BEIJING CAP HIGH TECHNOLOGY KUB100 Series User manual

www.capitalinstrument.com

Digital Ultrasonic Flaw Detector KUB100 series

KUB100 series are portable and digital Ultrasonic Flaw Detector, the detector can rapidly,

non-destructively and accurately test, locate and evaluate multi-defects, such as welding bead,

crack, slag and blowhole etc.. The detector can be used in the laboratory, also can be used at the

project site. The detector is widely used in the manufacturing, steel metallurgy, metal processing

industry, chemistry etc. that the fields need testing defect and control ling quality, it is also widely

used in in-service inspection and life span evaluation for the fields of aircraft, railway traffic,

boiler, pressure vessels etc.

Safety tips

◇The detector is the device for industry ultrasonic non-destructive testing, can not use to

medical testing;

◇To ensure safety operation, the operator must have special knowledge of non-destructive

testing;

◇The detector must be used under allowed environment condition, especially, the detector can

not be used under the strong magnetic field and strong corrosion environment;

◇To avoid unnecessary loss and ensure safety, please operate the detector according to the

manual.

◇Contact us when the detector appear fault, please don’t disassemble and repair it by yourself.

Declaration:Our company has no responsibilities for any consequences caused by misuse,

please operate the detector in proper according to the manual.

Features

KUB100 series Ultrasonic Flaw Detector are all digital, and have features of high speed, high

accuracy, high efficiency, high reliability, good over-all properties, and real-time operation. The

detectors designed using advance technology, so they have outstanding site properties.

Multi-channel inspection, you can choose save as, it is useful for inspection.

Large capacity storage for waveform, the waveform can be loaded.

High speed and long time video for inspection process.

Multi- shortcuts key, menu operation, digital shuttle roller, convenient to operate, advanced

technology.

◇TFT color screen with 5.7 inches,the color and bright can be set according to environment.

◇Disassemble battery, online charging, offline charging and charge while working, convenient

to change battery. Long time working outside and no worries. Small volume, light weight and

portable.

◇Damping match meets working requirement with different sensitivity and resolution .

◇Four working modes:normal probe,angle probe,dual-crystal probe,through probe.

◇Amplify receive

Real-time sample:high speed ADC,fully display the wave detail.

Rectify:Full, positive, negative, reflective

Gate:dual-gate , support time gate and sound path gate.

Gain:Multi-grade adjustable, has basic gain, scan gain, compensation gain, Support gain locked

and auto gain.

◇Alarm type

Beep alarm and led alarm.

◇Alarm condition

It can be chosen among wave in gate, wave out gate, wave in curve and wave out curve

◇Data save

The detector designs save shortcut key, very convenient to operate. The save as, load, play and

delete can be carried out quickly.

◇Inspection function

Peak memory:Search the highest wave in real-time, recording the maximum value of the defect.

Echo envelope:Peak trace depiction for defect echo, it provides detail info for judging defect.

Crack height measurement:Automatically measure and calculate crack height.

B-SCAN:Real-time scan, cross-section display, B-SCAN can display the workpiece shape which

make the result displayed directly.

Aperture:Auto calculating flaw equivalent i.e. Фvalue.

DAC、AVG:normal/angle probe inspect forged piece and the detector can find the highest wave of

the defect and automatically calculate equivalent Φ, the DAC and AVG can be done in section.

Record:Record waveform in real-time, save and play.

Defect location:Horizontal value L, depth H, sound path S.

Defect quantitative:Flexible displays according to setting reference.

Defect qualitative:Manual experience judgment by envelope waveform.

Curved surface correction:Inspection for curved surface workpiece, revise the curvity conversion.

◇Real-time clock record

Date, time tracking record and save.

◇Communication

High speed USB provides transportation data.

◇Screen protection

While standby,the screen bright will decrease or shut off automatically, this make the detector

save energy, and extend life span.

Functions

The functions of KUB100 series are shown in the Table 1.

