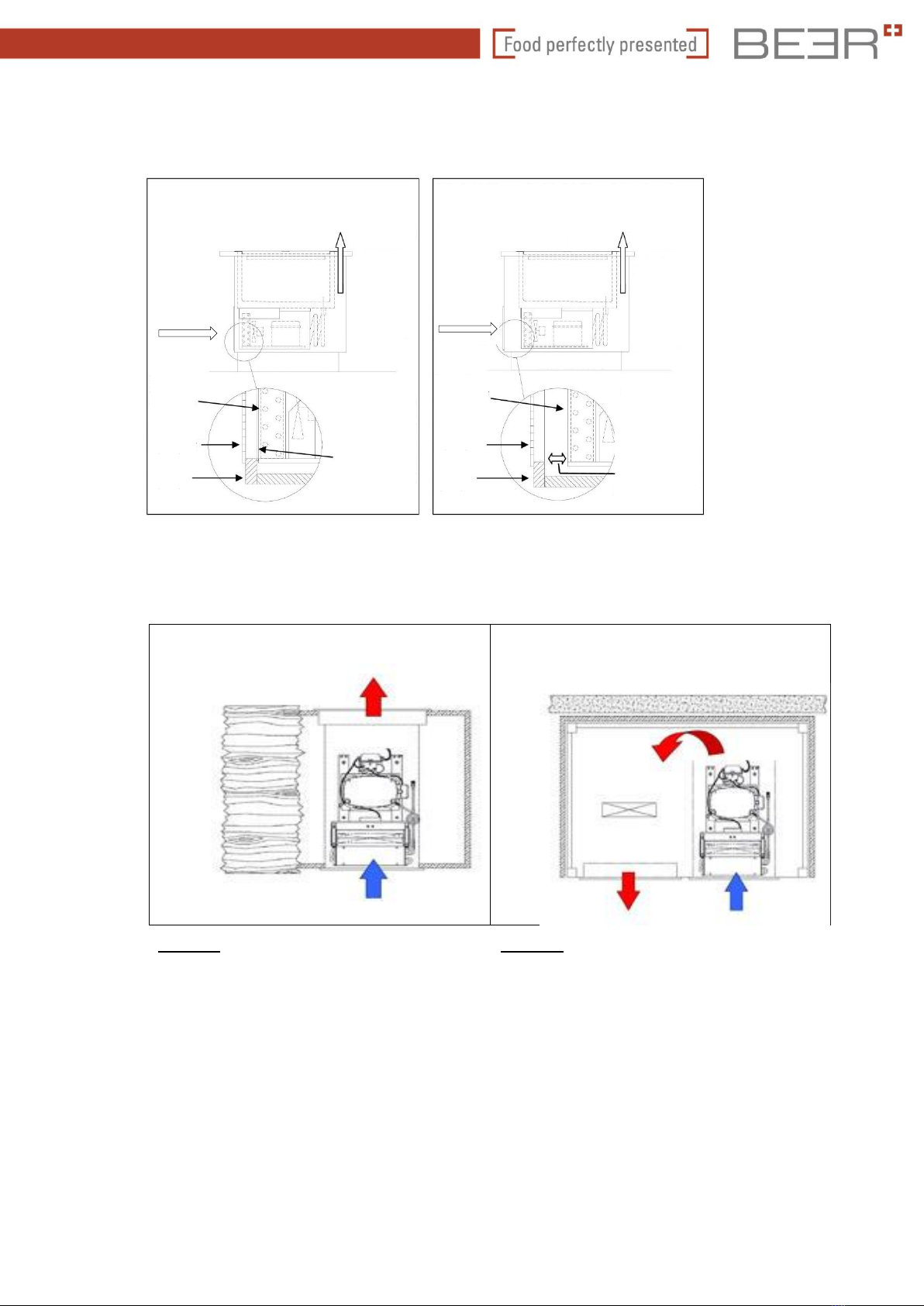

1.11 Two installation options...............................................................................................12

1.12 Air routing for self-cooled appliances...........................................................................12

1.13 Drawings and technical data........................................................................................14

1.14 Installation and mounting instructions for wall positioning............................................14

2 General information concerning the control unit.................................................................14

2.1 Product description......................................................................................................14

2.2 Control box circuit diagram..........................................................................................15

