Instructions manual CHEF 10 VVE 3 of 19

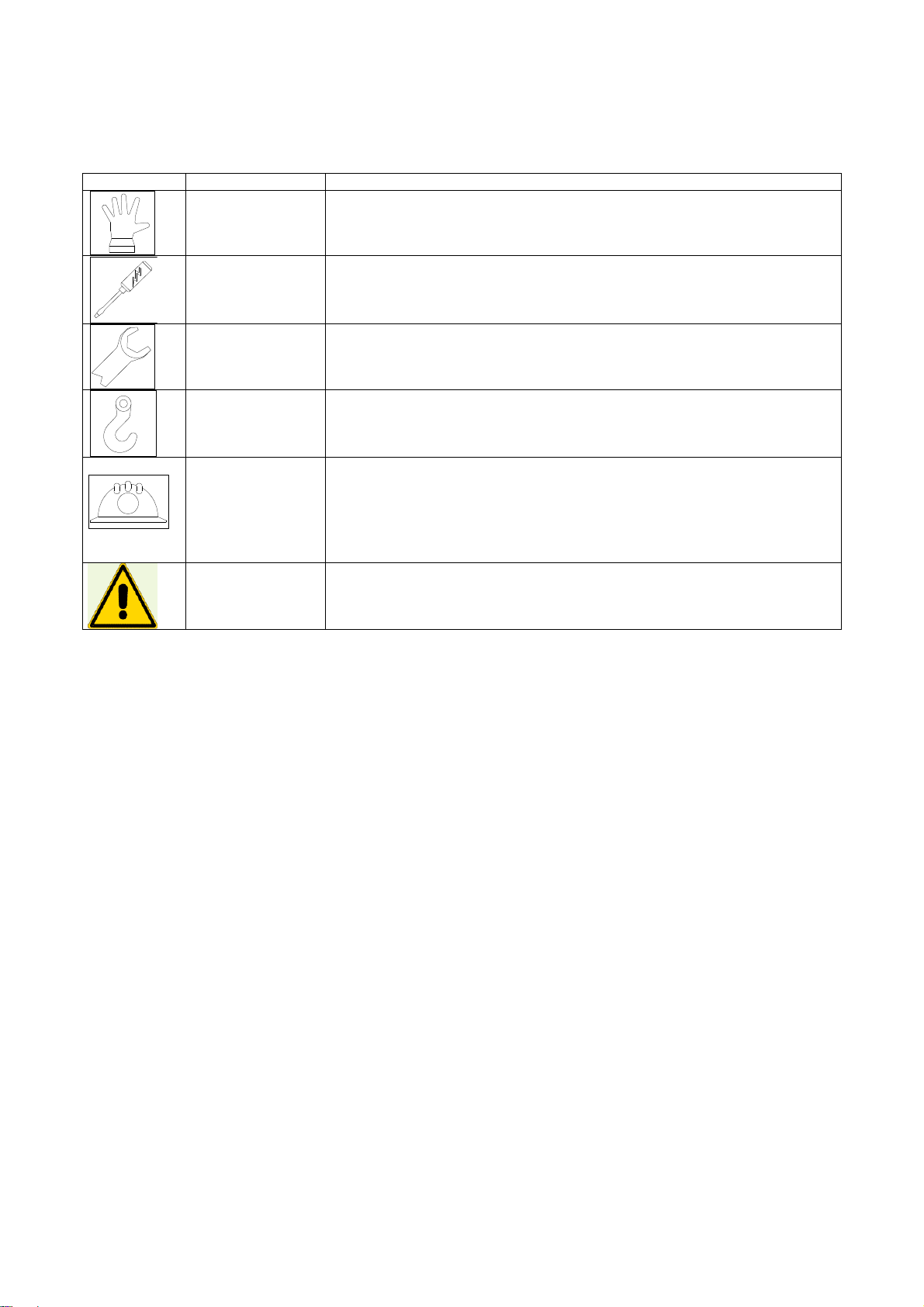

SAFETY INSTRUCTIONS.

The safe and systematic use of the mixer is subordinated to compliance with behaviour and standards listed

hereafter.

Safety standards

Personnel must be in good physical and mental conditions and be adequately instructed on the use

of the mixer having read this publication.

The safety manager of the company, of the operating area and of the department, when choosing

the person who must use this equipment (a person suitable for the job according to Standards in

force), must consider his/her cultural preparation, physical suitability and the psychological aspect

(mental stability, sense of responsibility, etc.). Moreover, based on the attitudes and capacity that

were verified, the manager must provide this person with proper training, having him/her read the

present publication, in order to have full knowledge of the mixer and of the rules of behaviour

applying to it.

The area around the mixer must be well lit, free from other objects and clean.

The personnel in charge of running, cleaning and carrying out maintenance on the mixer must wear

the required PPE (personal protective equipment).

Do not wear dangling clothing or fluttering hems (ties, napkins, torn suits, open jackets etc.) to avoid

getting entangled.

During maintenance and cleaning, the operator must disarm the master switch and place the system

in safe conditions (for example, removing the plug).

Never leave the mixer unattended while it is running. Be careful of abnormal noises or behaviour.

Keep away from rotating parts. Never open the grid before the equipment has come to a complete

stop.

At the end of work, empty the machine completely, disconnect the master switch cutting the power,

place it in safe conditions and clean it with a neutral degreasing agent (i.e. with Marseille soap).

Safety devices.

The mixer is equipped with some devices which protect its operation as well as the safety of the operator.

