4DE3561

3.10 Final Testing

Overriding the Rearm Timer

Since battery saving is of utmost importance in normal use of the

detector unit, an automatic timer inhibits the detector for

approximately 2 minutes after each transmission. During this

period, the transmitter cannot be triggered again by subsequent

motion within the protected area. The detector is automatically

rearmed 2 minutes after the last motion was detected.

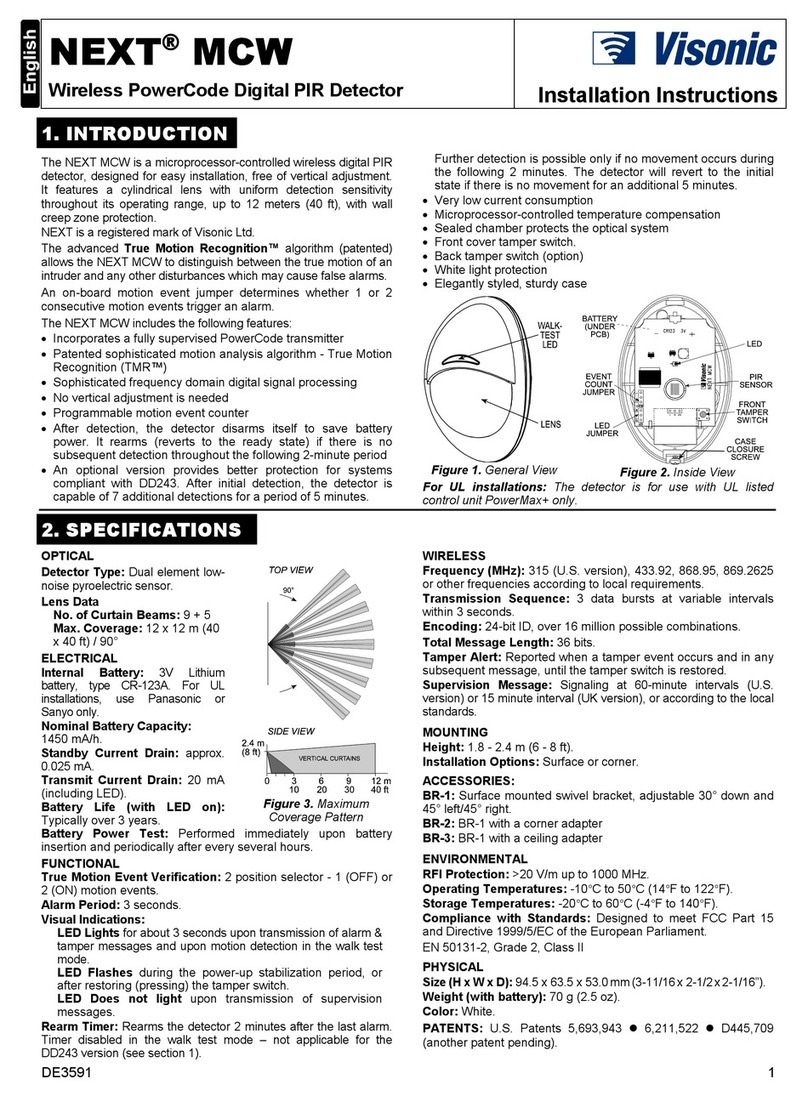

For rapid walk testing of each beam in the coverage pattern, you

must eliminate the 2 minute inhibit interval between successive

alarms. The NORM/TEST selector (Figure 7), when set to TEST,

overrides the 2-minute rearm timer, and also sets the pulse

counter to 1 PULSE. Remember that in the TEST mode, tamper

and low battery alerts will be transmitted at 1/2 second intervals

instead of the usual 2-minute intervals. When the selector is reset

to NORM, the rearm timer reverts to normal operation.

Testing Procedure

A. Snap the battery clip onto the 9 Volt alkaline or lithium battery

and allow ten minutes for the unit to stabilize before testing.

B. Adjust the vertical calibration angle per Table 1.

C. Set the Normal/Test selector to TEST.

D. MASK beams which look at potential sources of false alarms

(see Section 3.8, Para. 5).

E. Replace the cover.

F. Walk-test the entire protected area by walking slowly across

it, observing the LED. The LED lights whenever you cross a

protective beam. Allow the unit to restabilize for 5 seconds

after each test.