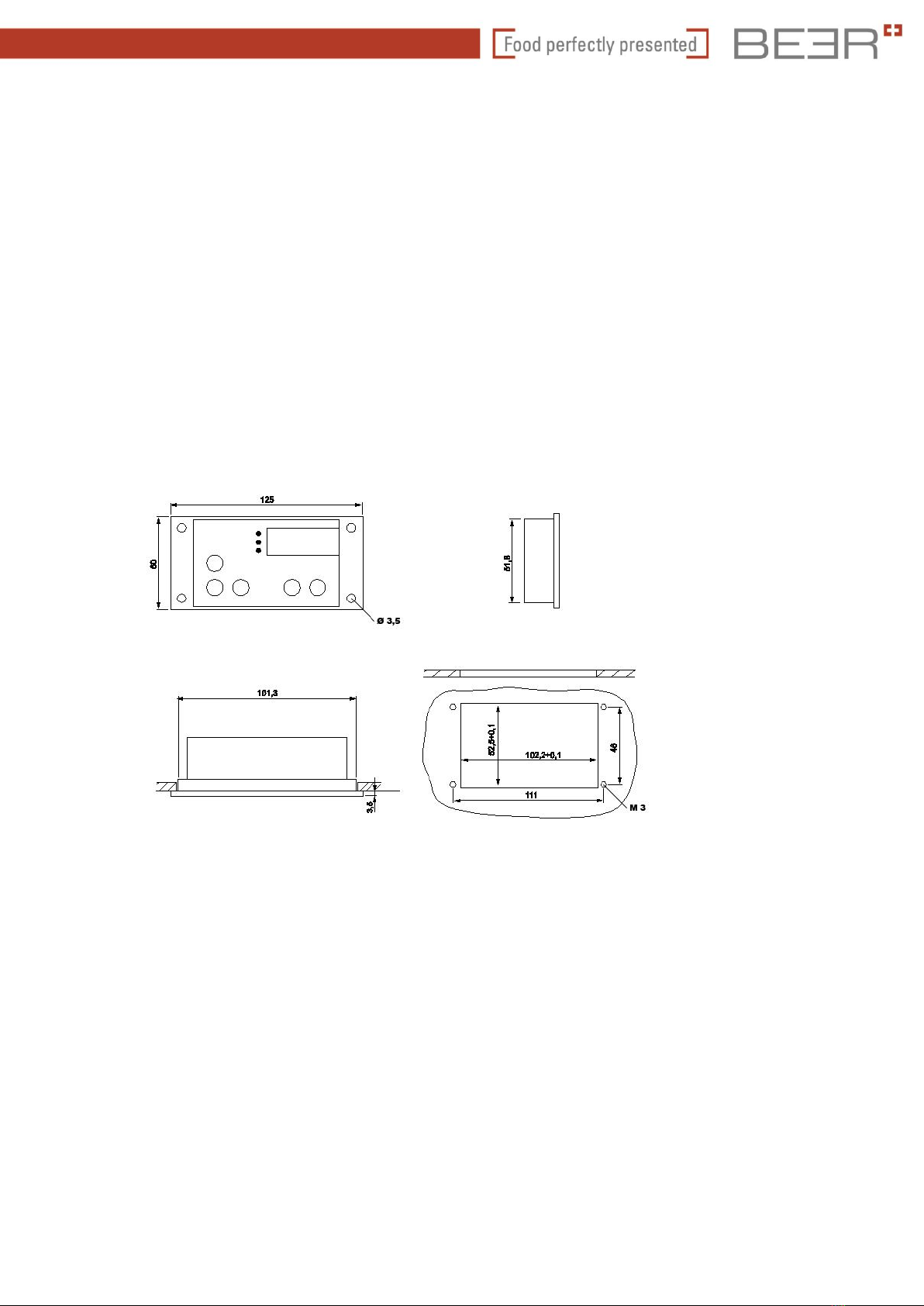

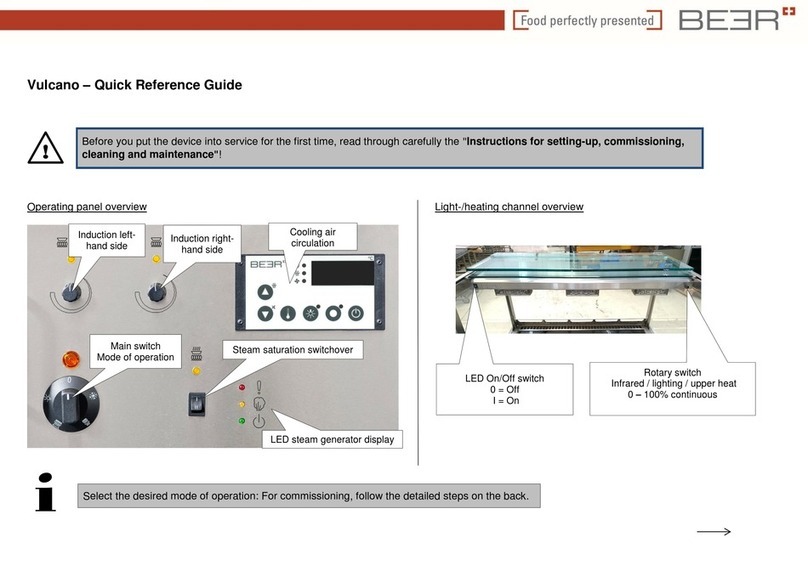

2.3 Operating panel (display) ............................................................................................16