They must not be removed or modified. Their functioning must be checked periodically.

Master switch: cuts power from the mixer, for maintenance in safe conditions.

Circuit breaker switch: cuts power if the electric motor overheats.

Fixed guards: All casings and guards fixed with screws or mechanical locks can be removed only for

maintenance, by specialised personnel and in the prescribed modalities. When the work is over, they

must be mounted immediately.

Mobile guards: Movement of the grid activates a micro switch which prevents the mixer from running

if the grid is open. If the grid is lifted while the mixer is running, it stops the cycle unconditionally, just

like an emergency stop. The start button must be pressed for the mixer to restart.

Safety Standards applied to the mixer.

EN 292 Safety of machinery.

EN 294 Minimum distances to prevent accidental contact.

CEI 17-13. Low-voltage switchgear and controlgear assemblies.

Community Directives: 89/392/EEC, 89/336/EEC, 91/368/EEC, 93/44 EEC, 93/68 EEC.

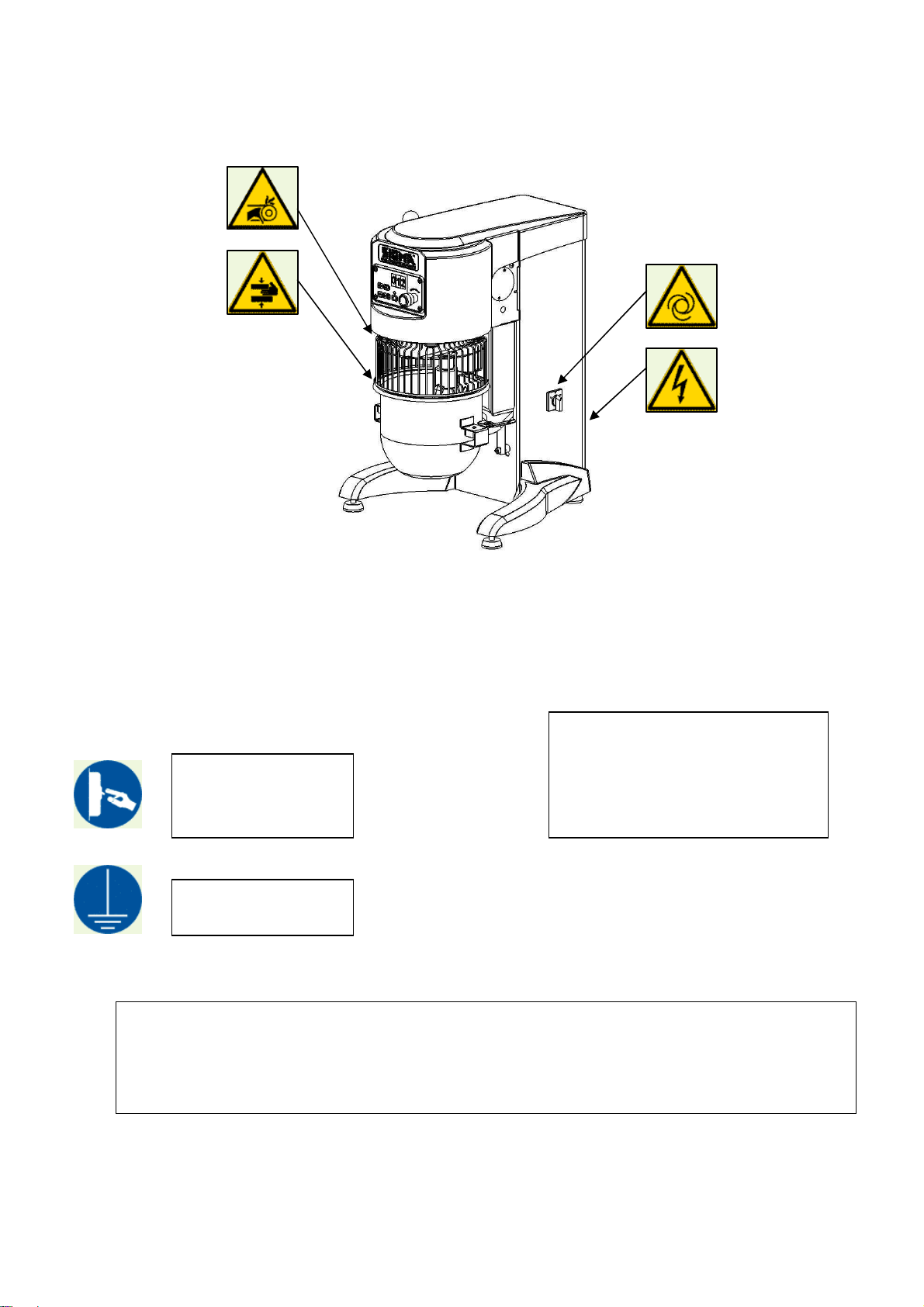

RESIDUAL RISKS

Danger for limbs: Going beyond the protective grid or removing the casing during maintenance, it is

possible to access the moving organs of the mixer.

They are dangerous areas where serious physical injuries can occur. Do not introduce limbs or other

objects without having placed the mixer in safe conditions.

Danger of electrocution: the mixer must not operator without an adequate earthing system. It must

be connected to a system built in compliance with construction standards in force in the country

where it is installed.

Automatic cycle: after starting up the mixer, it follows an automatic operating cycle. Never go past

the safety barriers with your limbs or other objects while it is running.