G. Set the pulse counter according to Section 3.9.

H. Set the NORMAL/TEST selector to NORM and wait outside

the coverage area. After 5 minutes, re-enter the coverage

area and verify that the LED lights and that the transmitter

output operates (response will be immediate only if the pulse

counter is set to 1 pulse).

If you continue moving within the detector's field of view, the

LED will turn OFF and the unit will remain disabled as long as

movement continues, due to the 2-minute battery saving

rearm timer. The unit will be rearmed provided that no motion

is detected for approximately 2 minutes, and will again be

ready to detect and signal.

CAUTION: The range and coverage area of the unit should

be checked at least once a year. To assure proper

continuous function, the end user should be instructed to

perform a walk test at the far end of the area to assure an

alarm signal prior to each time the alarm system is armed.

3.11 Using Beam Locator BL-1

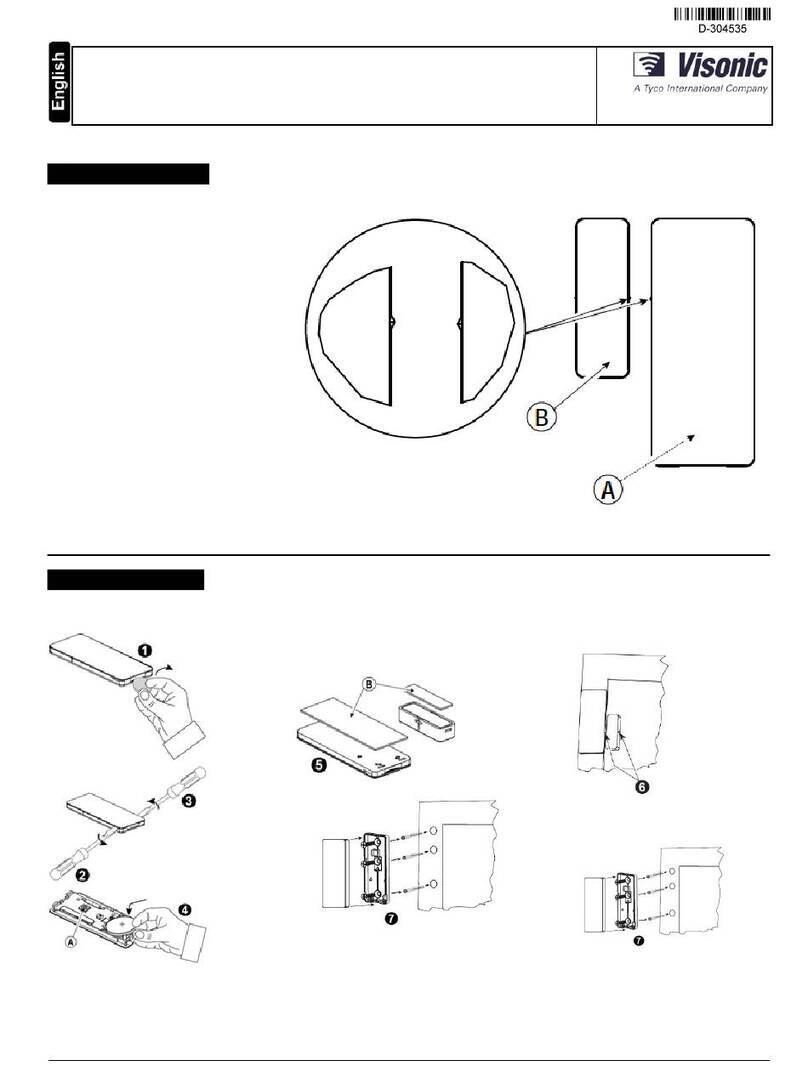

To use the beam locator BL-1, mount the BL-1 on the 3 pins of

the special header at the top of the printed circuit board. The

BL-1 will cover the pyroelectric detector and its mini-LED will face

forward. The mini-LED will light when installed.

Replace the cover. The beam locator LED now projects visible

light beams through all lens segments, in the same direction as

each corresponding detection beam. Stand within the coverage

area, facing toward the PIR and observe the lens.