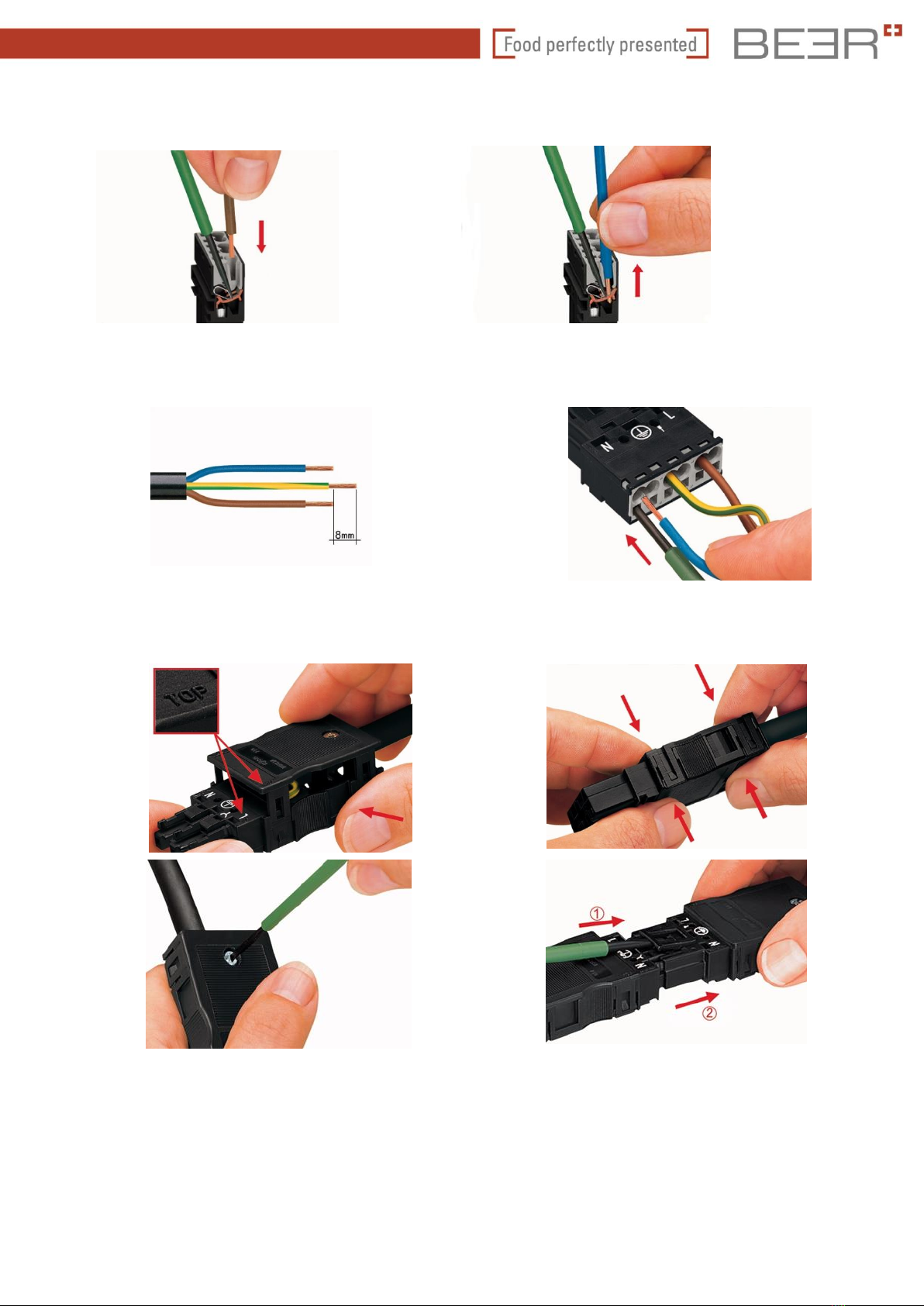

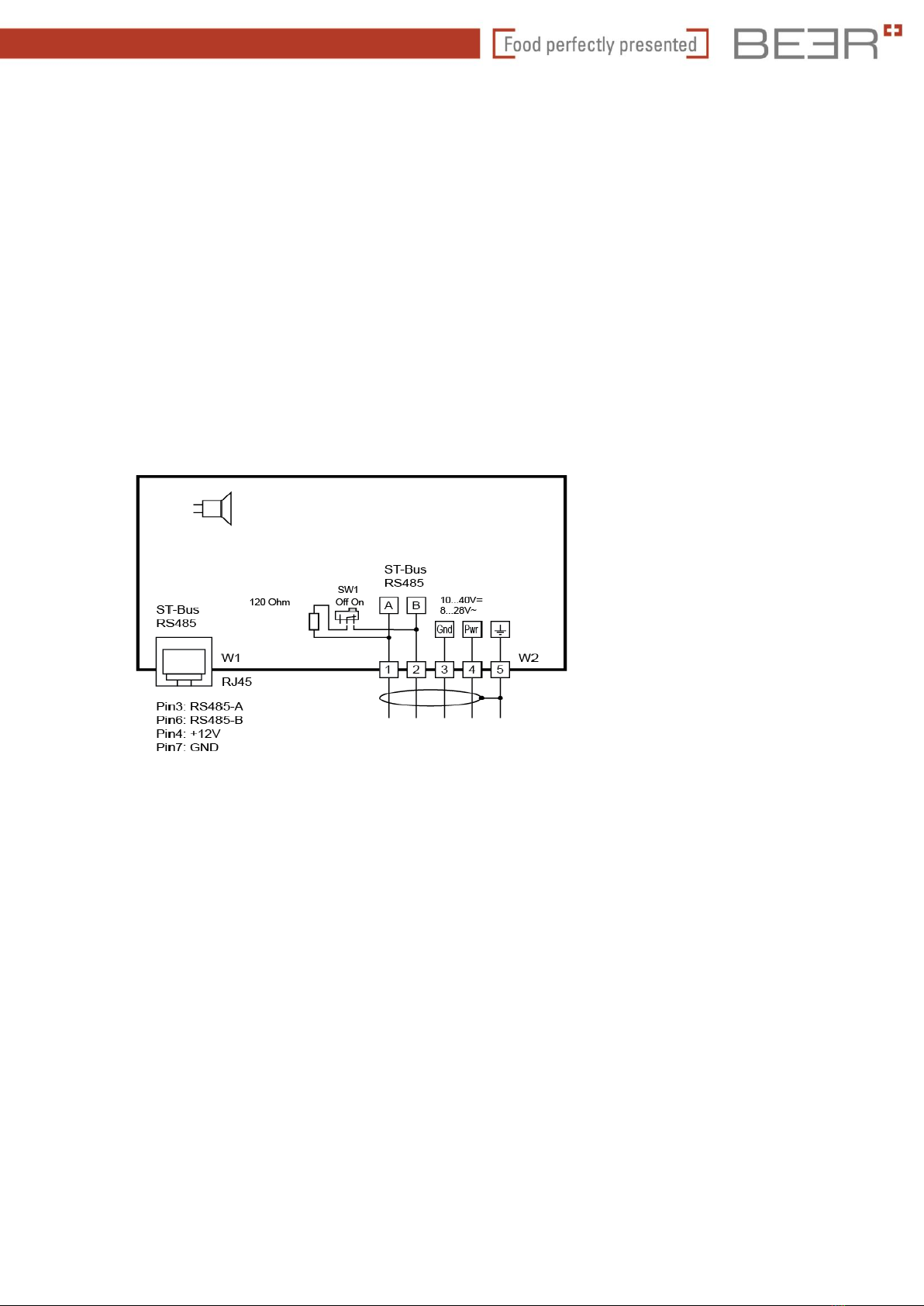

2.4 Wiring diagram............................................................................................................17

3 Parametrisation..................................................................................................................18

3.1 Description of the operating keys.................................................................................19

3.2 Parametrisation information.........................................................................................20

3.3 Status displays and error messages............................................................................26

3.4 Technical data for display:...........................................................................................27

4 Technical data of the control system..................................................................................28

4.1 ST-Box parameter groups ...........................................................................................28

4.2 Most important variable parameter values, basic parameters......................................29

4.3 Status messages.........................................................................................................41

4.4 Error messages...........................................................................................................41

4.5 Parameter description .................................................................................................42

4.6 Technical data for control box ST 200.........................................................................52

5 Customer service...............................................................................................................53