Table 1 Functions of KUB100 series

MODEL KUB100 Series

FUNCTION KUB100 KUB110 KUB120 KUB130 KUB140

SCREEN TFT TFT TFT TFT TFT

DAC √ √ √ √ √

AVG ╳√ √ √ √

STANDARD INSIDE ╳√ √ √ √

GATE ALARM √ √ √ √ √

CURVE ALARM √ √ √ √ √

WAVE FREEZE √ √ √ √ √

CHANNEL 10 10 100 100 100

WAVE 100 100 1000 1000 1000

Video ╳5min×10 5min×20 5min×20 5min×20

60min×1 60min×1

AUTO CALIBRATION √ √ √ √ √

REJECT √ √ √ √ √

PEAK MEMORY √ √ √ √ √

ECHO ENVELOPE ╳√ √ √ √

THICKNESS B-SCAN ╳√ √ √ √

COLOR B-SCAN ╳ ╳ ╳ √ √

AUTO GAIN √ √ √ √ √

ECHO CODE ╳ ╳ √ √ √

APERTURE

CALCULATION

╳ ╳ √ √ √

WELDING GRAPH ╳ ╳ ╳ ╳ √

CRACK HEIGHT

MEASUREMENT

╳ ╳ ╳ ╳ √

CURVED SURFACE

CORRECTION

╳ ╳ √ √ √

PC SOFTWARE √ √ √ √ √

BATTERY 1 1 2 2 2

√:HAVE THE FUNCTION ╳:HAVE NO THE FUNCTION

Specifications

The specifications of KUB100 series are shown in the Table 2.

Table 2 Specifications of KUB100 series

KUB100 KUB110 KUB120 KUB130 KUB140

TESTING RANGE 0~6000mm 0~9999mm 0~25000mm

VELOCITY 1000~9999m/s 400~20000m/s

GAIN 0dB~110dB

DISPLAY DELAY -20µs~+3400µs

PROBE DELAY 0µs~99.99µs

FREQUENCY 0.2~10MHz 0.2~15MHz 0.2~20MHz

NOISE LEVEL ≤10%

PROBE DAMPING 100Ω,150Ω,200Ω,500Ω

PROBE RPEATING

FREQUENCY 10~1000Hz 10~2000Hz

SENSITIVITY >62dB(DEPTH: 200mm,FLAT-BOTTOM HOLE Ф2)

RESOLUTION >40dB(5P14)

LINEARITY REJECT 0~80%(DIGITAL REJECT)

VERTICAL LINEARITY

ERROR ≤3%

HORIZONTAL

LINEARITY ERROR ≤0.1%

DYNAMIC RANGE ≥32dB

PULSE SQUARE WAVE

PULSE ENERGY FIXED MULTI-GRADES ADJUSTABLE

PULSE WIDTH 50~300ns AUTO MATCH/ 50~1000ns

ENVIROMENT

TEMPERATURE -10℃~50℃

ENVIROMENT

HUMIDITY 20%~95%RH

POWER VOLTAGE DC:7.2V; AC:220V

WORKING HOURS ≥ 20 hours

SIZE 220×175×59(mm)

WEIGHT 1.3 kg including battery

Unit

The face of KUB100 series Ultrasonic Flaw Detector is shown in the Fig. 1.

Fig.1

⑴Keypad (2) Hand-belt (3)TFT screen (4) Power indicator (5)Alarm indicator

(6) Digital shuttle roller (7)supporter (8)USB port (9)Reset and off port

(10) Charging port (11) Receiving port (12) Receiving/transmitting port (13) Protecting shell

Keypad introduction

The detector keypad is as shown in the Fig.2.

Fig.2

function selecting keys

Down arrow, use to use to select KUB menu downward.

ENTER key, to confirm each operation.

Up arrow, use to select KUB menu upward.

Power indicator

Alarm indicator

Base function keys, it includes RANGE, GATES, GAIN, MODE and ECHO, the detail

info. refer to Table3.

Calibration function keys, it includes PROBE, CAL, ANGLE, PULSER and SETUP, the

detail info. refer to Table3.

Save function keys, it includes CHNL, WAVE, VIDEO, RESET and RESV, the detail info.

refer to Table3.