An illuminated lens segment indicates that you are positioned

within the corresponding detection beam of that segment.

By walking through the

coverage pattern you can

determine the location of all

detection beams for precise

pattern adjustments or masking

of lens segments which are

exposed to potential sources of

false alarms.

After using the beam locator,

take the cover off and remove

the BL-1 from the on-board pin

header. Figure 12 - BL-1 Installation

4

44

4. WARNINGS

. WARNINGS. WARNINGS

. WARNINGS

Visonic Ltd. wireless systems are reliable are tested to high

standards. However, due to their low transmitting power (required

by FCC and other regulatory authorities), there are some

limitations to be considered:

A. Receivers may be blocked by radio signals on or near their

operating frequencies, regardless of the code selected.

B. Receivers can only respond to one transmitted signal at a time.

C. Wireless equipment should be tested regularly (at least once a

week) to determine if there are sources of interference and to

protect against faults.

WARNING! Changes or modifications to this unit not

expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment

WARRANTY

WARRANTYWARRANTY

WARRANTY

Visonic Ltd. and/or its subsidiaries and its affiliates ("the Manufacturer") warrants its

products hereinafter referred to as "the Product" or "Products" to be in conformance with

its own plans and specifications and to be free of defects in materials and workmanship

under normal use and service for a period of twelve months from the date of shipment by

the Manufacturer. The Manufacturer's obligations shall be limited within the warranty

period, at its option, to repair or replace the product or any part thereof. The Manufacturer

shall not be responsible for dismantling and/or reinstallation charges. To exercise the

warranty the product must be returned to the Manufacturer freight prepaid and insured.

This warranty does not apply in the following cases: improper installation, misuse,

failure to follow installation and operating instructions, alteration, abuse, accident or

tampering, and repair by anyone other than the Manufacturer.

This warranty is exclusive and expressly in lieu of all other warranties, obligations or

liabilities, whether written, oral, express or implied, including any warranty of

merchantability or fitness for a particular purpose, or otherwise. In no case shall the

Manufacturer be liable to anyone for any consequential or incidental damages for breach

of this warranty or any other warranties whatsoever, as aforesaid.

This warranty shall not be modified, varied or extended, and the Manufacturer does not

authorize any person to act on its behalf in the modification, variation or extension of this

warranty. This warranty shall apply to the Product only. All products, accessories or

attachments of others used in conjunction with the Product, including batteries, shall be

covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or

attachments of others, including batteries, used in conjunction with the Products.

The Manufacturer does not represent that its Product may not be compromised and/or

circumvented, or that the Product will prevent any death, personal and/or bodily injury

and/or damage to property resulting from burglary, robbery, fire or otherwise, or that the

Product will in all cases provide adequate warning or protection. User understands that a

properly installed and maintained alarm may only reduce the risk of events such as

burglary, robbery, and fire without warning, but it is not insurance or a guarantee that such

will not occur or that there will be no death, personal damage and/or damage to property

as a result.

The Manufacturer shall have no liability for any death, personal and/or bodily injury

and/or damage to property or other loss whether direct, indirect, incidental,

consequential or otherwise, based on a claim that the Product failed to function.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or

damage arising under this limited warranty or otherwise, regardless of cause or origin, the

Manufacturer's maximum liability shall not in any case exceed the purchase price of the

Product, which shall be fixed as liquidated damages and not as a penalty, and shall be the

complete and exclusive remedy against the Manufacturer.

Warning: The user should follow the installation and operation instructions and among

other things test the Product and the whole system at least once a week. For various

reasons, including, but not limited to, changes in environmental conditions, electric or

electronic disruptions and tampering, the Product may not perform as expected. The user

is advised to take all necessary precautions for his /her safety and the protection of

his/her property.

6/91

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 10 NORTHWOOD DRIVE, BLOOMFIELD CT. 06002-1911. PHONE: (860) 243-0833, (800) 223-0020. FAX: (860) 242-8094

VISONIC LTD. (UK): FRASER ROAD, PRIORY BUSINESS PARK, BEDFORD MK44 3WH. PHONE: (0870) 730-0800 FAX: (0870) 730-0801

INTERNET: www.visonic.com

VISONIC LTD. 1998 , D-3561-0 NEW : DE3561- (REV. 5, 4/98)