System function keys about the detector, it includes DISP, SCALE, ALARMS, SETUP

and INFO, the detail info. refer to Table3.

Function keys about the special function of the detector, it includes SCAN, WELD,

DIAM, CRACK and CSC, the detail info. refer to Table3.

Gate shortcuts key, the detail info about gate can be set directly by pressing GATE key.

Gain shortcuts key, the detail info about gain can be set directly by pressing GAIN key.

Channel shortcuts key, the detail info about channel can be checked directly by pressing

GAIN key.

Angle shortcuts key, the detail info about angle can be set and calibrated directly by

pressing ANGLE key

Curve function key, DAC and AVG can be switched by pressing CURVE key.

Expand shortcuts key, the wave in the gate will expand automatically by pressing

EXPAND key.

Color shortcuts key, you can directly set the color of the screen according to your

requirement by pressing COLOR key.

Parameter shortcuts key, you can enter into the parameter setting GUI to set each

parameter, it includes almost all parameters.

Standard shortcuts key, you can enter into the standard setting GUI to select the standard

according to your requirement.

Auto gain shortcuts key, the wave in the gate will arrive the reserved height ( default

value )

Peak memory shortcuts key, the peak memory and echo envelope will be opened or

switched by pressing PEK MEM key.

Record shortcuts key, the detector will directly enter into the video operation GUI, or

stop recording by pressing RECORD key.

The wave will be frozen by pressing FREEZE key.

Digital shuttle roller, mainly used to increase or decrease, step selection.

The keypad area is divided into three parts as shown in the Fig.2. The first part is the first row,

that is function selection key composed of F1,F2,F3,F4 and F5.You can select the function option

in accordance with the main menu below the screen by pressing these five keys.

Second part is the second row includes three basic operation buttons which are UP,ENTER,

DOWN key, different parameters at the right screen in the KUB menu can be switched by

pressing UP and DOWN key, press ENTER key to confirm operation and enter into the next

step.

The third part is the area of function group and shortcuts.

Menu structure

The menu structure of the KUB100 series is shown in the Table3.

BASE CAL SAVE SYSTEM CURVE FUNC

RANGE RANGEmm PROBE P-TYPE CHAN SELECT DISP LIGHT DAC DRAW AVG DRAW SCAN B-SCAN

MTLVELm/s P-FREQ SAVE COLOR DB-BAS

dB

DB-BAS

dB

B-DIR

D-DLY us X-VAL DELETE ECHO-H ECHO-H PERIOD

P-DLY us P-SIZE SAVE

AS

GSTART

mm

GSTART

mm

A-SCAN

GATES SELECT CAL AUTO WAVE SELECT SCALE GRID EDIT ADJUST EDIT ADJUST WELD PARAM

GSTART

mm

MANUAL SAVE UINITS mm INDEX INDEX

WIDTH mm FRONT LOAD H-AXIX ECHO-H ECHO-H

THRESH P-DLY DELETE GSTART GSTART

Table 3 Menu structure

mm

GAIN DB-BAS dB ANGLE AUTO VIDEO SELECT ALARMS KEY SND OFFSET DAC-RL OFFSET AVG-HL DIAM EOU

DIAM

DB-STP dB MANUAL RECORD BEEP ALM DAC-SL AVG-ML GSTART

DB-SCN dB ANGLE PLAY LED ALM DAC-EL AVG-LL P-SIZE

DB- CMP

dB

ANGLE-K DELETE ALM TYPE ALM

REF

ALM

REF

P-FREQ

MODE LOGIC PULSER ENERGY RESET ALL

CHNL

SETUP STANDARD SETUP FLAW

TYP

SETUP AVG

REF

CRACK HEIGHT

AUTOSNAP P-WIDTH ALL

WAVE

FLAW-D REF-D PT-A mm

DETECT PRF ALL

VDO

FLAW-L P-SIZE PT-B

mm

P-DAMP RECALL SHUTDOWN DAC

REF

P-FREQ GSTART

mm

ECHO RECTIFY SETUP THICK RESV INFO YY-MM-DD DISP DAC

SHOW

DISP AVG

SHOW

CSC O-DIAM

REJECT AUTO-80 HH:MM TYPE TYPE I-DIAM

FILL PEAK

MEM

FW VER FITTING FITTING CSC

ECHO ENC ENVELOPE OTHER DELETE DELETE

Table of contents

Popular Security Sensor manuals by other brands

Buckleys

Buckleys Calibration Pro operating instructions

Petzl

Petzl CONNECT ADJUST TECHNICAL NOTICE

Singing rock

Singing rock SIT WORKER SPEED STEEL General Instructions for Use

B.E.G. LUXOMAT

B.E.G. LUXOMAT PICO-DALILINK 93908 manual

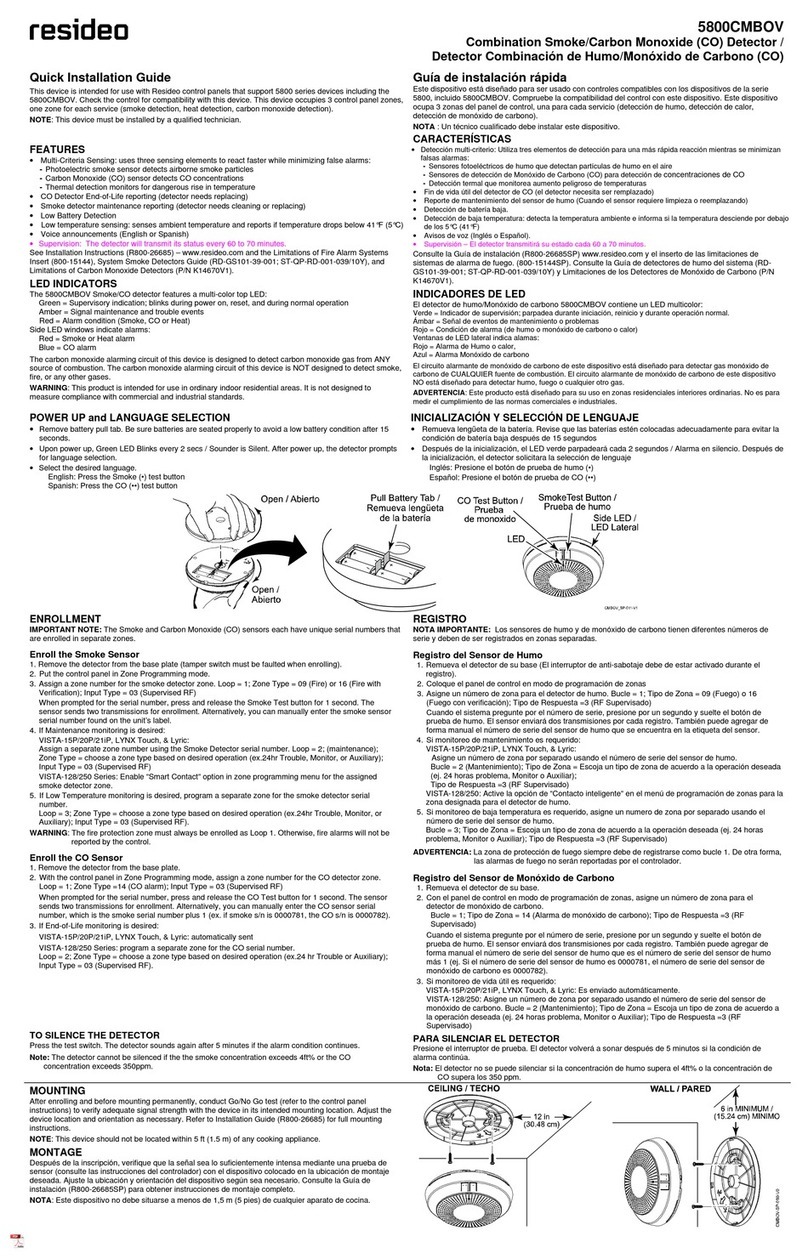

resideo

resideo 5800CMBOV Quick installation guide

MSA

MSA FlameGard 5 MSIR HART manual